Assembly comprising shoveling and milling machine arm frame and milling and digging device

A milling and milling machine technology, which is applied to mining equipment, earthwork drilling, tunnels, etc., can solve the problems of reducing the frequency of blasting, high construction safety risks, and slow progress, and achieves the increase and expansion of the working range and variable angle Applicable occasions, reduce the effect of severe vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

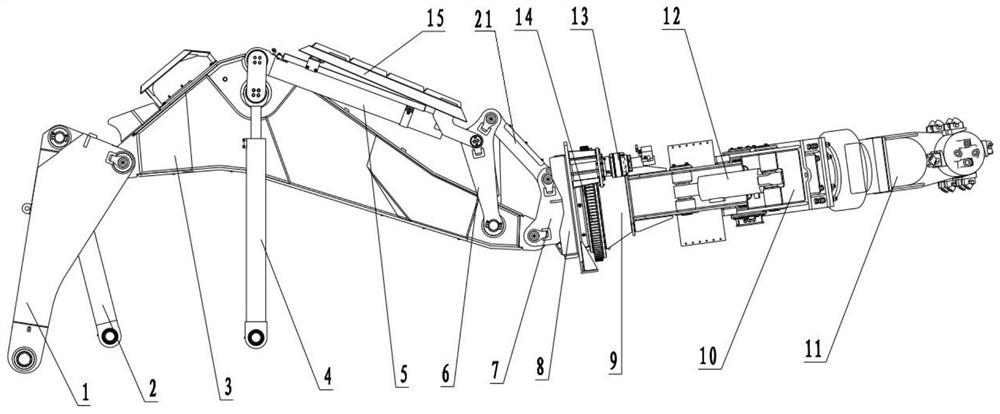

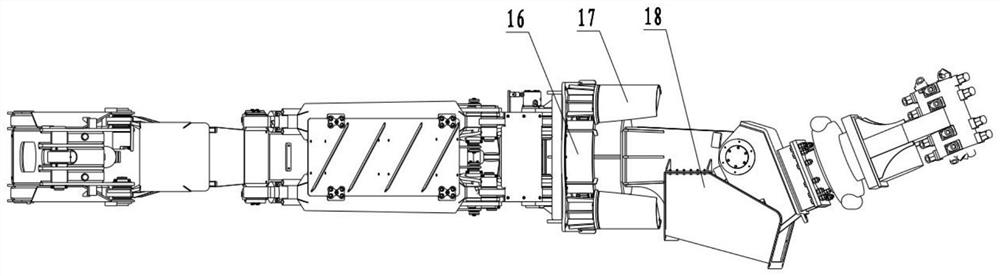

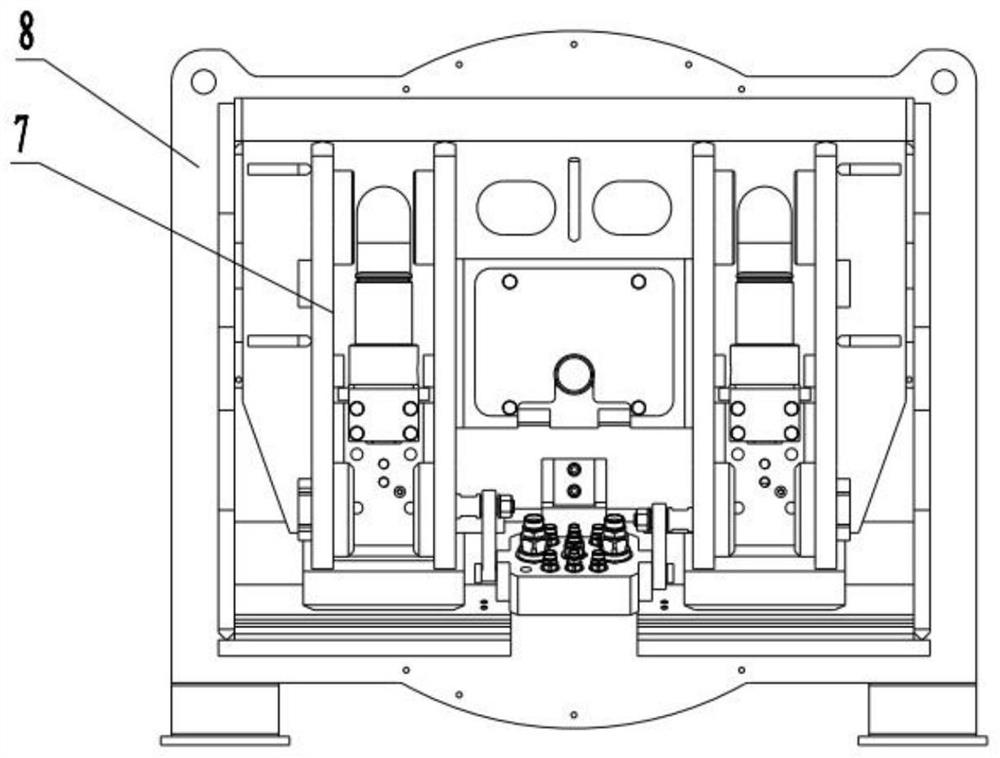

[0030] see Figure 1 ~ Figure 4 , an assembly comprising a shovel milling machine arm frame and a milling and digging device, the quick change device 7 of the shovel milling machine arm frame is connected to the base 8 of the milling and digging device;

[0031] The arm frame of the scraper milling machine includes a boom 1, a boom cylinder 2, a stick arm 3, a stick cylinder 4, a rocker 6, a connecting rod 21, a rocker cylinder 5, and a quick change device 7; one end of the boom 1 is connected to The frame of the scraper milling machine is rotatably connected, and the other end is rotatably connected to the first end of the stick arm 3 through a pin shaft; the second end of the stick arm 3 is rotatably connected to the quick change device 7 through a pin shaft; one end of the boom cylinder 2 It is hinged with the frame, and the other end is hinged with the boom 1; one end of the stick cylinder 4 is hinged with the frame, and the other end is hinged with the stick arm 3; one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com