Undercurrent external heat exchanger bed of circulating fluidized bed

A circulating fluidized bed, external technology, applied in the field of large circulating fluidized bed boilers, can solve the problems of poor heat transfer performance, serpentine tube abrasion and vibration, etc., to improve flow and heat transfer performance, reduce serious vibration, The effect of improving the overall heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

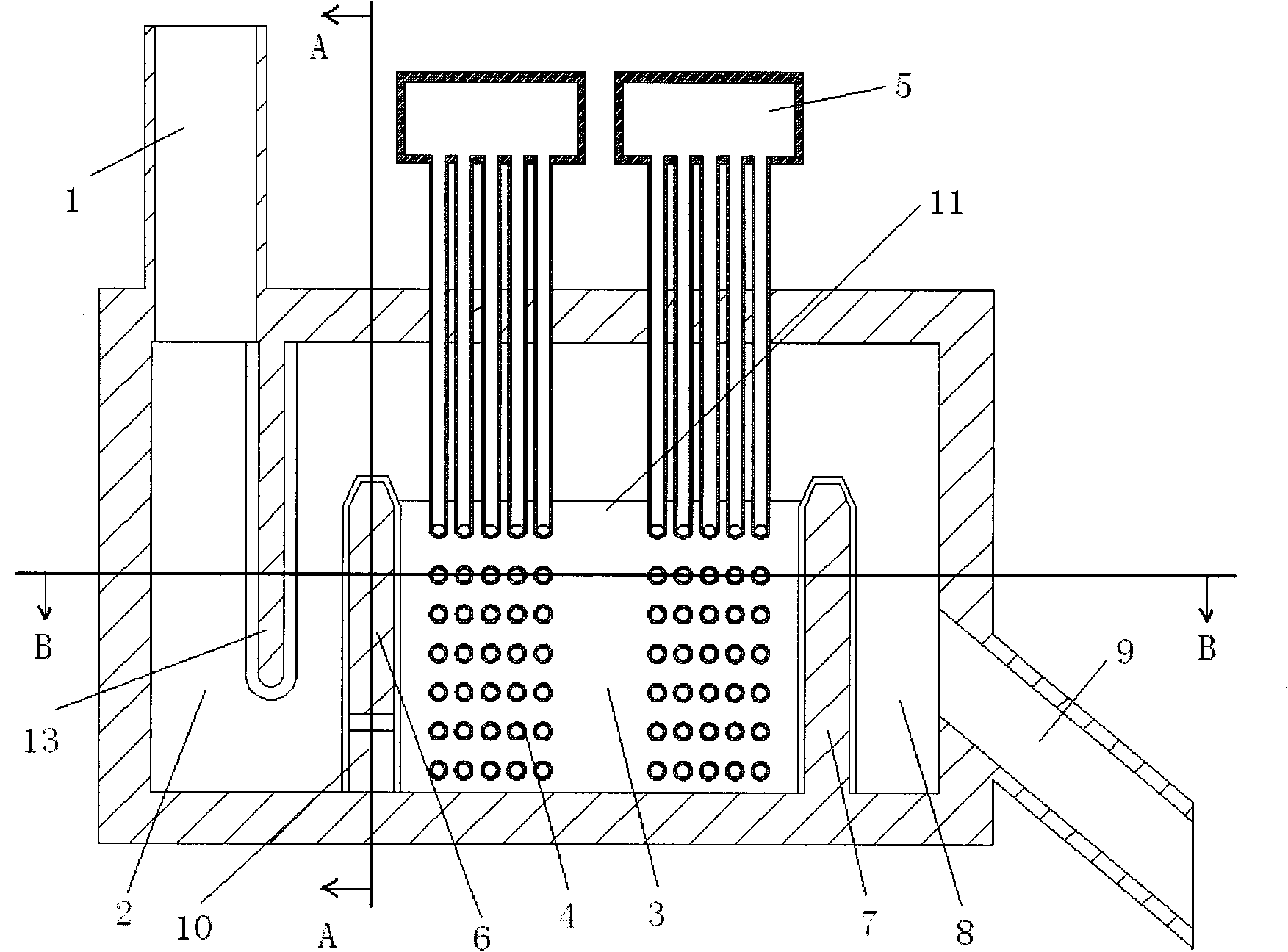

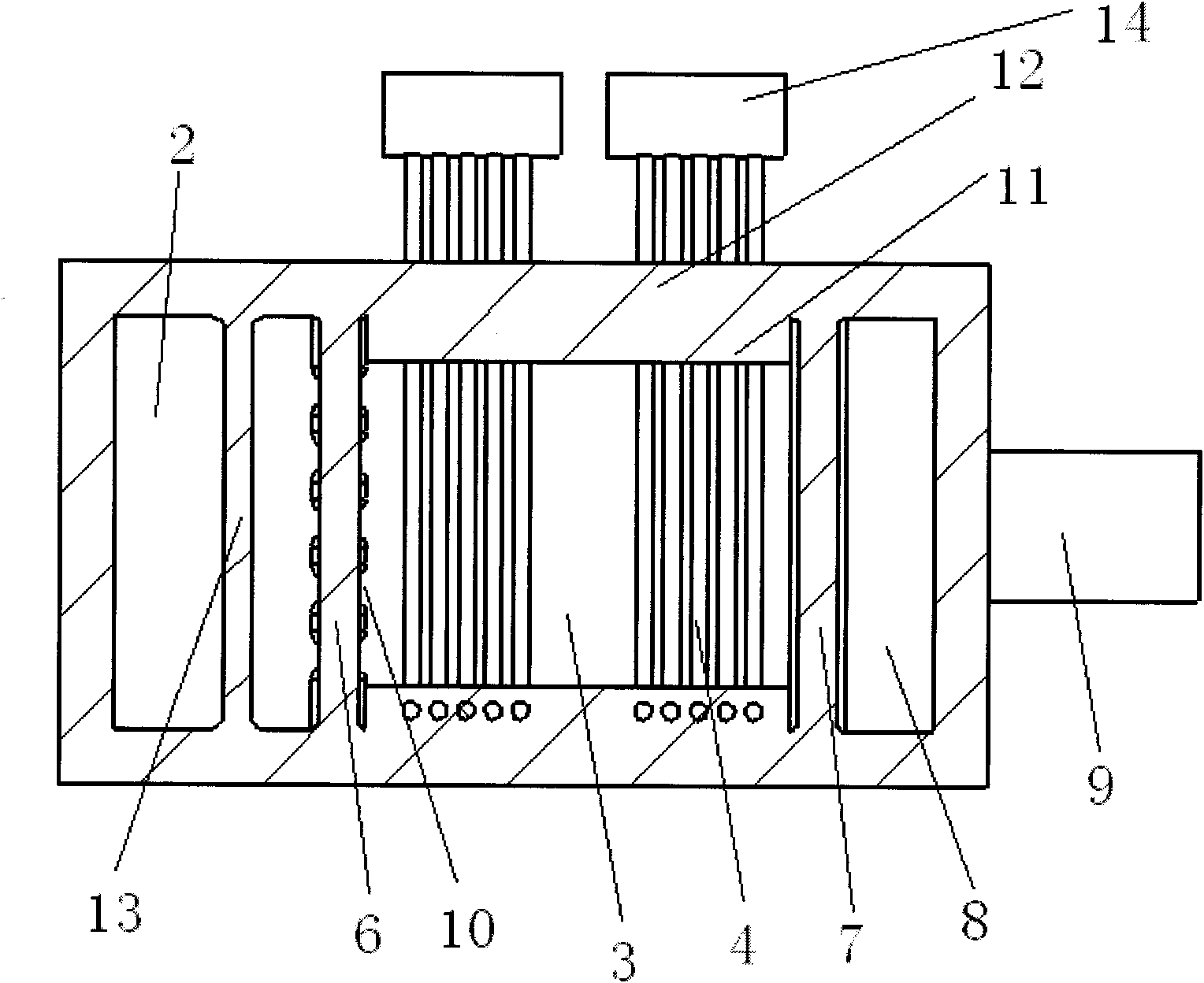

[0014] The specific structure and working principle of the invention are illustrated below in conjunction with the accompanying drawings.

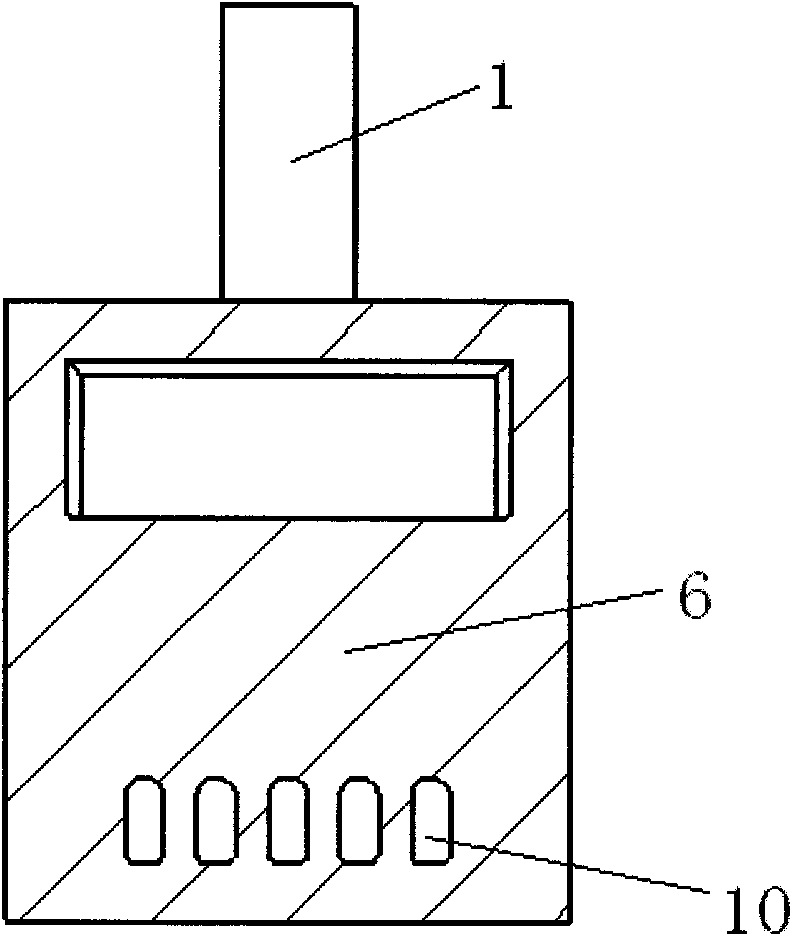

[0015] figure 1 It is the front view of the submerged external heat exchange bed of the circulating fluidized bed. The submerged external heat exchange bed includes a feed riser 1, a feed chamber 2, and a heat exchange chamber 3. The serpentine tube installed in the heat exchange chamber is heated Surface 4, overflow chamber 8, ash return pipe 9, inlet header 14 and outlet header 5. The feeding chamber is divided into two parts by a third partition wall 13 . A first partition wall 6 is arranged between the feed chamber 2 and the heat exchange chamber 3, and a row of underflow holes 10 are set at the bottom of the first partition wall 6 (see figure 2 ), the underflow hole communicates the lower part of the feed chamber 2 with the lower part of the heat exchange chamber 3. The height of the underflow hole 10 is generally 50cm-80cm, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com