Centering device for drill rod in hole of engineering driller

A technology for engineering drilling rigs and inner drill pipes, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc. It can solve the problems of reducing torque and damage to the hole wall, and achieve the effects of reducing torque, reducing damage to the hole wall, and reducing severe vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

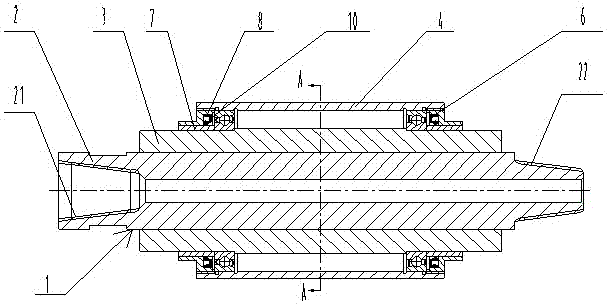

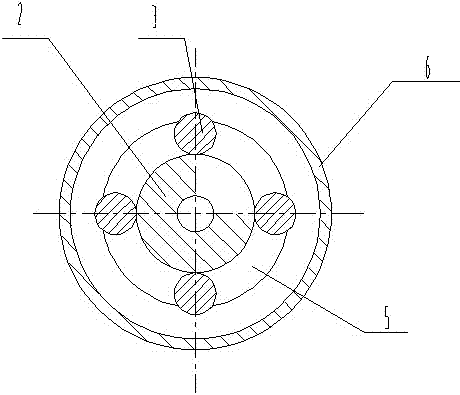

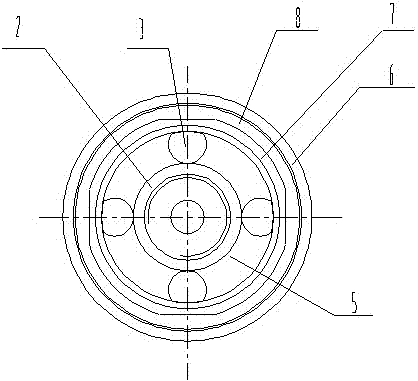

[0021] Such as figure 1 , 2 As shown in , 3, the centralizer used for the drill pipe in the engineering drilling rig hole of the present invention includes a body 1, and the body 1 mainly includes a mandrel 2, a rib 3 and an outer shell 4, the mandrel 2 is located at the center, and its The two ends are respectively provided with a tapered internal thread 21 and a tapered external thread 22. During use, the tapered internal thread 21 and the tapered external thread 22 at both ends are respectively connected with the threaded ends (male end, female end) of the drill rod in the hole. head) is connected by tightening to form the drill string to transmit motion and torque; the middle of the mandrel 2 is hollow to form a passage for the mud, water or gas required for drilling; the ribs 3 are two or more, uniform It is arranged on the outer surface of the mandrel 2, that is, evenly arranged along the circumferential direction. The ribs 3 can be two, three, four, five, six, eight or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com