Patents

Literature

30results about How to "Affect the mixing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

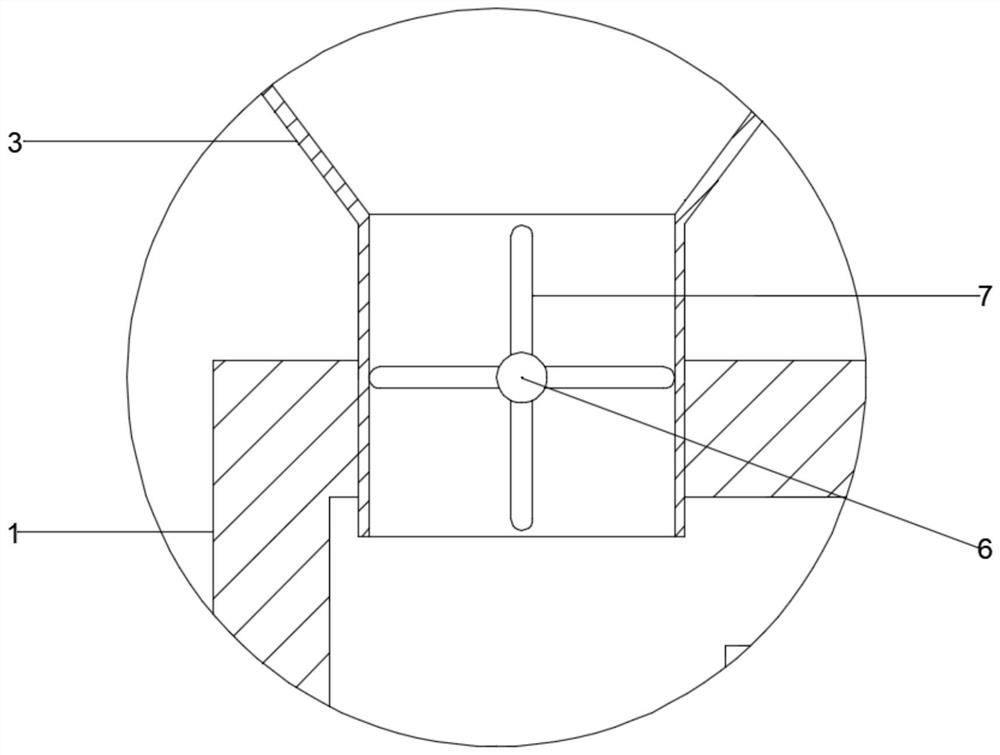

Mixer feeding device with dustproof function

InactiveCN107362888AImprove the mixing effectPlay a buffer roleTransportation and packagingMixer accessoriesEngineering

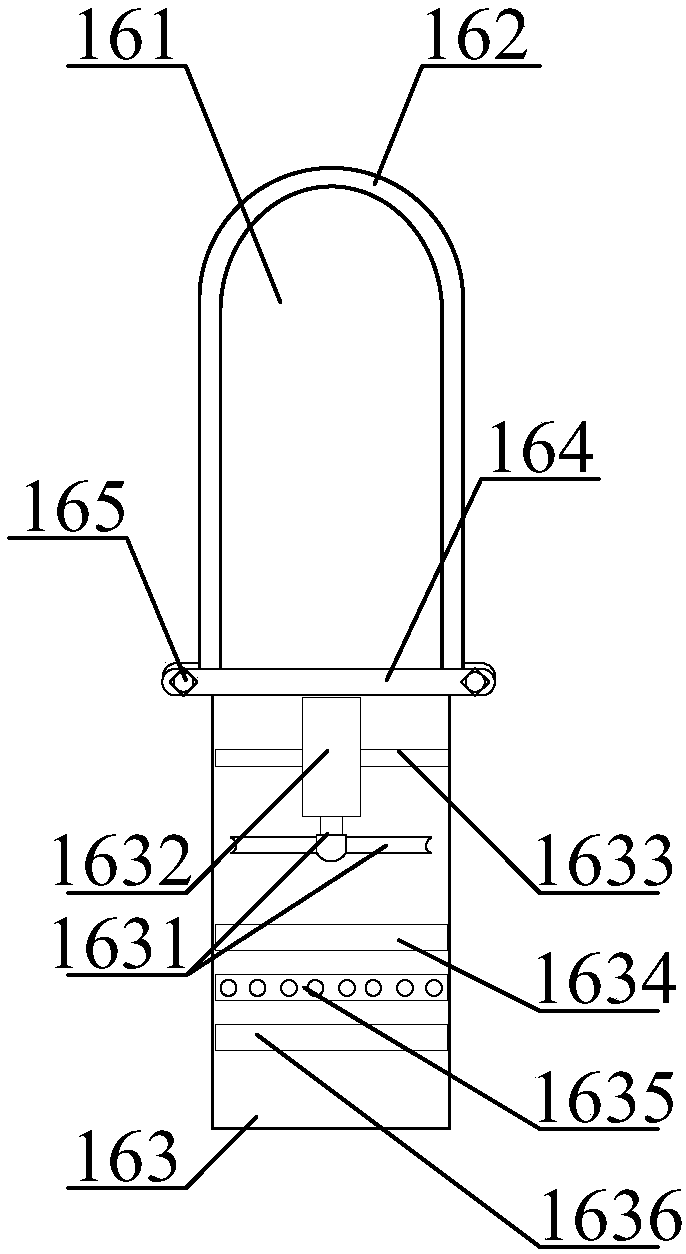

The invention discloses a mixer feeding device with a dustproof function. The mixer feeding device comprises a dustproof plate, a fan, a dust suction cover, a smashing motor and a feeding cabin. After materials pass through the dustproof plate, the dustproof plate can be tightly attached again under elastic force action of a return spring; thus, environmental pollution caused by dust fly is effectively prevented; a fan is utilized to suck dust floating in air into a dust collection box by a dust suction pipe, and the dust suction cover is arranged to be used for increasing a dust suction area to further improve a dust collection effect and efficiency; environmental pollution caused by dust is further prevented; rotation of the smashing motor is utilized to further drive a smashing blade on a smashing rotation shaft to rotate to smash the materials entering a smashing cabin; the feeding cabin is arranged to achieve a buffer effect and further enable the materials to fall down slowly after passing through the feeding cabin; the materials are prevented from directly falling into the bottom of a following stirring device and affecting a material stirring effect; equipment practicability is further improved.

