High voltage feed vacuum state device with motion compensation

A motion compensation, high-voltage technology, applied in accelerators, electrical components, etc., can solve problems such as hardening, poor reliability, and fracture, and achieve the effect of eliminating motion resistance, high transmission voltage, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with the preferred embodiment shown in accompanying drawing, be described in further detail:

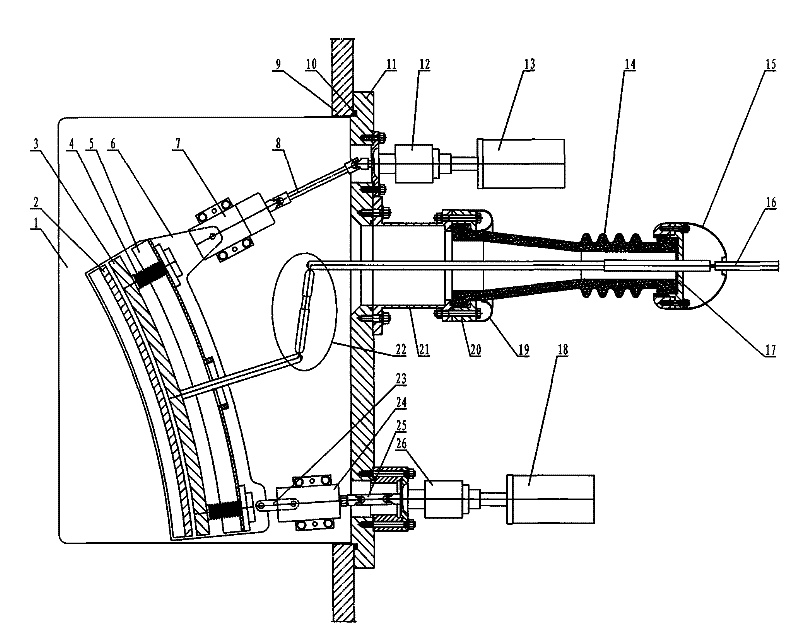

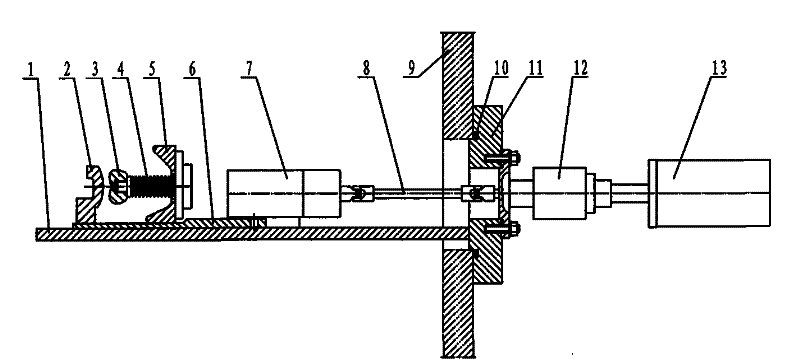

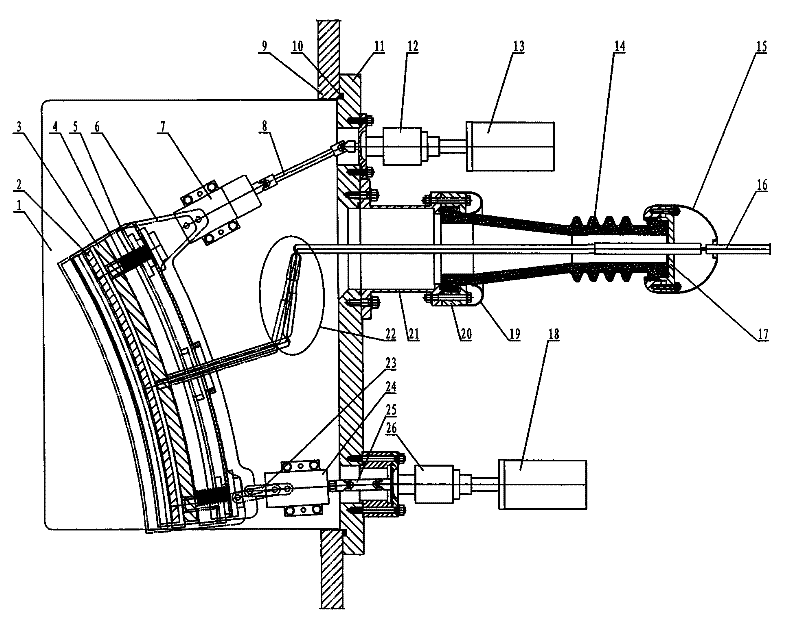

[0014] See figure 1 , 2 , 3, 4, 5, the described high-voltage feed-in vacuum device with motion compensation includes a high-voltage feed-in conductive rod 22, and its feature is that the conductive rod 22 is located in the vacuum cavity 9, and the conductive rod 22 One end is connected to the high-voltage electrode 3, and a ground electrode 2 is provided corresponding to the high-voltage electrode 3. The other end of the conductive rod 22 passes through the transition sleeve 21 and the outer insulating ceramic 14 to connect to the high-voltage output piece 16. The transition sleeve 21 is installed in the vacuum chamber through the flange 11. 9, one end of the outer insulating ceramic 14 is connected to the transition sleeve 21 through a pressure ring 20 and bolts, the other end of the outer insulating ceramic 14 is equipped with a gland 17, and the two e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com