Noise reduction device of automobile hub shot blasting machine

A technology of automobile hubs and shot blasting machines, which is applied in the direction of shock absorbers, shock absorbers, mechanical equipment, etc., can solve problems such as affecting the health of the staff, hindering the work and rest of the staff, fatigue damage in high-stress areas of the structure, etc., to achieve Reduce severe vibration, ensure normal operation, and reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

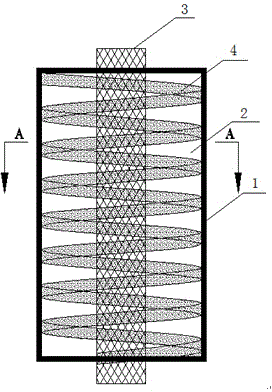

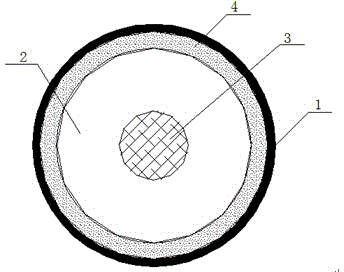

[0020] Such as figure 1 with figure 2 As shown, a noise reduction device for an automobile hub shot blasting machine of the present invention includes a stainless steel housing 1, and an acrylonitrile-modified ethylene-propylene rubber 2 is arranged inside the stainless steel housing 1, and the acrylonitrile-modified ethylene-propylene rubber The middle part of 2 is inserted with a Ni-Ti-based crystal-type memory damping alloy round steel 3 along the height direction, and the acrylonitrile-modified ethylene-propylene rubber 2 is embedded with an AL-Zn superplastic damping alloy spring 4, and the AL-Zn superplastic The plastic damping alloy spring 4 is arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com