Owner:深圳市泽同国际商务服务有限公司

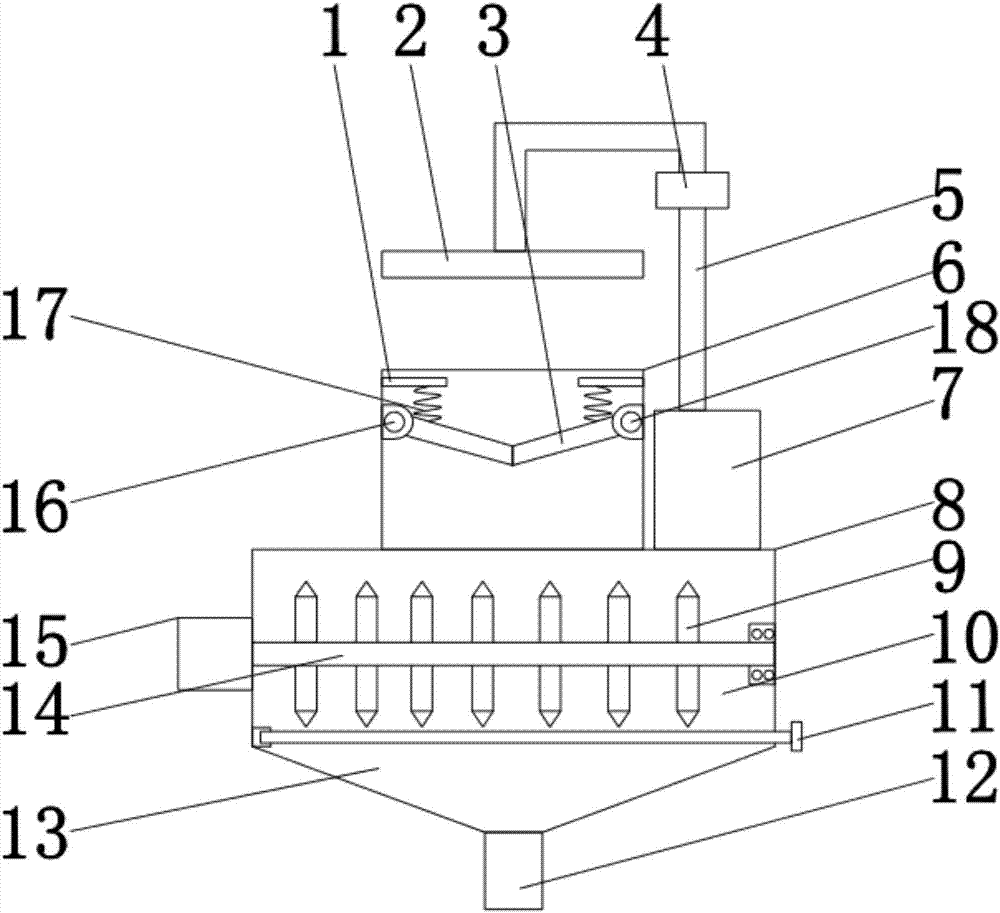

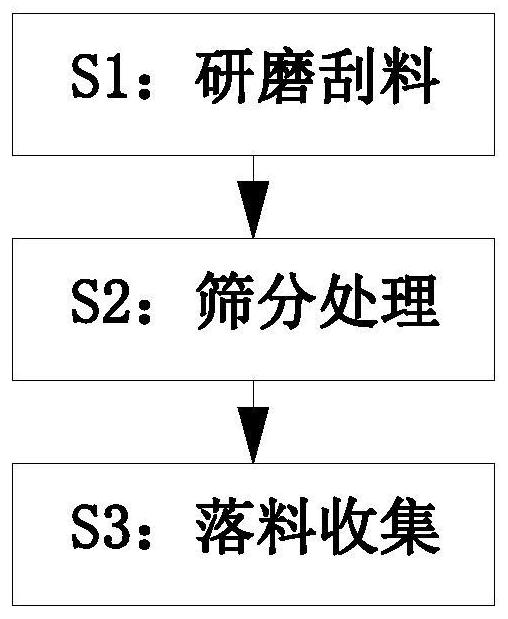

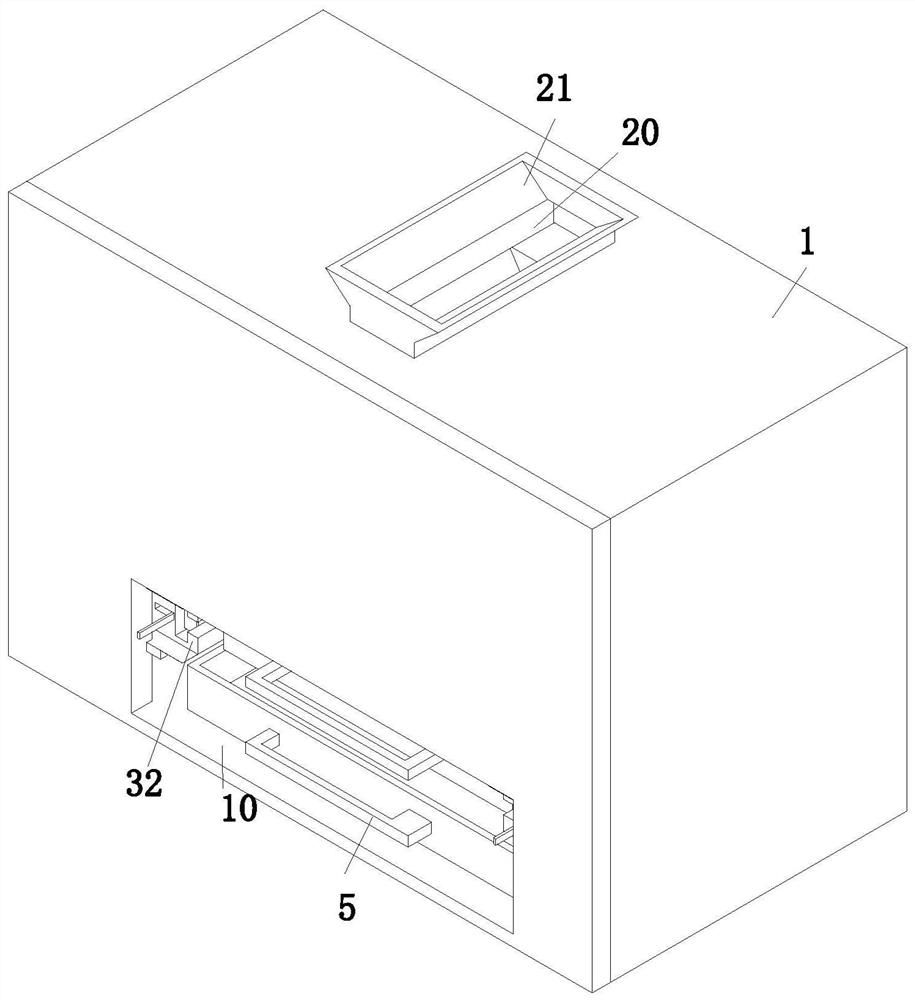

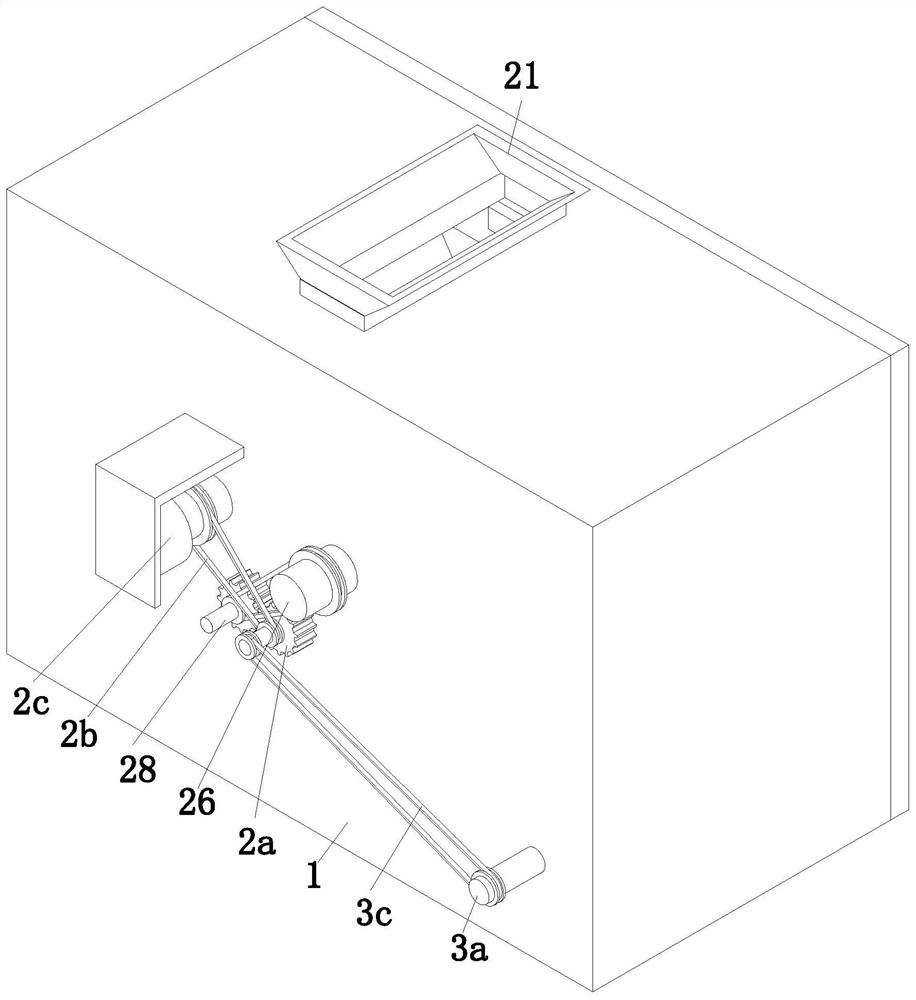

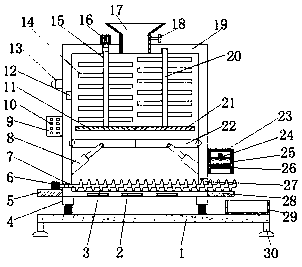

Water-based printing ink preparation method

InactiveCN113134423AFine ink raw materialsEasy to stir and mixSievingScreeningPrinting inkGrinding mill

The invention relates to a water-based printing ink preparation method. A water-based printing ink preparation device is used. The water-based printing ink preparation device comprises a preparation box, a grinding mechanism, a screening mechanism, a scraping mechanism and a collecting box, the preparation box is of a rectangular structure, the grinding mechanism, the screening mechanism and the collecting box are sequentially arranged on the inner wall of the preparation box from top to bottom, and the scraping mechanism is arranged on the grinding mechanism. According to the method, the grinding mechanism can conduct double grinding on ink raw materials, so that the ground ink raw materials are finer, mixing and stirring of the ink raw materials are facilitated, the mixing stirring effect behind the ink raw materials is prevented from being influenced due to the fact that the grinding of the ink raw materials is not fine, meanwhile, the ink raw materials adhered to a first grinding roller and a second grinding roller on the grinding mechanism are scraped off by adopting the scraping mechanism, so that the adhered raw materials are prevented from influencing the grinding of a grinding roller, and therefore, the grinding effect of the grinding roller is not good.

