Patents

Literature

35results about How to "Reduce severe vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

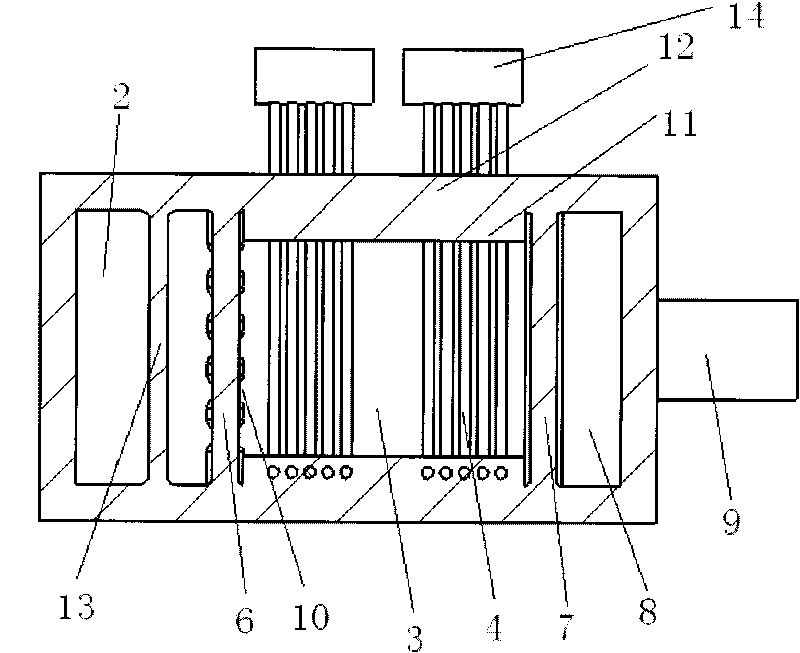

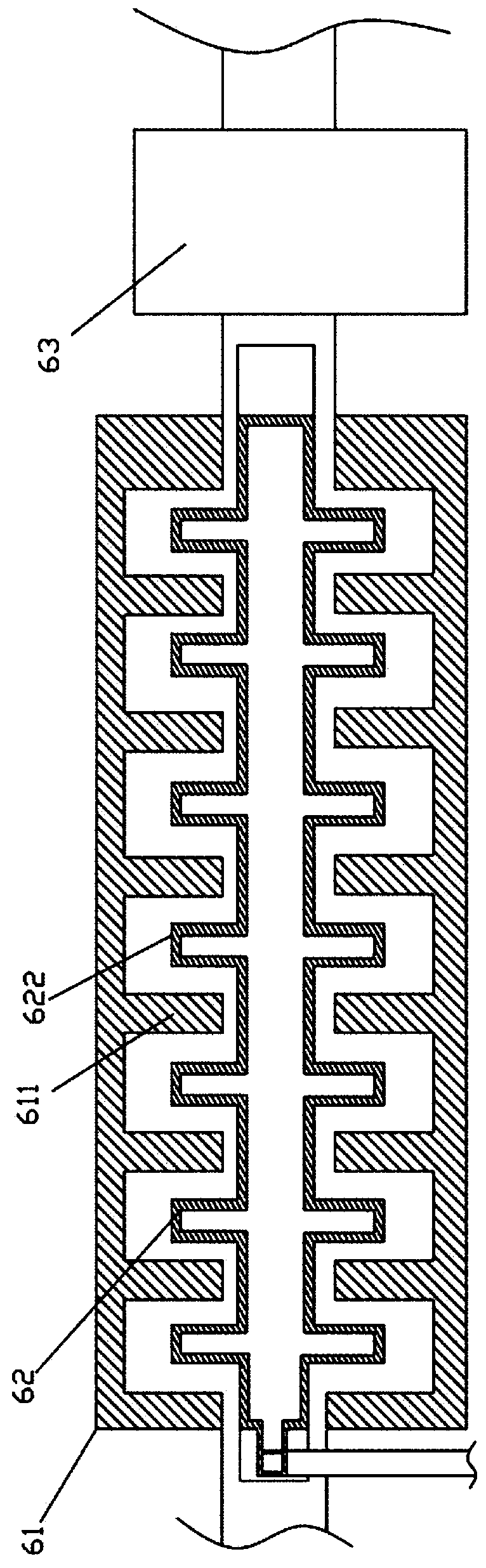

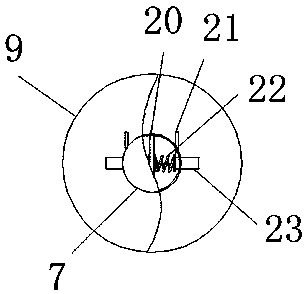

Rotor structure of switched reluctance motor for reducing vibration and noise

InactiveCN101667757AImprove vibrationImprove noiseMagnetic circuit rotating partsEngineeringControl theory

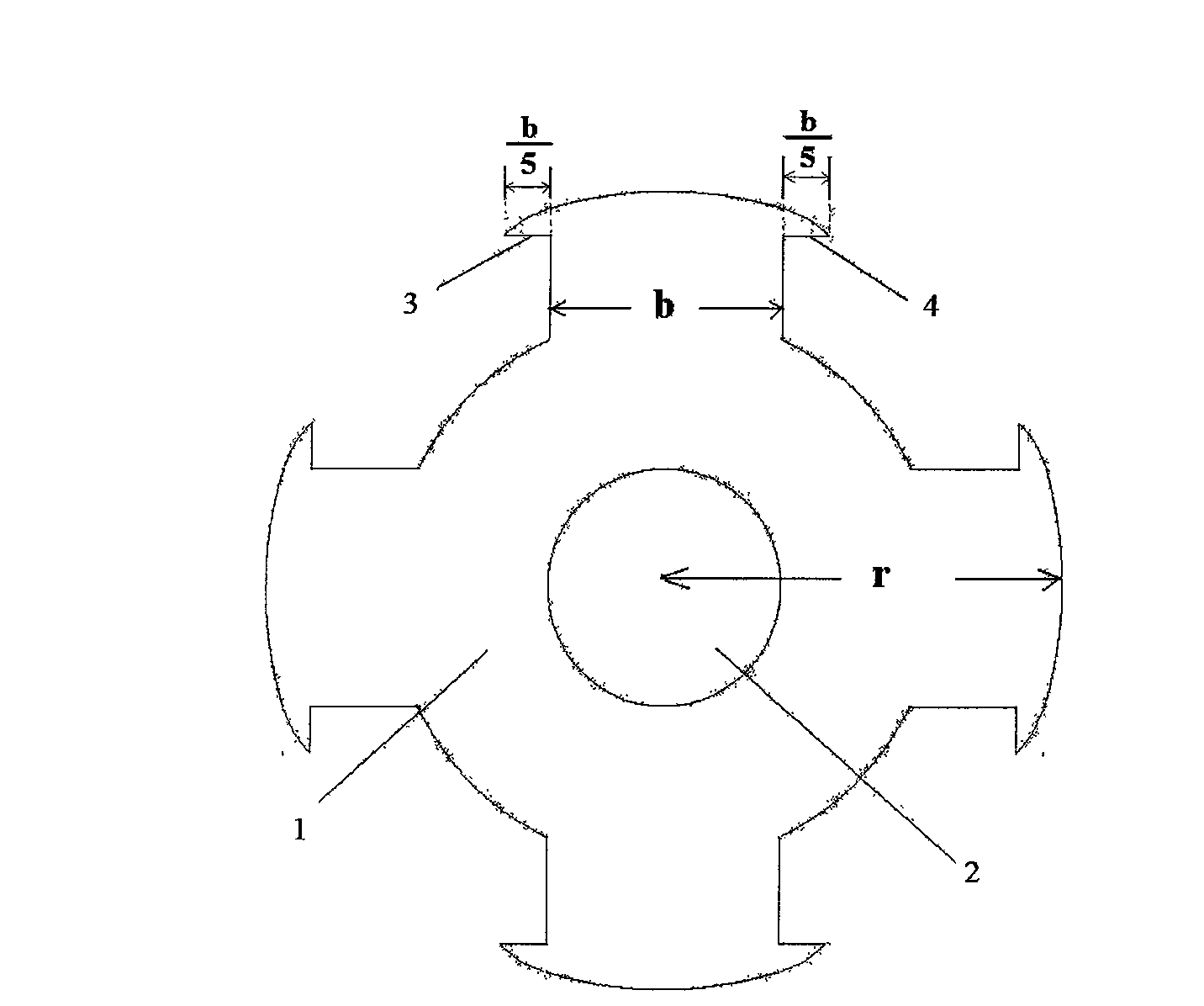

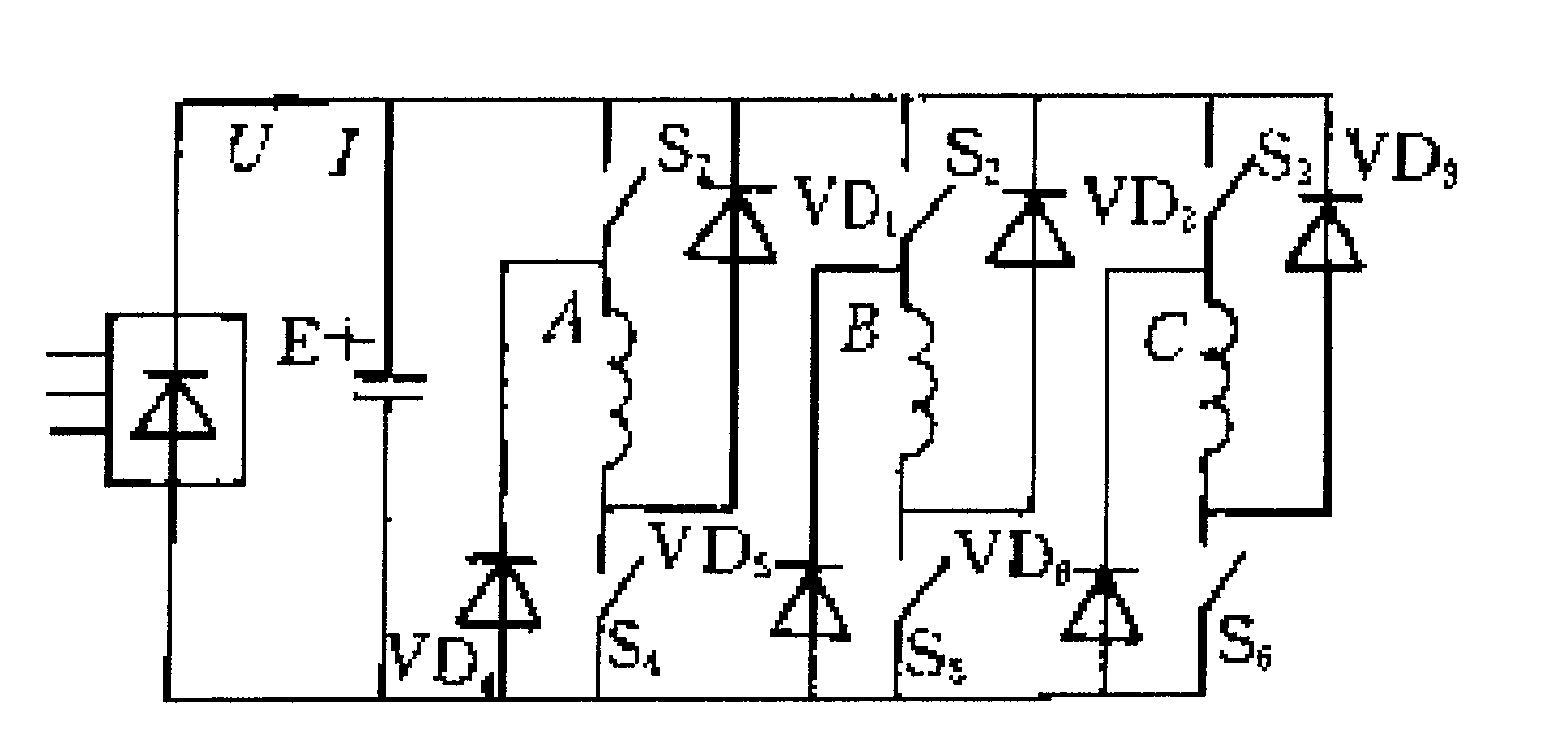

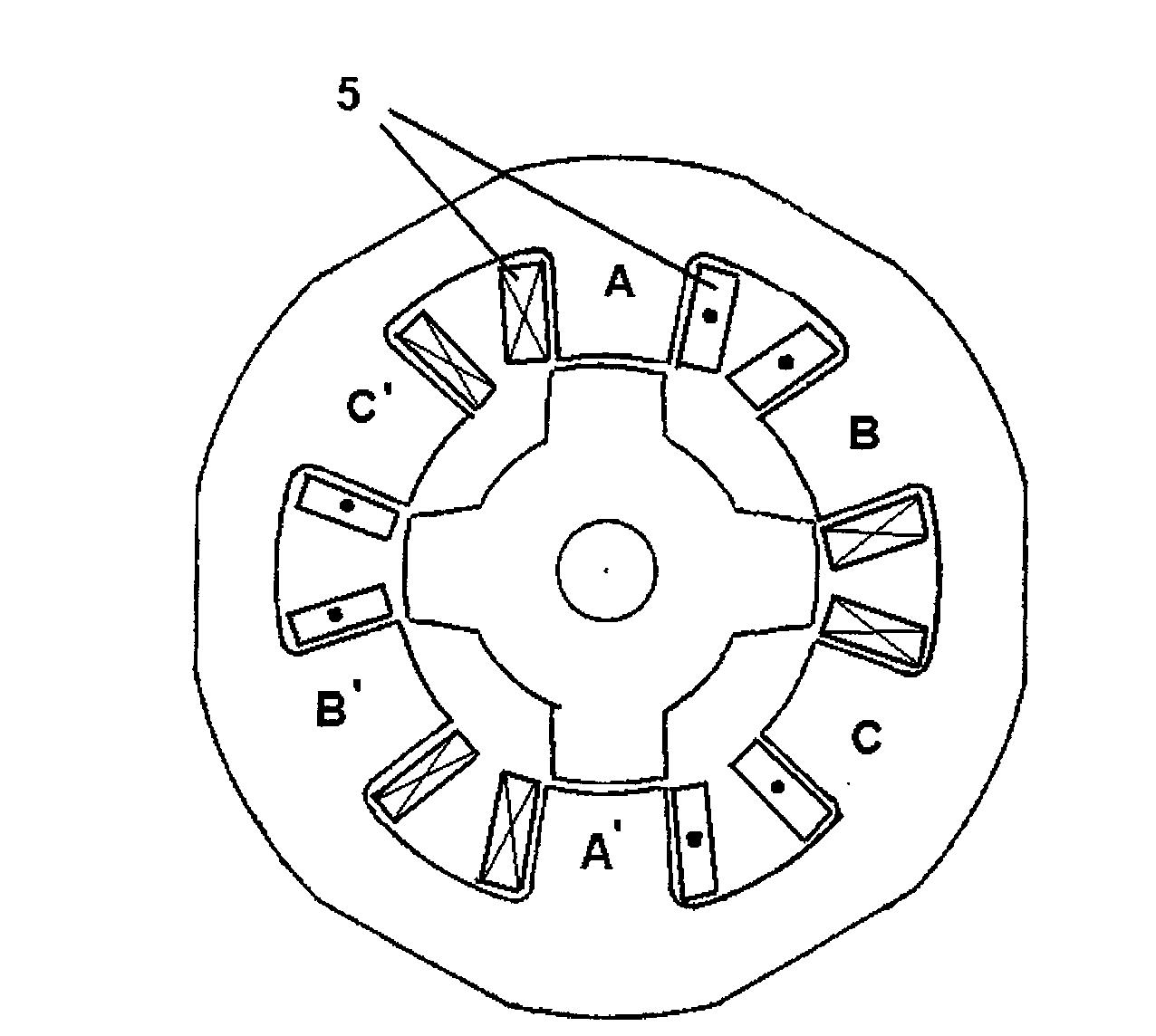

The invention relates to a rotor structure of a switched reluctance motor for reducing vibration and noise. The rotor structure is formed by stacking silicon steel sheets, and a salient pole structurewith a an arc-shaped pole tip is arranged at the tail end of a rotor pole, wherein the structure of rotor salient pole is that an arc-shaped pole tip extends left and right along the circumference ofthe rotor outer diameter at the tail end of each rotor salient pole. The invention can reduce great sudden change of radial force which is caused when a rotor edge and a stator pole edge are superposed in the rotation process of the motor rotor, reduces the compression and expansion vibration of a motor housing structure caused by sudden change of the radial magnetic attraction, reduce the torquefluctuation which is caused when the motor rotor edge and the stator pole edge are superposed during rotation and reduce the torque pulsation.

Owner:HEBEI UNIV OF TECH

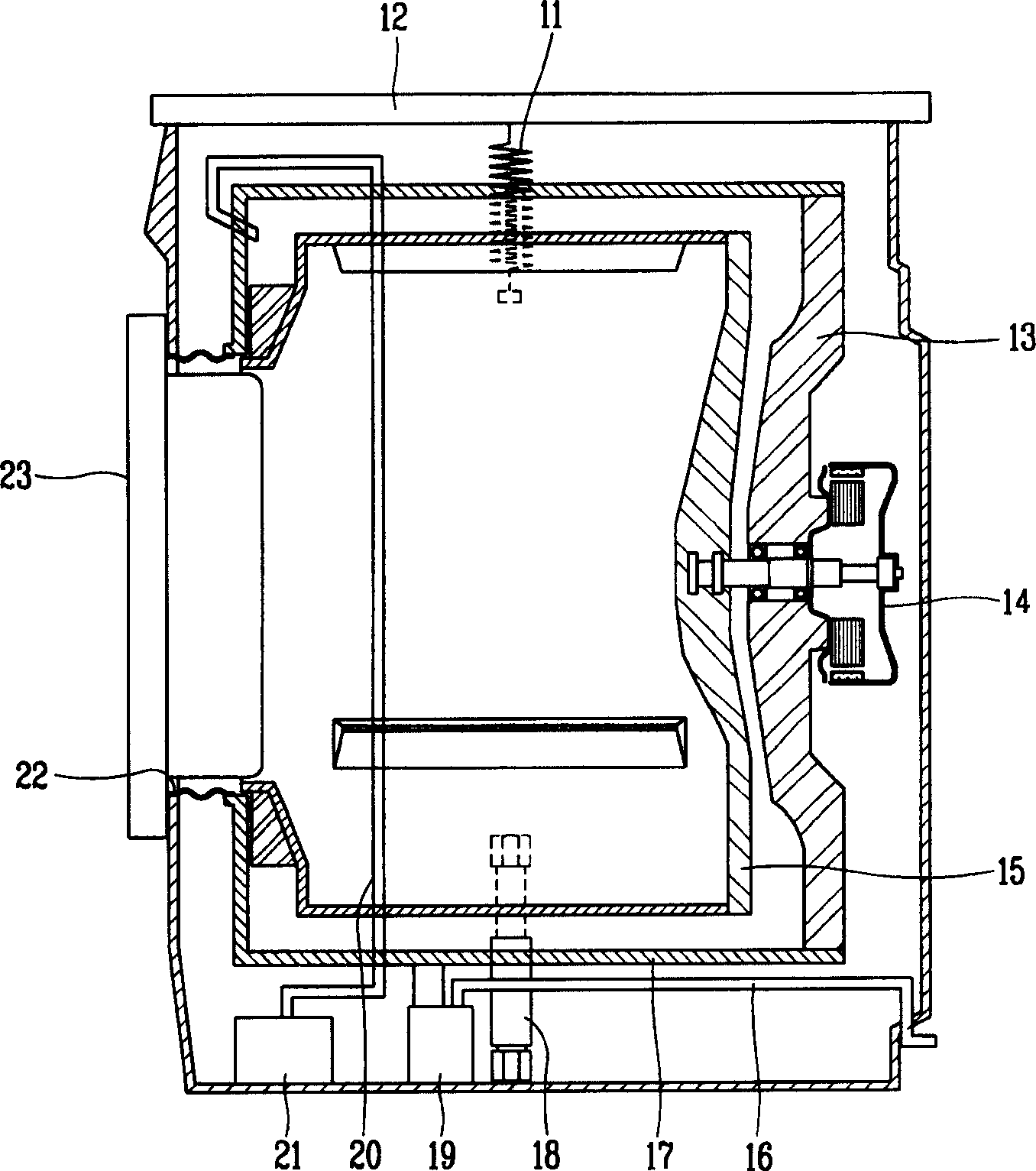

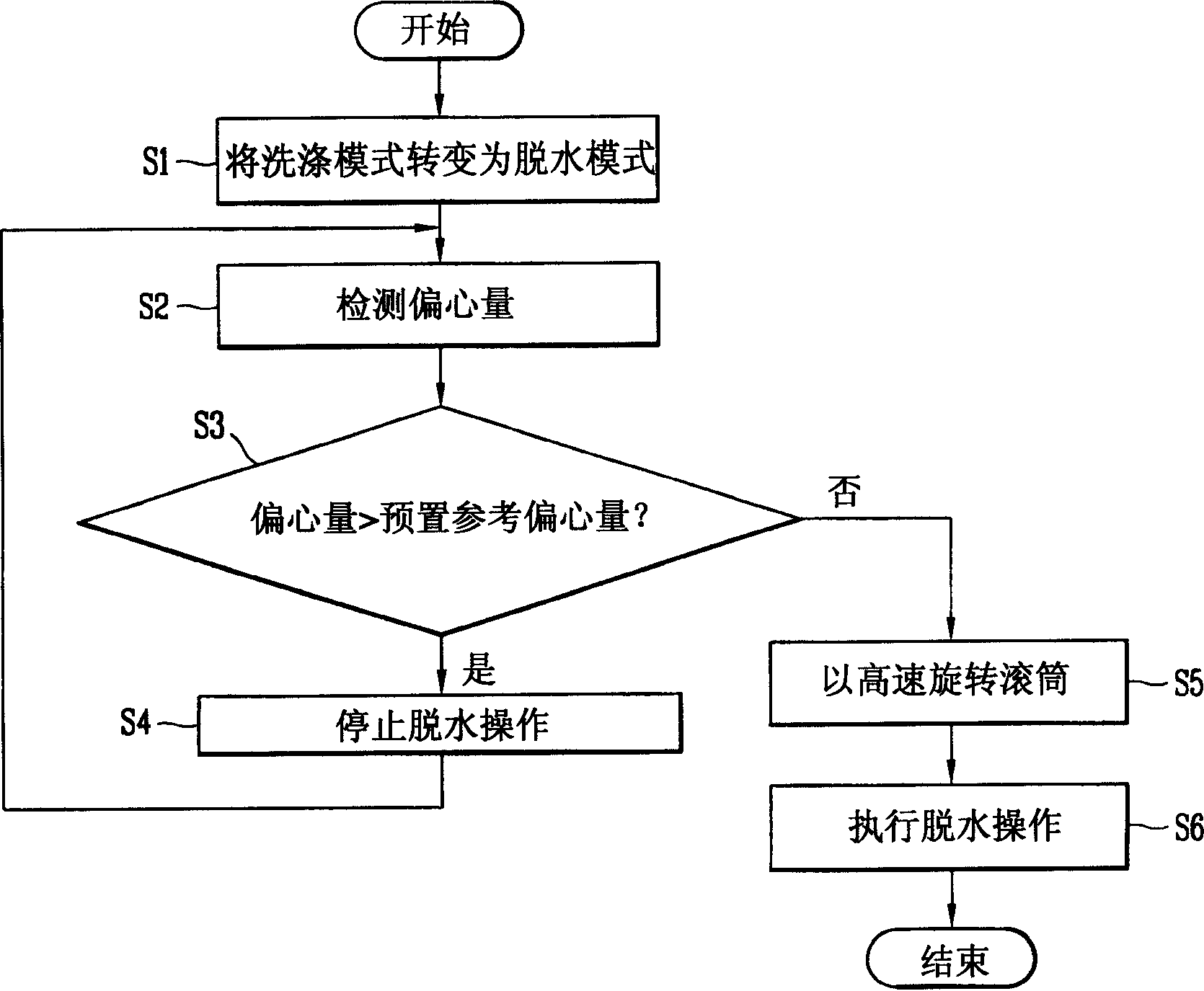

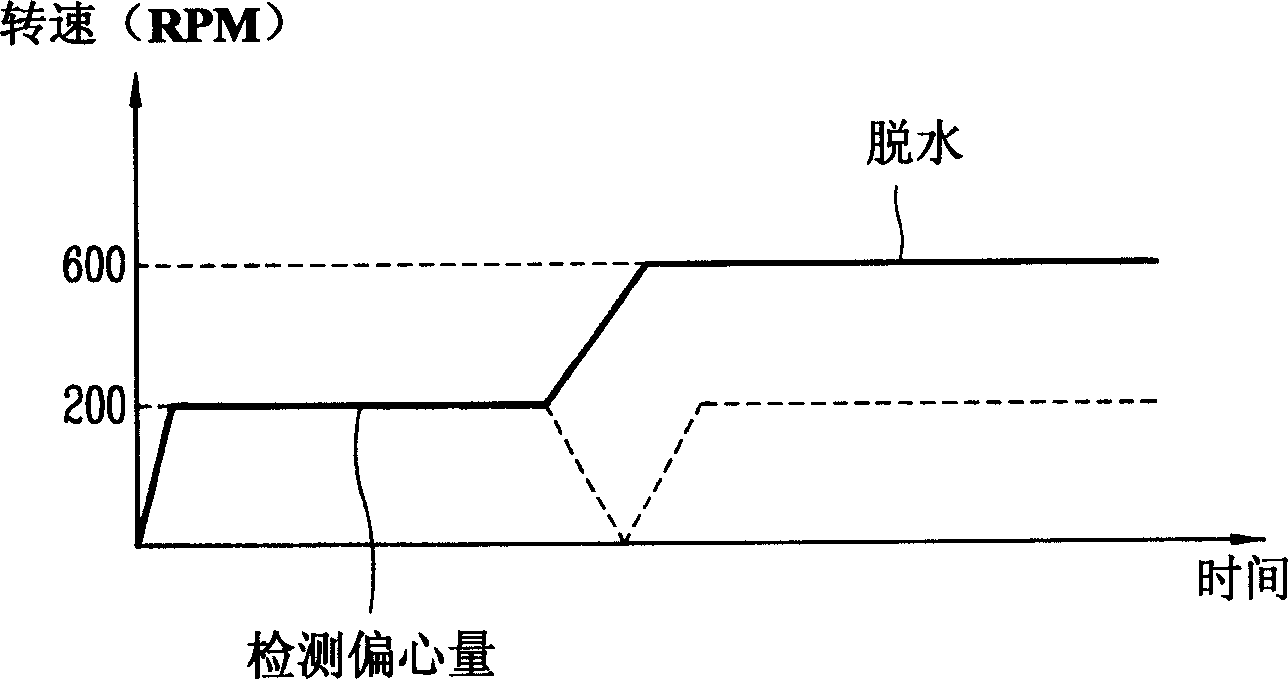

Method for controlling dewatering operation of washing machine

InactiveCN1621597AReduce severe vibrationReduce noiseOther washing machinesControl devices for washing apparatusLow speedEngineering

A method for controlling the dehydration operation of a washing machine, comprising: detecting an initial reference eccentric position and an initial eccentric amount of the drum when the drum of the washing machine rotates at a low speed; detecting the current eccentric position of the drum when the drum rotates at a high speed and then rotates at a low speed again and the current eccentricity amount; and controlling the dehydration operation according to the detected initial reference eccentricity position, the initial eccentricity amount, the current eccentricity amount and the current eccentricity amount.

