Bottom die used for boring and milling cone face of fixed bead hole

A bead hole and cone surface technology, which is applied in the field of tools for processing bead rings, can solve problems such as difficult processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

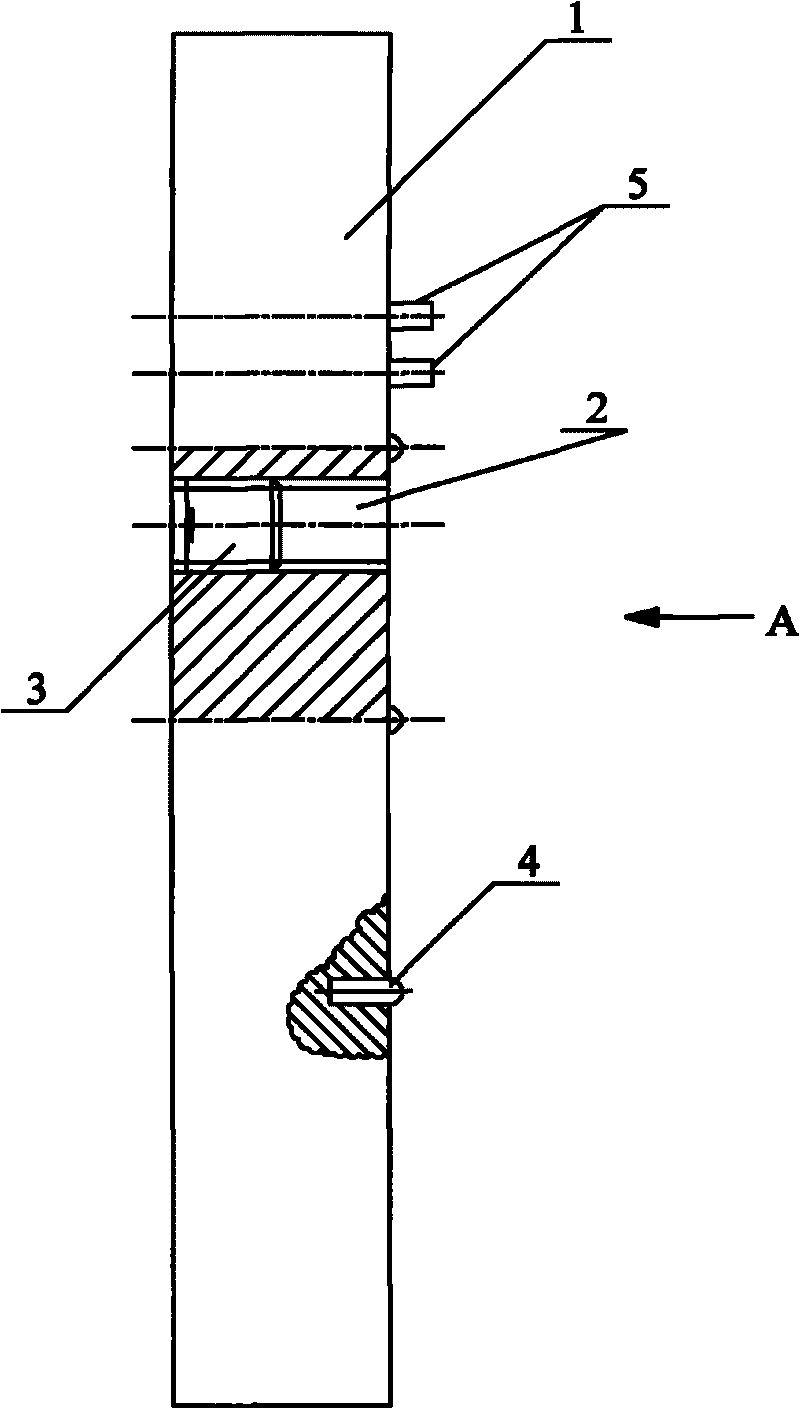

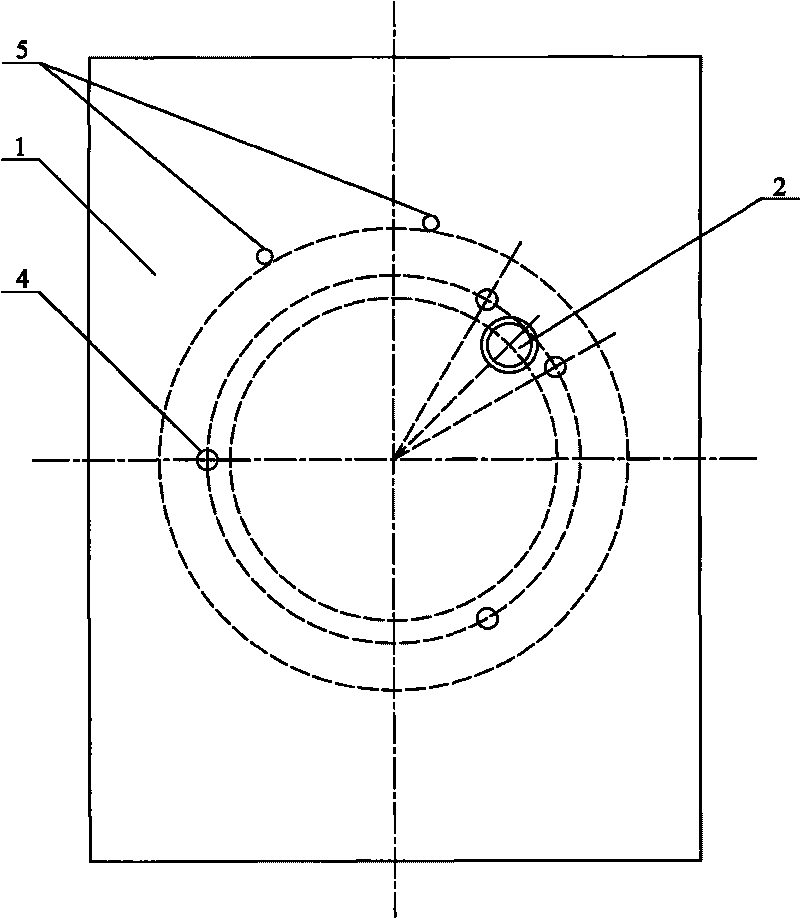

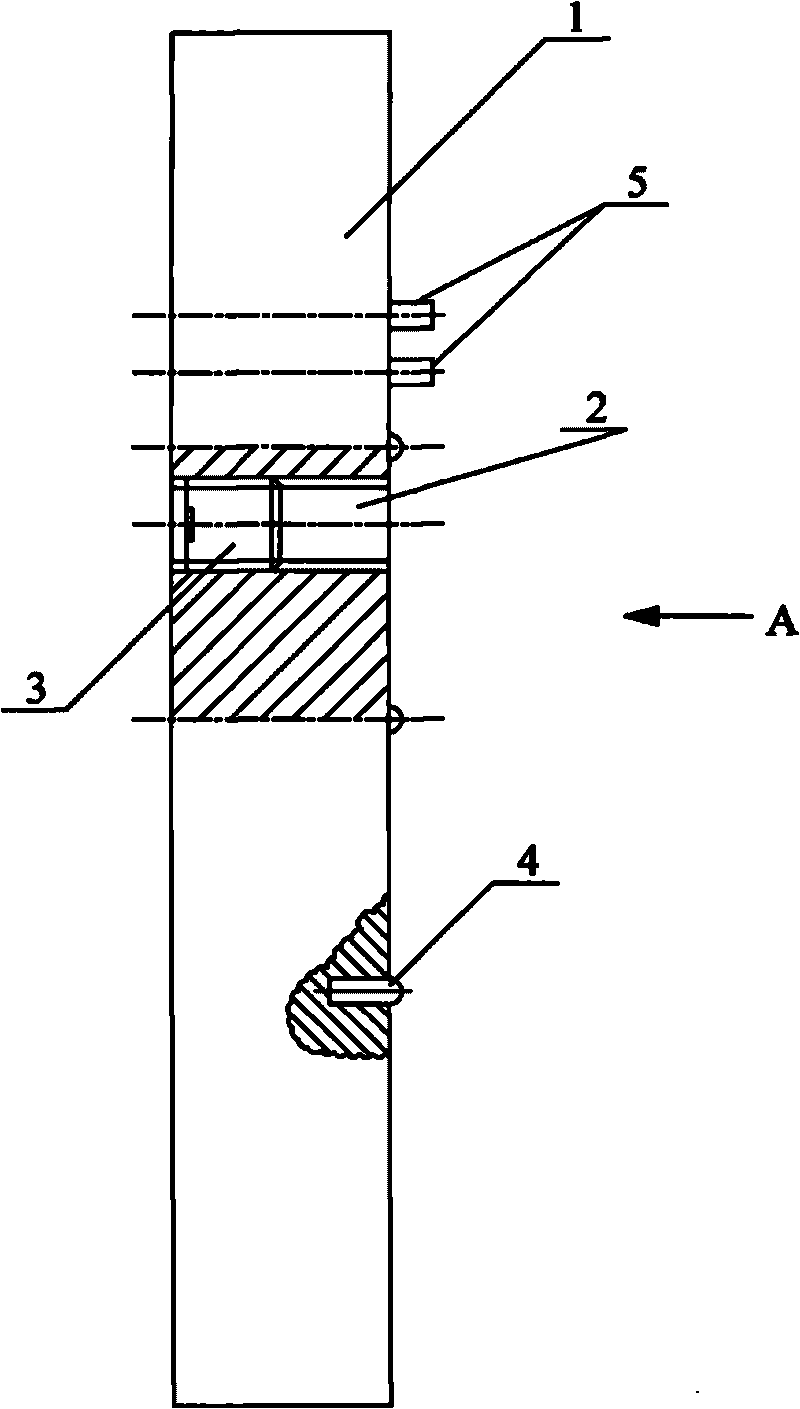

[0011] like figure 1 and figure 2 As shown, the bottom mold in this embodiment includes a base plate 1 on which a threaded through hole 2 penetrating through the upper and lower sides of the base plate 1 is arranged, and an adjusting bolt 3 is threaded in the threaded through hole 2 .

[0012] Four support points 4 of equal height are attached to the upper side of the base plate 1 . Preferably, the above four fulcrums 4 are on the same circumference. Two of the fulcrums 4 are close to the threaded through hole 2 , distributed on both sides of the threaded through hole 2 , and equidistant from the threaded through hole 2 .

[0013] In addition, two positioning pins 5 on the same circumference are connected to the upper side of the bottom plate 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com