Control method of single-rack steckel mill for reducing final pass speed of rolling pieces

A last-pass, steckel rolling mill technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problem of only 1.5m/s or more, and achieve the effect of preventing burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

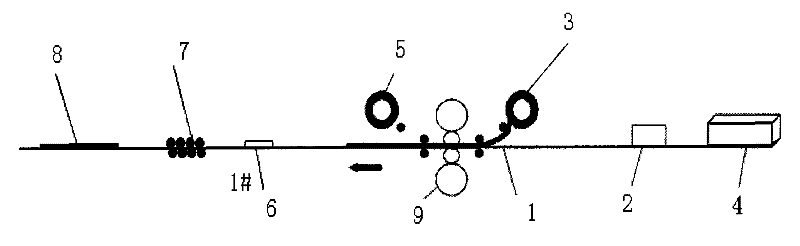

[0016] A control method for reducing the speed of the last pass of a single-stand steckel rolling mill. After the rolling process ends, the rolling process runs from the front of the rolling mill to the rear of the rolling mill according to the speed required by the process after the rolling of the rolled piece is completed, so as to realize the reduction of the speed of the steckel rolling mill. The speed at which the rolled piece passes through the rolling mill in the last pass.

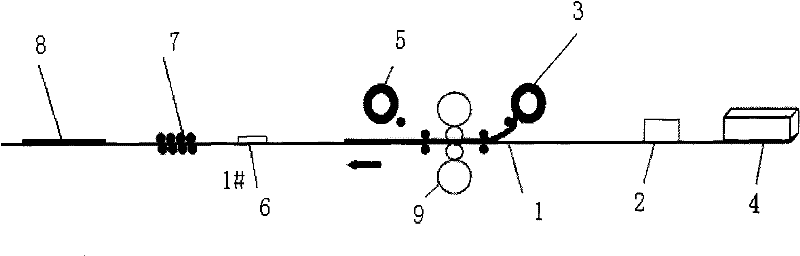

[0017] In this embodiment, the flat rolled plate blank is selected. The actual size of the blank is 150*3120*16200mm, and the thickness of the finished product is 13.6mm. The rolling procedure is the same. The blank is rolled for 10 passes, and the first stage is rolled for 5 passes. be warm. When the temperature reaches the technical requirements, start the second stage of coil rolling until the end of the rolling process. The specific process is as follows, see figure 1 :

[0018] (1) After th...

Embodiment 2

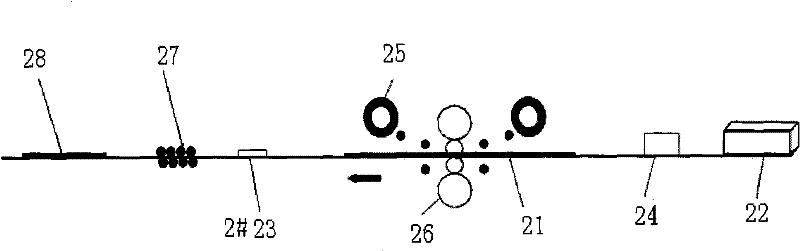

[0021] Another control method for reducing the speed of the last pass of a single-stand steckel rolling mill. In this embodiment, a flat-rolled plate blank is selected. The actual size of the blank is 150*3150*8150mm, the thickness of the finished product is 21mm, and the rolling is carried out in 9 passes. The first stage is rolled for 5 passes, and it is warmed after completion. When the temperature reaches the process requirements, the second stage of rolling starts until the end of the rolling process. The specific process is as follows, see figure 2 :

[0022] (1) After the billet 21 is tapped from the heating furnace 22, it enters the descaling box 24 for descaling. After the first stage of rolling, it stops and swings at the 2# detection position area 23 behind the rolling mill 26 to wait for temperature. When the temperature drops to the process requirements, the second stage of rolling is carried out.

[0023] (2) The billet 21 starts the second-stage rolling, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com