Owner:LG ELECTRONICS INC

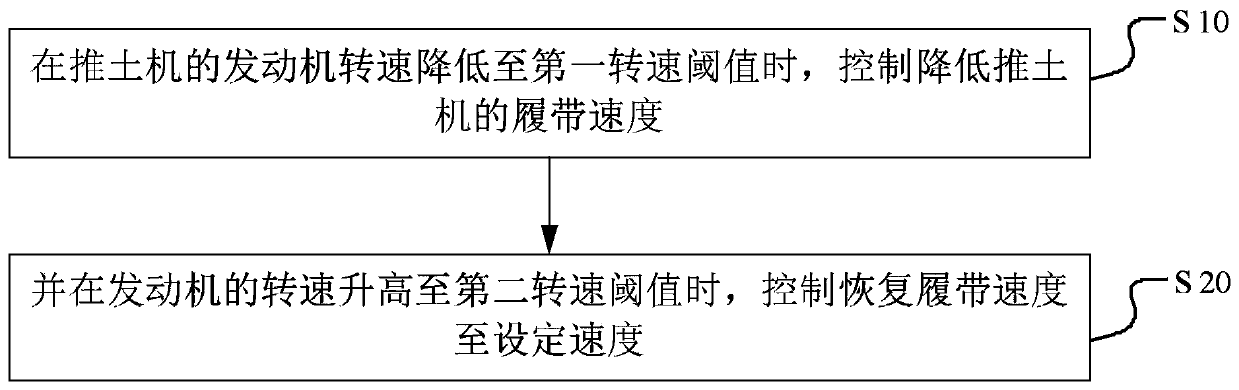

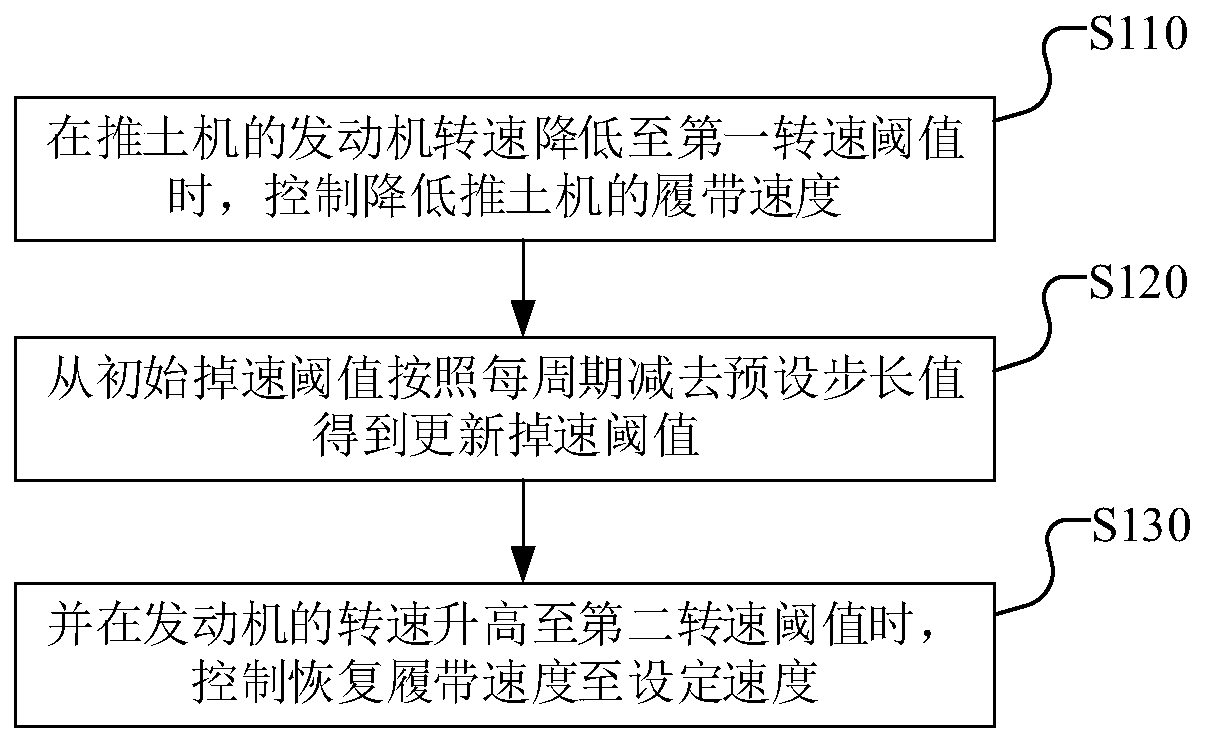

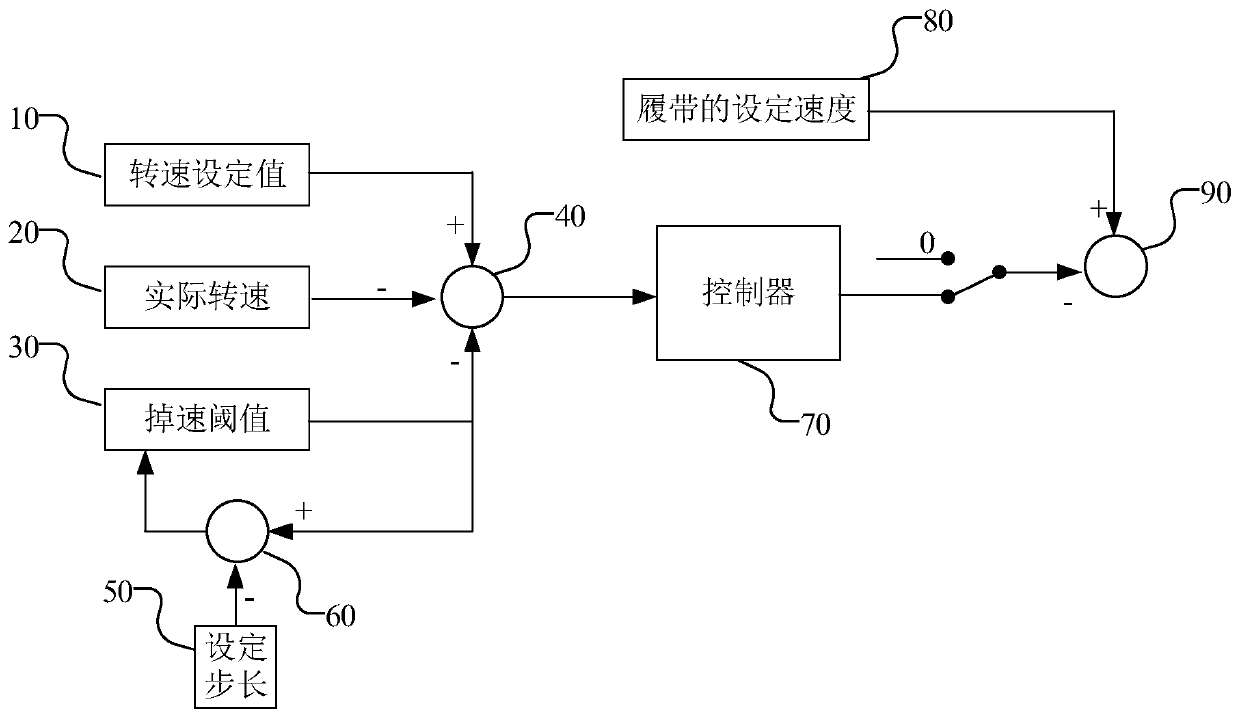

Bulldozer crawler belt speed control method and device and bulldozer

ActiveCN110905022ATrack speed reductionReduce severe vibrationMechanical machines/dredgersBelt speedControl theory

The embodiment of the invention discloses a bulldozer crawler belt speed control method and device and a bulldozer, and the control method comprises the following steps: controlling to reduce the crawler belt speed of the bulldozer when the rotating speed of an engine of the bulldozer is reduced to a first rotating speed threshold value; when the rotating speed of the engine rises to a second rotating speed threshold value, controlling the crawler belt speed to be recovered to the set speed, wherein the first rotating speed threshold value is smaller than the second rotating speed threshold value. By distinguishing the rotating speed threshold value for entering the flameout prevention function and the rotating speed threshold value for exiting the flameout prevention function, the problems of high acceleration speed and large vibration during slipping of the whole vehicle are effectively solved, and violent vibration, caused by slipping, of the whole vehicle is relieved.

Owner:WEICHAI POWER CO LTD +1

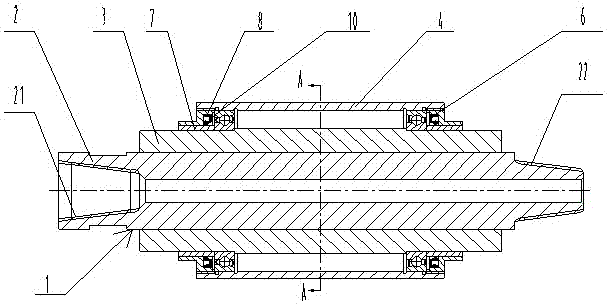

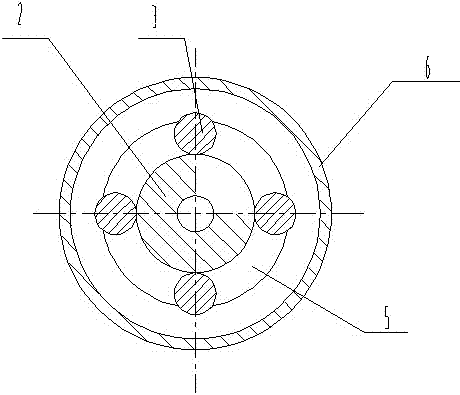

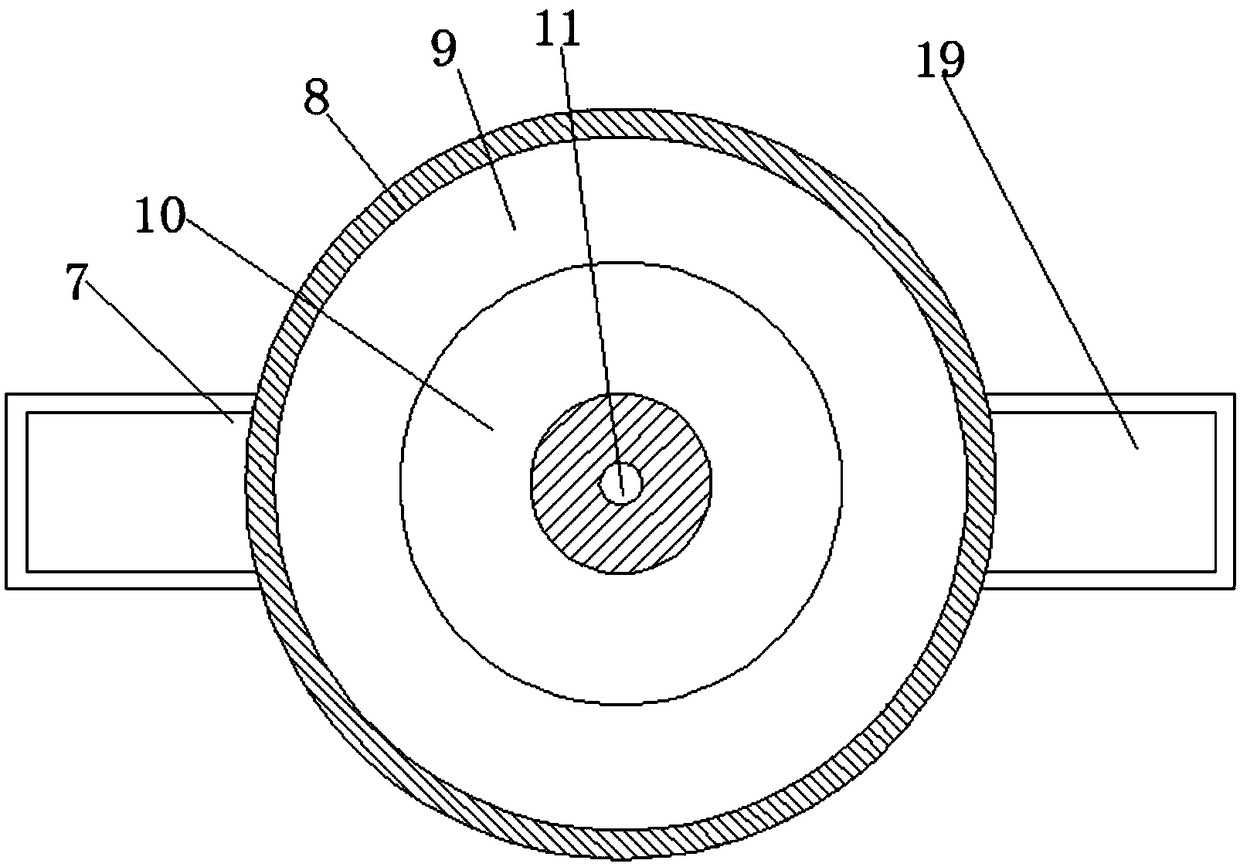

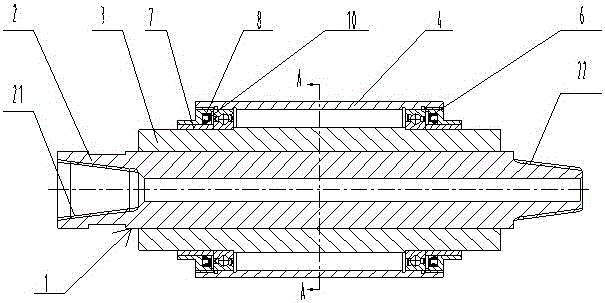

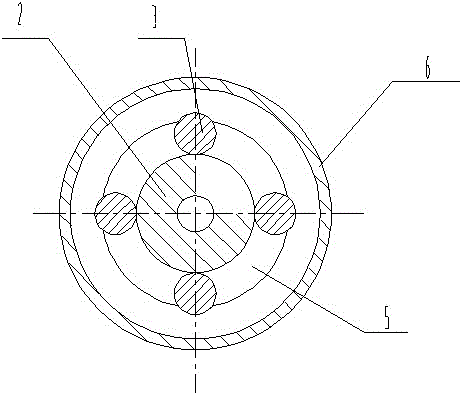

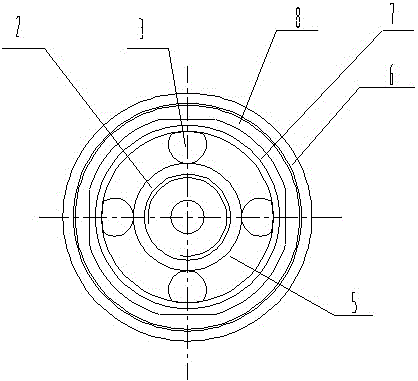

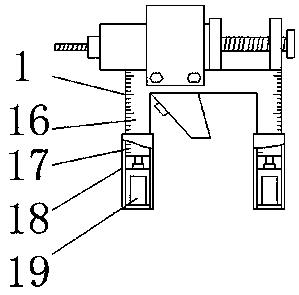

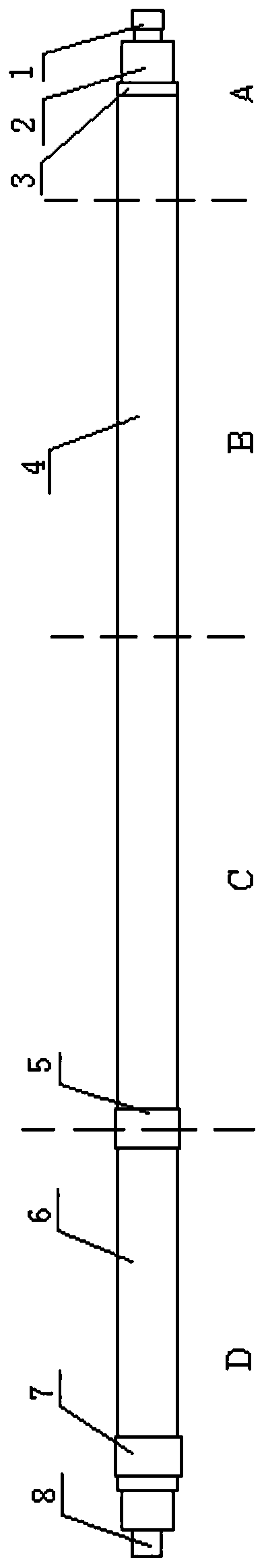

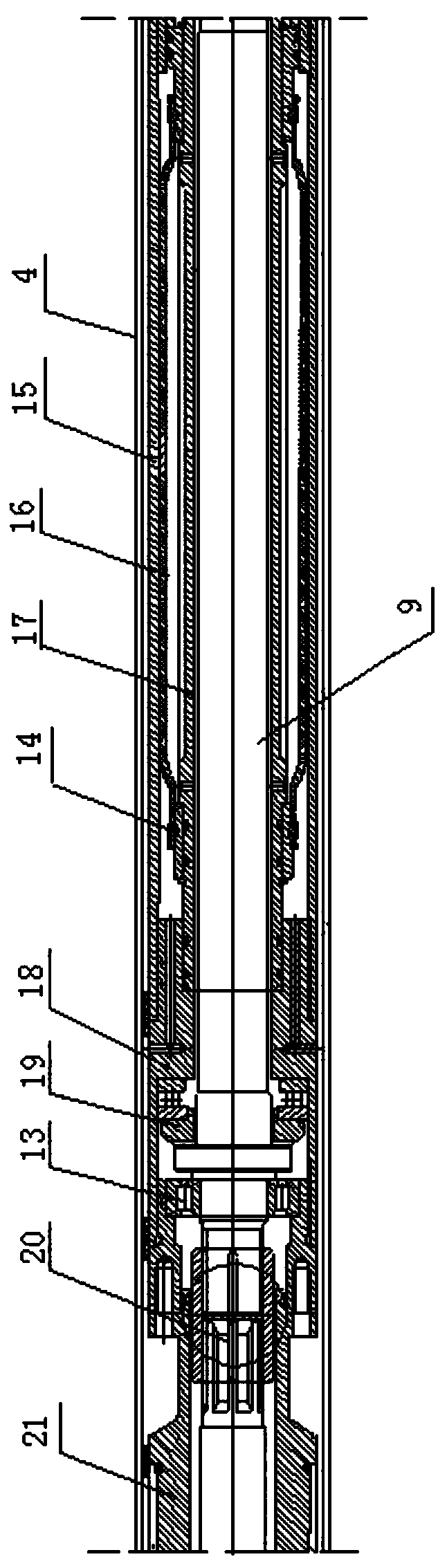

Centering device for drill rod in hole of engineering driller

ActiveCN103615201AAvoid oblique holesMeet the process requirementsDrilling rodsDrilling casingsRolling-element bearingStructural engineering

The invention discloses a centering device for a drill rod in a hole of an engineering driller. The centering device comprises a central spindle, ribs and an outer shell. The hollow central spindle is located at the center, wherein the two ends of the central spindle are provided with a conical internal thread and a conical external thread respectively. The number of the ribs is two or more, and the ribs are evenly arranged on the outer surface of the central spindle to be firmly connected with the central spindle. A gap is reserved between every two adjacent ribs to form a through groove. The two ends of the outer shell are respectively provided with a rolling bearing, wherein the inner side of the rolling bearing is arranged on the outer surface each rib in a supporting mode, the outer side of the rolling bearing is in close fit with the inner surface of the outer shell, and the ribs and the outer shell rotate relative to each other through the rolling bearing. The centering device can keep the thin and long drill rod running stably, make the axis of a drill bit be close to the center line of the drilled hole as much as possible, effectively prevent the hole from inclining, mitigate violent vibration of a drill rod elastic system in the hole in the radial direction and in the axial direction, and reduce deflecting friction between the drill rod and the drill bit; besides, the drill rod does not make direct contact with the wall of the hole so that damage to the wall of the hole can be reduced effectively, and torque required for drilling is reduced.

Owner:CHONGQING EXPLORATION MACHINER FACTORY

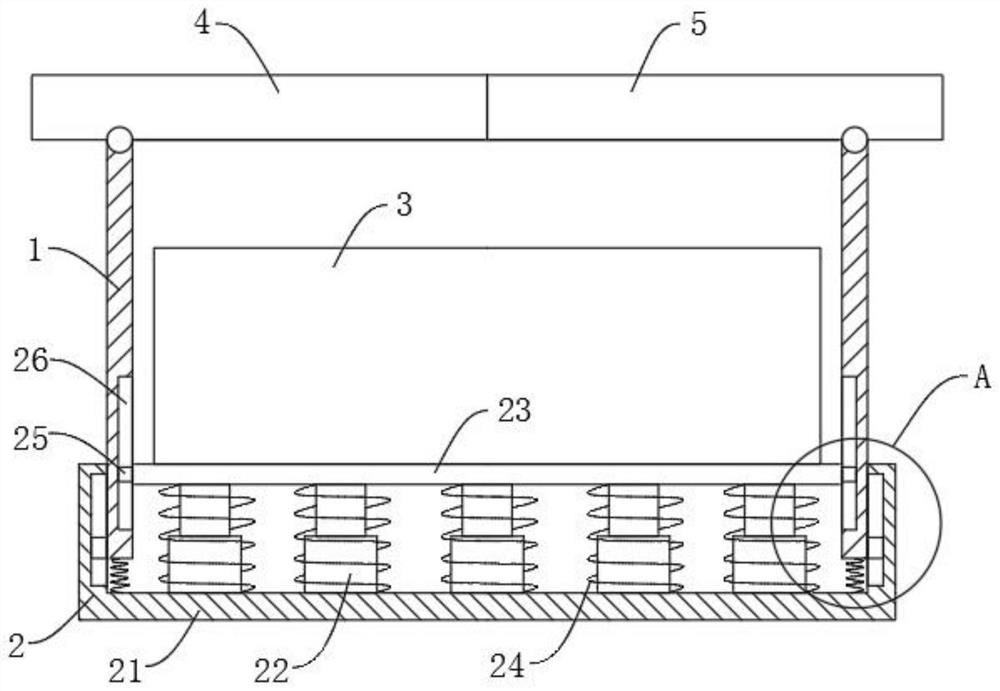

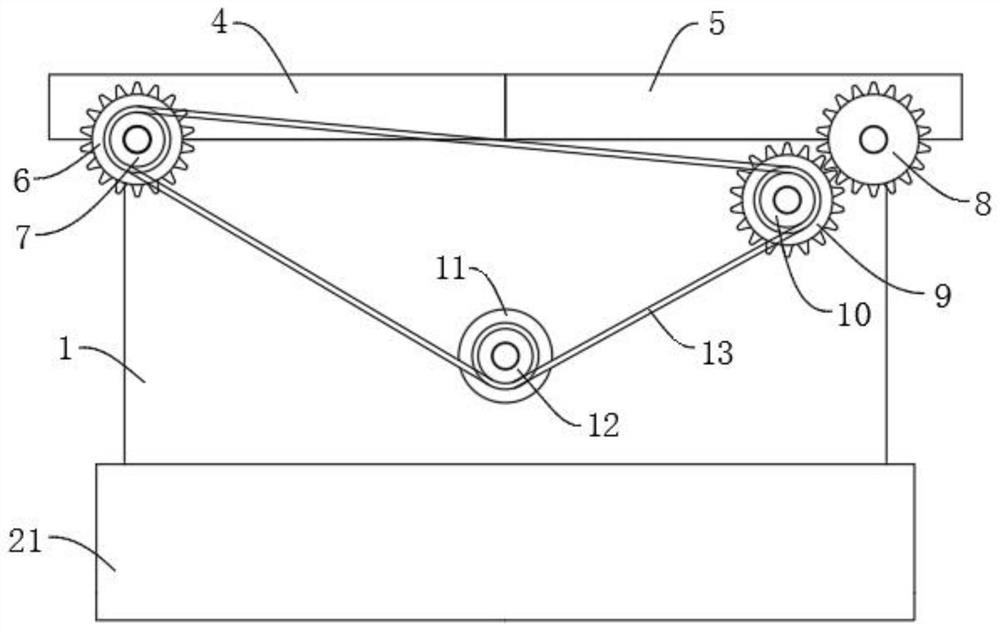

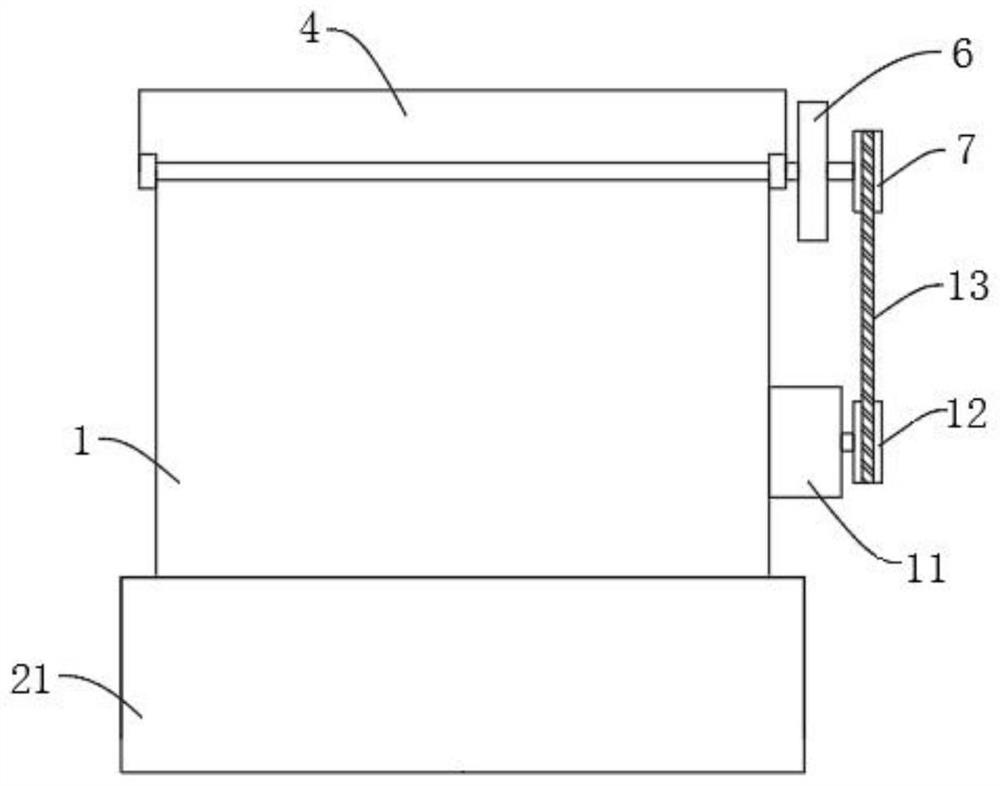

Buffer device for garment processing

InactiveCN112943855ATo achieve the buffer effectImprove buffering effectConveyorsNon-rotating vibration suppressionPulleySupport plane

The invention discloses a buffer device for garment processing. The buffer device comprises a buffer base, ventilation pipes are fixedly connected to the two sides of the buffer base, air bags are slidably connected to the outer side walls of one ends of the ventilation pipes, rubber sleeves fixedly sleeve the outer side walls of the air bags, a first cavity, a second cavity and a supporting frame are arranged in the buffer base, a fixed pulley support is fixedly connected to the top of the supporting frame, and a driving fixed pulley is rotationally connected with the inner side wall of the fixed pulley support. According to the buffer device for garment processing, by arranging the ventilation pipes, the air bags and the rubber sleeves, the air bags expand due to inflation of air, so that a garment processing outer frame obtains a good buffering effect, and strenuous vibration generated in the processing process of a garment processing device is effectively reduced; and meanwhile, a plurality of springs is avoided, and errors caused by displacement generated in the garment processing process when the springs exceed the elastic limit range of the springs are avoided.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

