Improved novel clamp for rotary milling of compressor blades

A technology of compressor and rotary milling, which is used in clamping, milling machine equipment, manufacturing tools, etc., can solve the problems of high requirements on the bottom surface of the blade root and unstable center of gravity of the profile.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

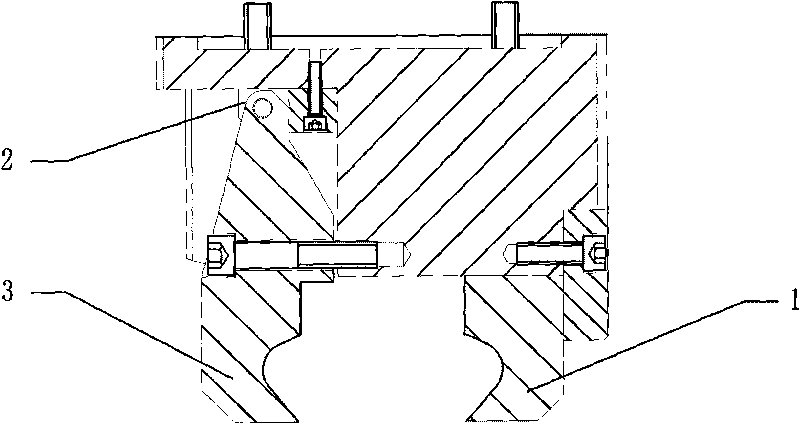

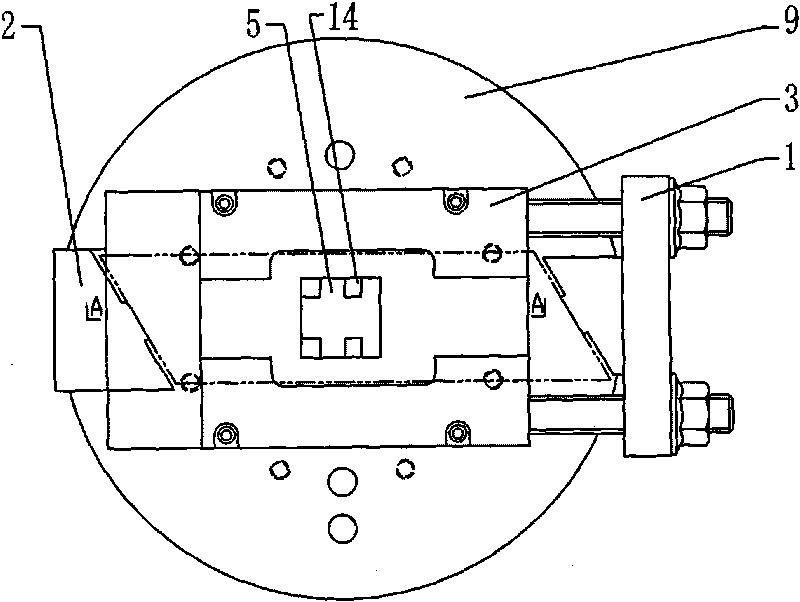

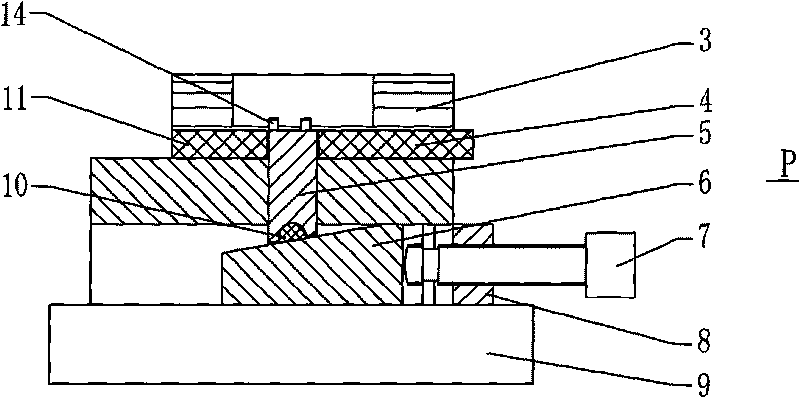

[0011] See figure 2 , image 3 and Figure 4 , the present invention includes a blade root support seat 3, the blade root side positioning block 2 and the blade root side pressing block 1 are respectively installed on both sides of the blade root support seat 3, the blade root support seat 3 is installed on the rotary disk 9, and the blade root support seat 3. The upper part of the wheel groove 12 is installed, and the bottom of the wheel groove 12 is installed with a pad. The bottom of the blade root support seat 3 is horizontally opened with a rectangular through groove 13, and a slider 6 is installed in the rectangular through groove 13. The slider 6 passes through the split pin 10 The guide rod 5 is connected, and the guide rod 5 vertically passes through the blade root support seat 3 . The cushion block is provided with two pieces 4,11; The cushion blocks 11,4 are installed on the air inlet side and the air outlet side respectively; The outer edge of the air outlet sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com