Construction method for hole forming of bridge pile foundation in karst area

A construction method and pile foundation hole technology, which are applied in the fields of foundation structure engineering, sheet pile wall, soil protection, etc., can solve the problems of prone to collapse accidents, increased engineering costs, and interruption of engineering implementation, so as to prevent slurry leakage and prevent leakage. The effect of concrete loss, improving pile quality and avoiding hole collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

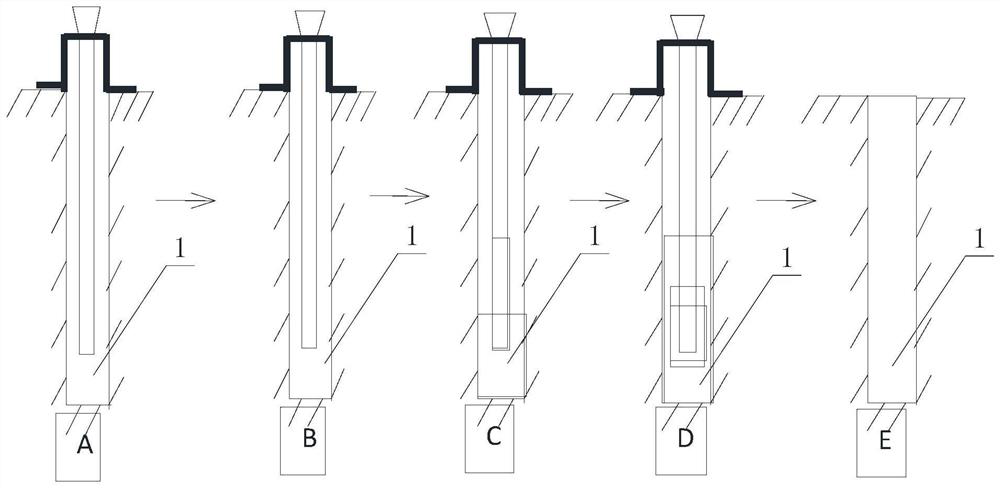

[0051] Method 1: Full shield method

[0052] If the range of the karst cave is large and the slurry leakage is serious, once the slurry leakage occurs, the slurry level in the hole drops rapidly, and the mud retaining wall cannot resist the pressure generated by the difference between the internal and external water heads generated during the slurry leakage. Wait for vicious accidents to occur, and the most effective way to prevent this is to use full casing construction. In the actual construction, the protective tube follow-up method is adopted.

[0053] Follow-up construction of the casing, that is, first place the casing according to the conventional method, after the drilling rig is in place to drill to a certain depth, remove the drilling rig, and then vibrate and sink the casing. Repeat this until the casing follows up to the bedrock surface. .

[0054] 1), hoist the steel casing

[0055] After the rotary drilling rig drills to the rock surface and is accepted, hoist...