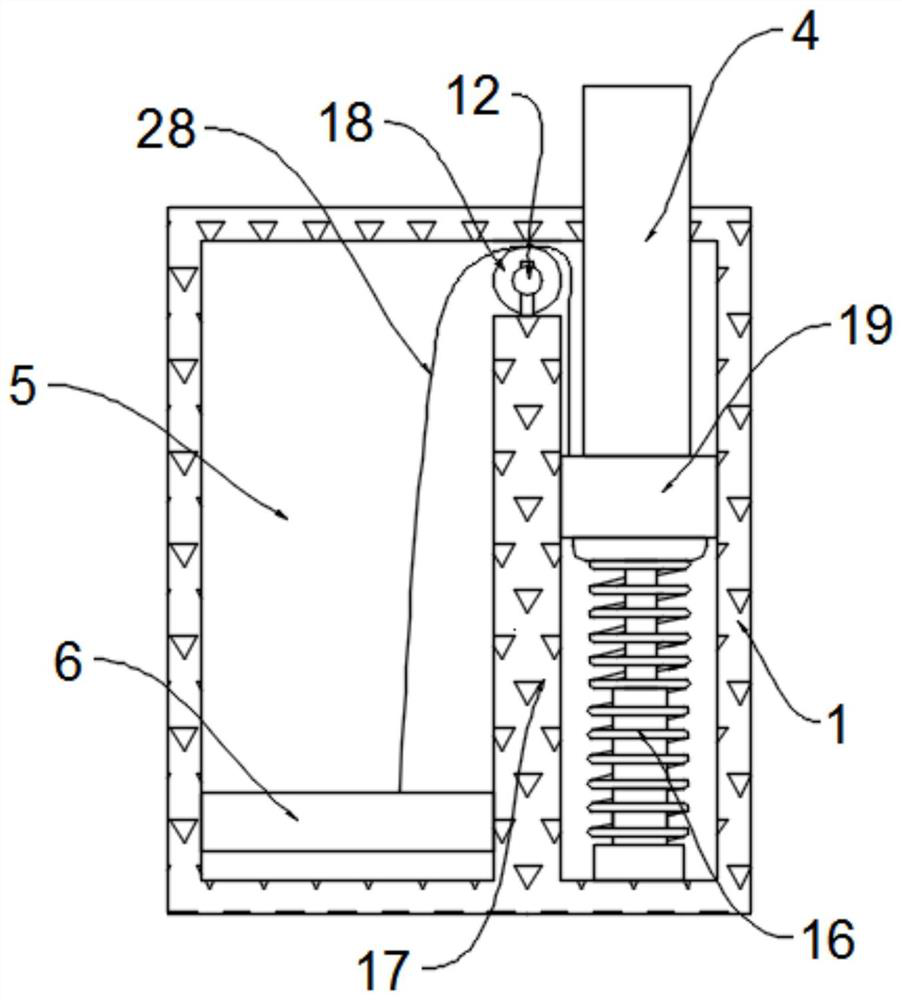

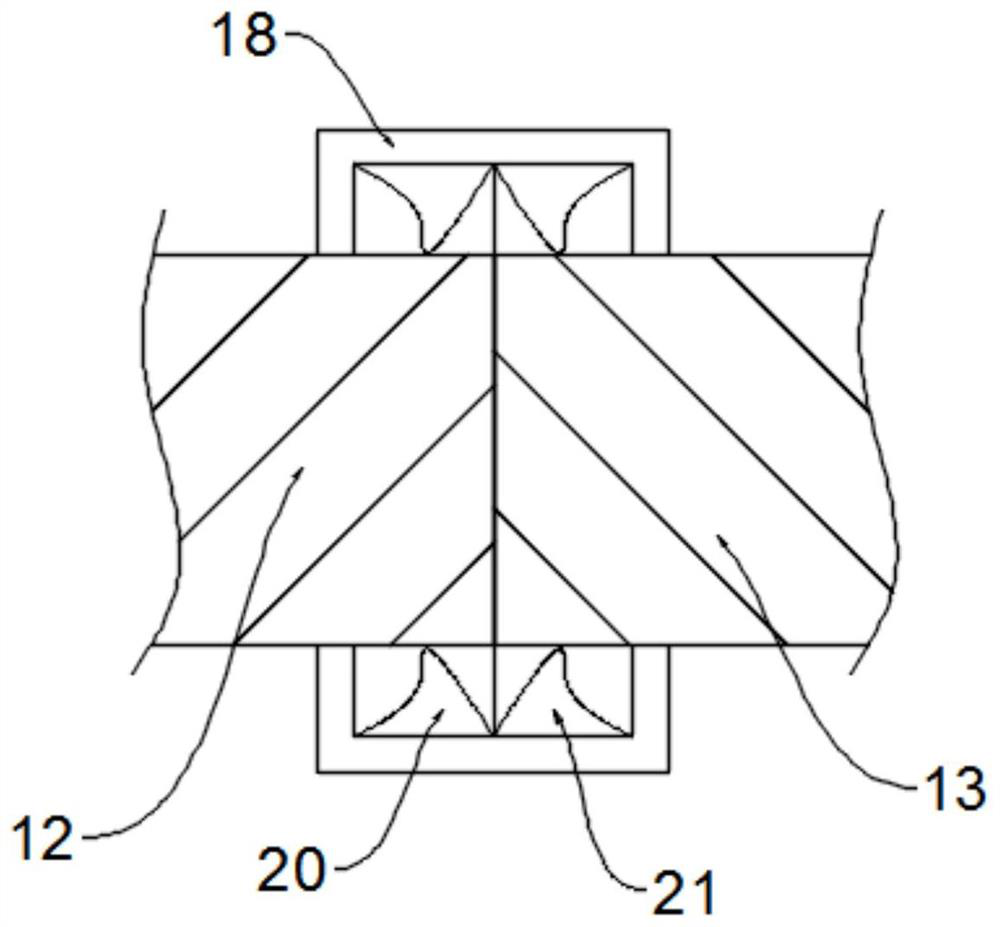

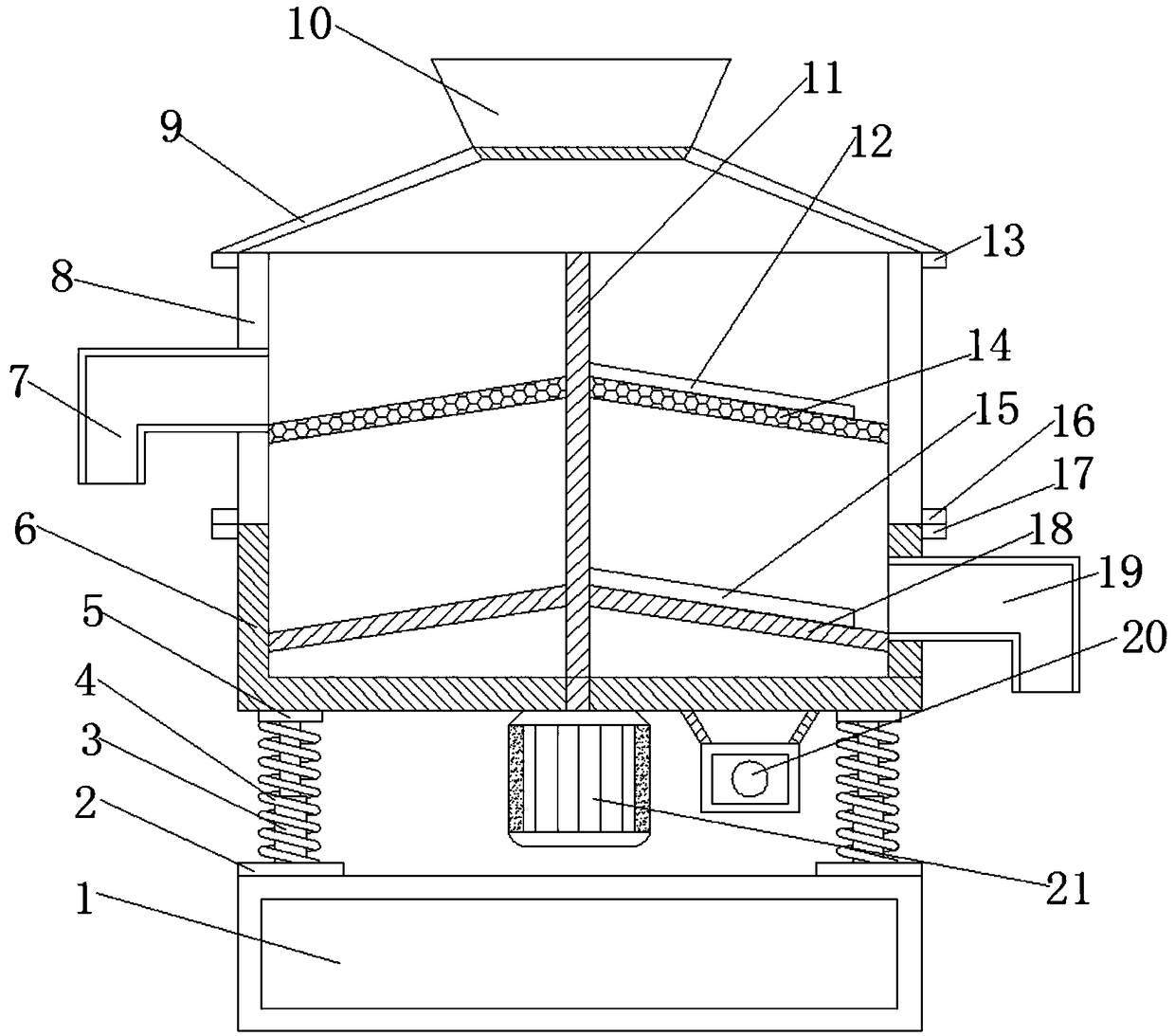

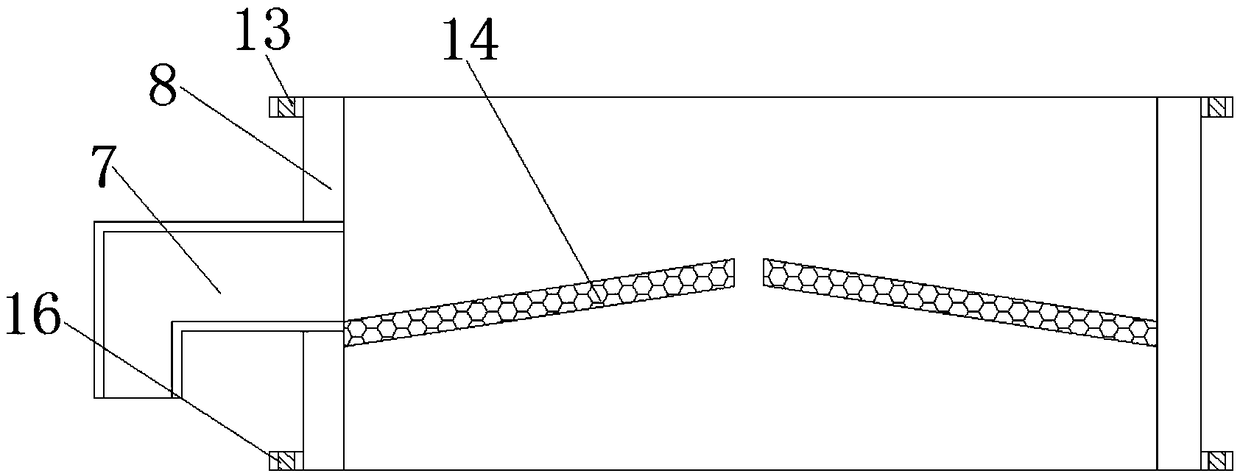

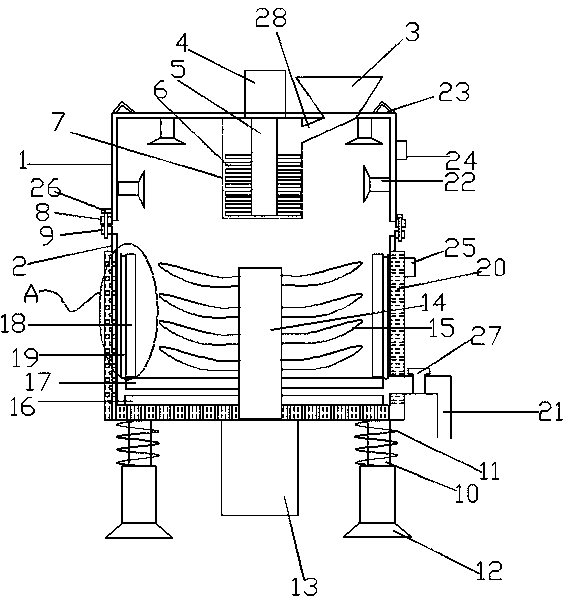

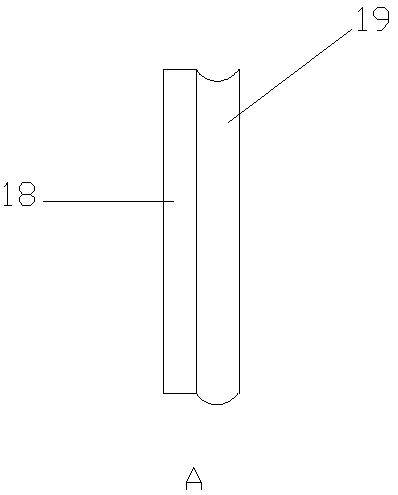

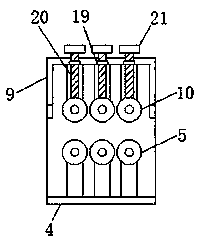

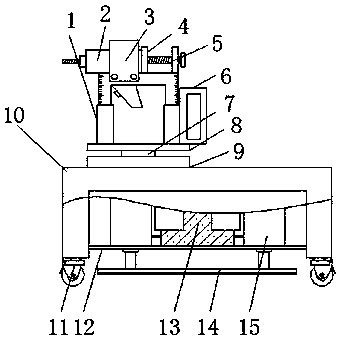

Traditional Chinese medicine powder screening device

InactiveCN109092669AReduce severe vibrationAvoid affecting useSievingScreeningElectric machineryEngineering

The invention discloses a traditional Chinese medicine powder screening device. The traditional Chinese medicine powder screening device comprises a main machine seat. Three first mounting plates areconnected to the top circumference of the main machine seat through bolts, hydraulic rods are connected to the tops of the three first mounting plates through bolts, three second mounting plates are connected to the tops of the three hydraulic rods through bolts, and the tops of the three second mounting plates are connected with a same bottom tank through bolts. According to the traditional Chinese medicine powder screening device, a shock absorption mode which combines the hydraulic rods and a shock absorption spring is installed on the combination part of the main machine seat and the bottom tank through the two mounting plates, so that severe shock caused by a shock motor in the device is reduced when the device is in operation. A motor is connected to the middle of the bottom of the bottom tank through bolts, an output shaft of the motor is connected with a rotating shaft positioned in the middle of a tank body; and the outer wall of the circumference of the rotating shaft is connected with a scraping plate, so that accumulated materials are scraped after screening, material taking by the device is facilitated, and the problem that the use of the device is affected due to thefact that coarse materials are stuck on a screen is solved.