Owner:有限会社林平

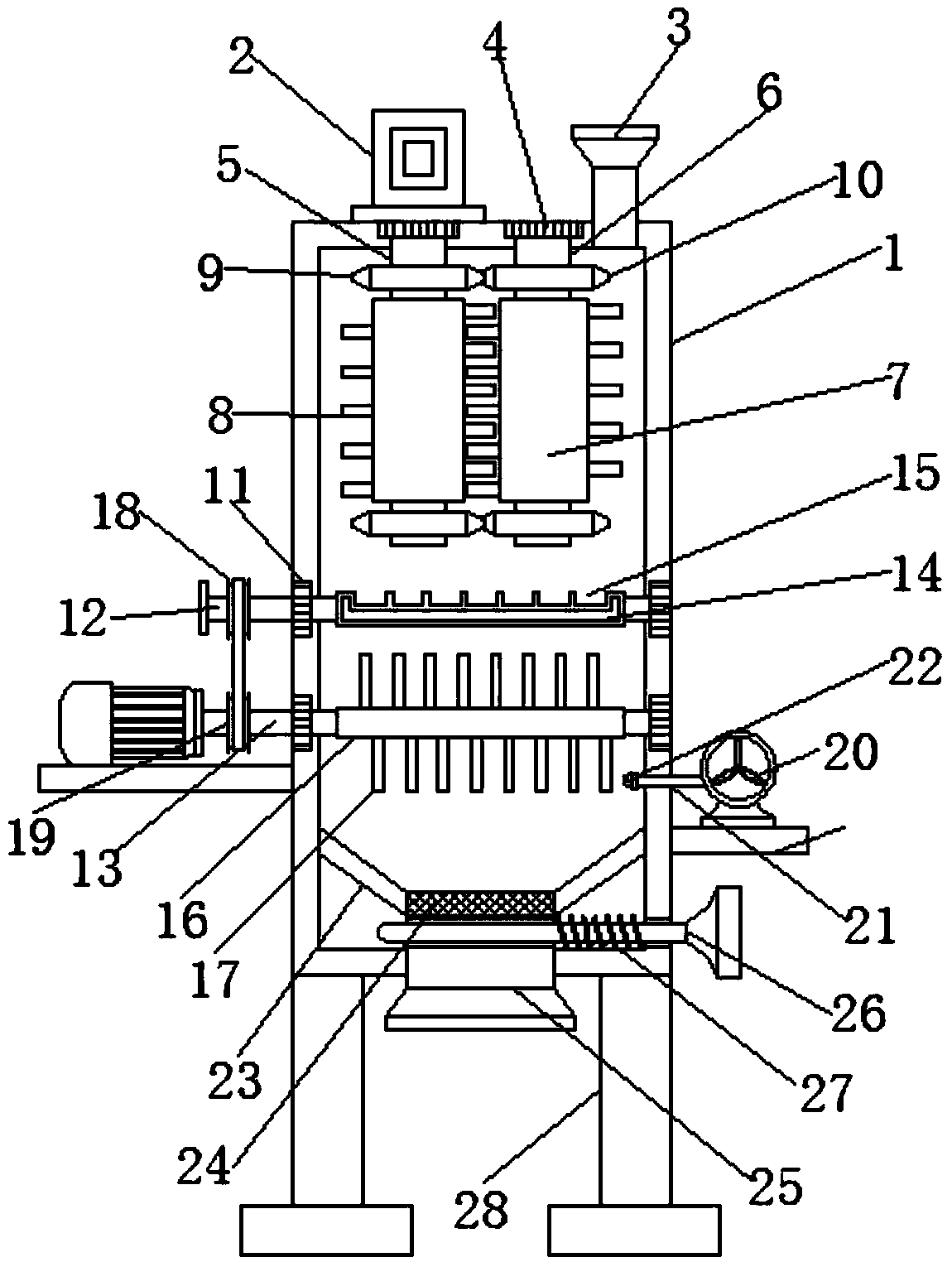

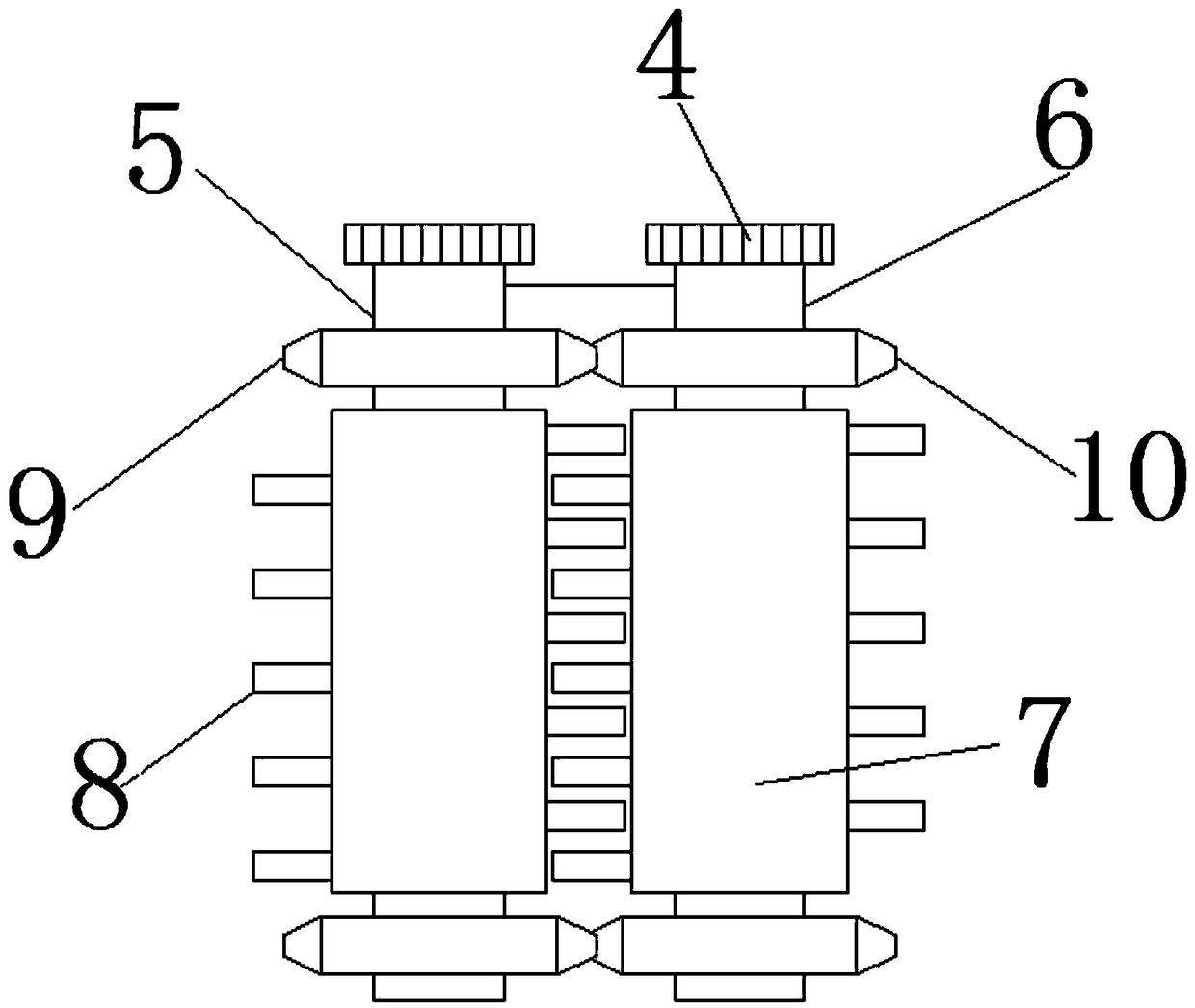

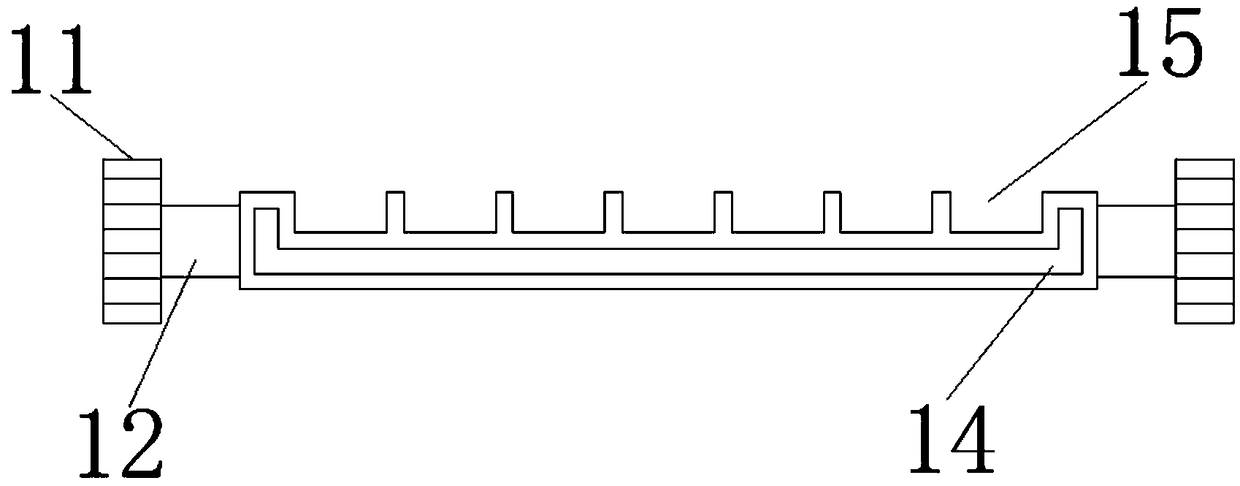

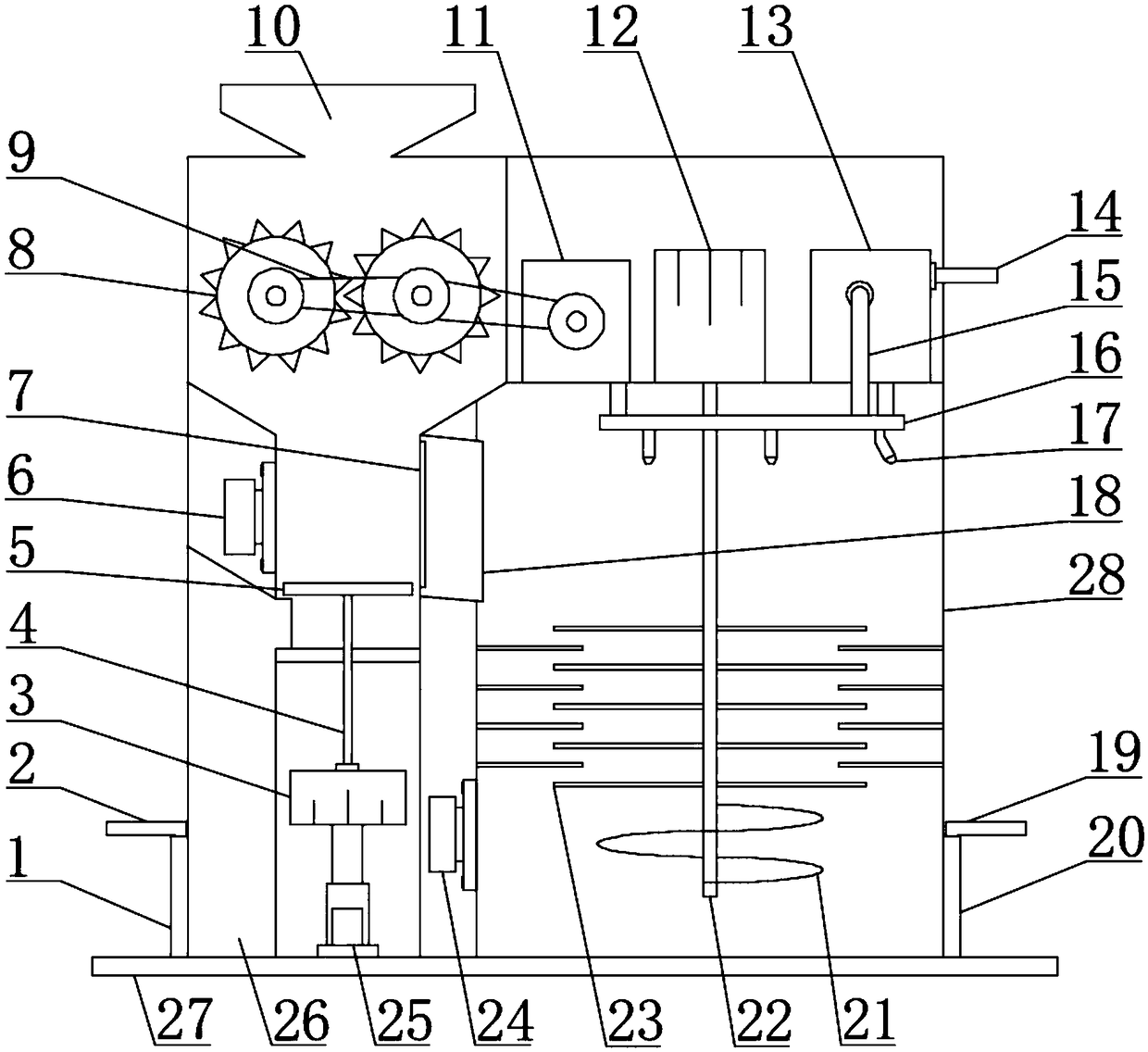

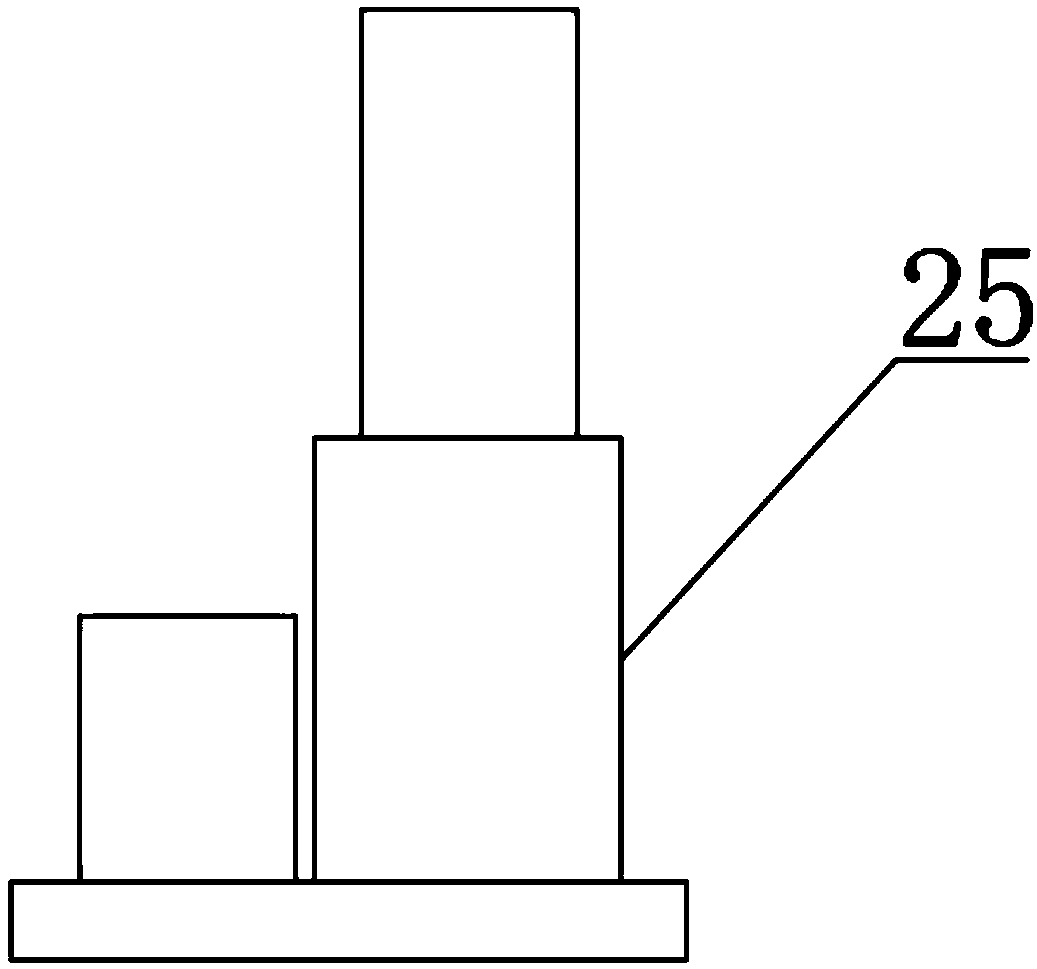

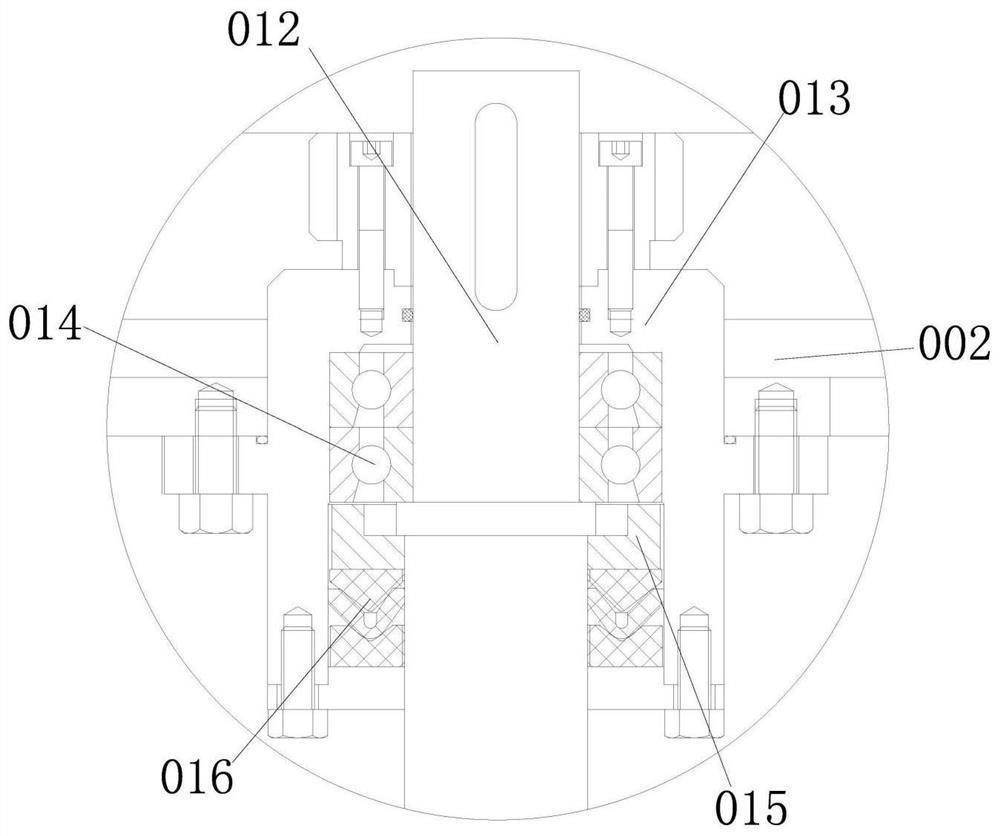

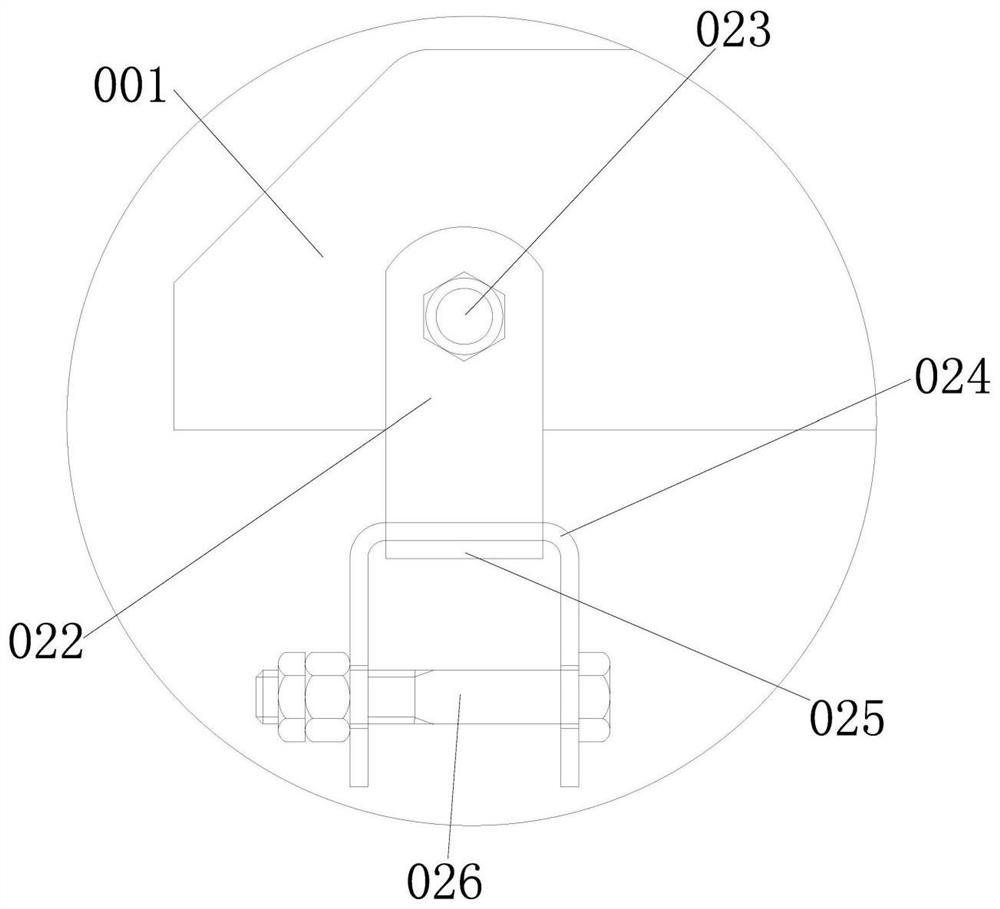

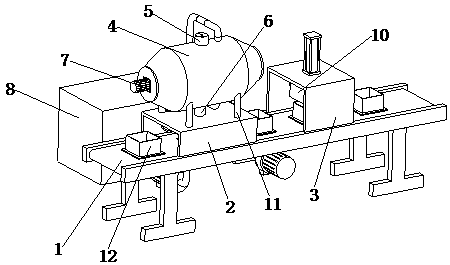

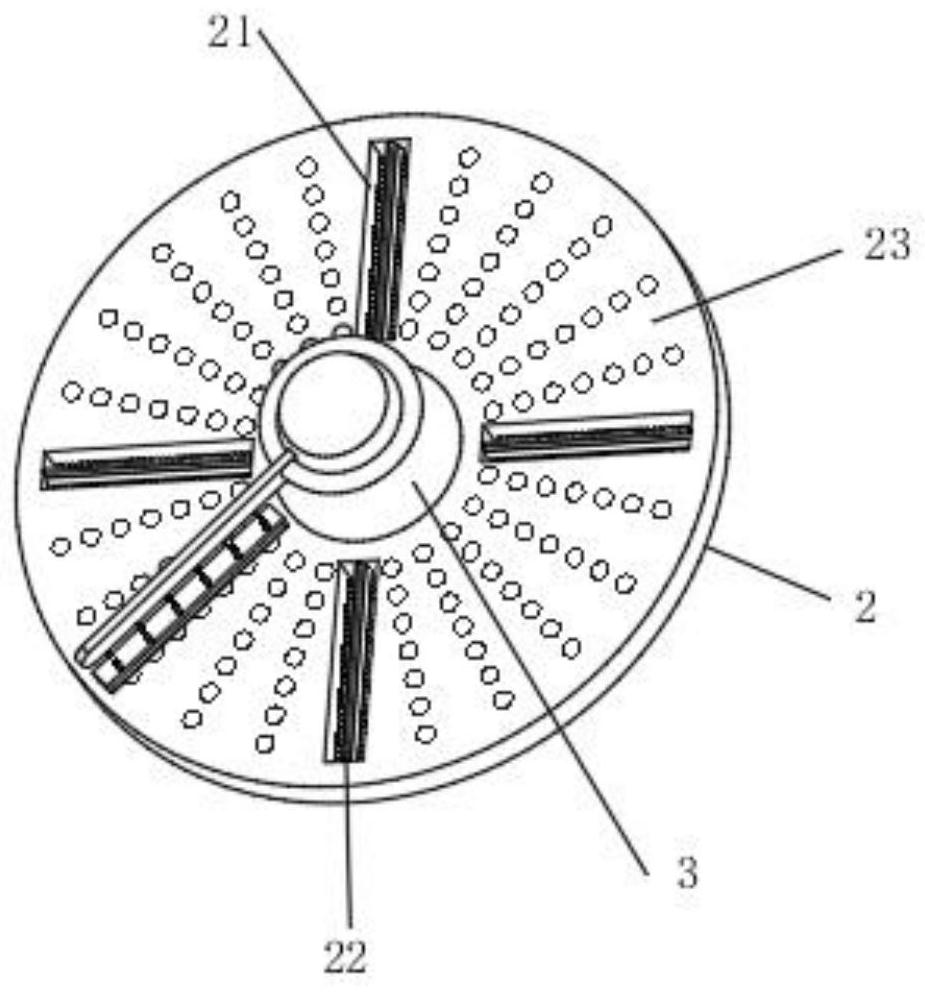

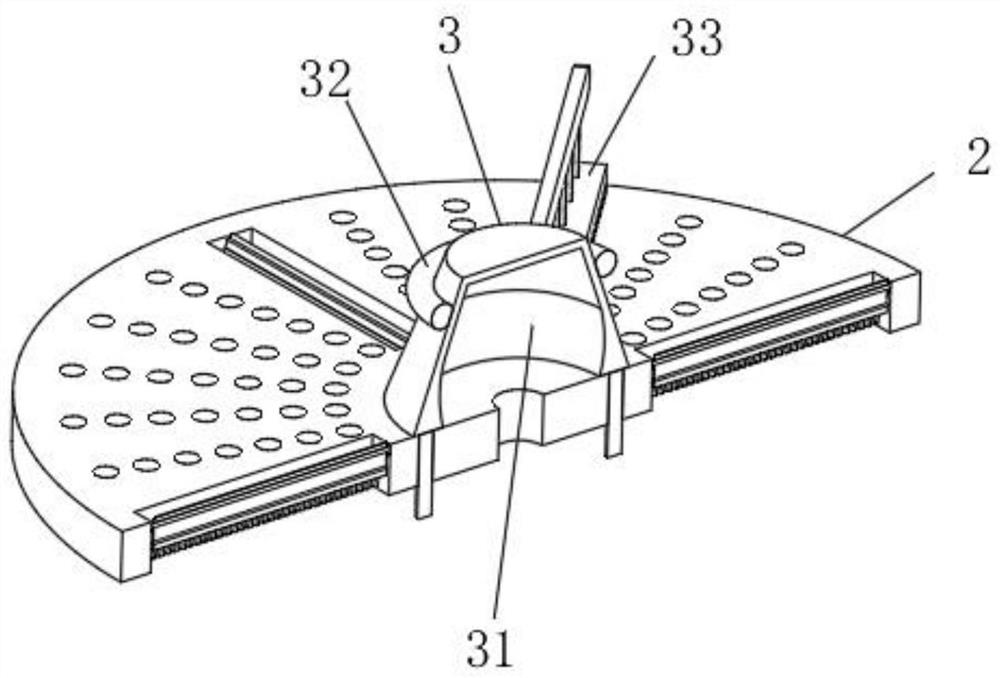

Multiple mixing device for powder coating used for plastic product

InactiveCN108993296AImprove stirring efficiencyLabor intensiveTransportation and packagingMixer accessoriesEngineeringPowder coating

The invention discloses a multiple mixing device for powder coatings used for a plastic product. The multiple-mixing device comprises a mixing box and a motor, wherein the upper surface of the mixingbox is fixedly connected with a feeding hopper; the top part of the inner wall of the mixing box is fixedly connected with two first bearings; the inner walls of two first bearings are respectively and fixedly connected with a driving shaft and a linkage shaft; and the outer walls of the driving shaft and the linkage shaft are respectively connected with a mashing rod. The multiple mixing device for the powder coatings used for the plastic product provided by the invention has the following advantages: through arrangement of the driving shaft, the linkage shaft and mashing rods, the powder coatings can be subjected to primary stirring, and the powder coatings with different volumes are subjected to crushing treatment, so the volumes of the powder coatings are consistent, and the stirring efficiency of the powder coatings is improved; through arrangement of a blanking tray, a stirring rod and stirring blades, secondary mixing of the powder coatings can be realized; and the blanking traycontrols the blanking amount of the powder coatings, so excessive blanking amount of the powder coatings to affect the mixing effect of the mixing box is avoided.

