Self-closing water saving valve

A self-closing, water-saving valve technology, applied in the direction of valve details, valve devices, functional valve types, etc., can solve the problems of short time for water outflow, damage to noisy water pipes, wear and tear of time control gasket 93, etc., to achieve convenient push and open , Reduce violent vibration, avoid water hammer sound and water pipe damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

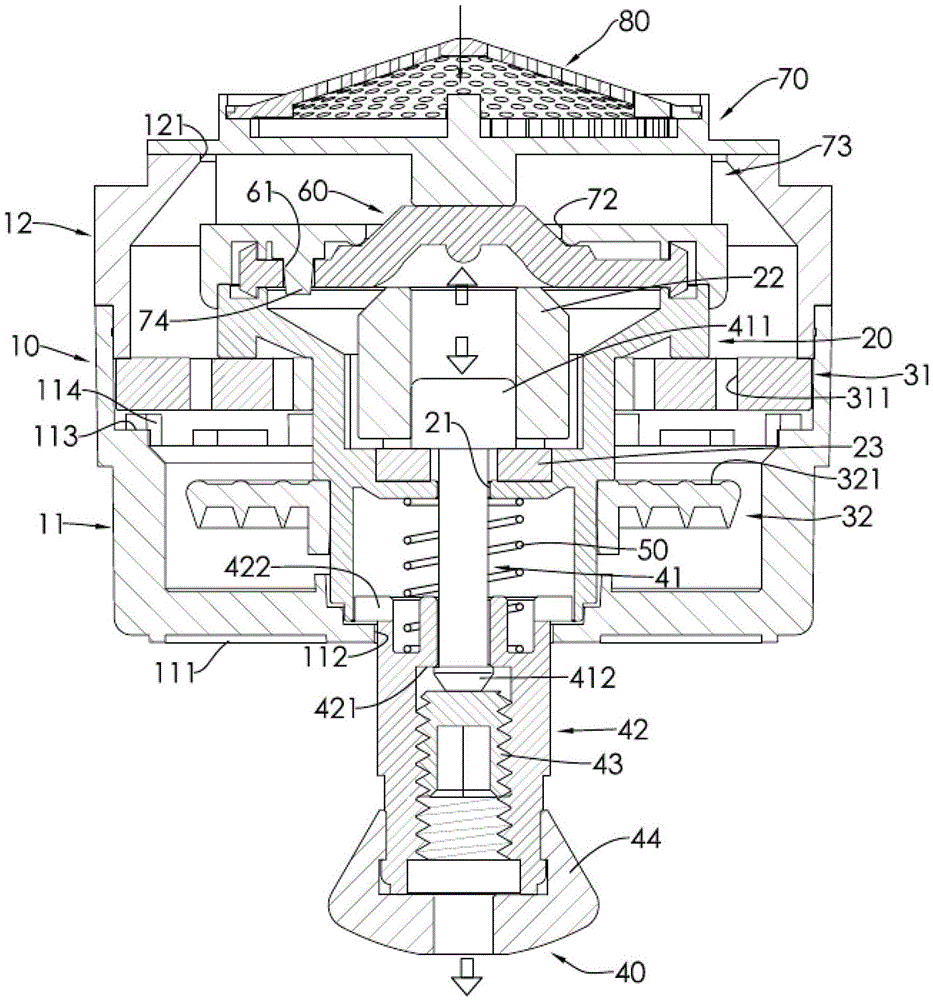

[0079] The technical means adopted by the present invention to achieve the intended invention purpose are further described below in conjunction with the drawings and preferred embodiments of the present invention.