Owner:天马(安徽)国药科技股份有限公司

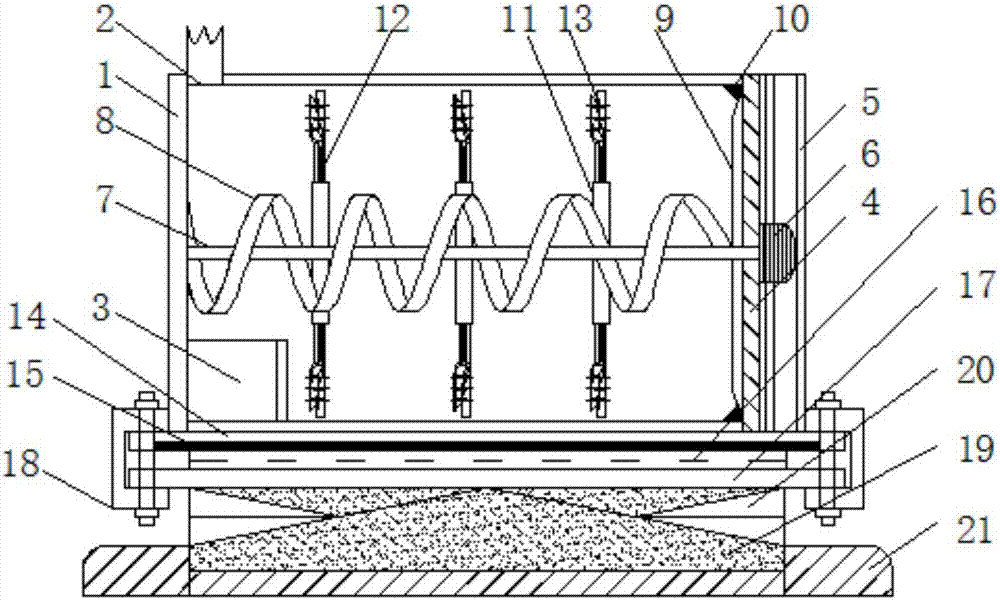

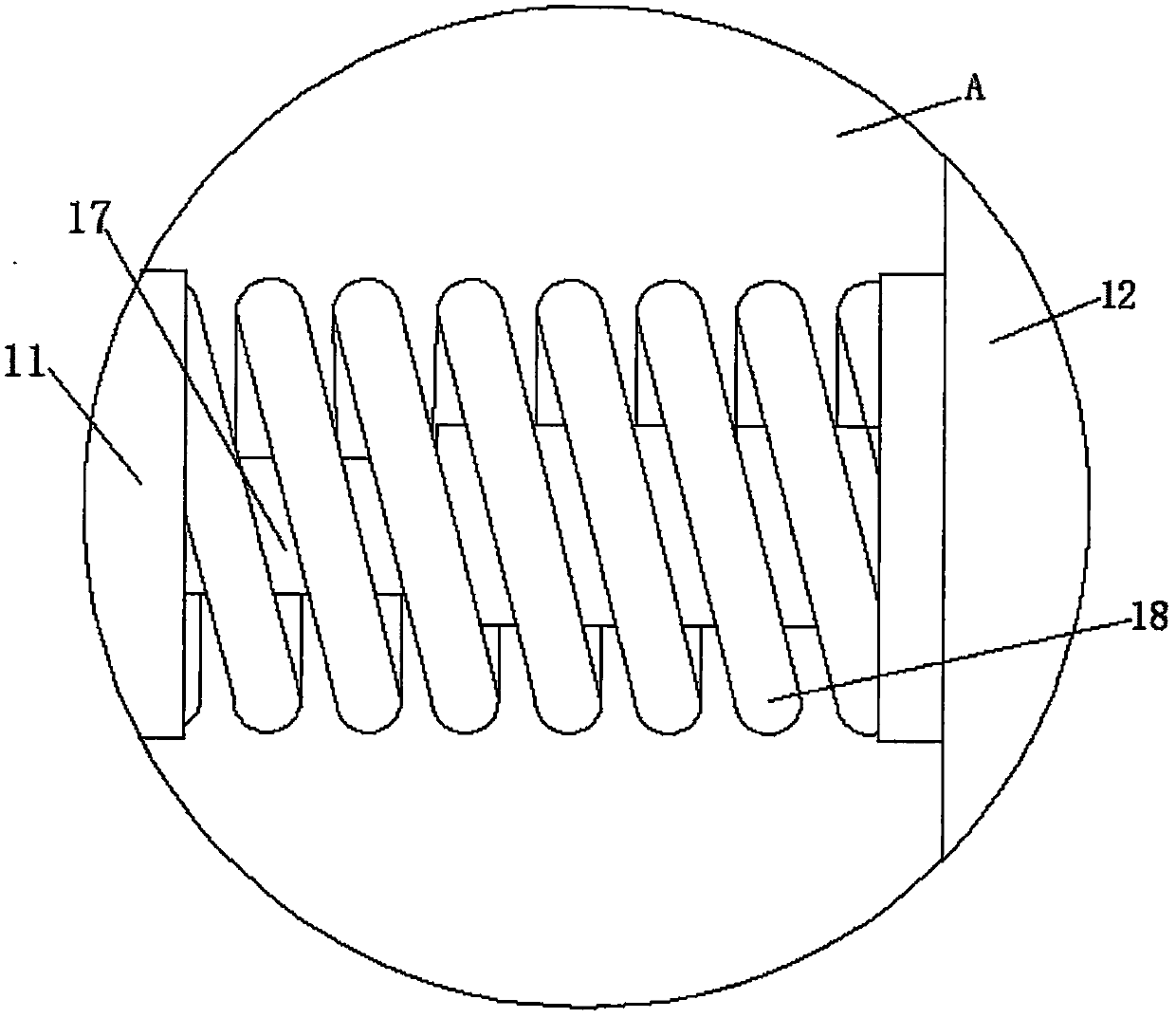

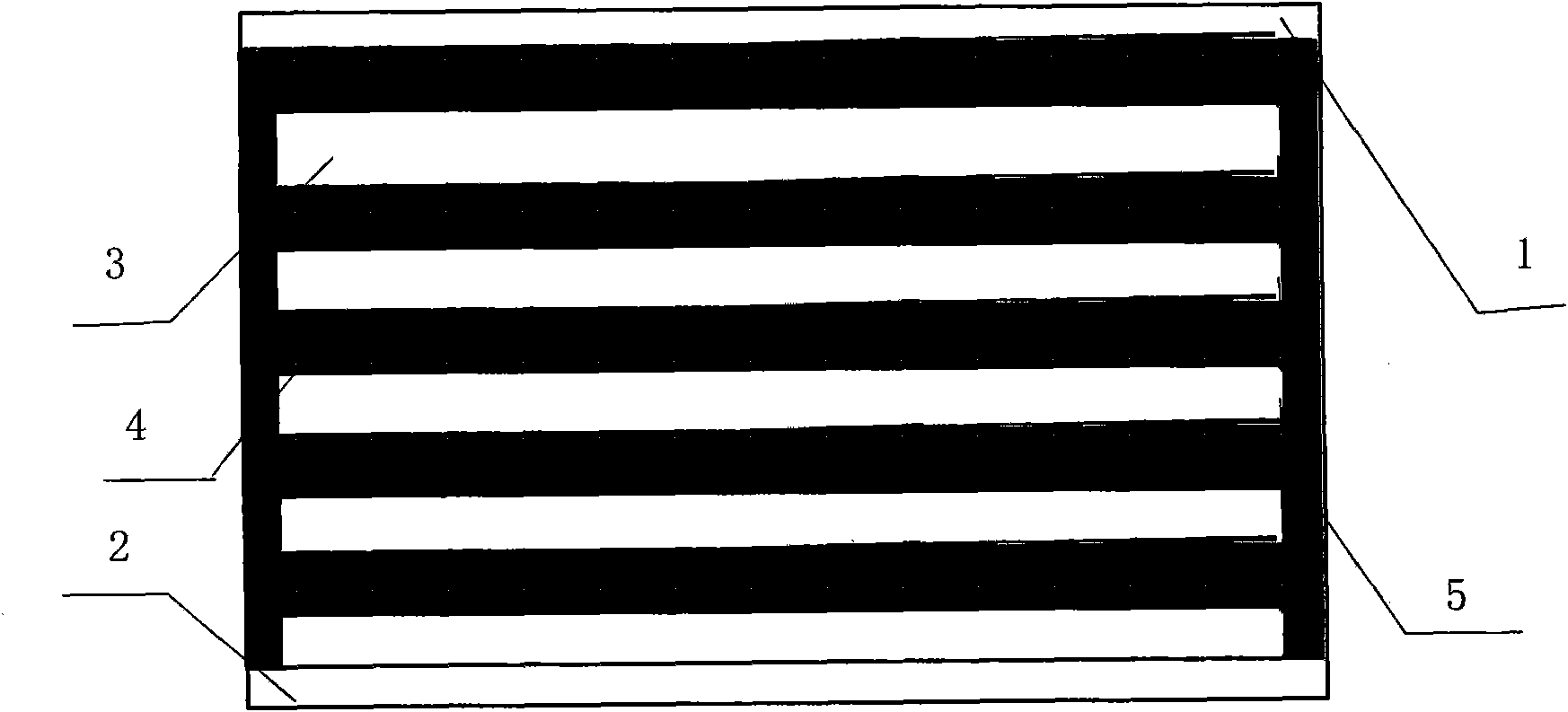

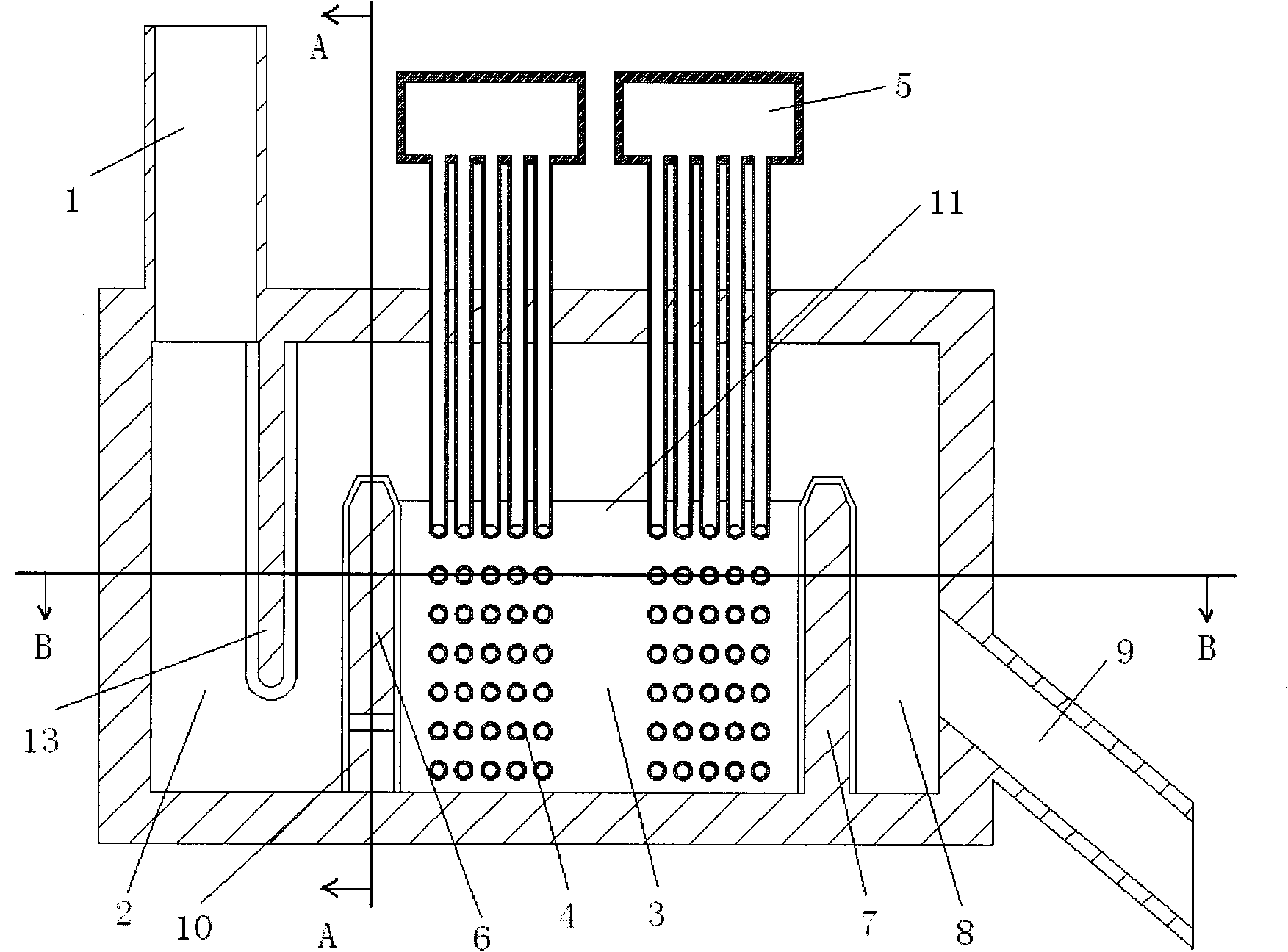

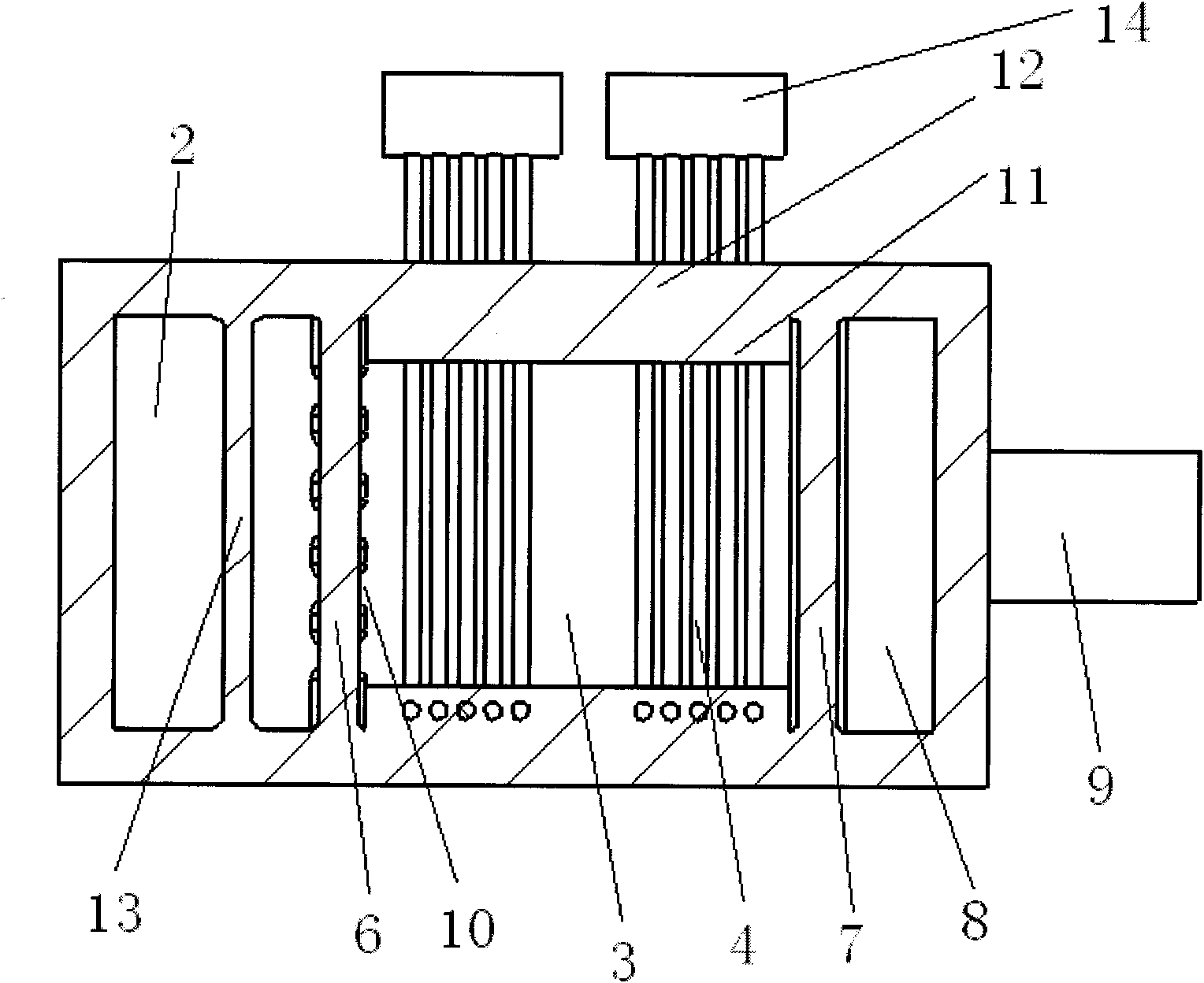

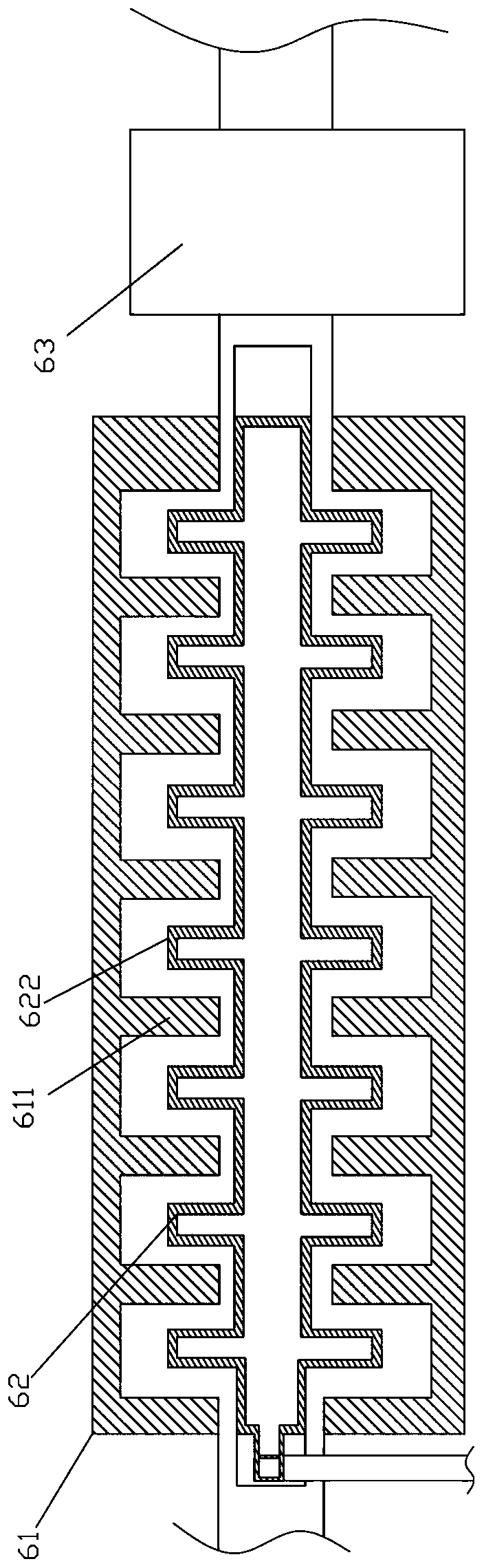

Undercurrent external heat exchanger of circulating fluidized bed

ActiveCN101701704AChange the fixation methodReduce severe vibrationFluidized bed combustionSteam boilersFluidized bedHeat transmission

The invention relates to an undercurrent external heat exchanger of a circulating fluidized bed, which comprises a feeding vertical pipe, a feeding chamber, a heat exchanging chamber, a coiled pipe heating surface arranged in the heat exchanging chamber, an inlet header, an outlet header, a first partition wall, a second partition wall, an overflow chamber, an ash returning pipe, and an undercurrent hole; wherein a row of undercurrent holes are arranged at the lower part of the first partition wall between the feeding chamber and the heat exchanging chamber so that both of the upper part and the lower part of the heat exchanging chamber are supplemented by high temperature circulating ash, thus improving the flowing and heat exchanging condition of a dead zone in the heat exchanging chamber; and the upper rand lower temperature gradient of the heating exchanging chamber decreases, which is beneficial to the mixing of the circulating ash; the integral heat exchanging performance of the heat exchanging chamber is enhanced; a walling is arranged next to a side wall; the bend part of the coiled pipe heating surface is buried in the waling, not only bears the support and fixes the coiled pipe and heat exchanger, reduces the vibration of the heat exchanger, but also protects the bend of the heat exchanging surface of the coiled pipe not to be corroded by the circulating ash. The technical solution of the invention is easily realized and beneficial to solve the problems of heat transmission, vibration and abrasion of the external heat exchanger.

Owner:TSINGHUA UNIV

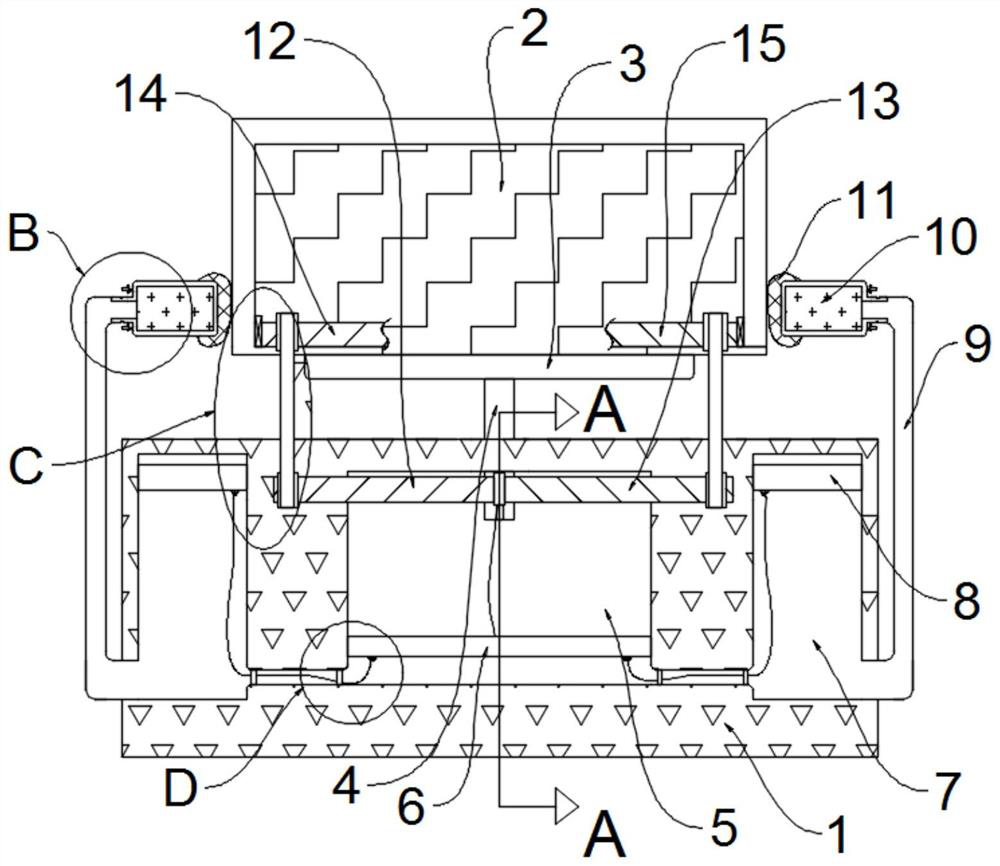

Crushing and mixing equipment for cosmetic production

InactiveCN108854626AAffect the mixing effectAvoid uneven mixingRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

Owner:HEFEI FENGJIE BIOLOGICAL TECH CO LTD

Vibration-proof noise-reducing agitator for feeds

InactiveCN107159043AReduce vibrationReduce severe vibrationFeeding-stuffTransportation and packagingMachine partsEngineering

The invention discloses a vibration-proof noise-reducing agitator feeds. The vibration-proof noise-reducing feed agitator comprises an agitator shell; the bottom of the inner cavity of the agitator shell is fixedly provided with a discharge outlet; a fixed plate is fixedly mounted on the left side of the agitator shell; a side plate is fixedly mounted on the side surface of the fixed plate; a rotating shaft movably connected with the output shaft of a driving motor is inserted into the central part of the side plate; a rotary fin sleeves the rotating shaft; the upper and lower ends of an air blowpipe are both fixedly provided with inclined plates located in the agitator shell; the upper and lower ends of the rotating shaft are both fixedly provided with installation rods; installation blocks are fixedly mounted on the tops of the installation rods; and agitation devices are fixedly mounted on the tops of the installation blocks. The vibration-proof noise-reducing feed agitator provided by the invention has the advantages of vibration prevention and noise reduction properties and overcomes the problem that violent vibration and frictional noise of machine parts due to great vibration and shaking during agitation of materials via conventional agitation devices result in noise pollution to surrounding environments and are not beneficial for prolonging the service life of machines.

Owner:张思银

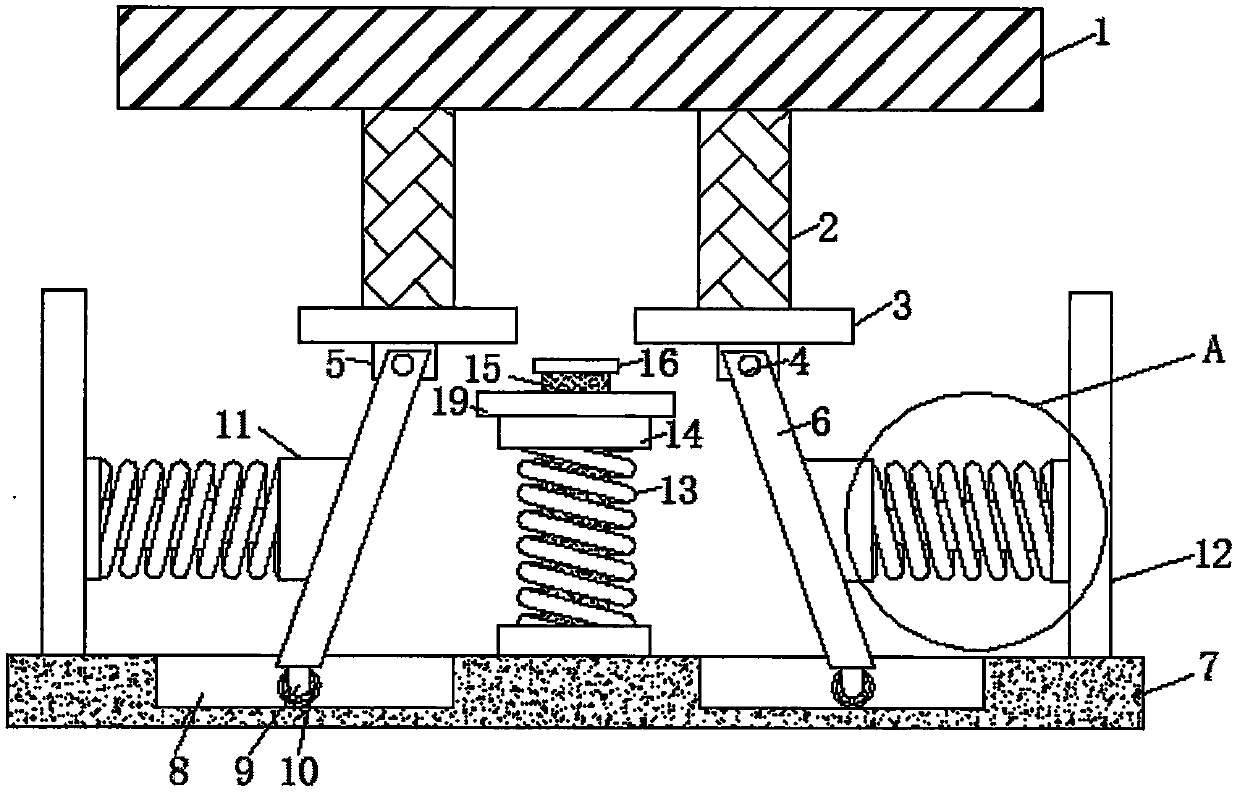

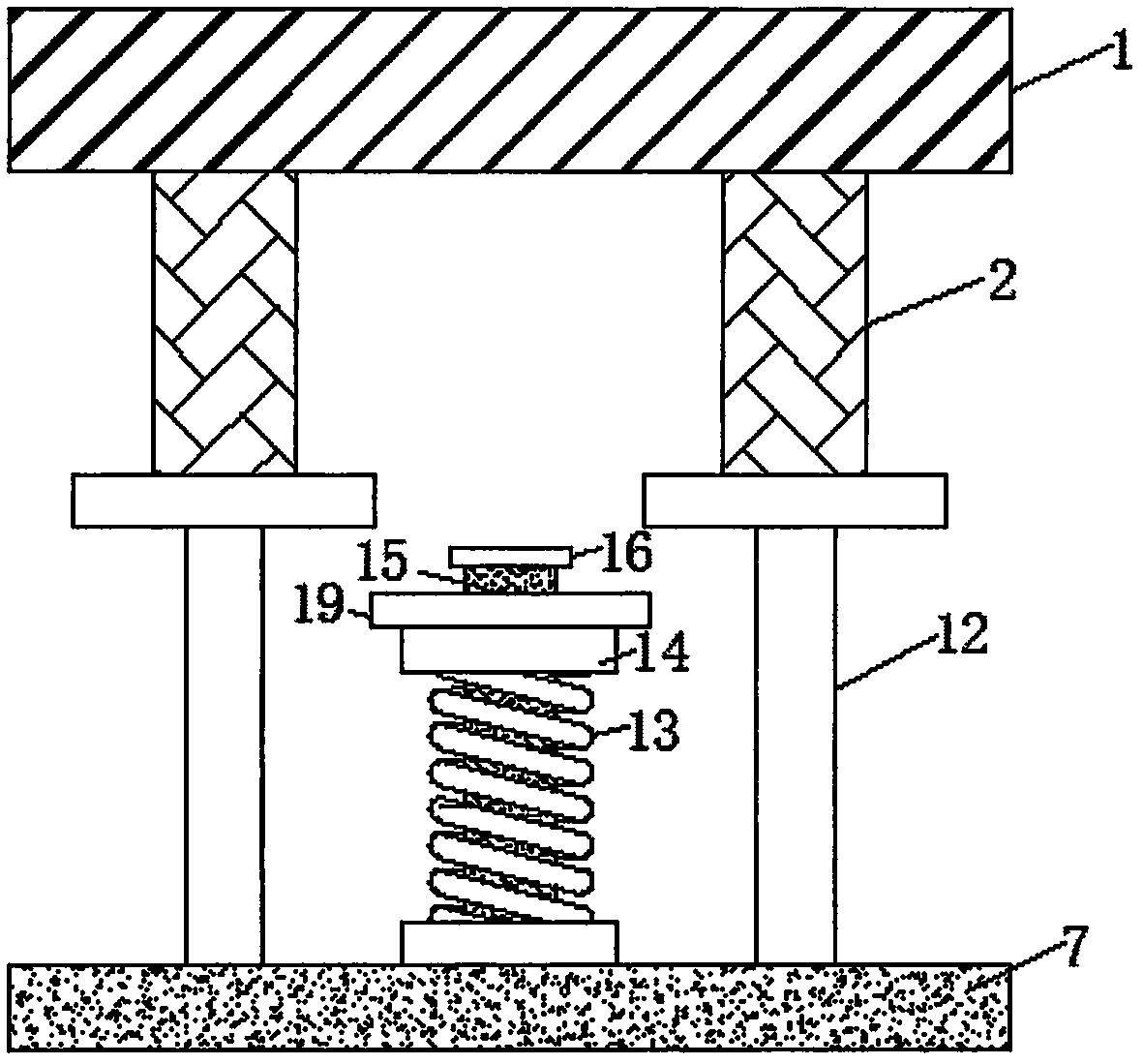

Driverless car seat with shock absorbing function

InactiveCN109591666AAchieve secondary dampingReduce severe vibrationSeat suspension devicesCar seatRoad surface

The invention discloses a driverless car seat with a shock absorbing function. The driverless car seat comprises a seat body; four supporting columns are fixedly connected to the bottom of the seat body, and the bottoms of the four supporting columns are fixedly connected with fixing plates; a shelf is arranged under the four supporting columns; and the bottoms of the fixing plates are fixedly connected with connection plates, and the front surfaces of the connection plates are movably connected with supporting rods through pin shafts. According to the driverless car seat, by arranging the supporting columns, the supporting rods, slide grooves, first springs, vertical columns and sliding wheels, when a driverless car passes through a rugged road, the comfort of the seat is improved to a certain extent; the fixing plates, a spring column, a slide sleeve and a second spring cooperate with one another, when the fixing plates are stressed and pressed downwards, the slide sleeve moves to extrud the second spring downwards and is pushed upwards through the reset effect of the second spring, and accordingly, secondary shock absorbing of the seat is achieved; and after multiple times of shock absorbing, the effect is obvious, the shock sensation is reduced, and accordingly, a driver can sit on the seat more comfortably.

Owner:李晓洋

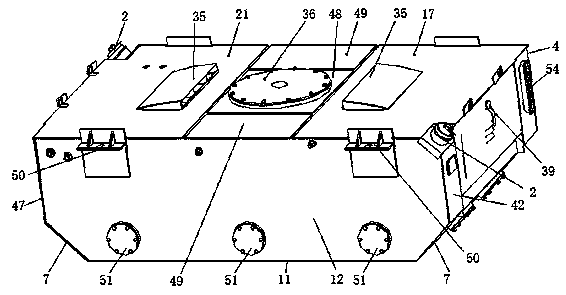

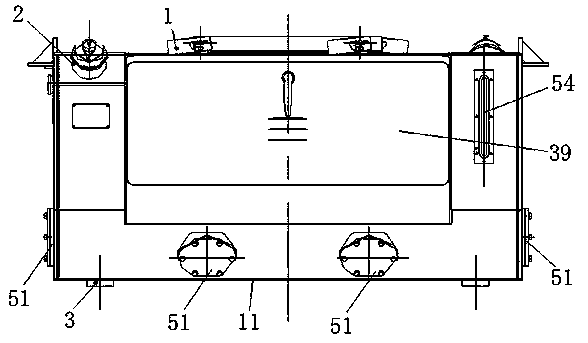

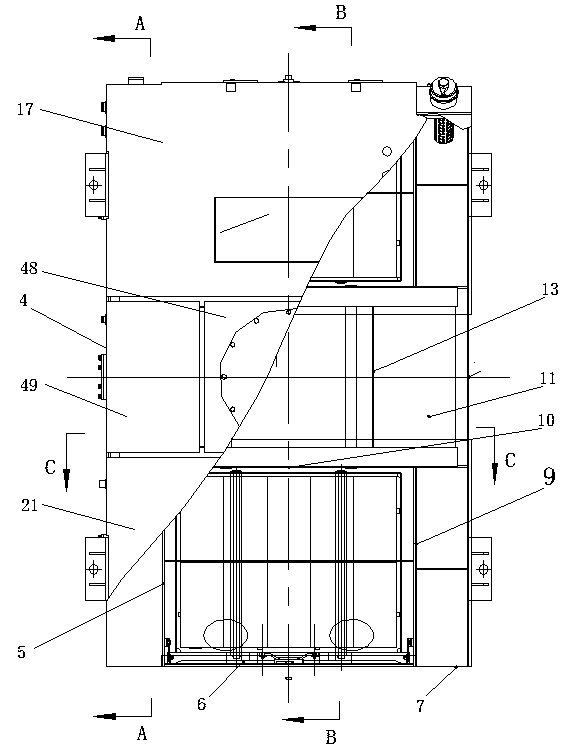

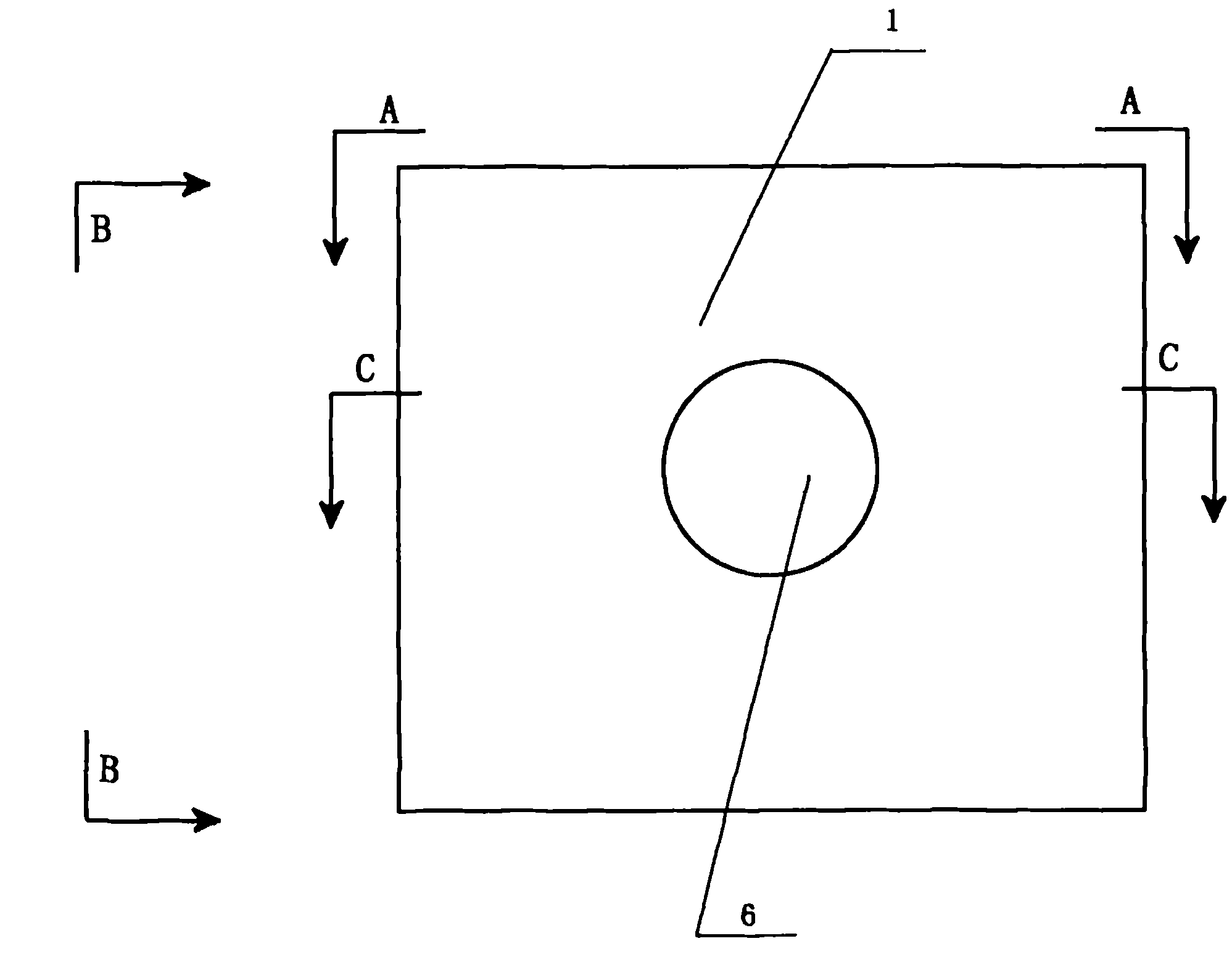

Combined type fuel tank for rail flaw detection vehicle

PendingCN108638844AReduce severe vibrationSave spaceRailway inspection trolleysFuel supplyDiesel locomotiveFuel tank

The invention relates to a combined type fuel tank for a rail flaw detection vehicle, and belongs to the technical field of fuel supply for diesel locomotives. The combined type fuel tank comprises afuel tank and storage battery boxes, wherein the two storage battery boxes are symmetrically arranged along the center line of the combined type fuel tank. The storage battery boxes are provided withheat dissipation openings and box doors, and guide rails for placing trays are arranged in the boxes. A body is provided with an oil filler, an oil level gauge, an electronic level gauge, an oil suction pipe and the like. Compared with the prior art, the fuel tank and the storage battery boxes are integrated as a whole, a lifting lug is arranged to integrally suspend the combined type fuel tank onan underpan of a vehicle body, the space of the underpan is greatly saved, the installation of flaw detection equipment and arrangement of piping are facilitated, and the demand for oil supply to a power system and a generator set is met; box body accessories of the combined type fuel tank are all arranged in a position convenient to quick repair and maintain; and structural plates inside the boxbody are all provided with through holes and groove-shaped holes, the free surface can be effectively reduced to attenuate the severe vibration of fuel during the running of the locomotives, and therunning stability is ensured.