Owner:蒙城县虹升塑粉有限公司

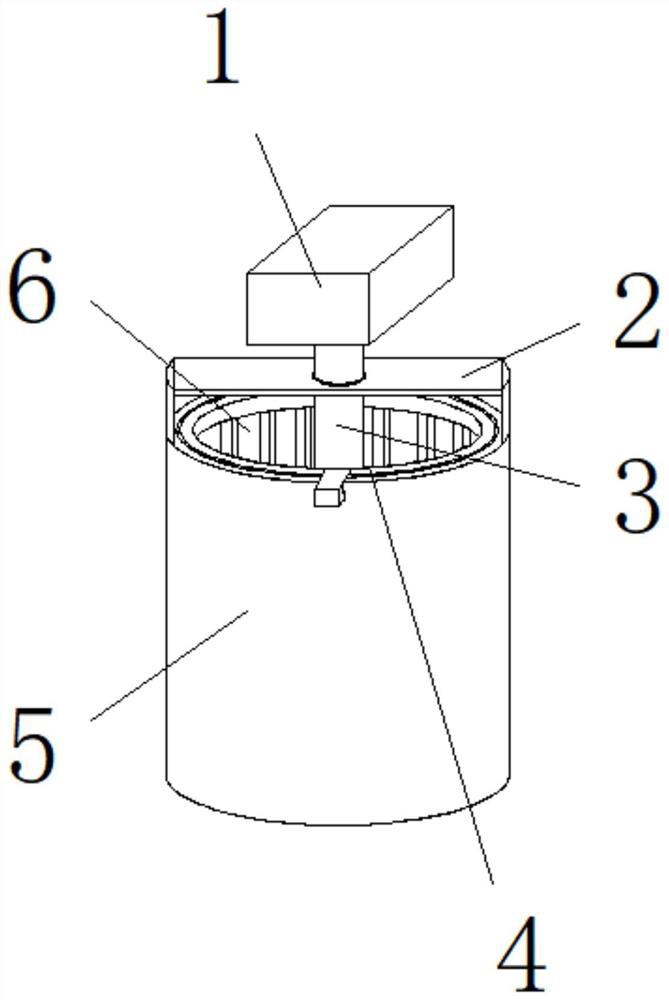

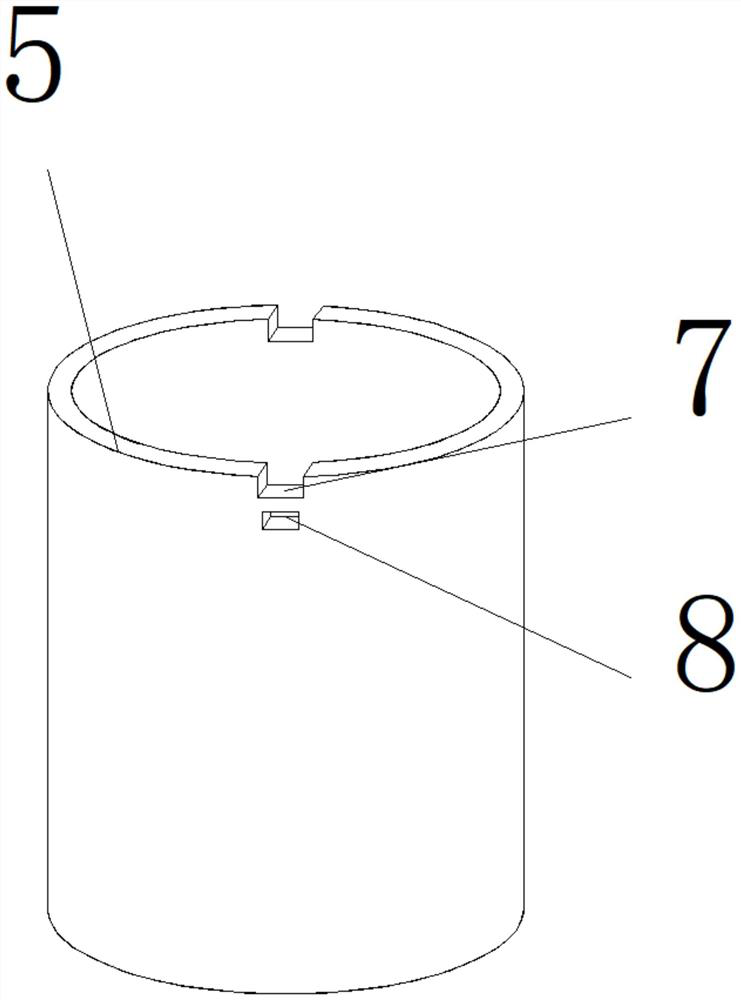

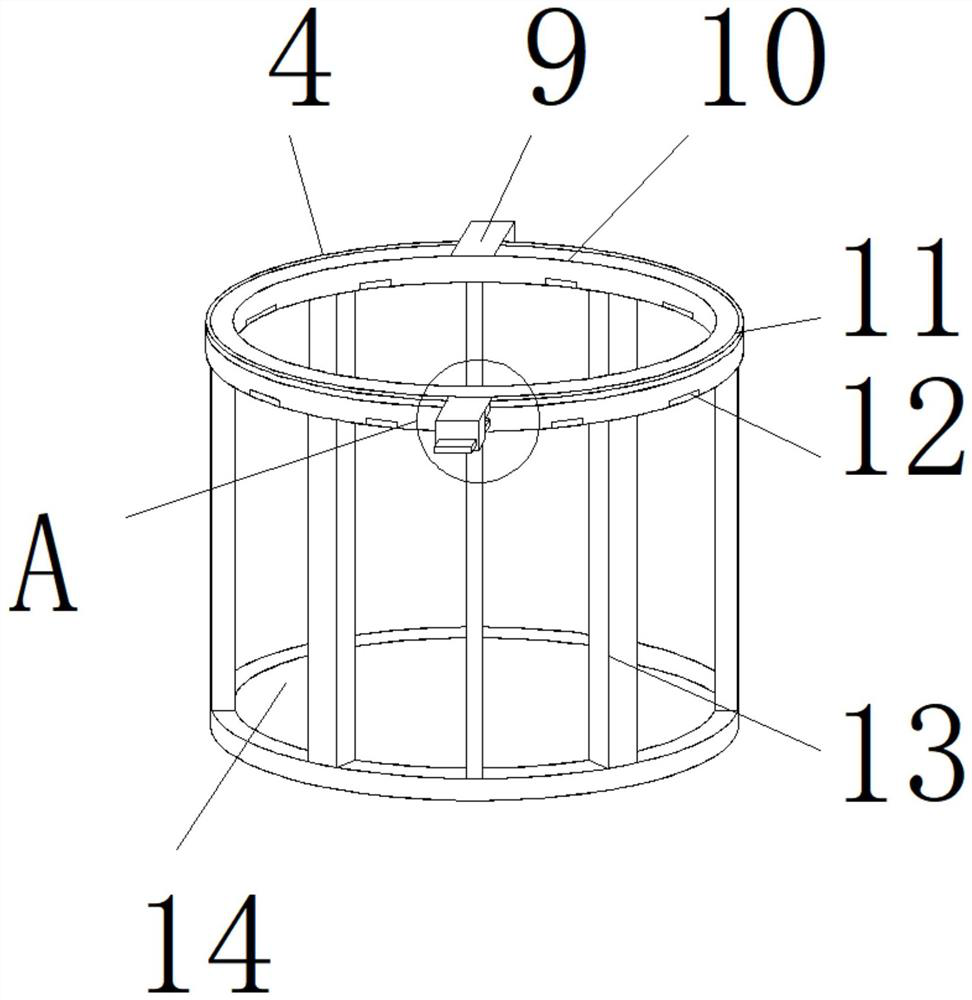

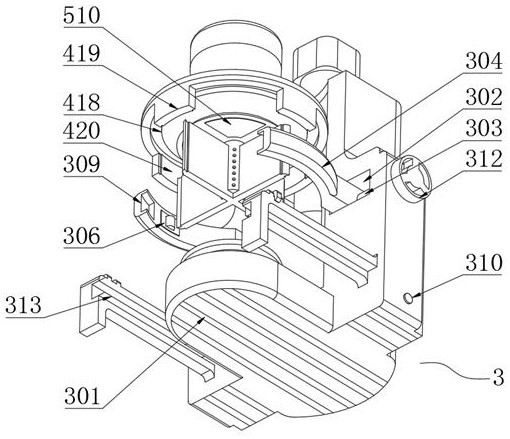

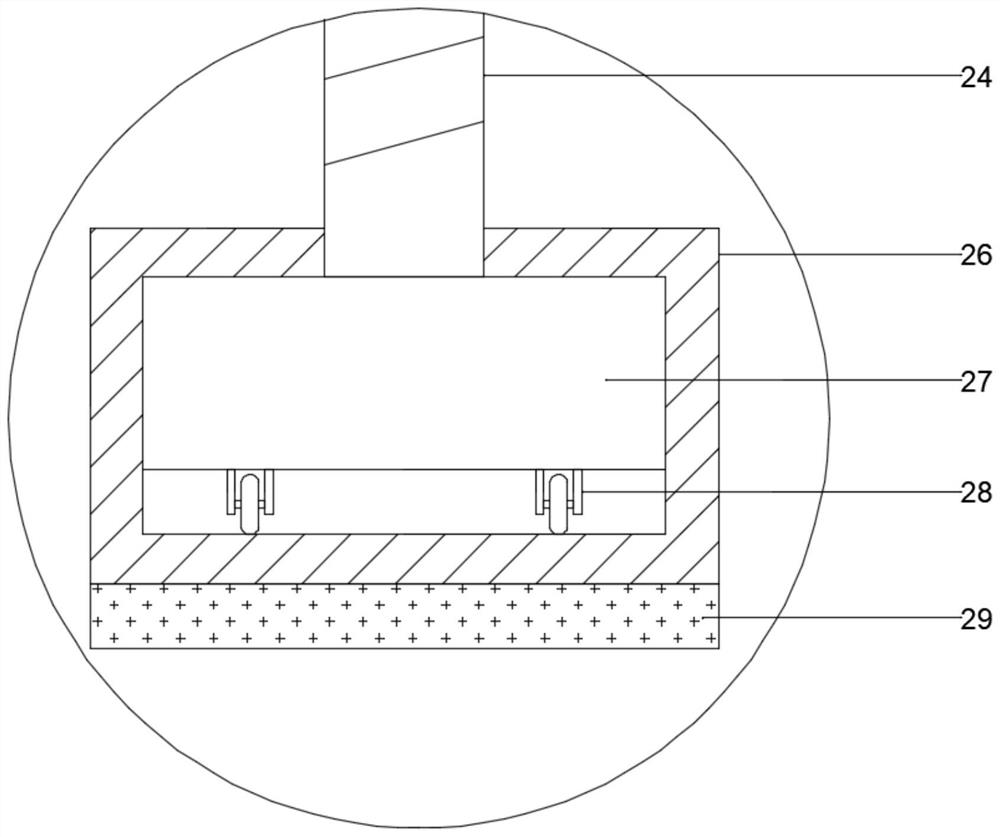

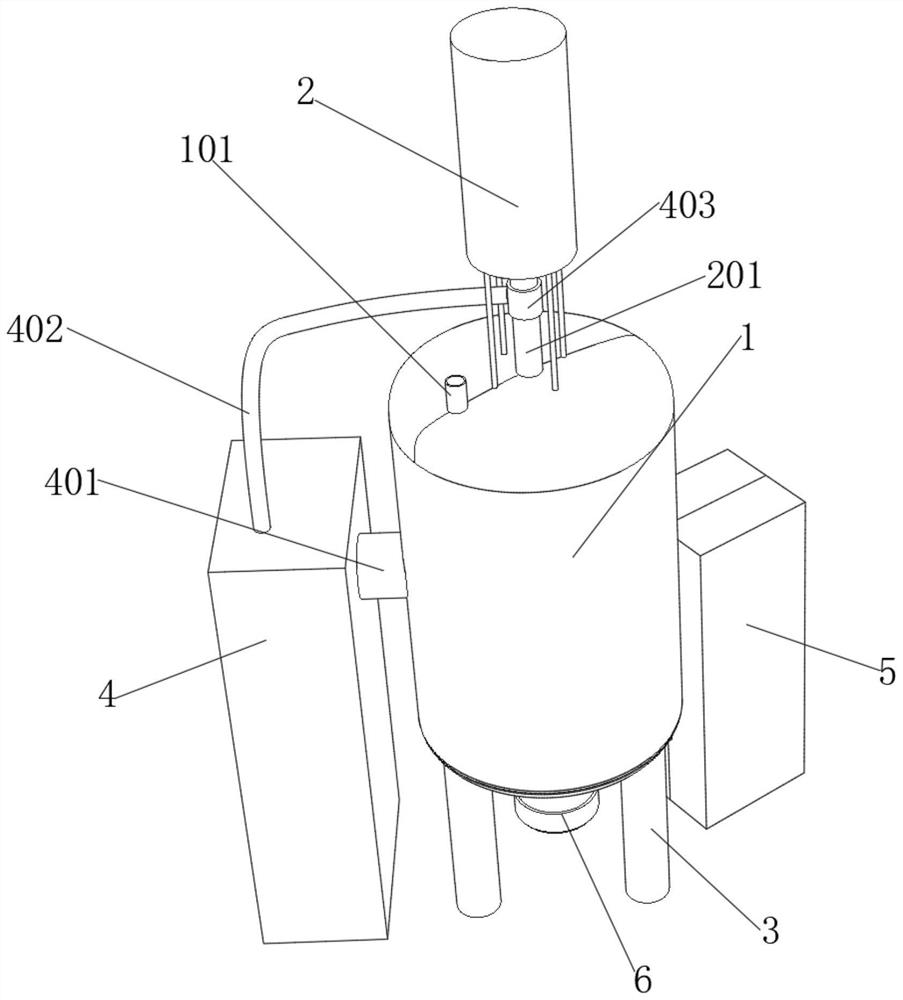

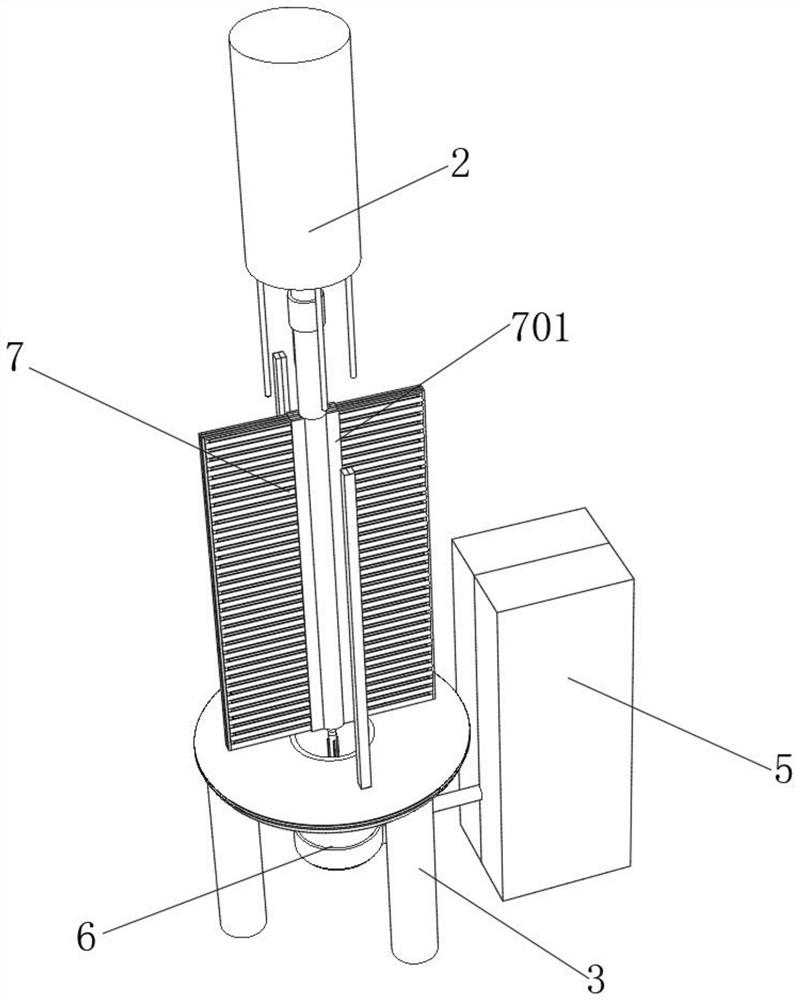

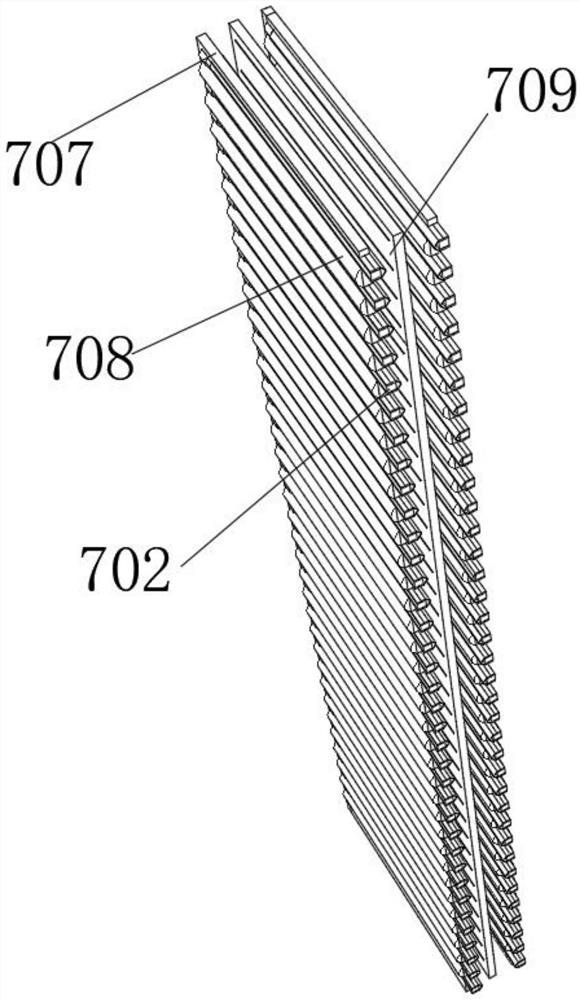

Crushing and mixing equipment for cosmetic production

InactiveCN108854626AAffect the mixing effectAvoid uneven mixingRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

Owner:HEFEI FENGJIE BIOLOGICAL TECH CO LTD

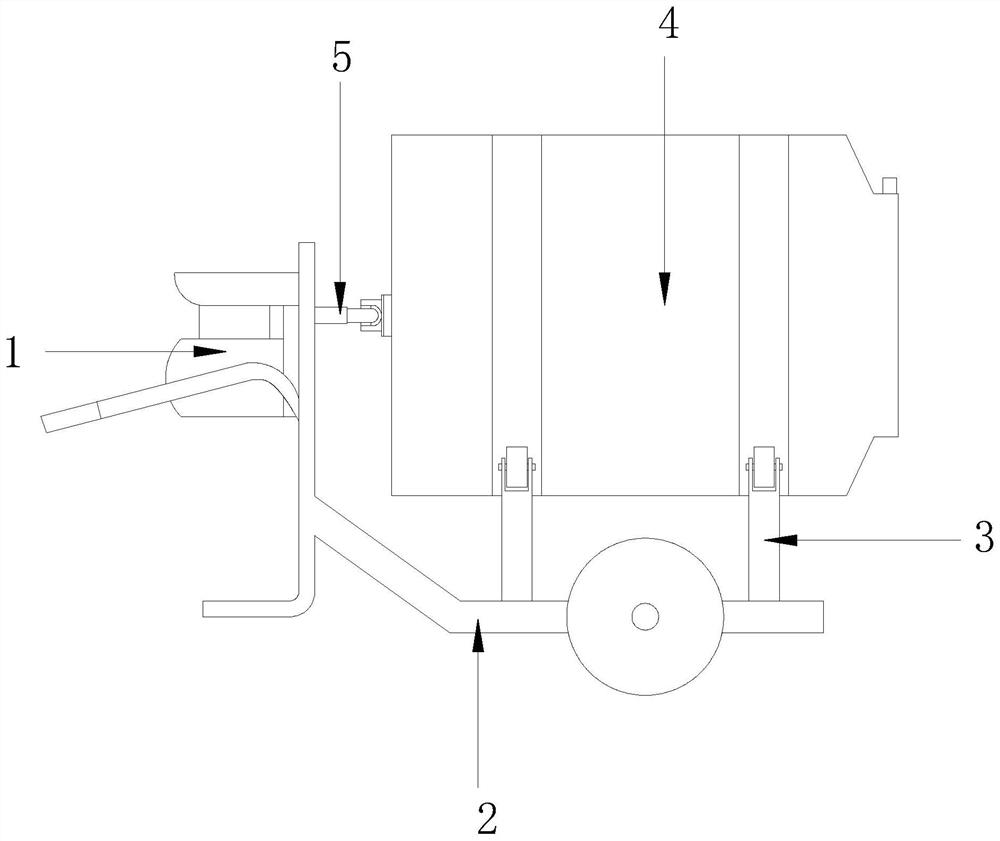

Feed stirring device for animal husbandry

InactiveCN108654500AAvoid savingAffect the mixing effectFeeding-stuffTransportation and packagingSpiral bladeEngineering

The invention discloses a feed stirring device for animal husbandry. The feed stirring device comprises a material discharge hopper and a stirring tank, wherein a third motor is welded with the middleposition of the upper surface of the stirring tank; a second drive rod is welded with the lower part of the third motor; a stirring rod is welded with the bottom end of the second drive rod; spiral blades are welded with the lower part of the stirring rod; a second motor is welded with one end of the upper surface of the stirring tank; a water pump is welded with the other end of the upper surface of the stirring tank; a water intake pipe is arranged at one side of the water pump; a spraying pipe is arranged under the water pump; a connecting pipe is arranged at the connecting part of the water pump and the spray pipe. The feed stirring device for the animal husbandry has the advantage