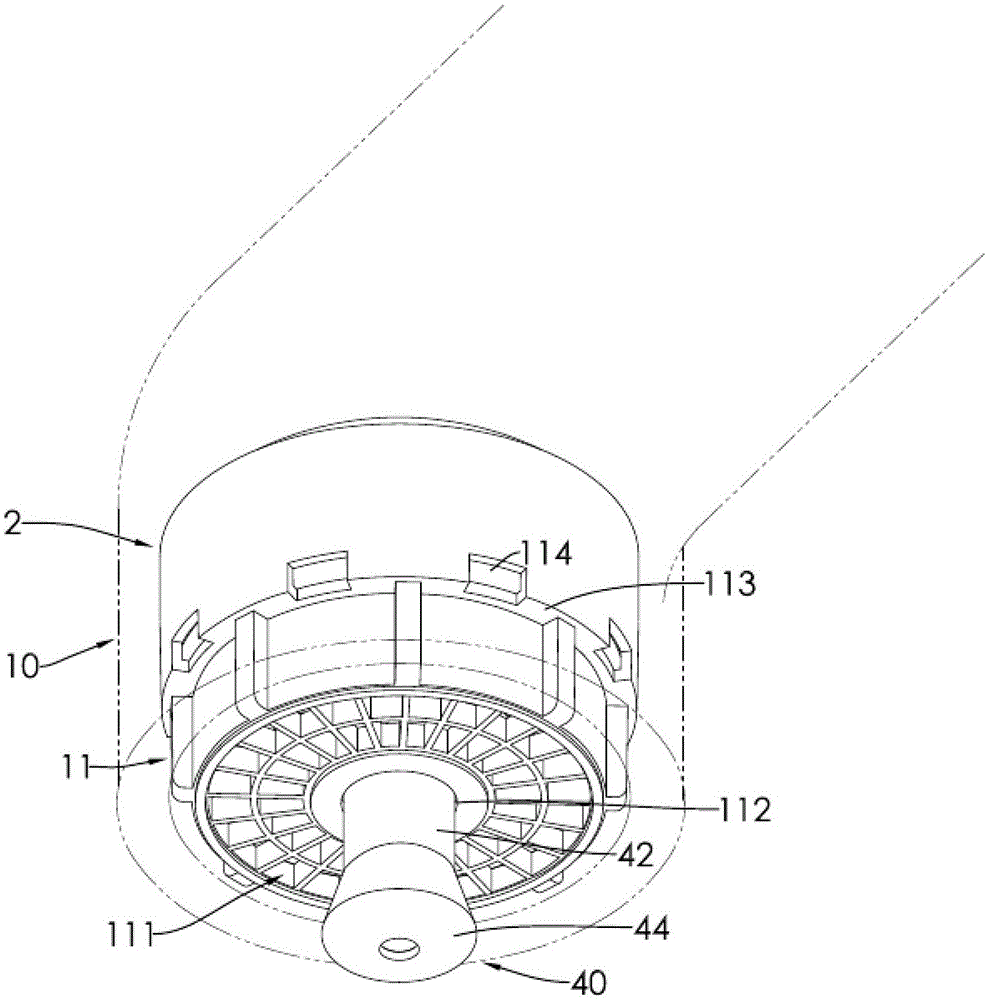

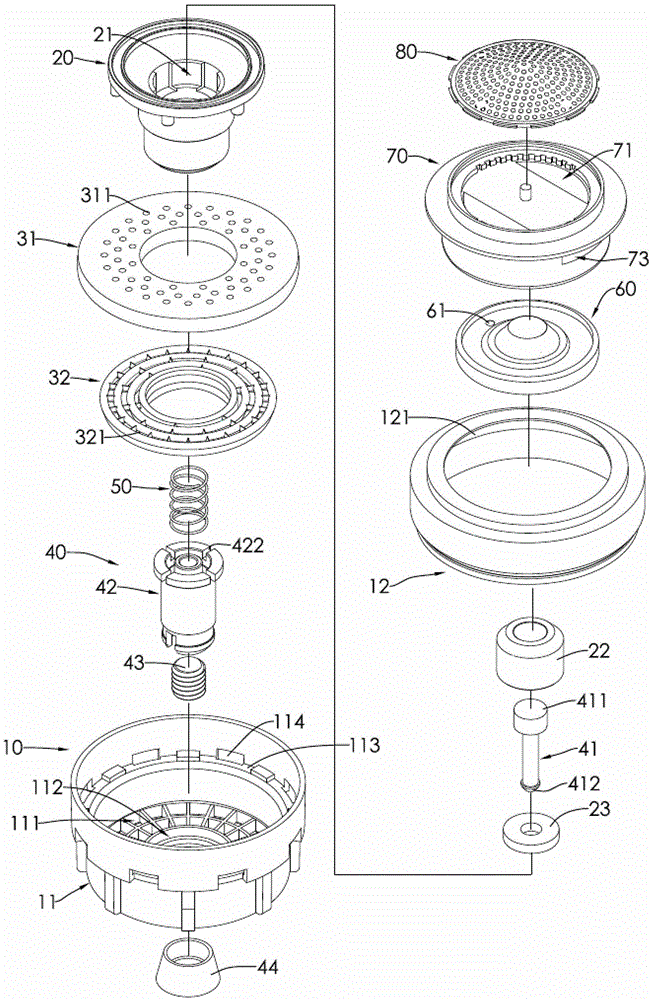

[0080] see figure 1 and figure 2 As shown, the self-closing water saving valve of the present invention includes a housing 10, a seat 20, a control rod 40, a sleeve 60 and a water inlet seat 70; in this embodiment, it further includes a valve seat 31 , a water outlet grid frame 32 , an elastic element 50 and a filter screen cover 80 .

[0081] see Figure 1 to Figure 3 As shown, the aforementioned housing 10 includes a base 11 and an upper cover 12, the base 11 and the upper cover 12 cover an inner space; the base 11 is provided with a water outlet 111 and a housing rod hole 112, and the water outlet 111 surrounds The housing rod hole 112, and the water outlet 111 is in the shape of a radial grid; the wall surface of the base 11 is in a step shape and has a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com