Owner:DALIAN JIAOTONG UNIVERSITY

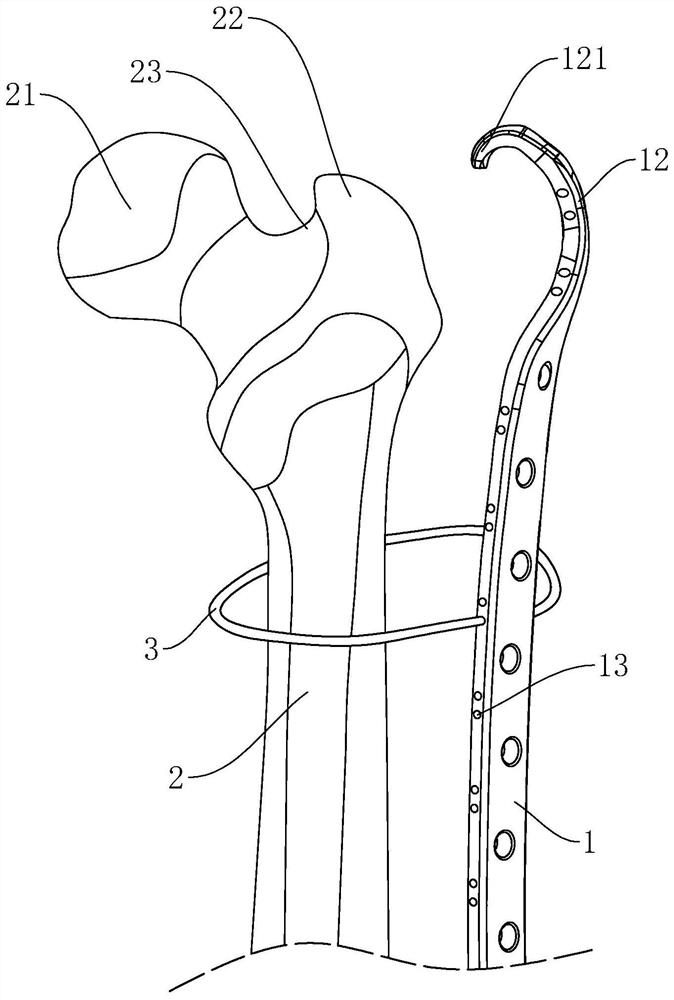

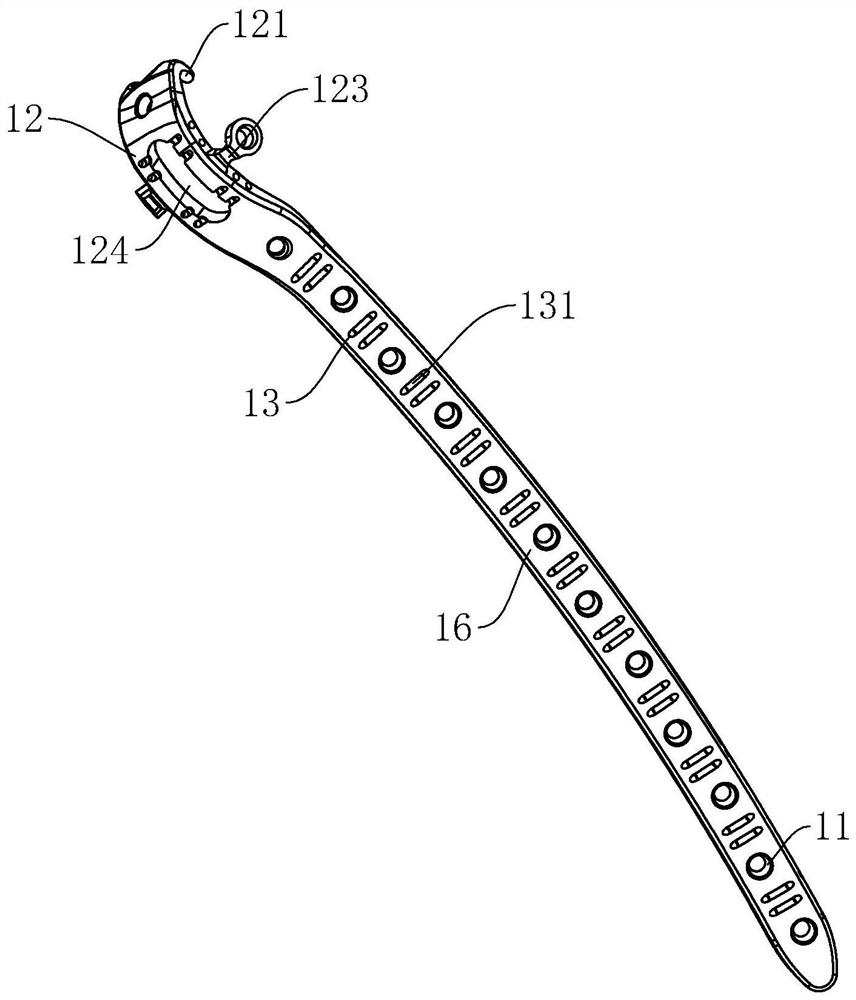

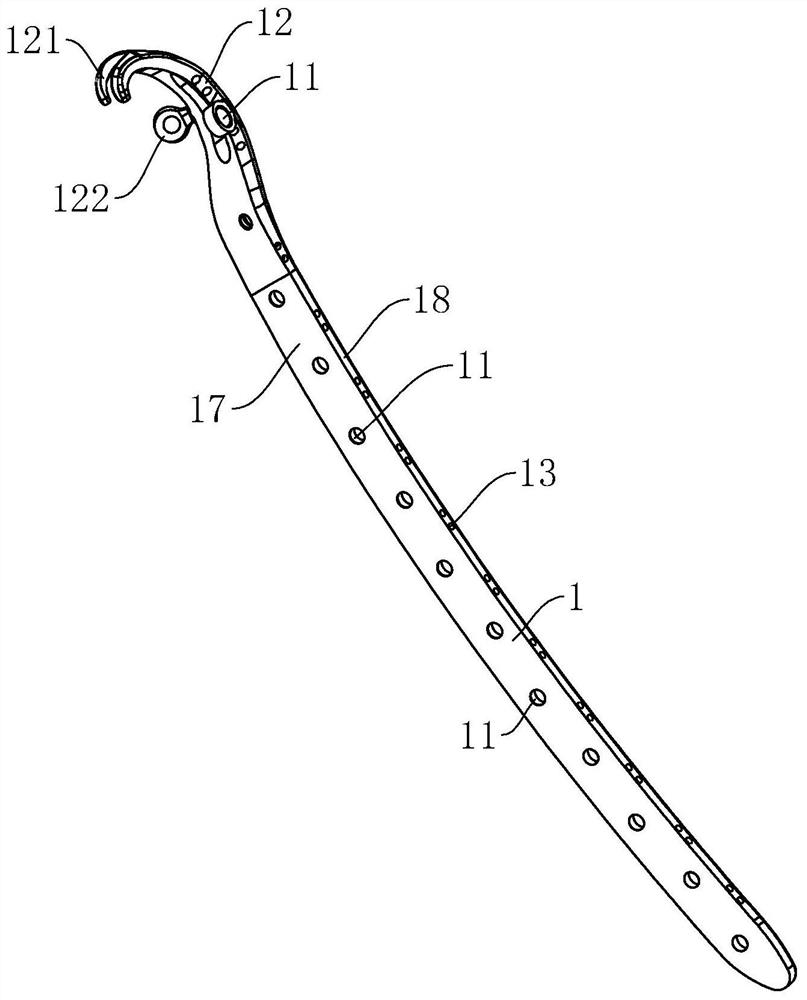

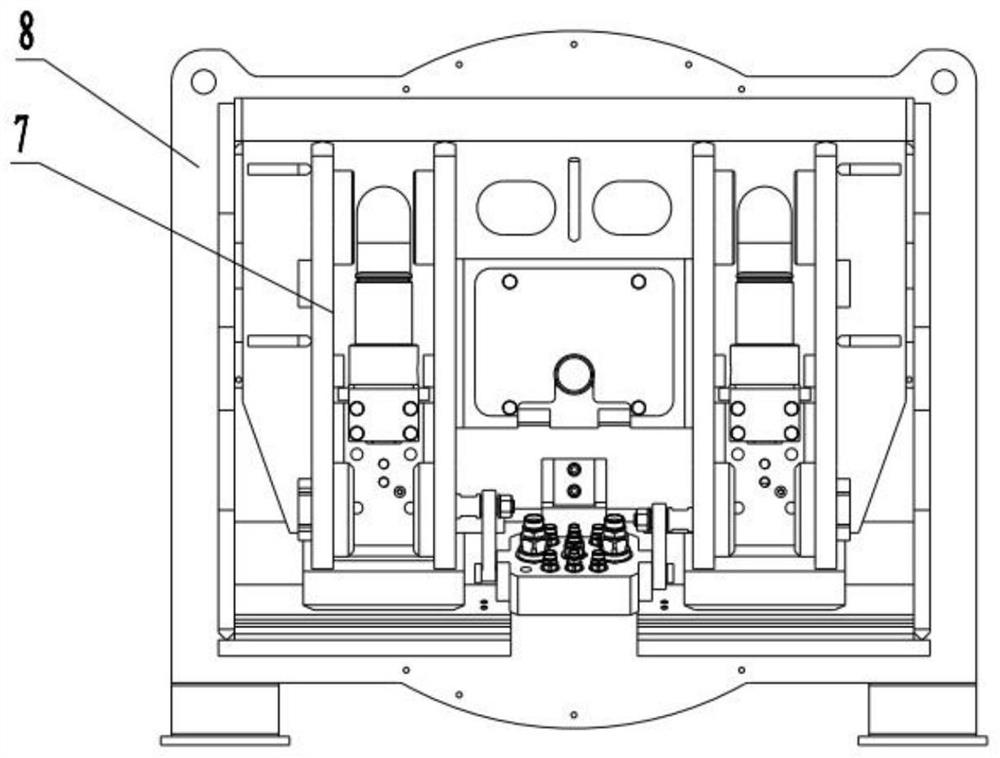

Proximal femur internal fixation plate and machining tool and technology thereof

ActiveCN113995491AReduce molding qualityReduce feed depthBone platesApparatus instrumentsInternal fixation

The invention relates to an internal fixation plate and a machining tool and process thereof, and belongs to the field of medical instruments. The internal fixation plate sequentially comprises a main plate, a buckling plate and a hook plate, wherein the opposite end surfaces, located in the thickness direction, of the main plate are an operation surface and a contact surface respectively, the opposite side surfaces, located in the width direction, of the main plate are threading surfaces, a plurality of threading holes are formed in the main plate, and the threading holes are formed from the operation surface to one of the threading surfaces. According to the invention, through inclined arrangement of threading holes, the feeding depth of a drilling tool during machining of the threading holes is reduced, so that the vibration amplitude of the drilling tool caused by large drilling depth is reduced, the state stability of the drilling tool during working is improved, and the effects of reducing vibration and damage of the drilling tool and improving the forming quality of the threading hole are achieved.

Owner:常州大章医疗器械有限公司

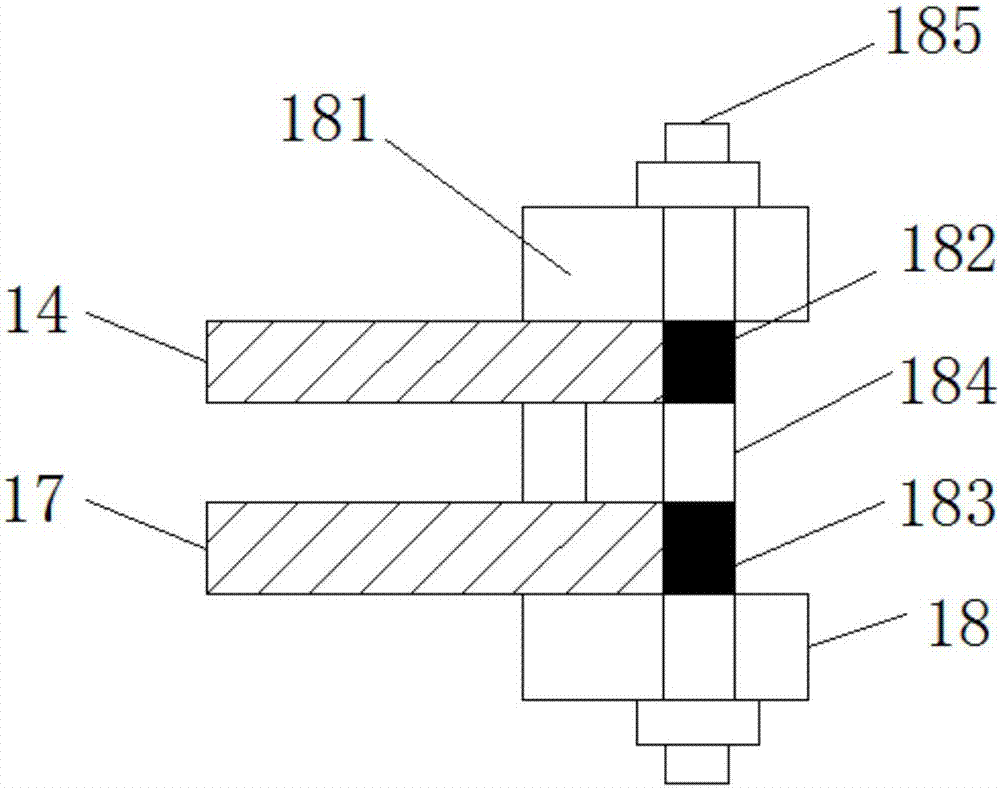

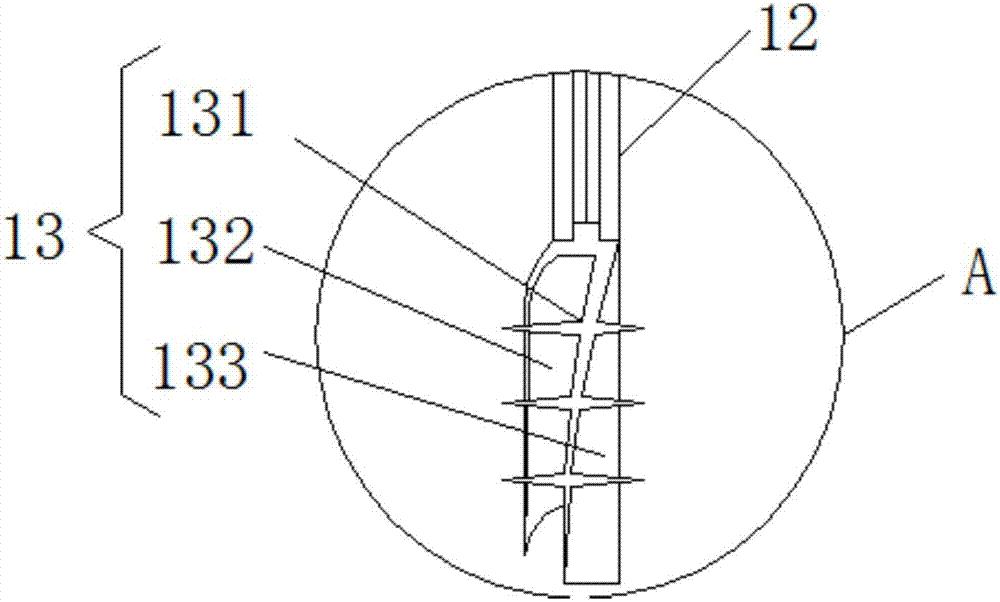

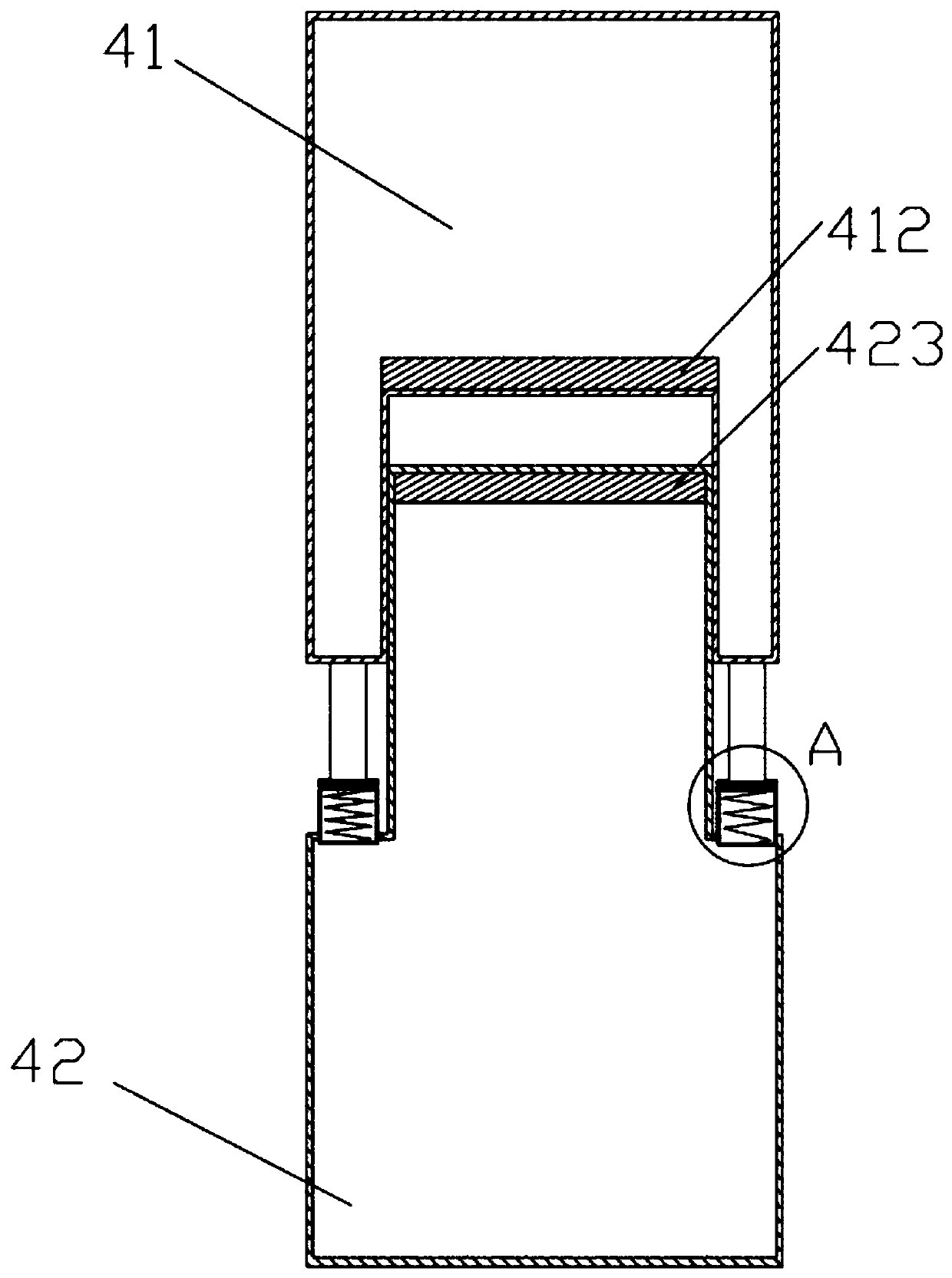

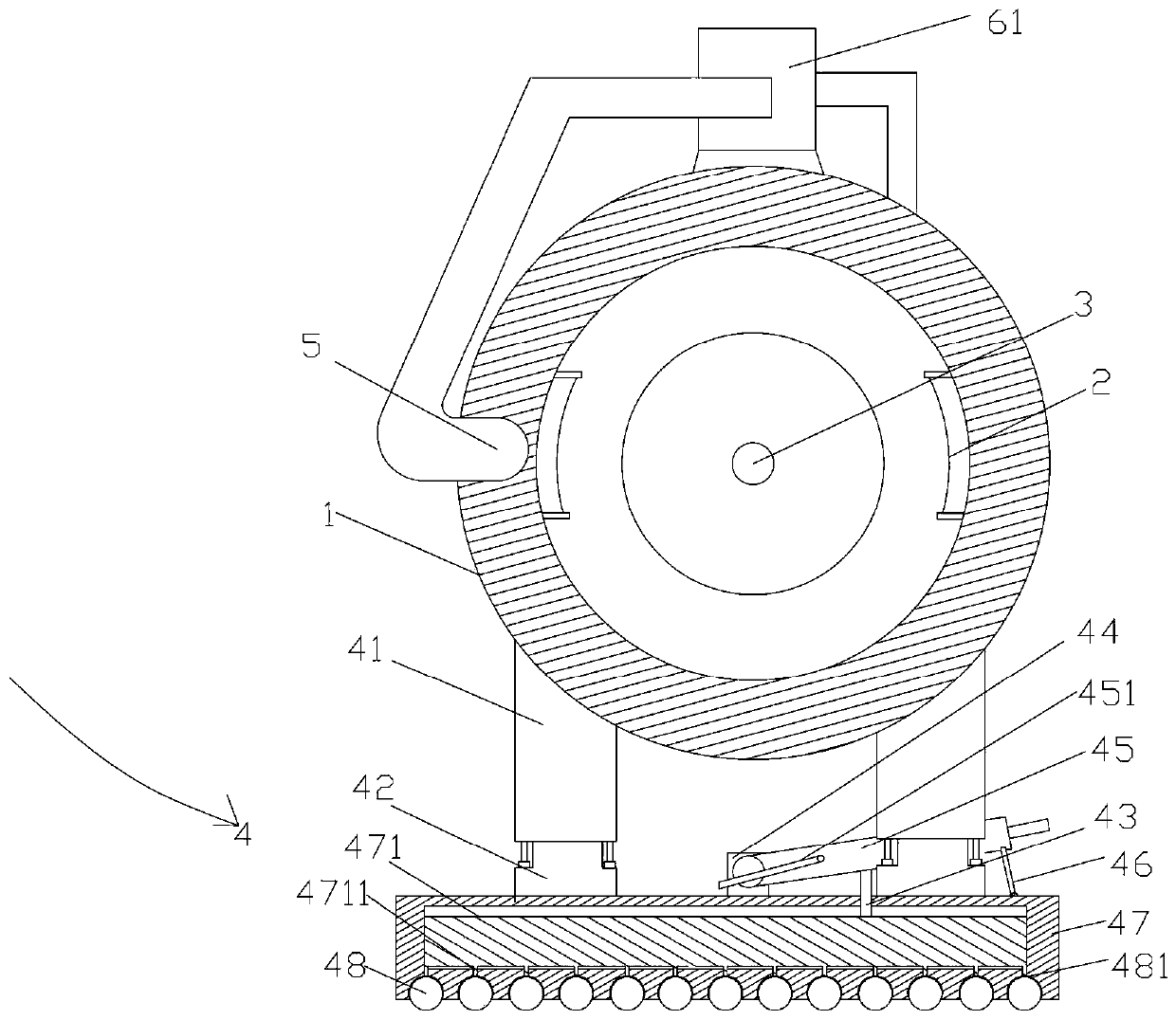

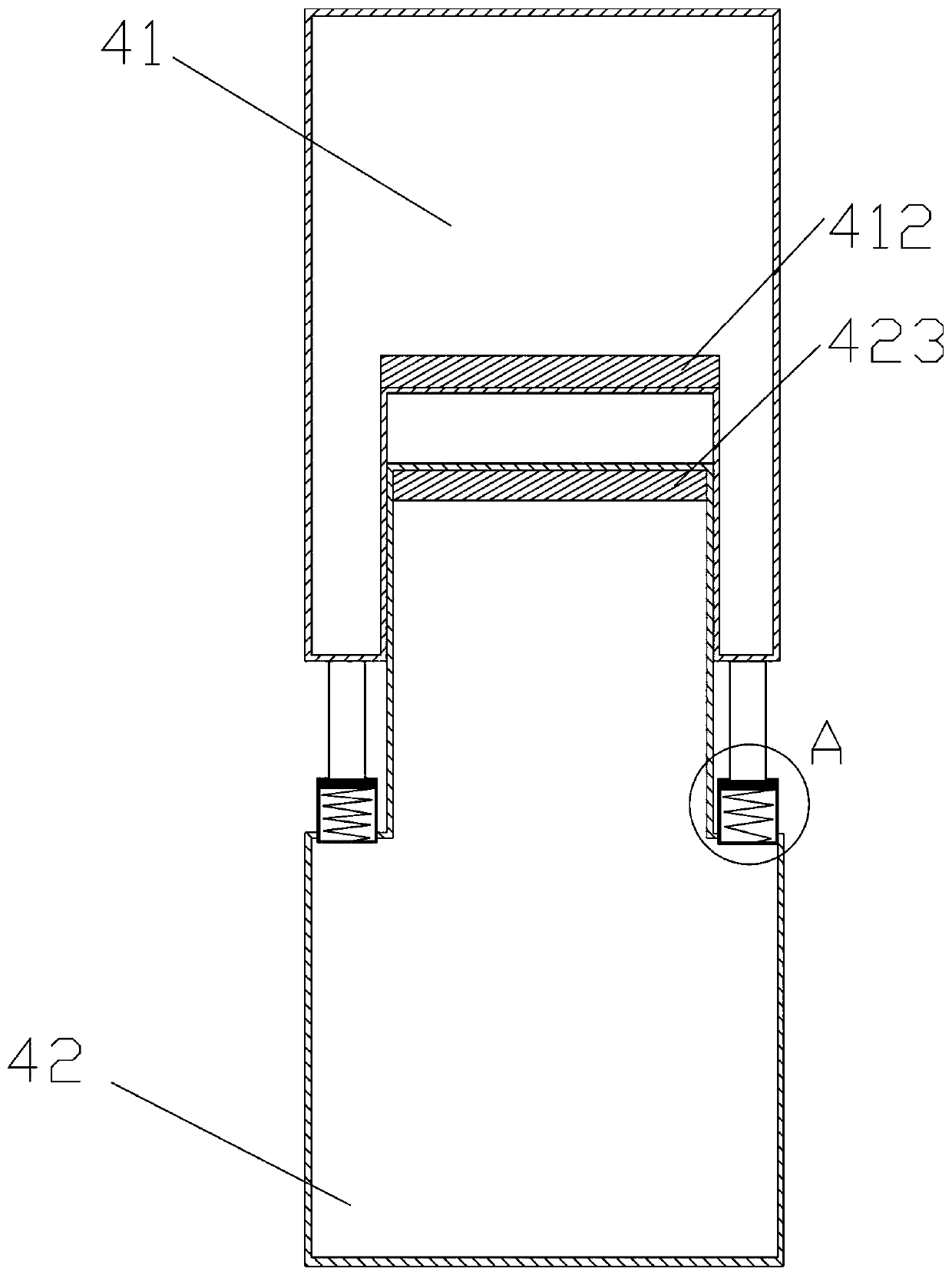

Cushioning type motor capable of working stably

InactiveCN111342598AReduce severe vibrationAvoid damageSupports/enclosures/casingsBrakeElectric machine

The invention discloses a cushioning type motor capable of working stably. The motor comprises a shell, a stator arranged in the shell and a rotor arranged in the shell. A base is arranged below the shell, and the base comprises a buffer device and a brake device. The brake device comprises a control assembly and a sliding assembly. The buffer device comprises supporting sleeves and supporting bosses, and the supporting sleeves sleeve the supporting bosses. The supporting sleeves can sleeve the supporting bosses to play a role in supporting the motor. When the motor works, strong vibration canbe generated, the vibration is transmitted to the base to drive the whole motor to vibrate, and through cooperation of the supporting sleeves and the supporting bosses on the base, the vibration of the motor can be relieved, a vibration buffering effect is achieved, and the working stability of the motor is improved.