that by arranging a second electronic vibrator on the stirring tank, the second electronic vibrator drives the tank wall of the stirring tank to vibrate, and the residual feed at the inner wall of the stirring tank is loosened and falls down, so as to avoid the accumulation of a large amount of feed atthe inner wall of the stirring tank, and further prevent the continuous accumulation of the feed from affecting the feed stirring effect.

Owner:金寨毛竹湾农业科技有限公司

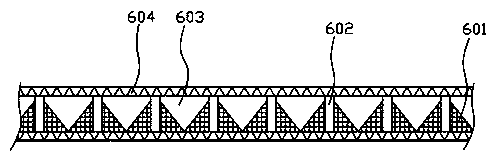

Device dedicated to soy sauce stirring

InactiveCN110172395AImprove filtering effectAvoid Soy Sauce ScatteringBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringFood flavor

The invention discloses a device dedicated to soy sauce stirring, comprising a casing, wherein the interior of the casing is provided with a spray chamber, a stirring chamber, a sterilization chamberand a cooling chamber in sequence from top to bottom, the spray chamber, the stirring chamber, the sterilization chamber and the cooling chamber are separated from one other by a filter screen, a partition plate a and a partition plate b; the filter screen comprises a filter cavity, filter mesh strips are respectively arranged on the upper and lower sides of the filter cavity, shift rods are arranged at equal intervals in the filter cavity, and right-angle-shaped filter nets are arranged on the left and right sides of the gear lever. The device can ferment soy sauce more thoroughly while stirring the soy sauce, the preservation time of the soy sauce is prolonged while the smooth progress of a next processing technology is benefited, and the flavor of the soy sauce is improved.

