Method for reducing flow rate of aluminium liquid in electrolysis bath and slowing down cathode abrasion

An electrolytic cell and flow rate technology, applied in the field of electrolytic aluminum, can solve the problems of fluctuating aluminum liquid, fast flow of aluminum liquid, abrasive cathode, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

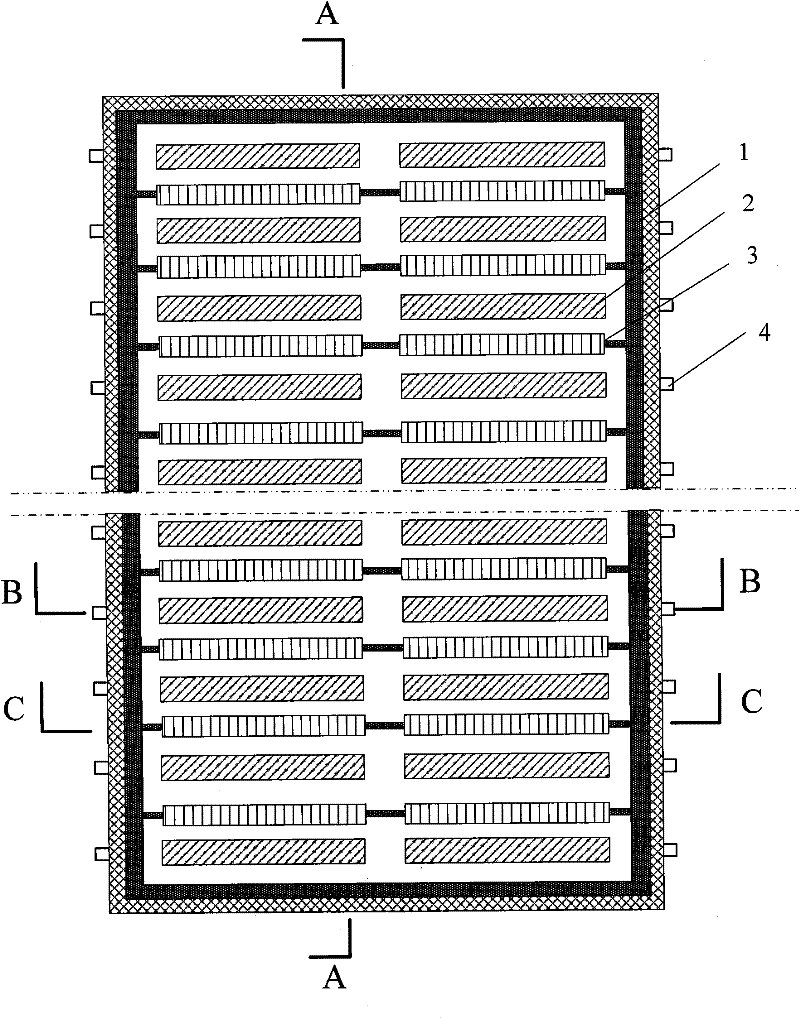

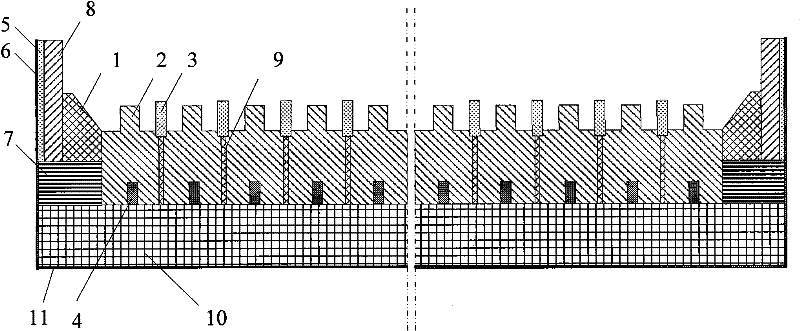

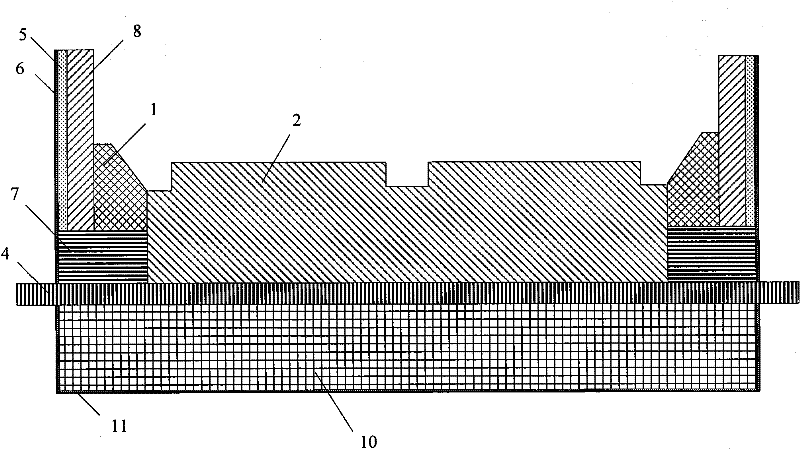

[0031] For an electrolytic cell with a cathode carbon block with a raised structure on the surface, a refractory material wallboard is arranged on the upper part of the carbon tamping paste between every two adjacent cathode carbon blocks in the electrolytic cell, and the wallboard is made of carbonitride Made of silicon. These wallboards are arranged along the direction parallel to the length direction of the cathode carbon block, and are arranged on the upper part of the carbon ramming paste between the two cathode carbon blocks. same height. The refractory wallboard between these two cathode carbon blocks has the functions of further blocking the flow rate of the aluminum liquid, reducing the fluctuation of the aluminum liquid, improving the stability of the aluminum liquid level in the electrolytic cell, and reducing the convex abrasion on the surface of the cathode carbon block.

[0032] The width of the refractory material wallboard arranged on the upper part of the above...

Embodiment 2

[0035] For an electrolytic cell with a cathode carbon block with a raised structure on the surface, a refractory material wallboard is arranged on the upper part of the carbon stamping paste between every two adjacent cathode carbon blocks in the electrolytic cell, and the wallboard is made of magnesium aluminum tip Made of crystal. These wallboards are arranged along the direction parallel to the length direction of the cathode carbon block, and are arranged on the upper part of the carbon ramming paste between the two cathode carbon blocks. surface. The refractory wallboard between these two cathode carbon blocks has the functions of further blocking the flow rate of the aluminum liquid, reducing the fluctuation of the aluminum liquid, improving the stability of the aluminum liquid level in the electrolytic cell, and reducing the convex abrasion on the surface of the cathode carbon block.

[0036] The width of the refractory material wallboard arranged on the upper part of ...

Embodiment 3

[0039] For an electrolytic cell with a cathode carbon block with a raised structure on the surface, a refractory material wallboard is arranged on the upper part of the carbon stamping paste between every two adjacent cathode carbon blocks in the electrolytic cell, and the wallboard is made of magnesium high Density refractory material. These wallboards are arranged along the direction parallel to the length direction of the cathode carbon block, and are arranged on the upper part of the carbon ramming paste between the two cathode carbon blocks. same height. The refractory wallboard between these two cathode carbon blocks has the functions of further blocking the flow rate of the aluminum liquid, reducing the fluctuation of the aluminum liquid, improving the stability of the aluminum liquid level in the electrolytic cell, and reducing the convex abrasion on the surface of the cathode carbon block.

[0040] The width of the refractory material wallboard arranged on the upper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com