Owner:陈章王

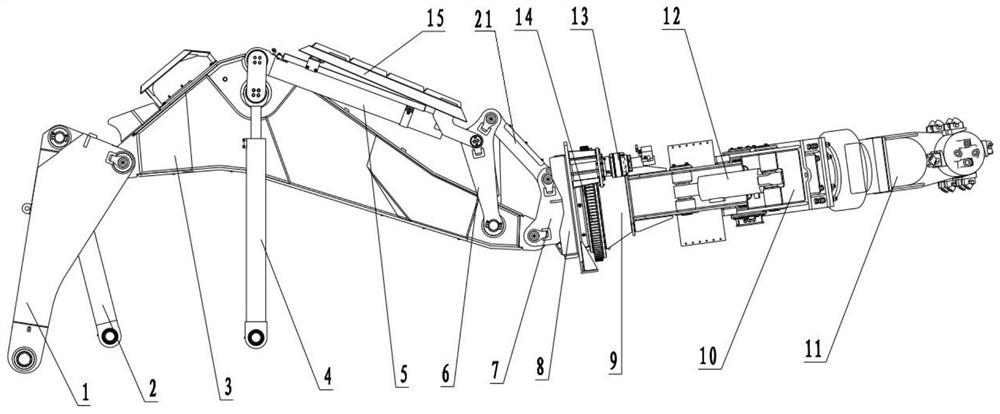

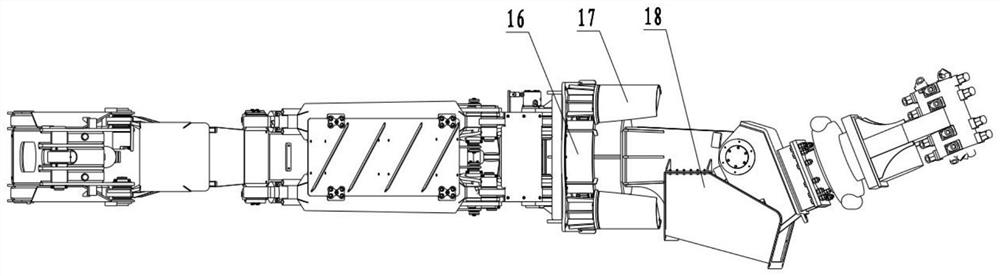

Assembly comprising shoveling and milling machine arm frame and milling and digging device

PendingCN111997644AExpand the scope of workIncrease working angleTunnelsBolt connectionManufacturing engineering

The invention provides an assembly comprising a shoveling and milling machine arm frame and a milling and digging device. A quick-changing device of the shoveling and milling machine arm frame is connected with the base of the milling and digging device; the milling and digging device comprises the base, a milling and digging arm, a milling and digging headstock, a milling and digging head and a stabilizing oil cylinder; the base is connected with one end of the milling and digging arm through a rotary support; the other end of the milling and digging arm is rotatably connected with the milling and digging headstock; the milling and digging head is mounted on the milling and digging headstock; one end of the stabilizing oil cylinder is rotatably connected with the milling and digging arm;and the other end of the stabilizing oil cylinder is rotatably connected with the milling and digging headstock. In the assembly, the rotary support is additionally arranged in the milling and diggingdevice to replace traditional bolt connection, so that the working range and the variable angle of the milling and digging head are greatly increased, and the usable occasions of the assembly are expanded. The quick-changing device is provided with an independent quick-changing oil cylinder and a quick-changing pin, so that the milling and digging device is quickly detached, a bucket and other types of construction equipment are mounted; and during the entire process, the quick-changing oil cylinder is adopted to lock the milling and digging device, so that the equipment universality is enhanced while lowering the manual labor intensity.

Owner:CHINA RAILWAY CONSTR HEAVY IND

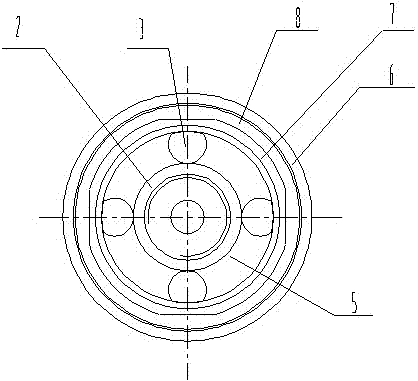

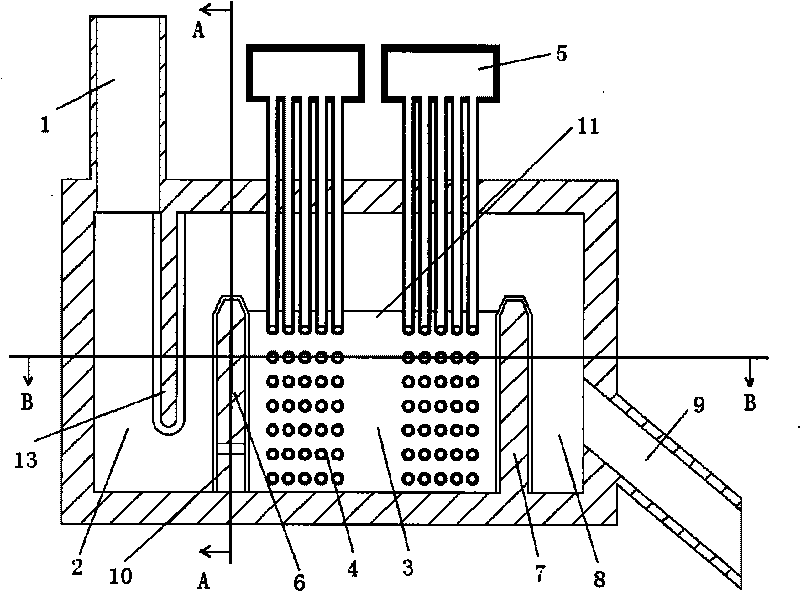

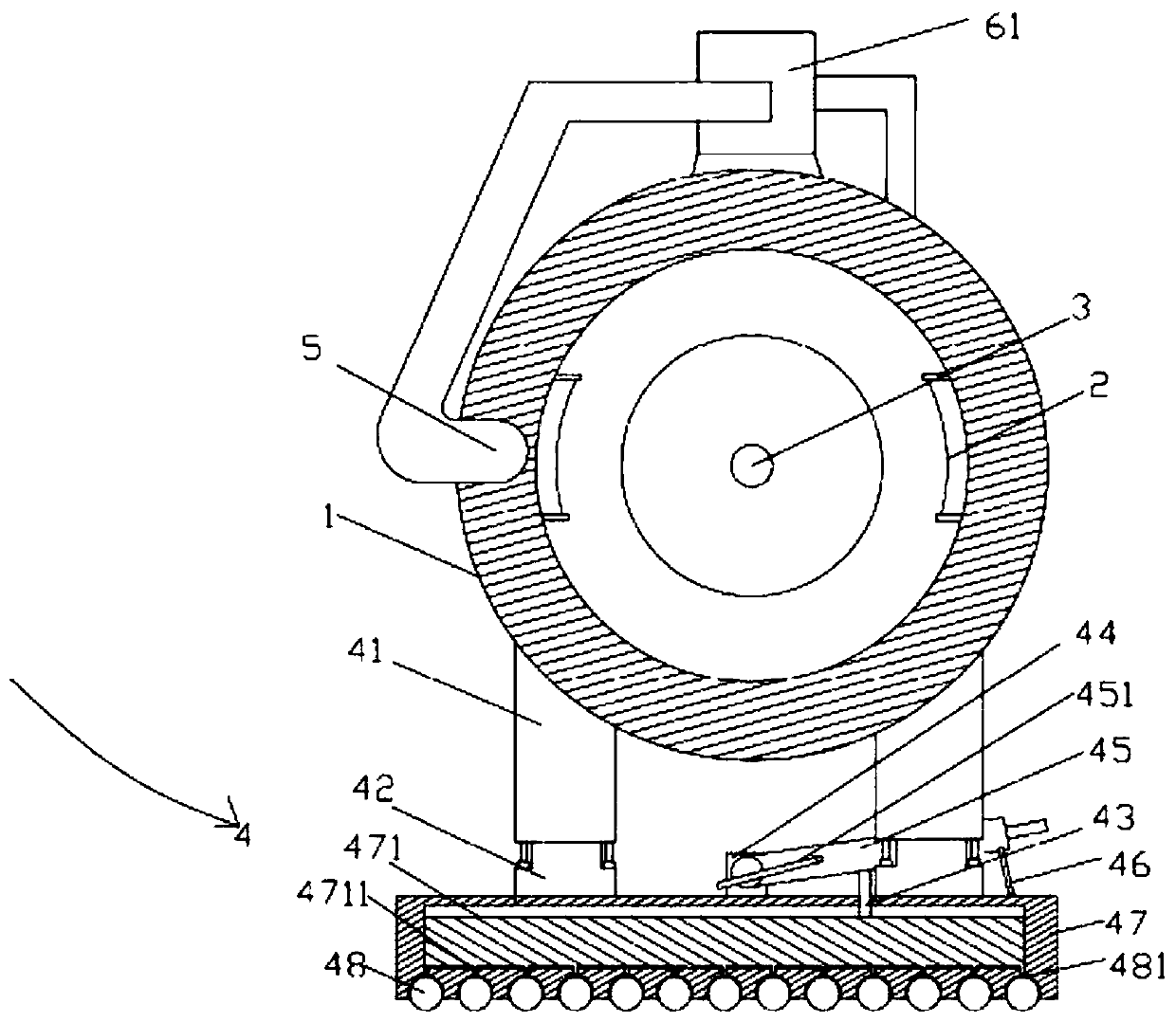

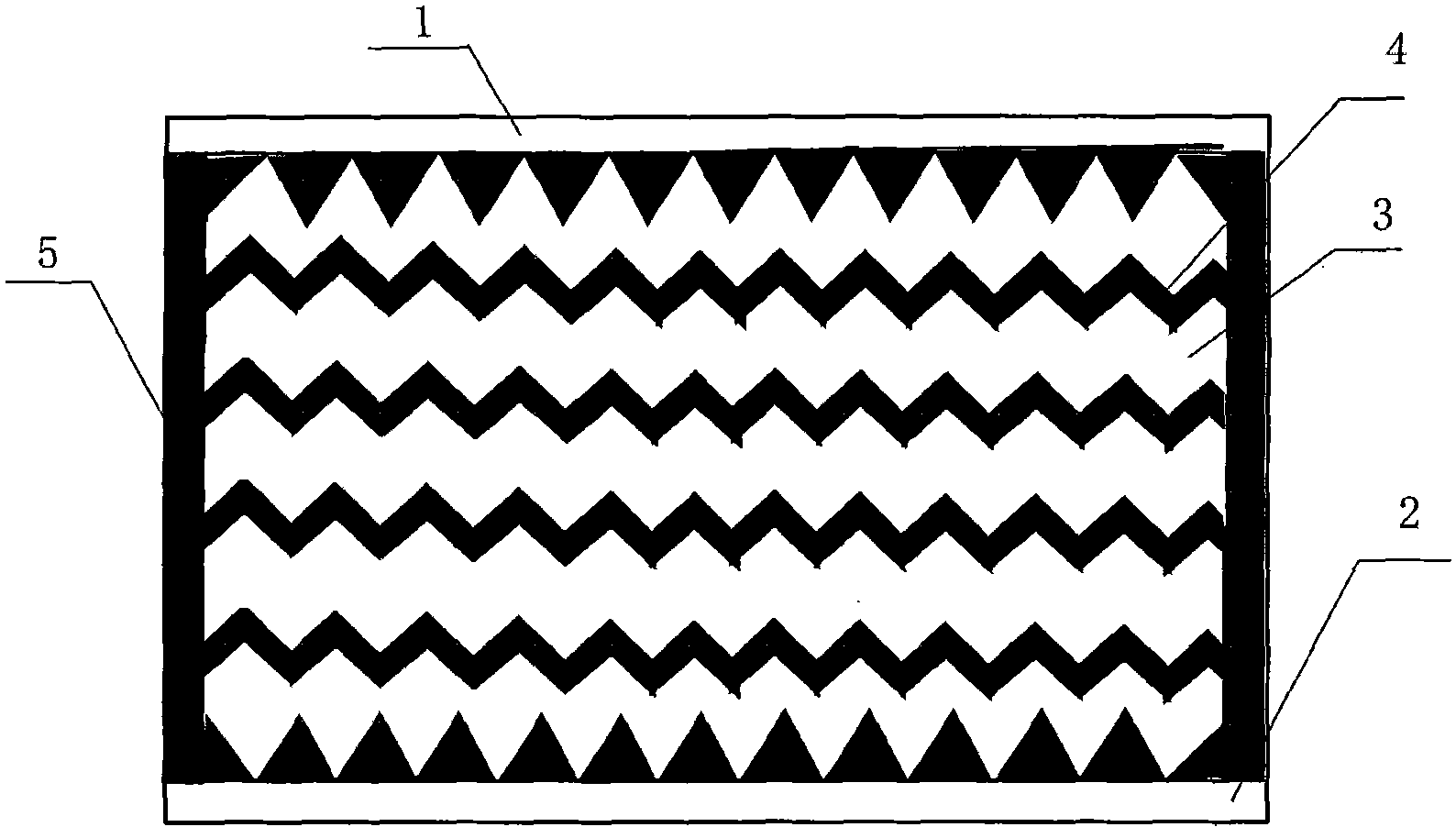

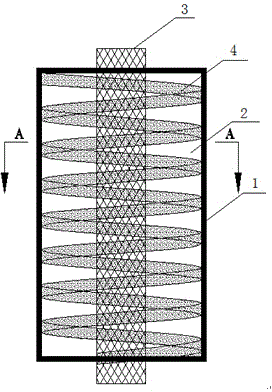

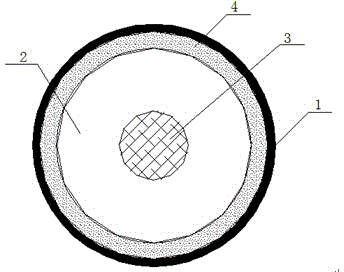

Vibration reduction damper of ship hatch cover guide frame

InactiveCN101979894AReduce severe vibrationGuaranteed uptimeNon-rotating vibration suppressionShock absorbersMarine engineeringAlloy

The invention discloses a vibration reduction damper of a ship hatch cover guide frame, which comprises a top plate (1) and a bottom plate (2), wherein a damper main body is arranged between the top plate (1) and the bottom plate (2); the damper main body is formed by alternately overlaying and connecting damping alloy plates (3) and damping rubber plates (4); the circumference of the damper main body is provided with a rubber flat plate (5); and an alloy pipe (6) is inserted in the damper main body and is positioned between the top plate (1) and the bottom plate (2). The vibration reduction damper of the ship hatch cover guide frame not only can effectively reduce violent vibrations generated by the guide frame to ensure the normal running of machines and equipment, but also ensure rest and health of shipmen.

Owner:泰州口岸船舶有限公司

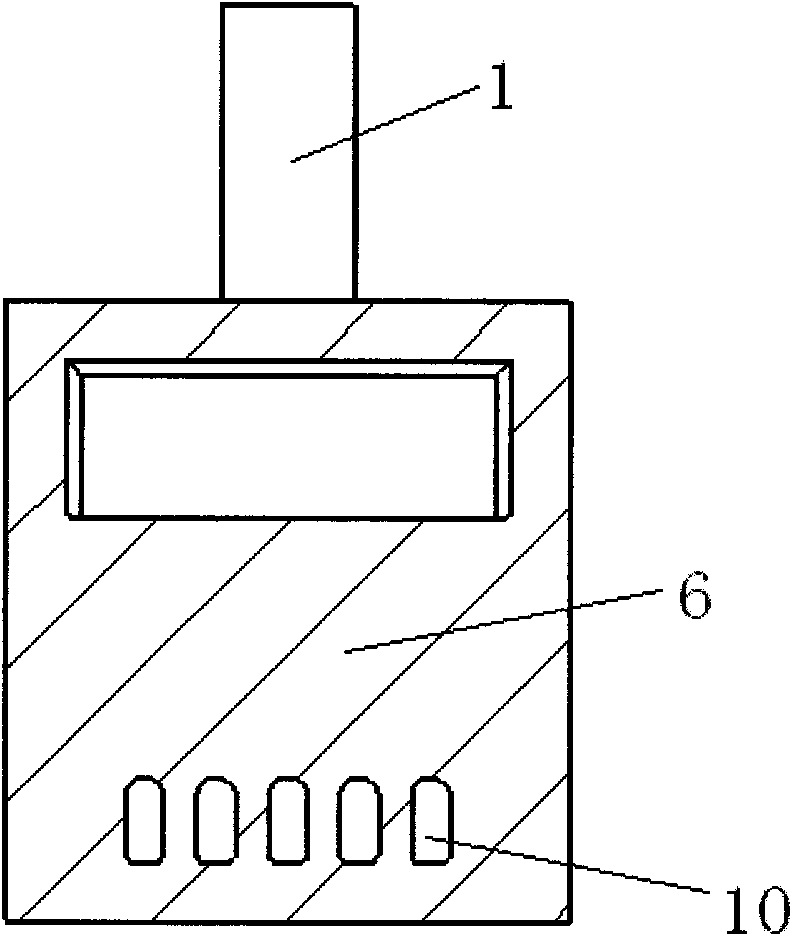

High-voltage rectification integrated transformer

InactiveCN114530304APlay a shock absorbing roleReduce severe vibrationTransformers/reacts mounting/support/suspensionTransformers/inductances casingsTransformerMechanical engineering

The invention relates to the technical field of transformers, in particular to a high-voltage rectification integrated transformer which comprises a box body, a transformer body, a first baffle and a second baffle, the transformer body is arranged in the box body, the first baffle is hinged to one side of the upper end of the box body, and the second baffle is hinged to the other side of the upper end of the box body. The first baffle is hinged to one side of the upper end of the box body, the second baffle is hinged to the other side of the upper end of the box body, the first baffle and the second baffle are oppositely arranged, a damping base is arranged at the lower end of the box body and connected with the transformer body, and a transmission mechanism is connected to one end of the hinged position of the first baffle and the second baffle. The transmission mechanism is connected to the outer side wall of the box body and used for driving the first baffle and the second baffle to rotate. The high-voltage rectification integrated transformer not only has a good damping effect, but also can effectively play a role in shielding rain and snow, and also can conveniently remove rain and snow.

Owner:襄阳卓尚电子科技有限公司

Hardware component type pipe fitting extrusion device

InactiveCN109201911AEffective clampingEffective protectionMetal-working feeding devicesPositioning devicesPipe fittingMachining

The invention provides a hardware component type pipe fitting extrusion device, and relates to the technical field of hardware component machining equipment. The hardware component type pipe fitting extrusion device comprises an operation table. Damping cushions are fixedly arranged on the two sides of the bottom of the operation table. An extrusion frame is fixedly arranged on the left side of the top of the operation table. A supporting plate is fixedly arranged on the top of the operation table. According to the hardware component type pipe fitting extrusion device, a threaded rod is drivento rotate through rotation of a rotation handle, and the threaded rod is used for driving a third clamping wheel to move in the horizontal direction; a first clamping wheel and the third clamping wheel are used for clamping pipe fitting materials in the horizontal direction, the third clamping wheel can move in the vertical direction along with the threaded rod, the position of a second clampingwheel (8) is fixed, the second clamping wheel (8) and the third clamping wheel are used for clamping the pipe fitting materials in the vertical direction, and accordingly hardware pipe fitting type materials different in size can be effectively clamped.

