Buried automatic quick exhaust valve

An exhaust valve, buried technology, applied in the field of buried automatic quick exhaust valve, can solve the problems of work failure, exhaust valve management and maintenance increase, freezing damage or freezing to death, etc., to prevent rust and failure , management and maintenance are simple and convenient, and the effect of closing quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

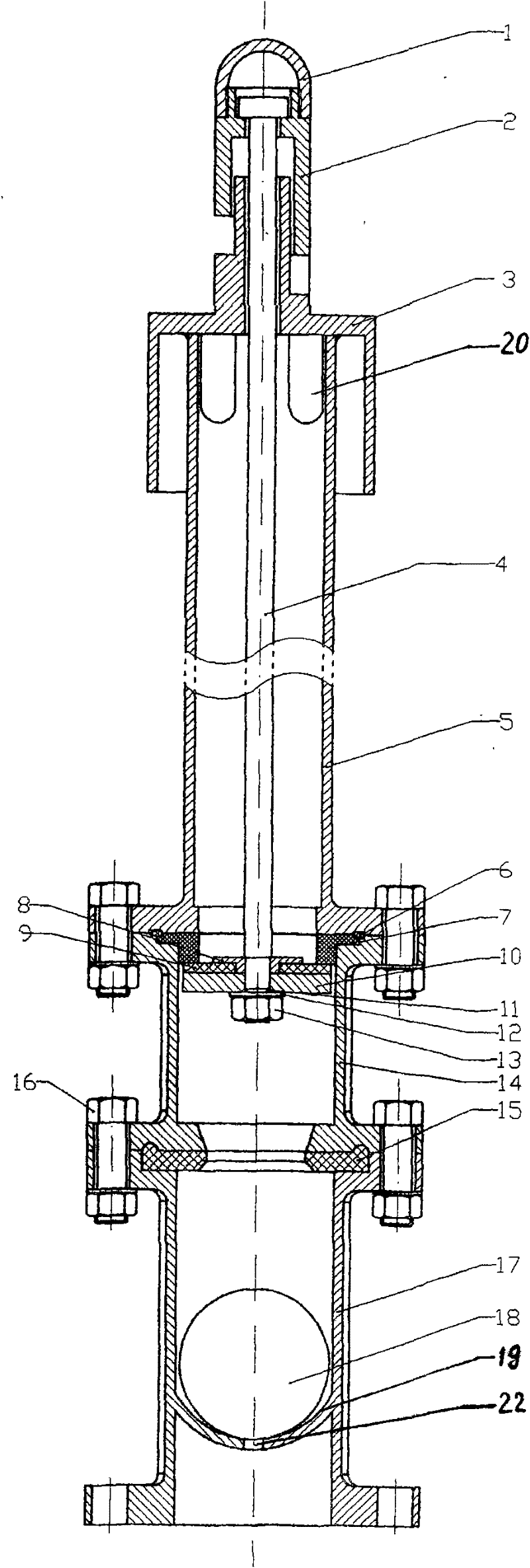

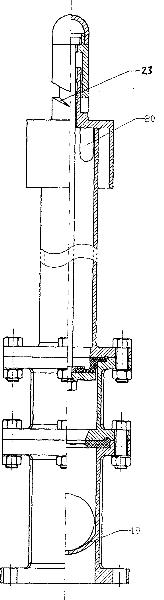

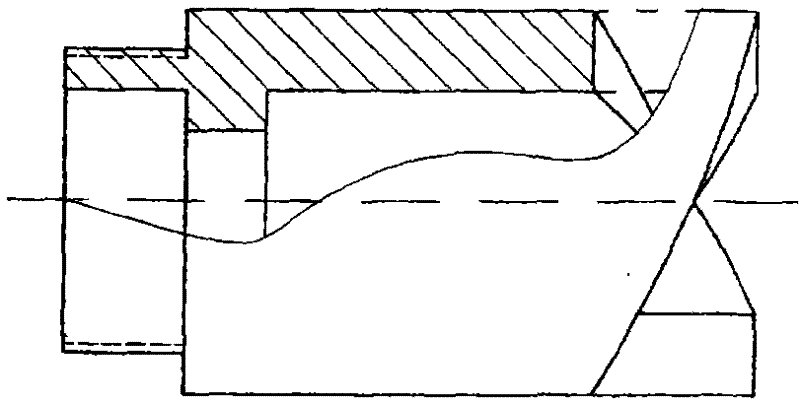

[0027] Such as figure 1 ——As shown in 7, the local buried automatic quick exhaust valve consists of an upper valve body 5, a middle valve body 14, a lower valve body 17, an intake and exhaust cover 3, a quick opening and closing device 2, a cover 1 and a hollow floating ball 18. It is characterized in that: the lower end of the upper valve body 5, the middle valve body 14 and the two ends of the lower valve body 17 are provided with flanges welded as one, and the upper valve body 5, the middle valve body 14 and the lower valve body 17 are connected to each other through the flanges at the ends; at least two exhaust holes 20 are evenly distributed on the upper end peripheral surface of the upper valve body 5, and the intake and exhaust cover 3 is welded on the upper end of the upper valve body 5 and connected with it. As a whole, the quick opening and closing device 2 is set on the intake and exhaust cover 3, the valve stem 4 is installed on the front end of the quick opening a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com