Spring self-limit filler cap

A fuel filler cap and spring limit technology, which is applied in the field of automobile body design, can solve the problem of easy rebound of the fuel filler cap and achieve the effect of eliminating the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

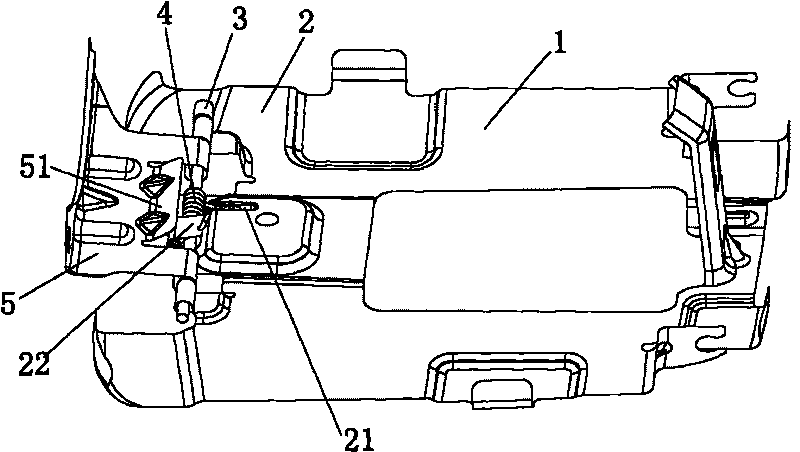

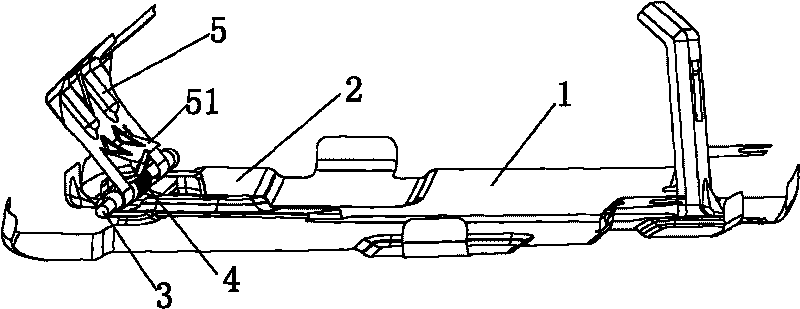

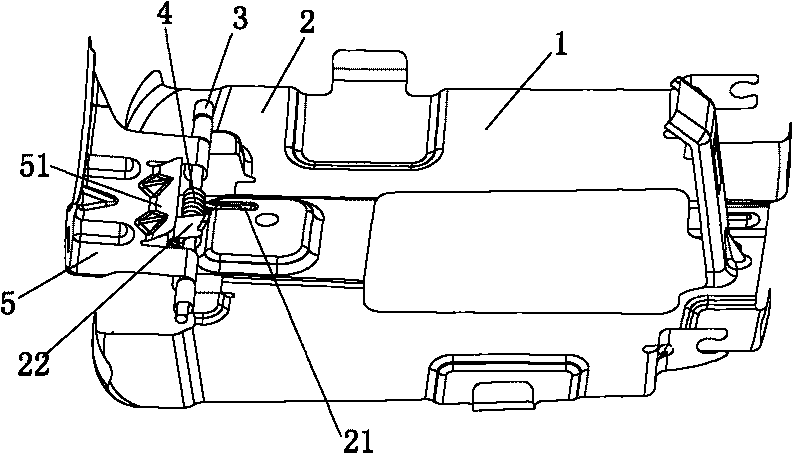

[0011] Such as figure 1 with figure 2 As shown, the spring self-limiting fuel filler cap in this specific embodiment includes: fuel filler cap outer plate 1 , fuel filler cap inner plate 2 , rotating shaft 3 , spring 4 , and rotating leaf plate 5 . The inner panel 2 of the fuel filler cap is provided with a spring fixing groove 21 and a spring limiting block 22 . The spring fixing groove 21 can be stamped out together when making the inner panel 2 of the fuel filler cap. The spring limiter 22 can be integrally formed with the fuel filler cap inner plate 2, for example, the spring limiter 22 can be stamped and bent together when making the fuel filler cap inner plate 2; of course, the spring limiter 22 can also be Make it separately, and then be fixedly connected with the inner panel 2 of the fuel filler cap.

[0012] A spring touch plate 51 is arranged on the rotating leaf plate 5 . The spring touch plate 51 is integrally formed with the rotating leaf plate 5, for example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com