Owner:JIANGYIN CHANGJING CAR & SHIP ACCESSORY

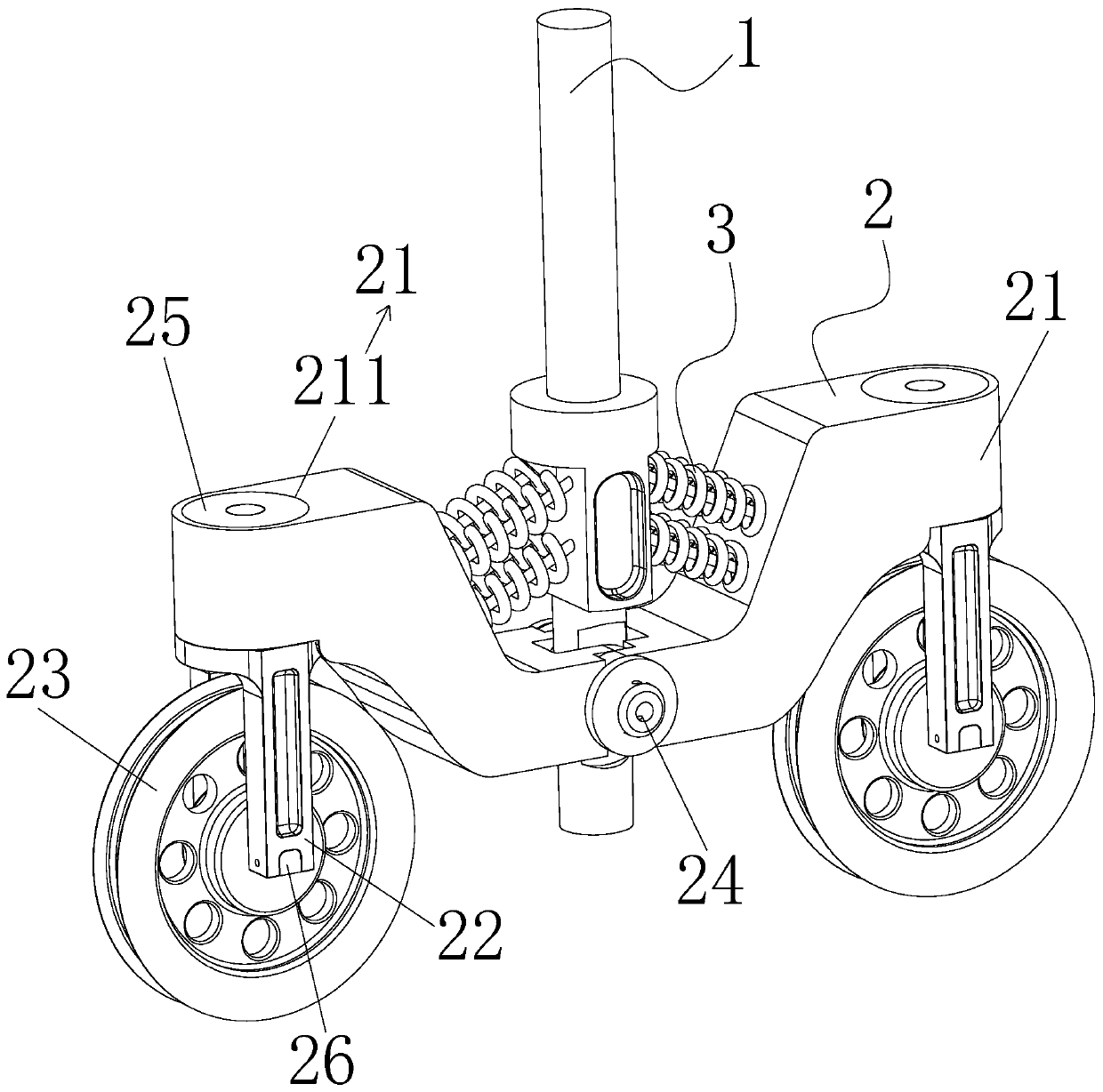

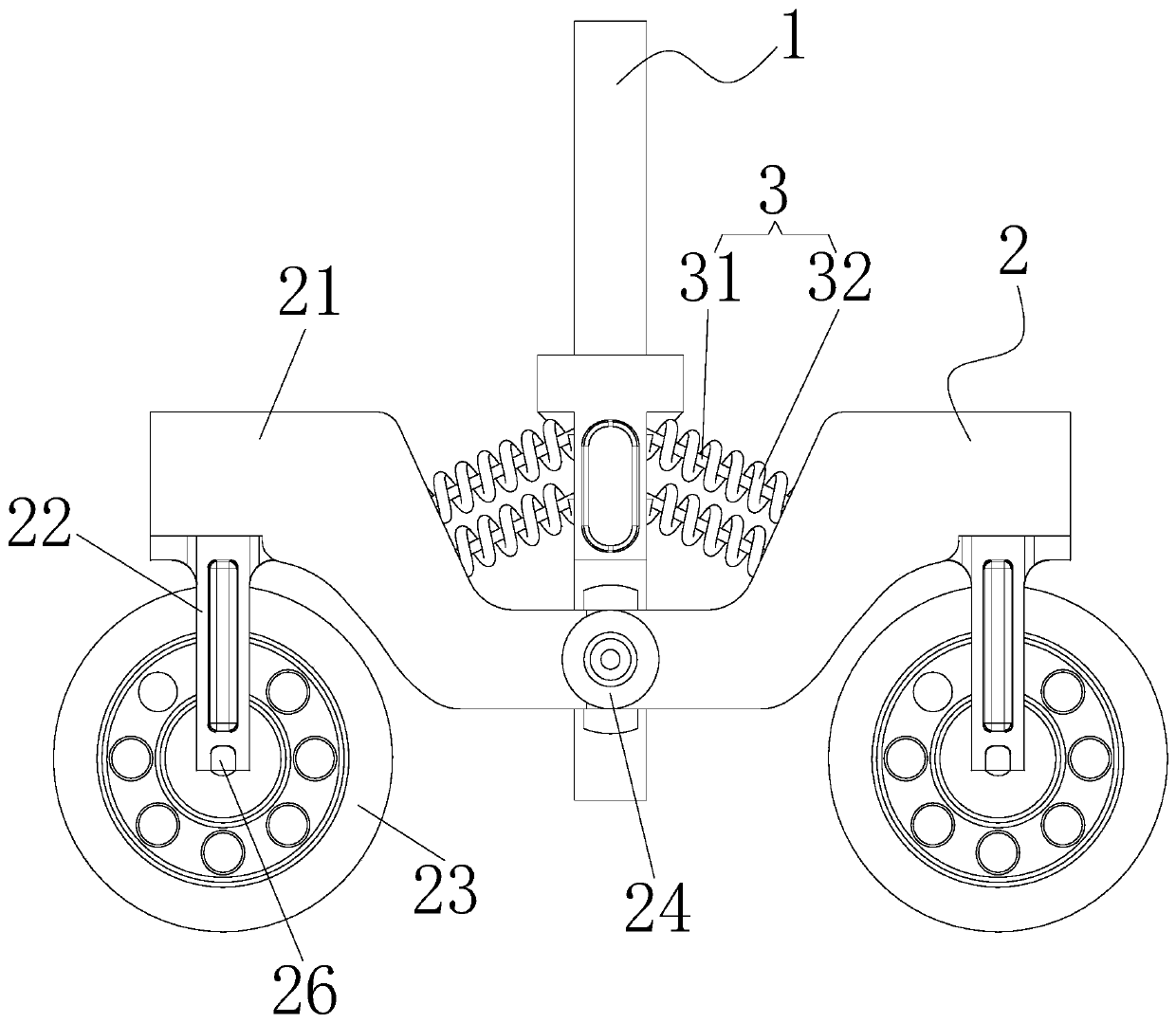

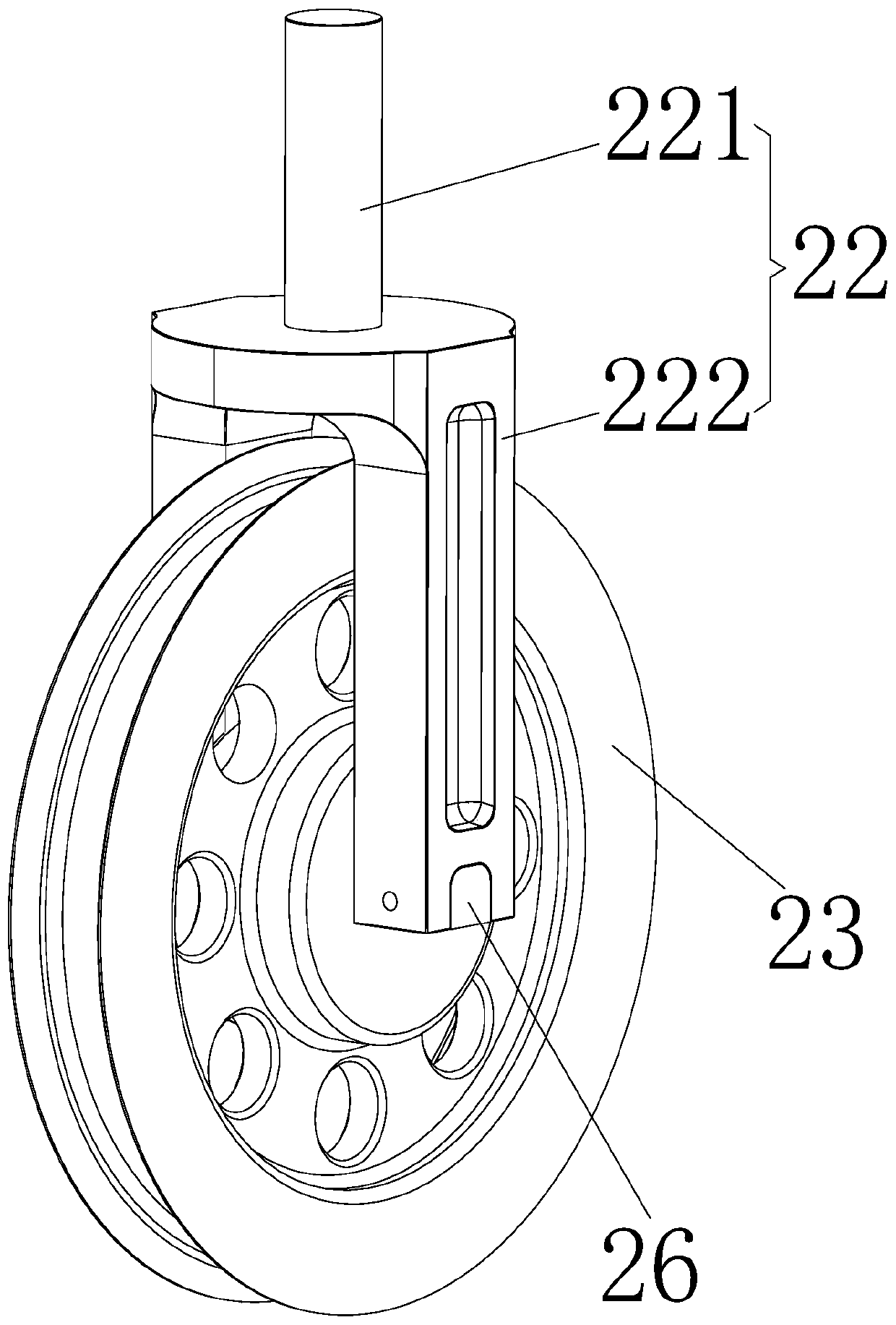

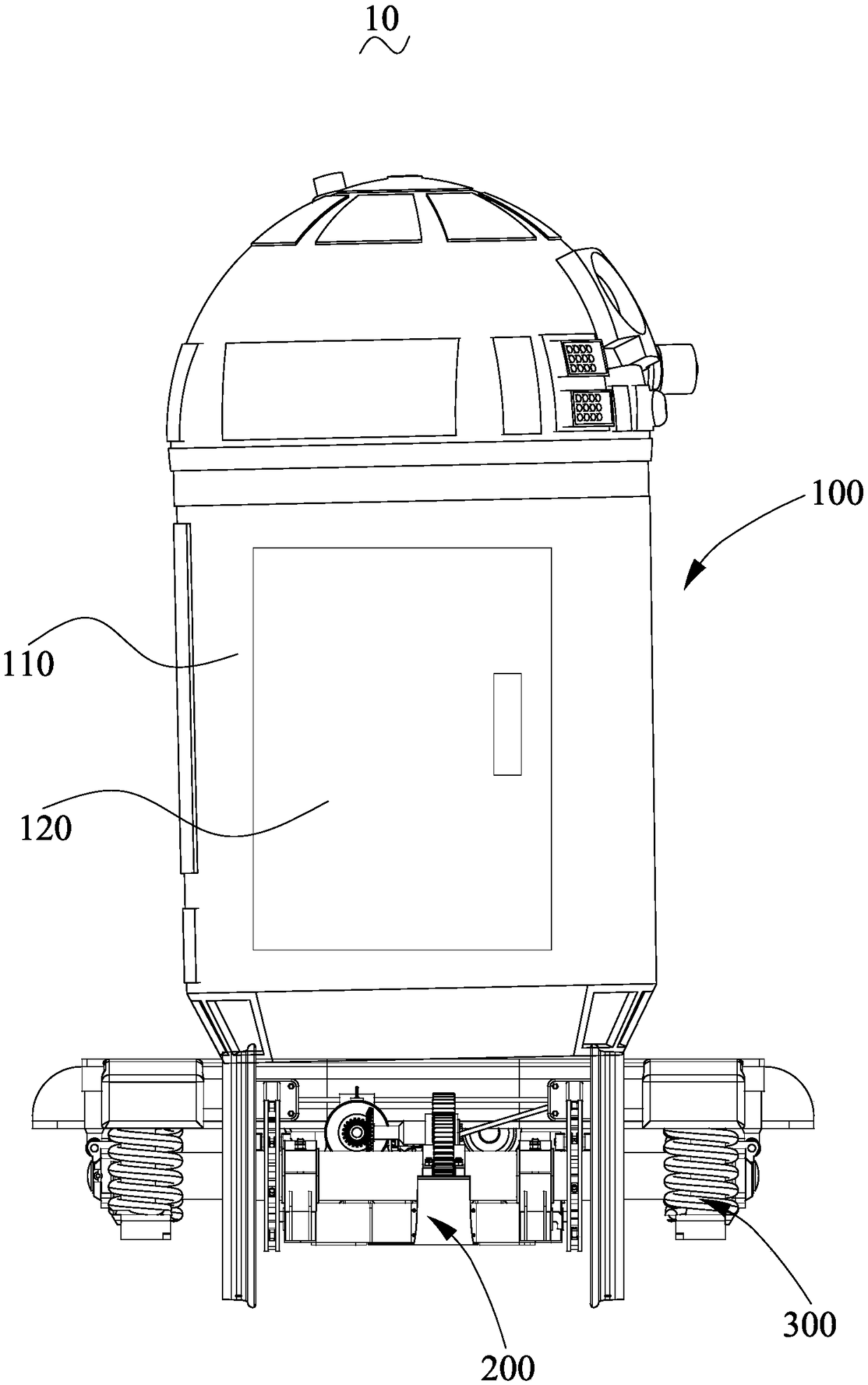

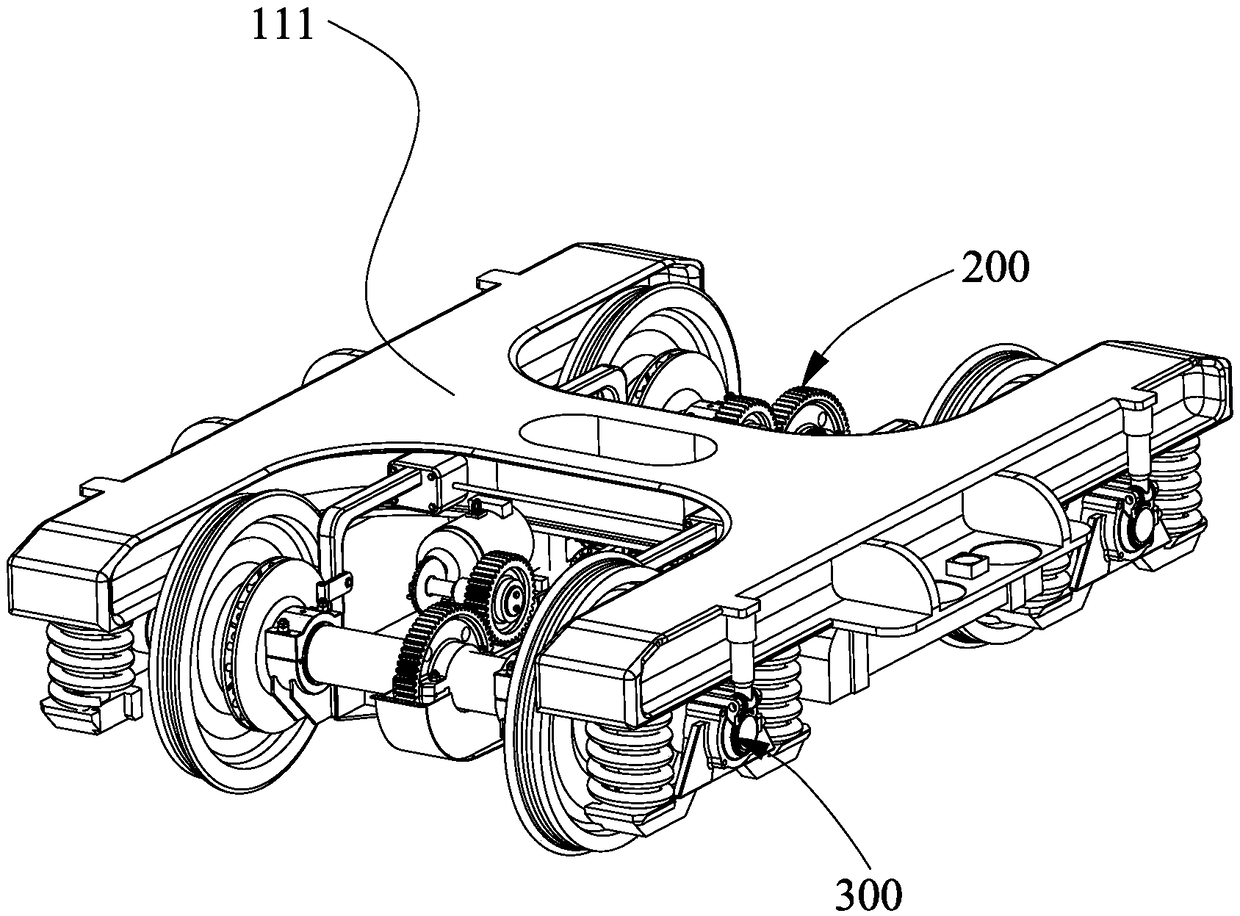

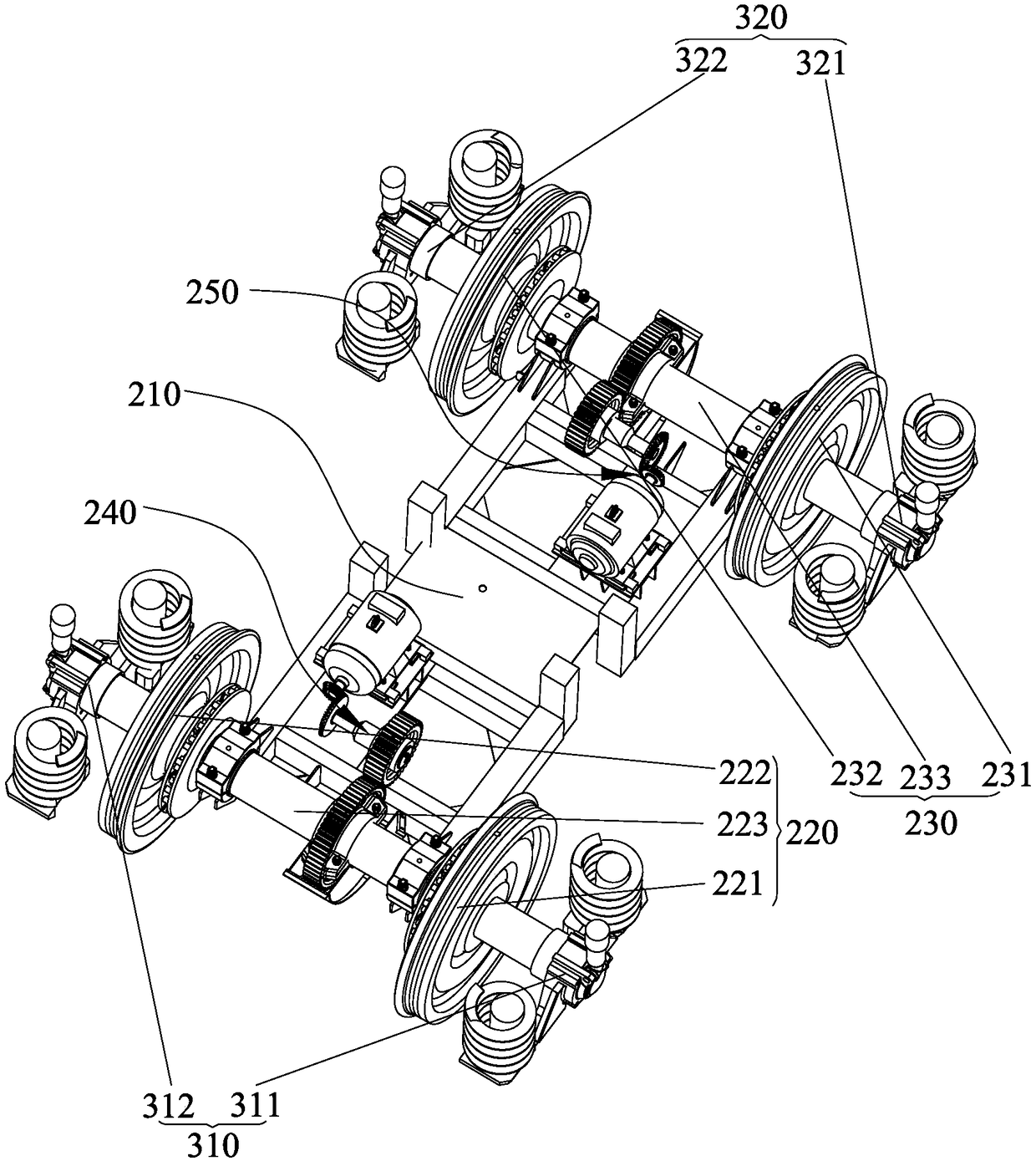

Rail damping walking device

PendingCN110615012AReduce severe vibrationImprove shock absorptionBogie-underframe connectionsVehicle frameEngineering

The invention discloses a track damping walking device which comprises a main shaft connected with a frame, the walking mechanisms and the damping mechanisms. The two sides of one end, away from the frame, of the main shaft are symmetrically hinged to the walking mechanisms capable of rotating, and the damping mechanisms are further arranged between the walking mechanisms and the main shaft. Eachwalking mechanism comprises a bogie, a wheel carrier and wheels, one end of the bogie is hinged to the main shaft, the other end is connected with the wheels through the wheel carrier, and a damping mechanism is further connected between the bogie and the main shaft. The invention has the advantages that the bogie is hinged with the main shaft, so that when the bogie drives at the connecting positions between the rails and enters a turnout or a small-radius curve, the bogie can rotate around the main shaft adaptively, the violent vibration occurring when the bogie runs at the positions is reduced, and the damping effect is improved; meanwhile, by arranging the damping mechanisms, the running vibration is further reduced, and the device is simple in structure and high in reliability.

Owner:安徽华集电交通科技有限公司

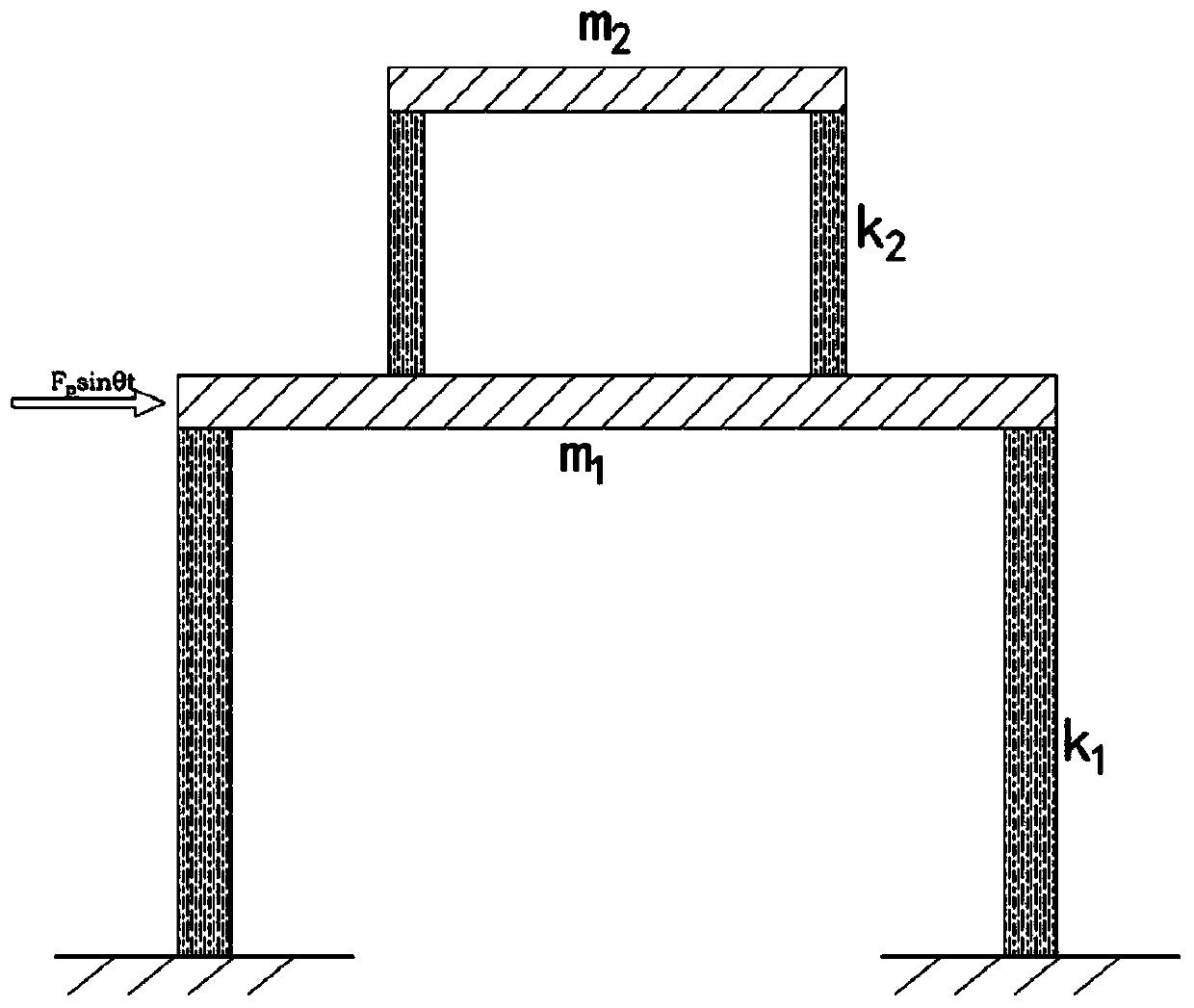

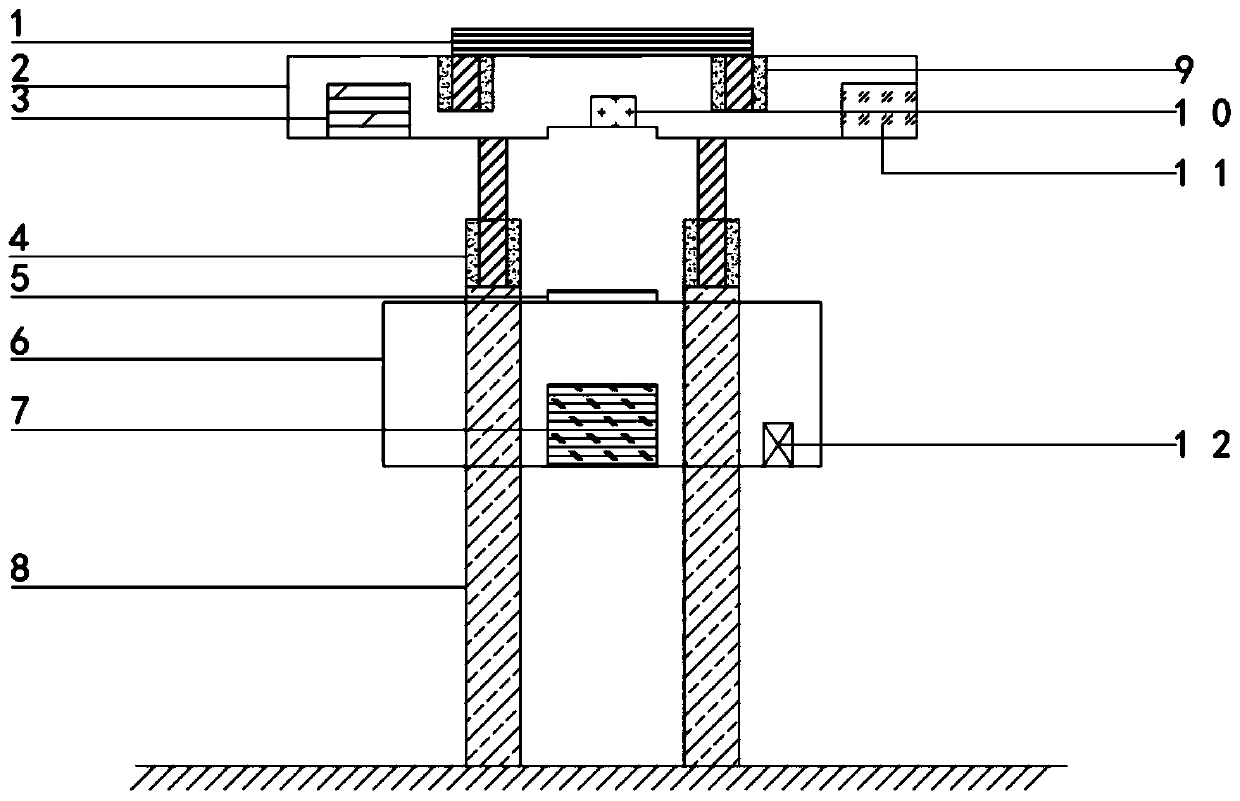

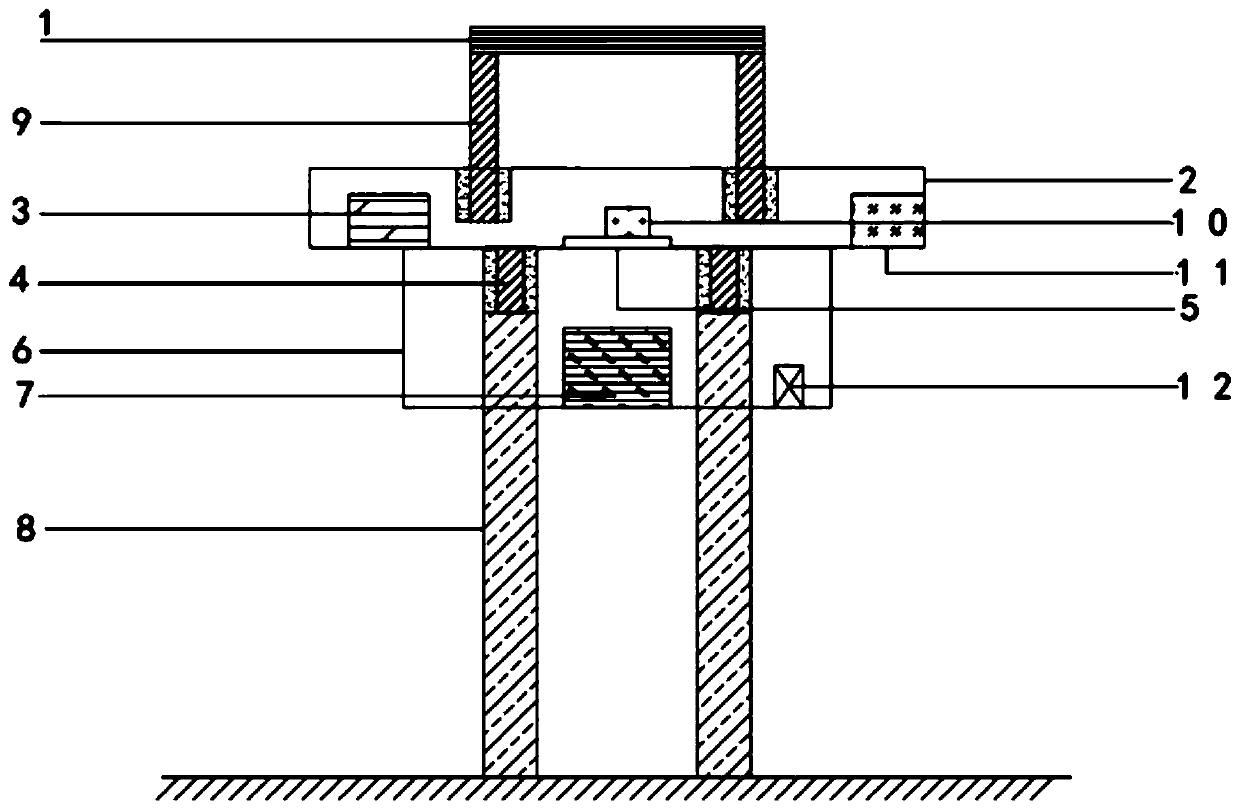

Self-protection system and method of wave-energy generating set in extreme marine environment

ActiveCN110578769AAvoid overall overturningReduce severe vibrationWaterborne vesselsEngine fuctionsMicrocomputerMicrocontroller

The invention discloses a self-protection system and method for a wave-energy generating set in an extreme marine environment. The self-protection system comprises two cylindrical rigid guide columns,wherein the bottoms of the two cylindrical rigid guide columns are buried deep in a seabed, and the tops of the two cylindrical rigid guide columns are exposed out of the sea surface. Working platform lifting devices are mounted at the tops of the guide columns, and a working platform is mounted at the top ends of the working platform lifting devices. A controller, a single-chip microcomputer, anelectromagnetic relay and a storage battery are mounted in the working platform. A vibration-absorption block lifting device is mounted at the top of the working platform. A vibration-absorption block is mounted at the top of the vibration-absorption block lifting device. According to the self-protection system and method, severe vibration of a floater and the working platform under an extreme sea condition is transferred to the vibration-absorption block fixedly connected with the working platform based on the power vibration-absorption principle, so that wave force directly borne by the working platform and the floater is exactly balanced by the acting force applied to the working platform and the floater by the vibration-absorption block, that is, severe vibration of the floater and the working platform is reduced by means of vibration energy absorbed by the vibration-absorption block from the floater and the working platform.