Embodiment 1

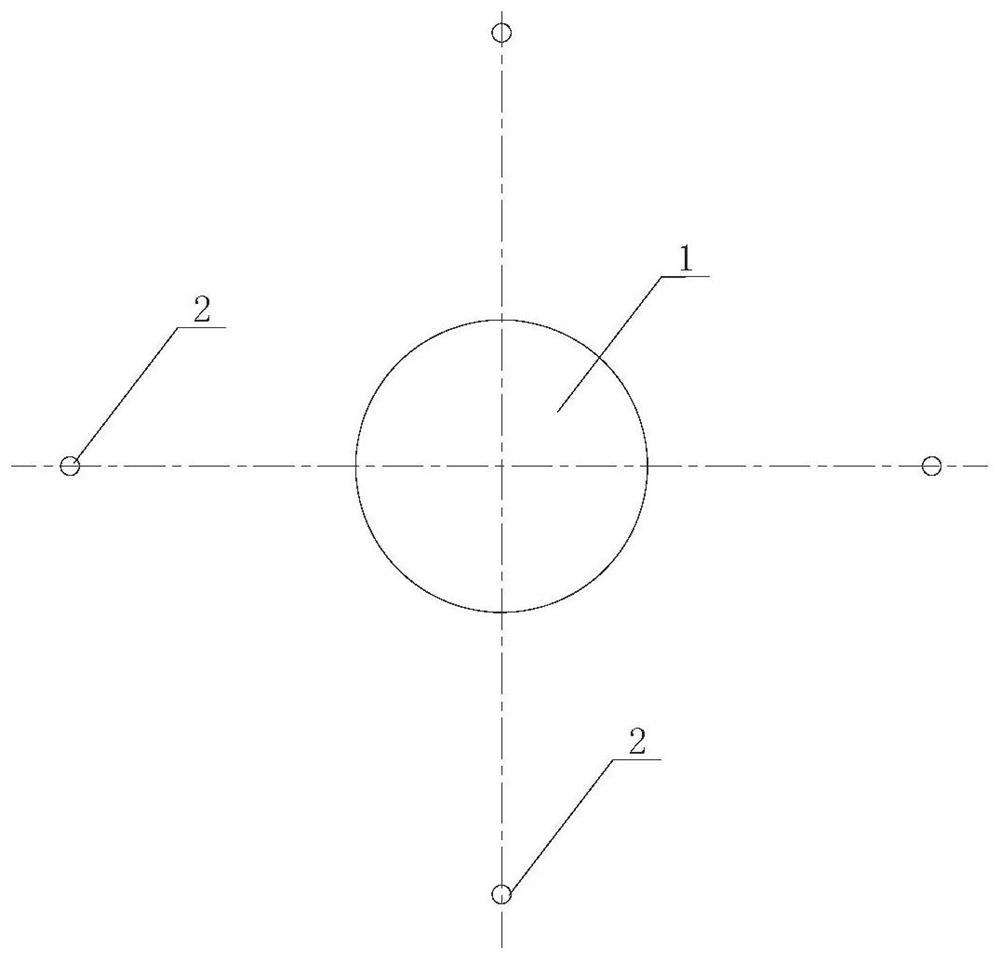

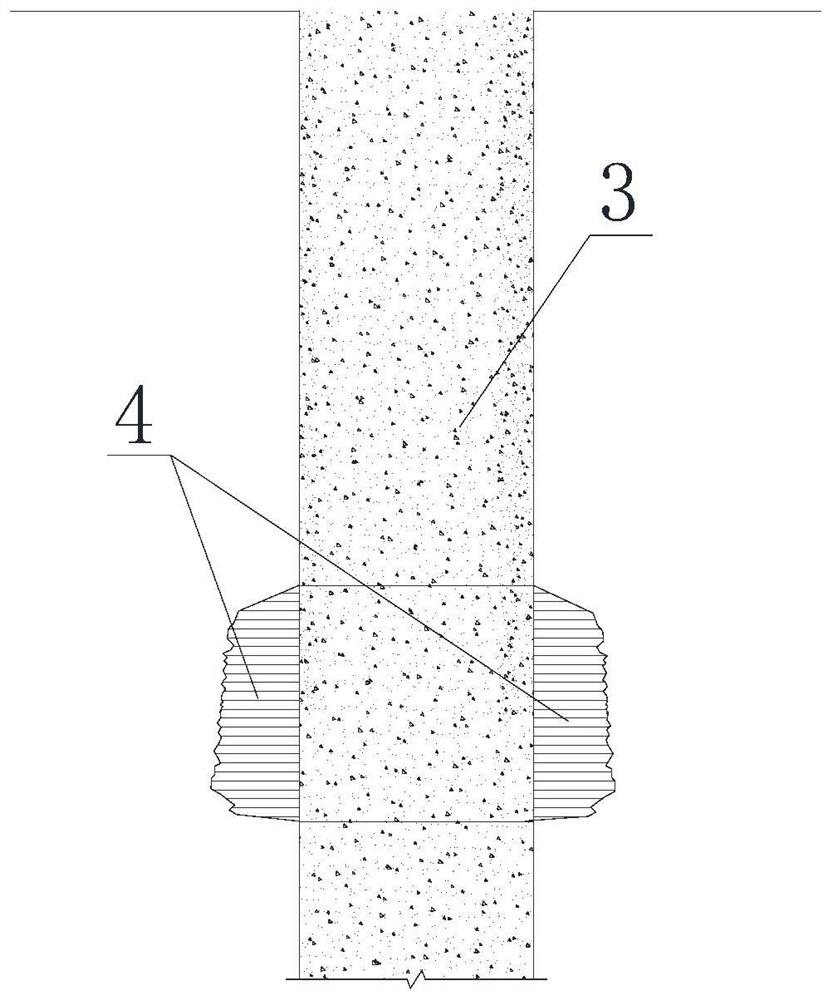

[0064] The bridge measurement and stakeout are controlled by the first-level wire. The plane pile position staking is carried out with a total station according to the center coordinates of the pile position that have been calculated and checked. After setting out the central pile position of the pile foundation, you can place the instrument on different control points to check and review, or use a large steel ruler to measure whether the distance between adjacent pile positions is correct. The construction team shall bury the guard piles 2 according to the site technical setting out pile positions. The bored pile 3 here is the pile foundation hole 1 before pouring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com