Integrated injection molding type PTC heater and preparation method thereof

A heater, all-in-one technology, applied in ohmic resistance heating, heating element materials, ohmic resistance heating parts and other directions, can solve problems such as increased labor hours, labor costs, low waterproof level of PTC heaters, and increased production costs, saving The cost of mold opening and the effect of solving the problem of waterproof and dustproof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

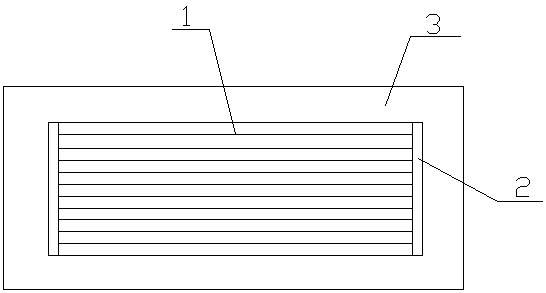

[0018] Such as figure 1 As shown, this embodiment provides an integral injection-molded PTC heater, including a PTC heating core 1 and a fixing plate 2, the PTC heating core 1 is arranged on the fixing plate 2, and the surroundings of the PTC heating core 1 and the fixing plate 2 A foamed silica gel 3 is provided, and the foamed silica gel 3 is integrally injection-molded with the PTC heating core 1 and the fixing plate 2 .

[0019] This embodiment also provides a method for preparing an integral injection-molded PTC heater, the steps of which are as follows:

[0020] Step 1: Clean the injection mold cavity, and spray liquid Teflon mold release agent in the injection mold cavity;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com