Owner:OCEAN UNIV OF CHINA

Centralizer for drill pipe in hole of engineering drilling rig

ActiveCN103615201BAvoid oblique holesMeet the process requirementsDrilling rodsDrilling casingsEngineeringScrew thread

The invention discloses a centering device for a drill rod in a hole of an engineering driller. The centering device comprises a central spindle, ribs and an outer shell. The hollow central spindle is located at the center, wherein the two ends of the central spindle are provided with a conical internal thread and a conical external thread respectively. The number of the ribs is two or more, and the ribs are evenly arranged on the outer surface of the central spindle to be firmly connected with the central spindle. A gap is reserved between every two adjacent ribs to form a through groove. The two ends of the outer shell are respectively provided with a rolling bearing, wherein the inner side of the rolling bearing is arranged on the outer surface each rib in a supporting mode, the outer side of the rolling bearing is in close fit with the inner surface of the outer shell, and the ribs and the outer shell rotate relative to each other through the rolling bearing. The centering device can keep the thin and long drill rod running stably, make the axis of a drill bit be close to the center line of the drilled hole as much as possible, effectively prevent the hole from inclining, mitigate violent vibration of a drill rod elastic system in the hole in the radial direction and in the axial direction, and reduce deflecting friction between the drill rod and the drill bit; besides, the drill rod does not make direct contact with the wall of the hole so that damage to the wall of the hole can be reduced effectively, and torque required for drilling is reduced.

Owner:CHONGQING EXPLORATION MACHINER FACTORY

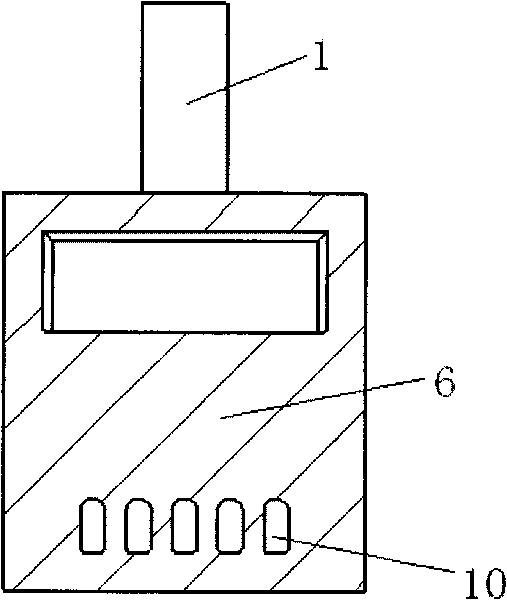

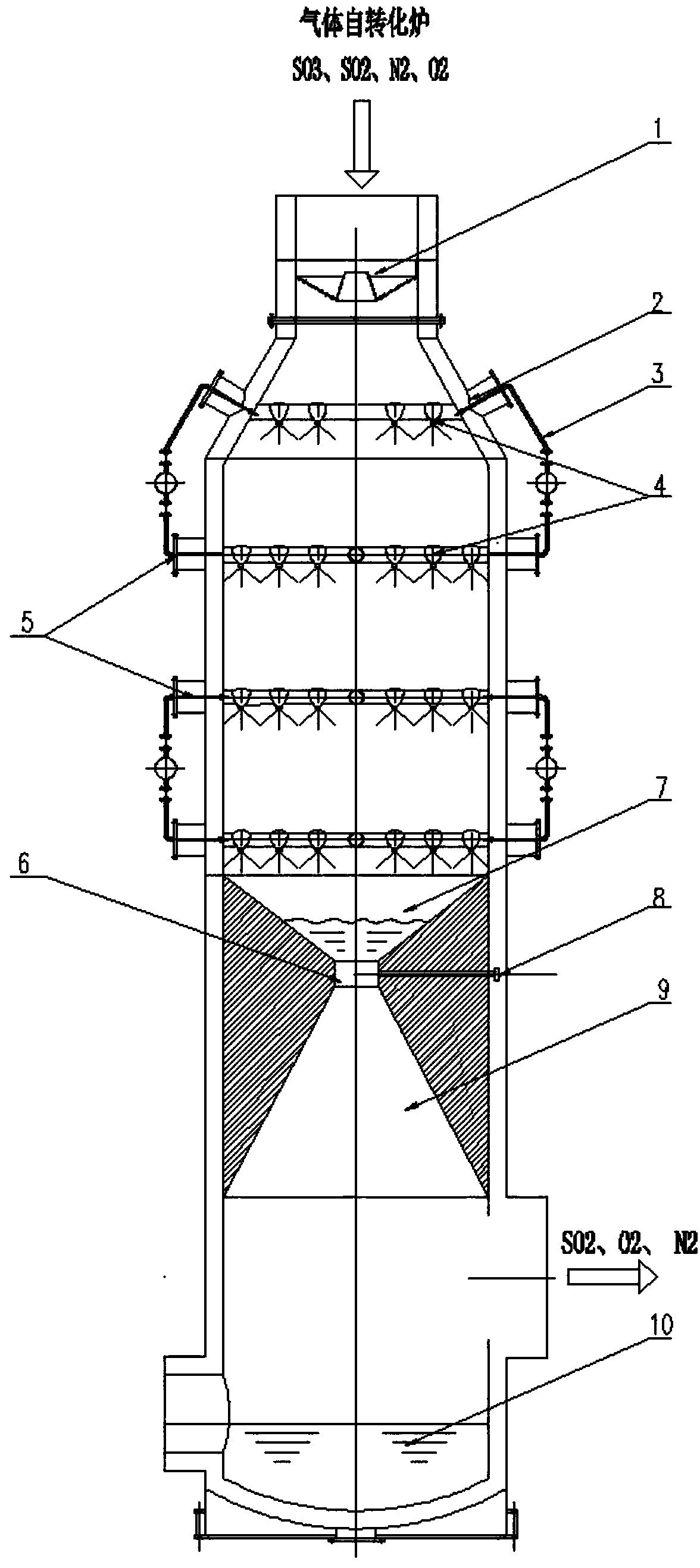

A Diluter Low-set Ultrasonic Spray Tower

ActiveCN105817120BEnsure the uniformity of layoutImprove uniformityGas treatmentDispersed particle separationFailure rateAcid concentration

A low-set ultrasonic spray tower with a diluter, including a tower body, a gas distributor is arranged at the top of the tower body, a circulating acid pipe is fixedly connected to the outside of the tower body, and a spray pipe is arranged in the tower body, and the circulating acid pipe passes through The circulating acid spray head is connected with the spray pipe, and it is characterized in that the spray pipe is evenly equipped with ultrasonic nozzles, and a sedimentation tank is arranged under the spray pipe, and the sedimentation tank is located in the middle section of the tower body, and a dilution tank is arranged below it. chamber, an expansion chamber is provided below the dilution chamber in the tower body, and a dilution acid tank is provided at the bottom of the tower body. The invention improves the uniformity of the sprayed liquid acid mist particles, the gas absorption efficiency is obviously high, the concentrated acid concentration accuracy after dilution is controlled within ±0.9%, the uniformity of the diluted acid is increased, the violent vibration of the diluter is effectively reduced, and the failure rate of the diluter is reduced by 30% %above. The invention expands the range of working conditions for acid concentration and acid temperature control in the process, and has good future economic benefits, huge market and broad industrialization prospect.

Owner:YANGZHOU UNIV

A hand-held electric drill drilling auxiliary electric drill stand

ActiveCN110355405BNo need to moveAchieve fixationWork benchesPortable drilling machinesStructural engineeringElectrical and Electronics engineering

The invention discloses a handheld electric drill punching auxiliary electric drill frame. The device comprises a mounting frame, a mounting seat and a movable frame, wherein a guide rail is arrangedon the movable frame; the mounting seat is slidably arranged on the guide rail; a turntable arranged at the bottom of the mounting frame is rotatably arranged on the mounting seat through a rotating shaft; the mounting frame consists of a movable frame and a shaping frame; one end of the movable frame is installed on movable rods of second electric push rods installed in the shaping frame; a bottom box is installed on the bottom surface of the movable frame; a storage battery and first electric push rods are installed in the bottom box; and a movable rod installed on the output end of each first electric push rod penetrates through the bottom of the bottom box and extends to a supporting plate. According to the device, the mounting frame is designed to be telescopic; drilling height can bechanged at any time; scale marks are arranged on the mounting frame, so that specific drilling height is changed according to the change of the scale marks; and reading is convenient.

Owner:BENGBU COLLEGE

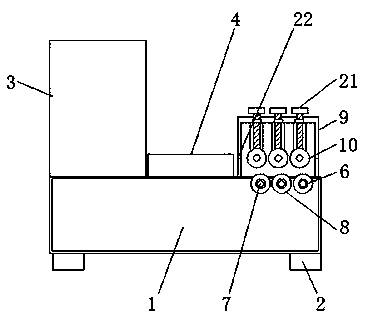

Reverse loosening machine for sandpit

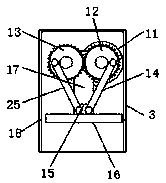

InactiveCN107376315AImprove work efficiencyReduce severe vibrationSki bindingsWater-skiingSandpitMechanical engineering

A sand pit loosening machine, which relates to the field of sports auxiliary equipment, includes a motor mechanism (1), a gear mechanism (2), a handle (3), a power cord (4), a shock absorbing device (5), The motor mechanism (1) is arranged at the middle upper end of the handle (3), the gear mechanism (2) is arranged at the lower end of the motor mechanism (1), and the motor mechanism (1) is electrically connected with the gear mechanism (2), and the handle (3) ) is provided with a switch (6), the switch (6) is connected to the motor mechanism (1) through the power cord (4), and a shock absorber (5) is arranged at the lower end of the motor mechanism (1). The upper end of the gear mechanism (2) is provided with a sand baffle (7). It can make up for the deficiencies of the existing technology, save time and effort, and can greatly improve work efficiency.

Owner:江苏横渡体育用品有限公司

Undercurrent external heat exchanger bed of circulating fluidized bed

ActiveCN101701704BChange the fixation methodReduce severe vibrationFluidized bed combustionSteam boilersHeat transmissionFluidized bed

Owner:TSINGHUA UNIV

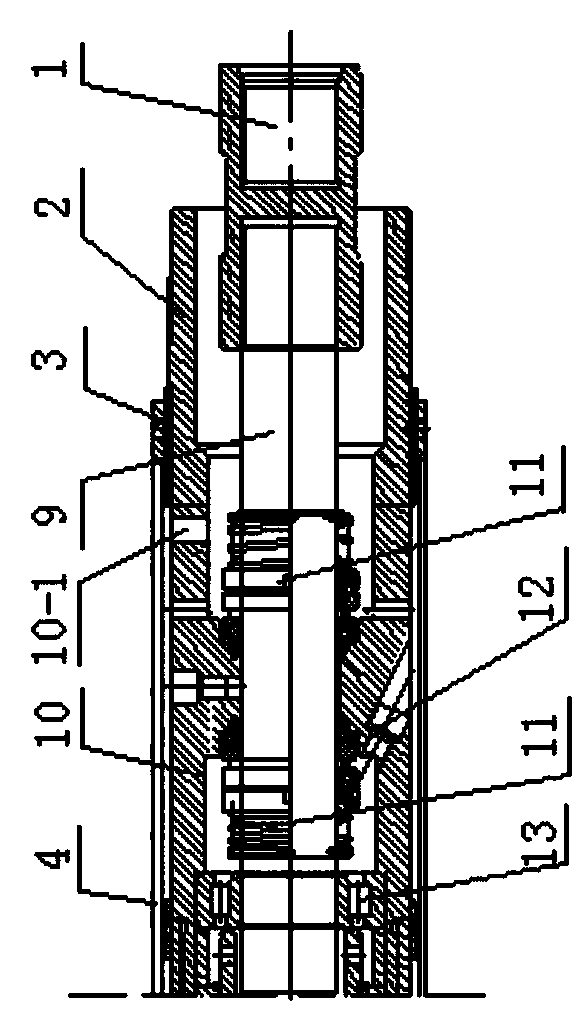

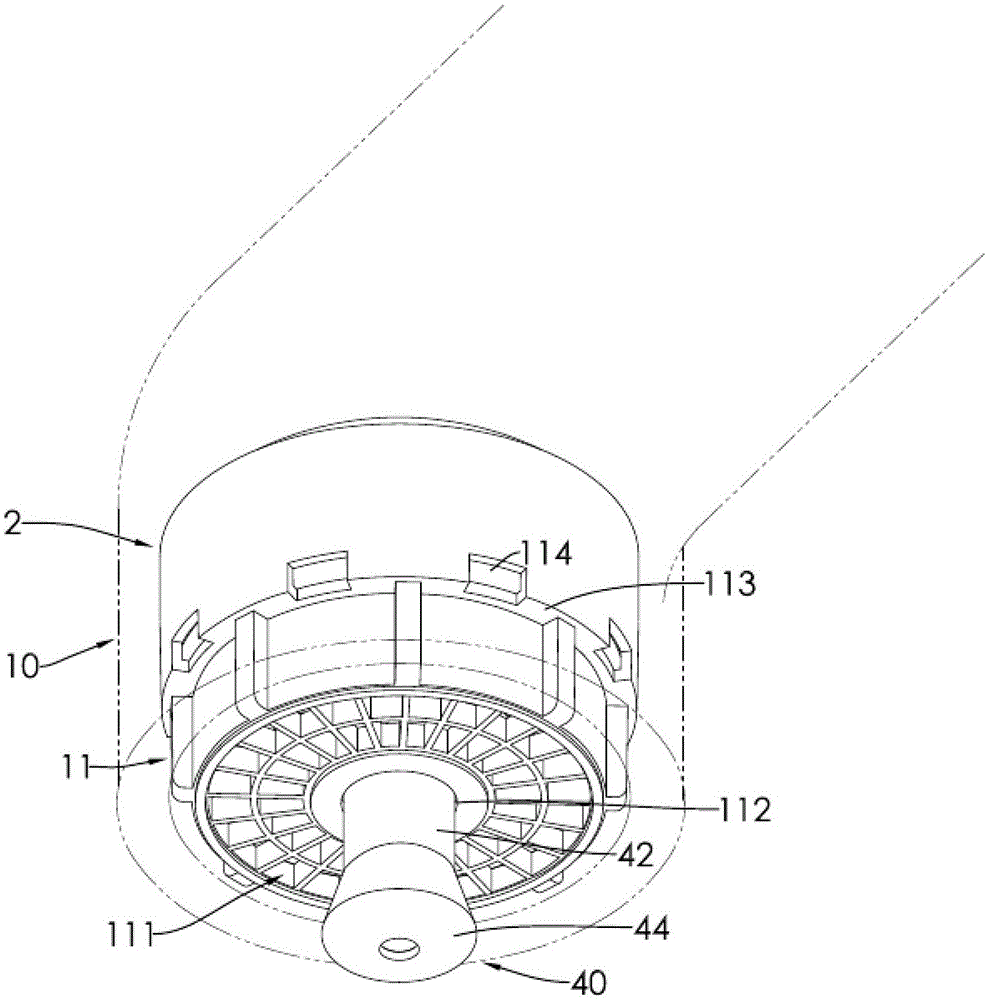

Transmission protection device of screw injection pump in the same well injection-production unit

ActiveCN104100523BCounteracts upward axial forceEliminate hidden dangers of resonanceMachines/enginesRotary/oscillating piston pump componentsCouplingDrive shaft

The invention discloses a transmission protection device of a screw reinjection pump in a same-well injection-production unit. The device is composed of a middle transmission shaft, sealed cavities of bearings, spline shaft transmission pairs, universal coupling type transmission shafts and flow guide covers. The middle transmission shaft is borne by a rolling bearing and a thrust bearing, the spline shaft transmission pairs are arranged in the sealed cavities and connected with the middle transmission shaft, and the universal coupling type transmission shafts are connected with the middle transmission shaft. The transmission protection device can effectively offset upward axial force of the screw reinjection pump, and therefore impact of the upward axial force on a power device of the same-well injection-production unit is avoided, and violent vibration formed by the eccentric motion, relative to the axes of the flow guide covers, of the screw reinjection pump through the axial force is obviously reduced. The transmission protection device enables the unit to stably run for 360 days, and the protection device conforms to index requirements of the application of an oil field.

Owner:TIANJIN RONGHENG GROUP

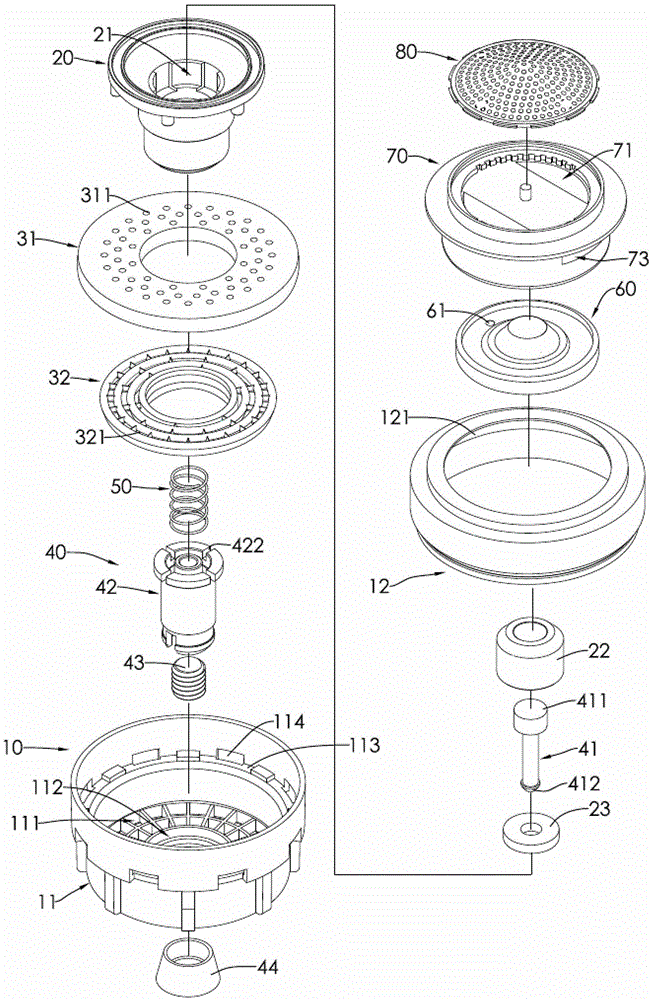

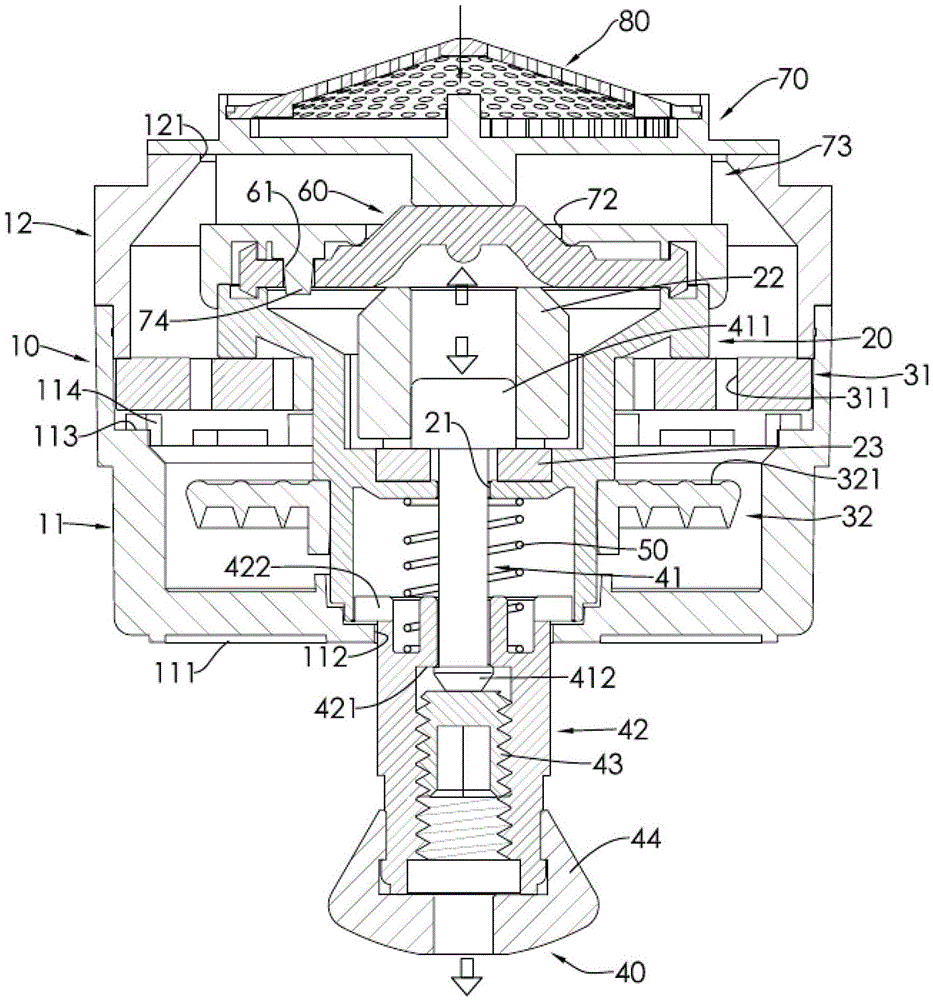

Self-closing water saving valve

ActiveCN103851243BAvoid damageTo achieve the effect of automatic shutdownValve members for absorbing fluid energyFluid-delivery valvesWater savingWater flow

The invention provides an automatic closing water-saving valve arranged on a faucet. The automatic closing water-saving valve comprises a shell, a bearing, a control rod, a sleeve part and a water inlet seat. When the automatic closing water-saving valve is opened, the control rod can slowly move down due to gravity and a slight water pressure until an upper abut-against part of the control rod seals up a bearing rod hole; then water flowing into a space between the bearing and the sleeve part from a sleeve hole of the sleeve part is gradually accumulated to squeeze the sleeve part upwards and enable the sleeve part to be deformed, so that the sleeve part seals up the water inlet seat to stop the water flow, and thus, an automatic closing effect is achieved. The deformation process of the sleeve part is progressive, and thus, the sleeve part has an effect of buffering to turn off water, so that water hammer sound is avoided. Moreover, the water pressure is not directly acted to the control rod, and thus, a force which needs to be applied when the control rod is operated is small.

Owner:NEOPERL INT

Industrial intelligent robot

InactiveCN108858215AReduce severe vibrationImprove performanceManipulatorEngineeringMechanical engineering

The invention discloses an industrial intelligent robot. The industrial intelligent robot comprises a robot body, a movable device and a shock reduction device. The movable device comprises a movablechasis, a front wheel movable assembly, a rear wheel movable assembly, a front wheel driving portion and a rear wheel driving portion. The front wheel movable assembly and the rear wheel movable assembly are mounted at the front end and the rear end of the movable chasis correspondingly. The front wheel driving portion is in drive connection with the front wheel movable assembly. The rear wheel driving portion is in drive connection with the rear wheel movable assembly. The shock reduction device comprises a front wheel shock reduction assembly and a rear wheel shock reduction assembly. The front wheel shock reduction assembly is arranged on the front wheel movable assembly. The rear wheel shock reduction assembly is arranged on the rear wheel movable assembly. A mounting plate is mountedat the bottom of a machine cabinet. The mounting plate is mounted on the front wheel shock reduction assembly and the rear wheel shock reduction assembly. According to the industrial intelligent robot, corresponding shock reduction device is arranged; severe shock generated in the walking process of the industrial intelligent robot is reduced; and then overall performance of the robot is improved.

Owner:沈春燕

Noise reduction device of automobile hub shot blasting machine

InactiveCN105987115AReduce severe vibrationGuaranteed uptimeHigh internal friction springsShock absorbersEthylene propylene rubberAcrylonitrile

The invention discloses a noise reduction device of an automobile hub shot blasting machine. The noise reduction device comprises a stainless steel shell. Acrylonitrile-modified ethylene propylene rubber is arranged in the stainless steel shell. Ni-Ti-based twin crystal memory damping alloy round steel is inserted into the middle of the acrylonitrile-modified ethylene propylene rubber in the height direction. An AL-Zn superplastic damping alloy spring is embedded into the acrylonitrile-modified ethylene propylene rubber. The stainless steel shell is filled with the acrylonitrile-modified ethylene propylene rubber. Severe vibration of the automobile hub shot blasting machine can be effectively reduced, and normal operation of a machine and equipment is ensured; and noise is lowered, and it is ensured that workers can normally work and take a rest.

Owner:QINGHAI T&C ALUMINUM

motor

ActiveCN108649736BReduce severe vibrationAvoid damageSupports/enclosures/casingsBrakeClassical mechanics

Owner:肇庆市智高电机有限公司

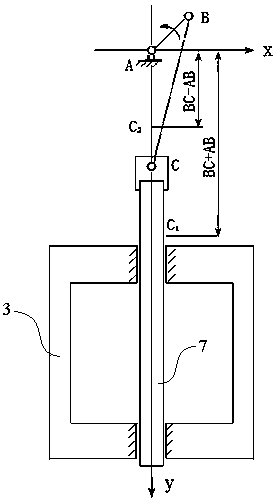

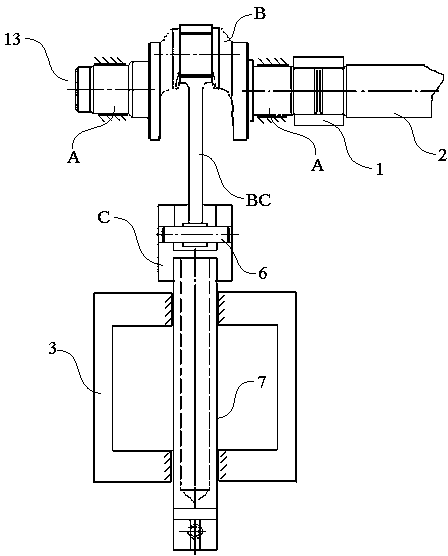

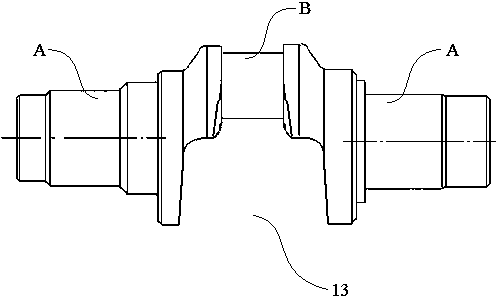

Slider-crank material penetrating mechanism installed in same plane

The invention discloses a slider-crank material penetrating mechanism installed in the same plane. The slider-crank material penetrating mechanism is composed of a crankshaft, a connection rod and a needle rod slide block. The crankshaft comprises a short shaft and a crank throw capable of rotating around the central line of the short shaft by 360 degrees. The short shaft is connected with an upper shaft of a template sewing machine. The upper shaft is supported by the top of a geared head. A crank is formed between the central line of the crank throw and the central line of the short shaft. The crank throw is connected with the large end of the connection rod. The small end of the connection rod is connected with the upper end of the needle rod slide block through a needle rod pin. The lower end of the needle rod slide block is connected with a needle rod which is supported by the middle and the bottom of the geared head. The technical requirements of all parts for the face-face parallelism and perpendicularity, the line-face parallelism and perpendicularity and the line-line parallelism and perpendicularity are more strict compared with the prior art, the violet vibration of the needle rod is reduced in the running process, vibration and noise of the sewing machine are greatly reduced, and the slider-crank material penetrating mechanism can meet the design requirements of the high-speed sewing machine, and is suitable for transformation of an existing material penetrating mechanism technology.

Owner:JIANGSU WANGONG TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com