Combined type fuel tank for rail flaw detection vehicle

A technology for rail flaw detection vehicles and fuel tanks, which is applied to vehicle components, railway inspection vehicles, railway car body components, etc., which can solve the problems of unconsidered compounding and space saving, so as to facilitate the installation of flaw detection equipment and pipe system layout, and reduce violent Vibration, space-saving effect of chassis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

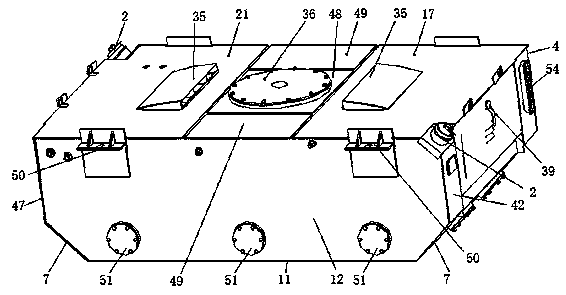

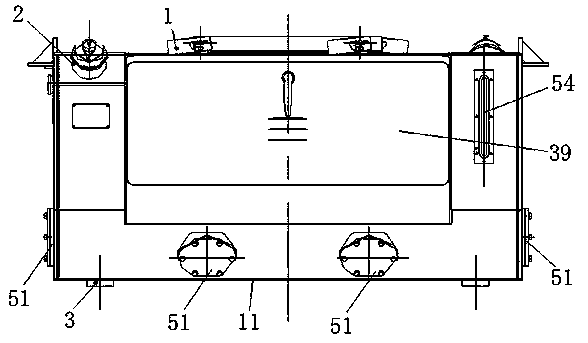

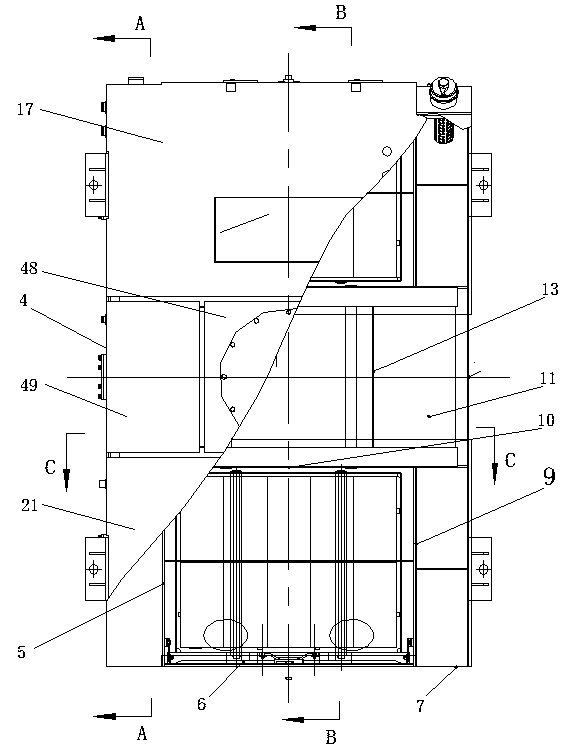

[0027] figure 1 , 2 , 3, and 4 show a structural diagram of a composite fuel tank for a rail flaw detection vehicle. The casing of the composite fuel tank for the rail flaw detection vehicle includes a fuel tank and a storage battery box. The box body is constructed by welding the top plate, the first side sealing plate 4, the second side sealing plate 12, the bottom middle cover plate 11, the two bottom side oblique sealing plates 7, the first side sealing plate 42 and the second side sealing plate 47 monolithic structure. The top plate adopts two first top middle cover plates 49 , a second top middle cover plate 48 , a first top edge cover plate 17 and a second top edge cover plate 21 through welding into one body. The tank is divided into two battery boxes and a plurality of interconnected fuel chambers by a partition plate, the batte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com