Differential pressure integrated microflow metering compensation valve

A compensation valve and differential pressure technology, applied in the field of differential pressure integral micro-flow metering compensation valve, can solve the problems of inability to solve the micro-flow leakage meter, difficulty in production and maintenance, and high requirements on machining accuracy, and achieve good anti-creeping performance and manufacturing. Simple assembly process and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention is further illustrated below by means of non-limiting examples given in the accompanying drawings.

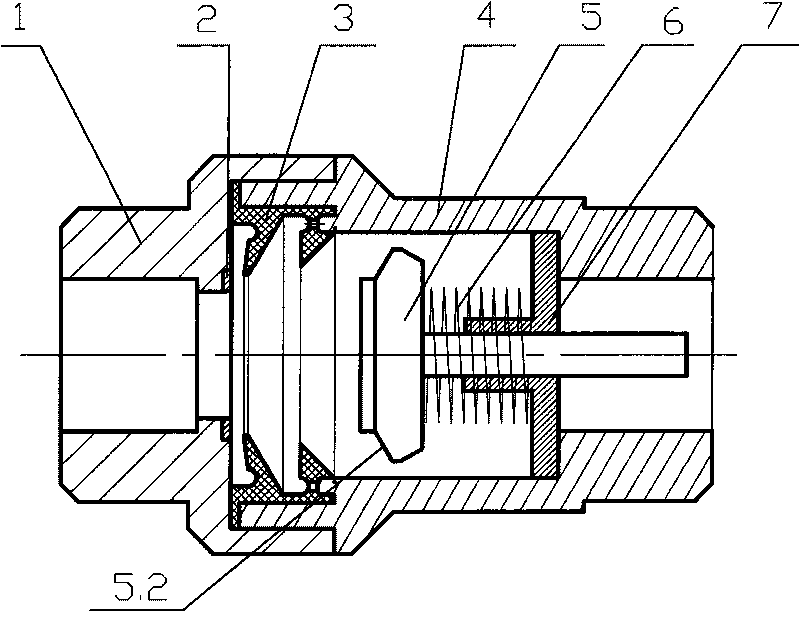

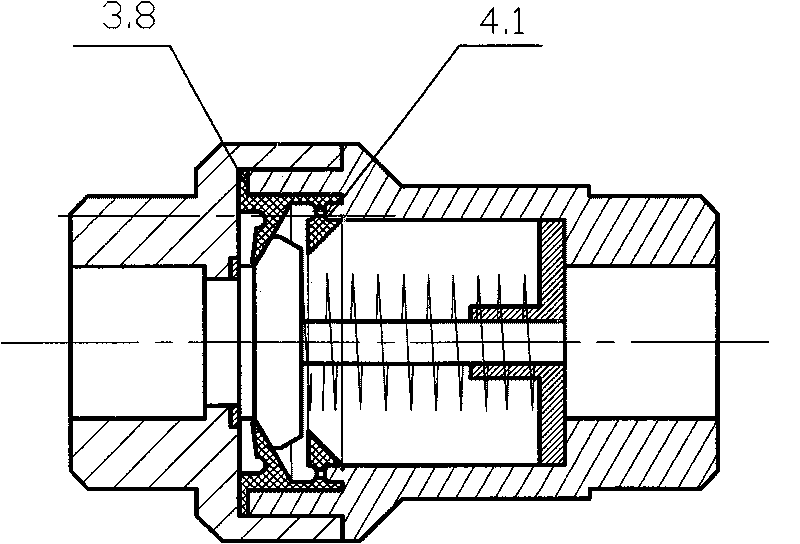

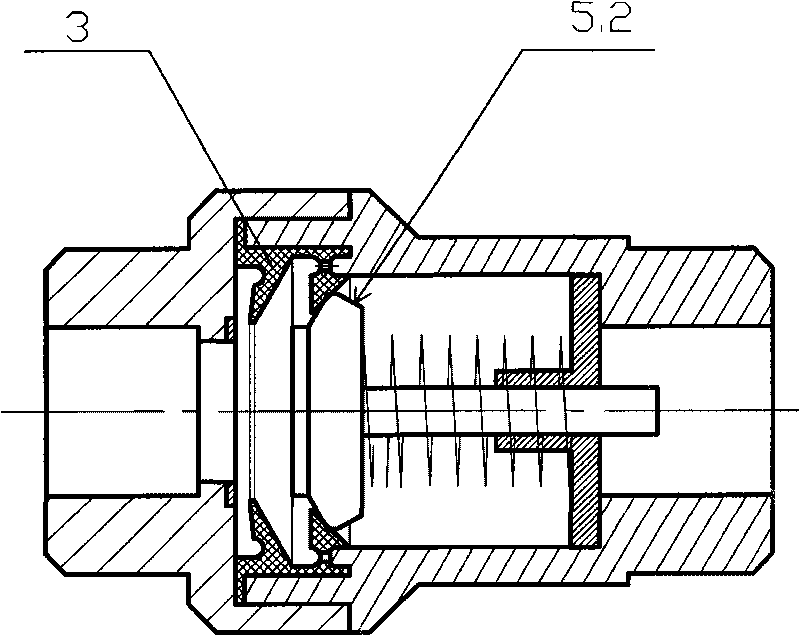

[0015] See the accompanying drawings: the differential pressure integral type micro-flow metering compensation valve in the figure includes a valve body 4 and a valve core 5, wherein the inlet end of the valve body is connected to a pipe joint (1), and one end of the valve core is supported by a compression spring (6) , so that the end face of the valve core is pushed against the gasket (2) on the end face of the pipe joint; it is characterized in that: a rubber differential pressure integral sleeve 3 is installed on the inner wall of the valve body inlet; the inner wall of the rubber differential pressure integral sleeve has The front ring gear 3.1 and the rear ring gear 3.2 are tooth-shaped in cross-section, and the front and rear ring gears respectively cooperate with the valve core moved into the rubber differential pressure integrating sleeve 3 to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com