Slider-crank material penetrating mechanism installed in same plane

A crank slider and plane technology, which is applied to sewing machine components, sewing machine needle seats, textiles and papermaking, etc., can solve problems such as noise pollution, vibration shock, and difficulty in ensuring the parallelism between the chute and the needle bar groove, etc. Small vibration and noise, reduce the effect of severe vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

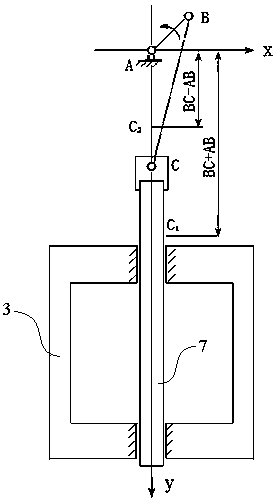

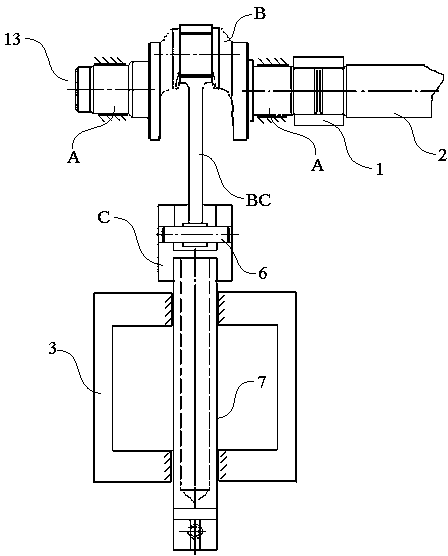

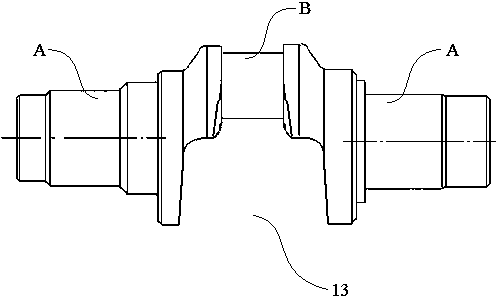

[0033] see figure 1 , figure 2 As shown, a crank slider threading mechanism installed on the same plane is composed of a crankshaft 13, a connecting rod BC and a needle bar slider C. The crankshaft 13 includes a minor axis A and a The bell crank B is rotated by 360° on the center line, the short shaft A is connected with the upper shaft 2 of the template sewing machine through the coupling 1, and the upper shaft 2 is supported on the top of the head box 3; the center line of the bell crank B is The distance from the center line of the minor axis A constitutes the crank AB, the crank throw B connects the big end 4 of the connecting rod BC, and the small end 5 of the connecting rod BC connects with the needle bar through the needle bar pin 6 The upper end of the slider C is connected, and the lower end of the needle bar slider C is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com