Asphalt pavement structure for alleviating urban heat island effect based on one-way heat conduction

An urban heat island effect and asphalt pavement technology, applied in the direction of on-site coagulation pavement, roads, roads, etc., can solve problems such as non-patent, and achieve the effect of improving road performance, high mechanical performance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

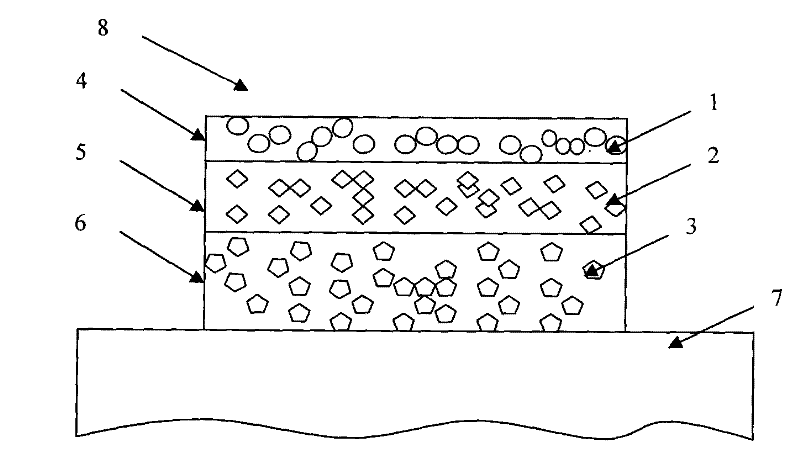

[0037] Refer to attached figure 1 .

[0038] The thermal conductivity of powder modified asphalt mixture is as follows:

[0039] Add the first micro-nano powder 1 with a thermal conductivity of 10-30w / m·k to the asphalt upper layer 4, the powder material is at least one of silicon oxide, aluminum oxide, and zinc oxide, and the powder particle size is 0.1-30w / m·k. 100 microns, the amount added is 10% to 40% of the amount of graded asphalt in the upper layer.

[0040] Add the second micro-nano powder 2 with a thermal conductivity of 50-90w / m·k in the asphalt middle surface layer 5, the powder is silicon carbide, the particle size of the powder is 0.1-100 microns, and the dosage is the graded asphalt in the middle surface layer 5% to 20% of the dosage.

[0041] Add the third micro-nano powder 3 with a thermal conductivity of 100-140w / m·k in the layer 6 below the asphalt, the powder is graphite, the particle size of the powder is 0.1 micron-100 microns, and the dosage is 5% of ...

Embodiment 2

[0046] Refer to attached figure 1 Add the first micro-nano powder 1 with a thermal conductivity of 10-30w / m·k to the asphalt upper layer 4, the powder material is silicon oxide, aluminum oxide, zinc oxide, and the particle size of the powder is 0.1-100 microns. The amount added is 10% to 40% of the amount of graded asphalt in the upper layer.

[0047] Add the second micro-nano powder 2 with a thermal conductivity of 100-140w / m·k in the asphalt mid-surface layer 5, the powder is flake graphite, and the particle size of the powder is 0.1-100 microns, and the dosage is the mid-surface layer 1% to 10% of asphalt dosage.

[0048] Add the third micro-nano powder 3 with a thermal conductivity of 100-140w / m·k in the asphalt lower layer 6, the powder material is flake graphite, the particle size of the powder is 0.1 micron-100 micron, and the dosage is as follows 5% to 15% of the amount of asphalt used in layer grading.

[0049] The powder addition method is to replace the mineral p...

experiment example

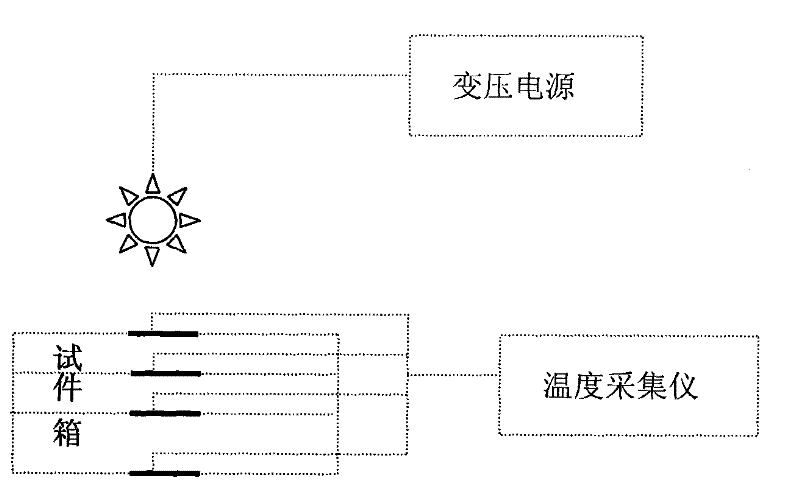

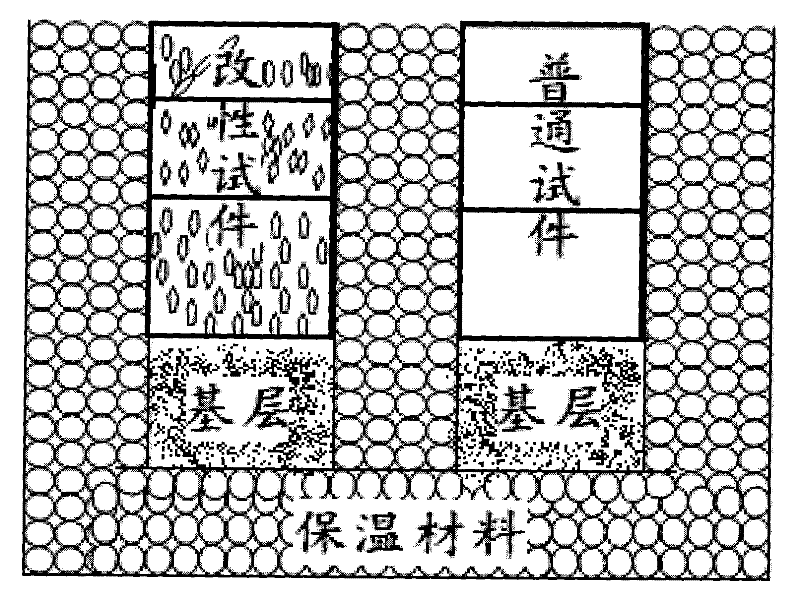

[0055] In order to confirm the effectiveness of this typical pavement structure layer, indoor experiments were carried out in the Road and Bridge Laboratory of the School of Transportation, Southeast University. The test is mainly to verify the effectiveness of the unidirectional heat conduction pavement layer structure and the performance difference compared with ordinary asphalt pavement. The experimental device mainly consists of a test box, a variable voltage power supply and a temperature acquisition system. The surrounding and bottom of the test box are made of thermal insulation materials. The test process is that the modified asphalt concrete specimen and the ordinary asphalt concrete specimen are placed in two incubators respectively, and by controlling the irradiation intensity and irradiation time of the mercury lamp and the wind speed on the surface of the specimen, the summer road surface radiation conditions are simulated, and the two methods are compared. The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com