Owner:浦江县泰如食品科技有限公司

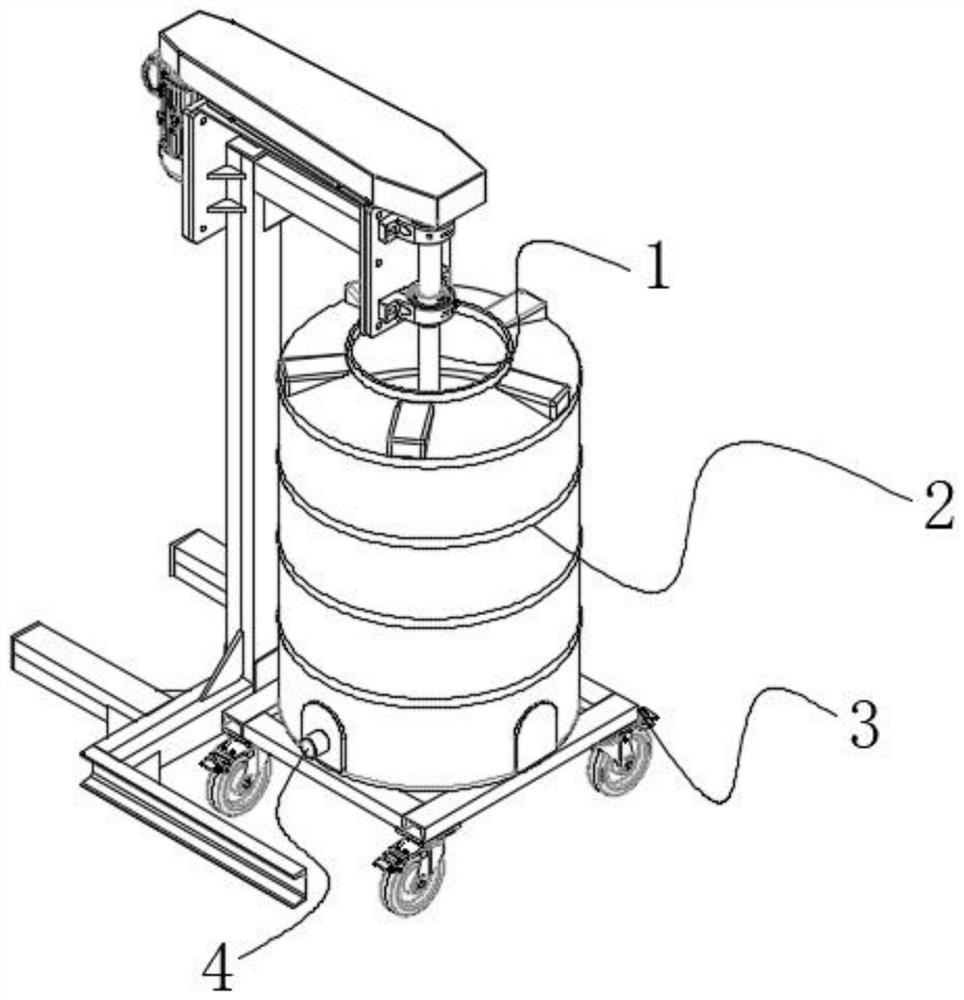

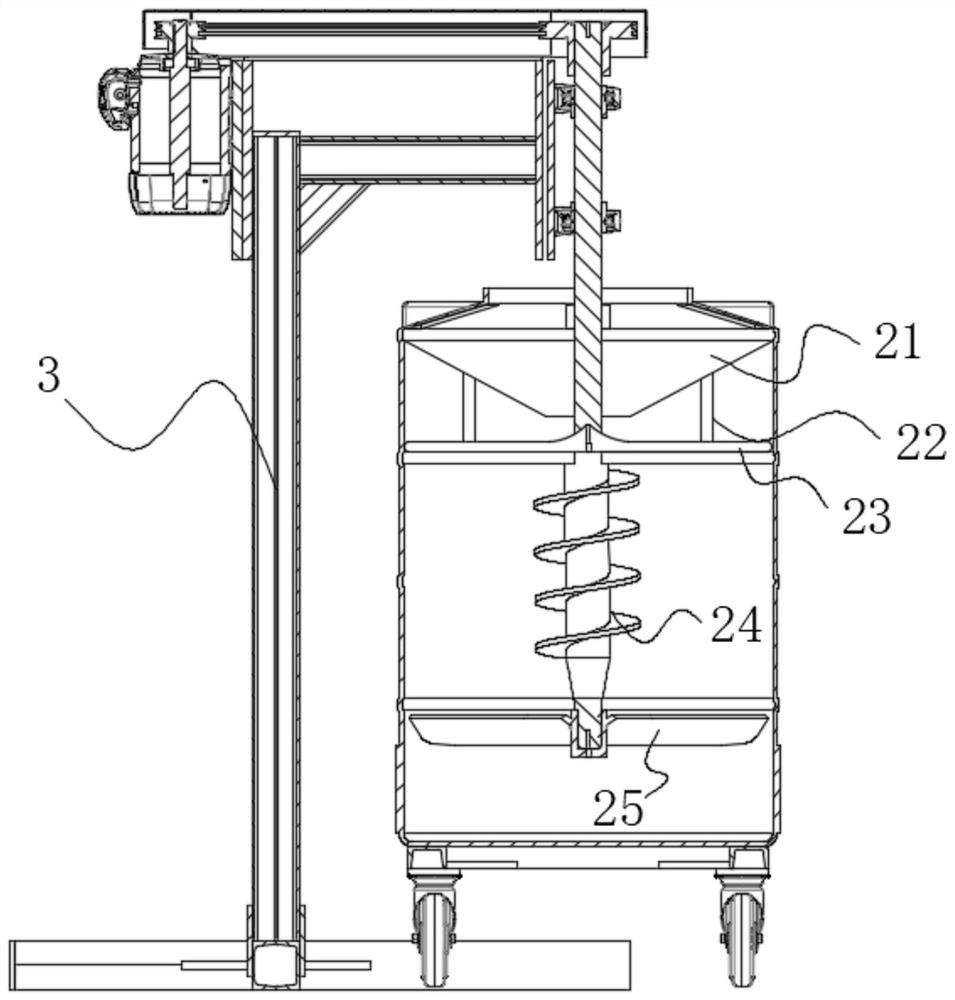

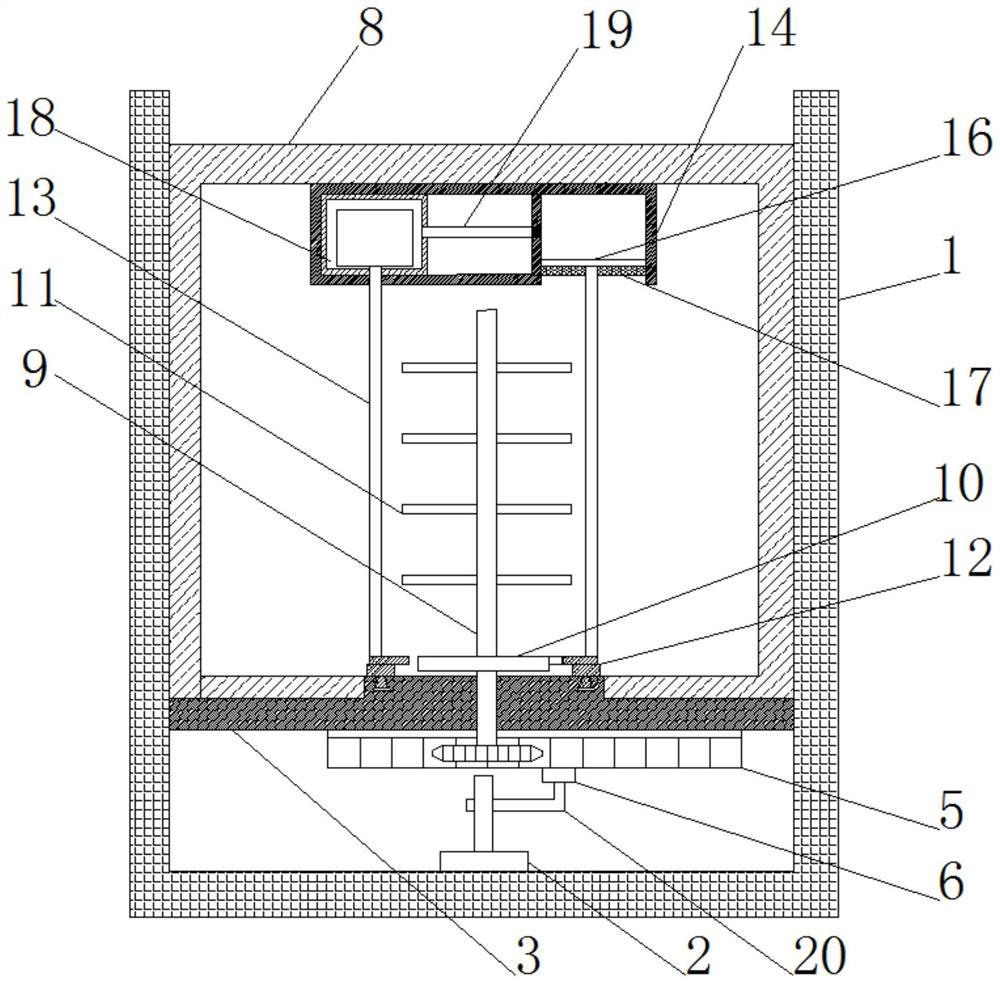

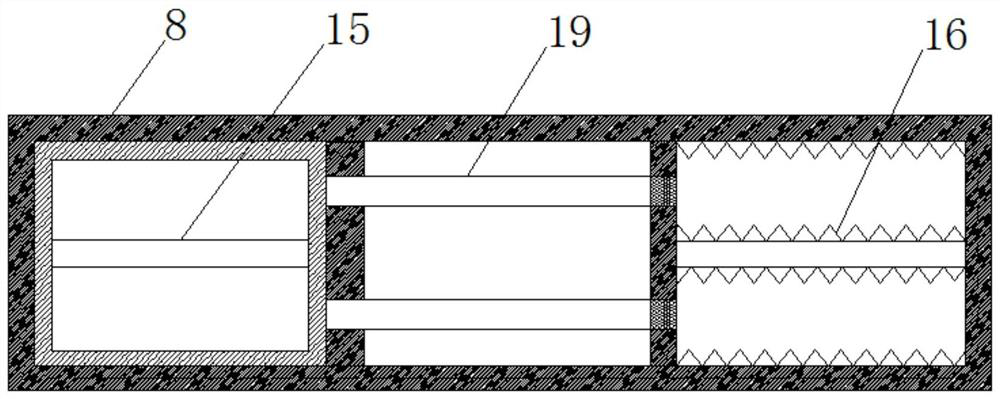

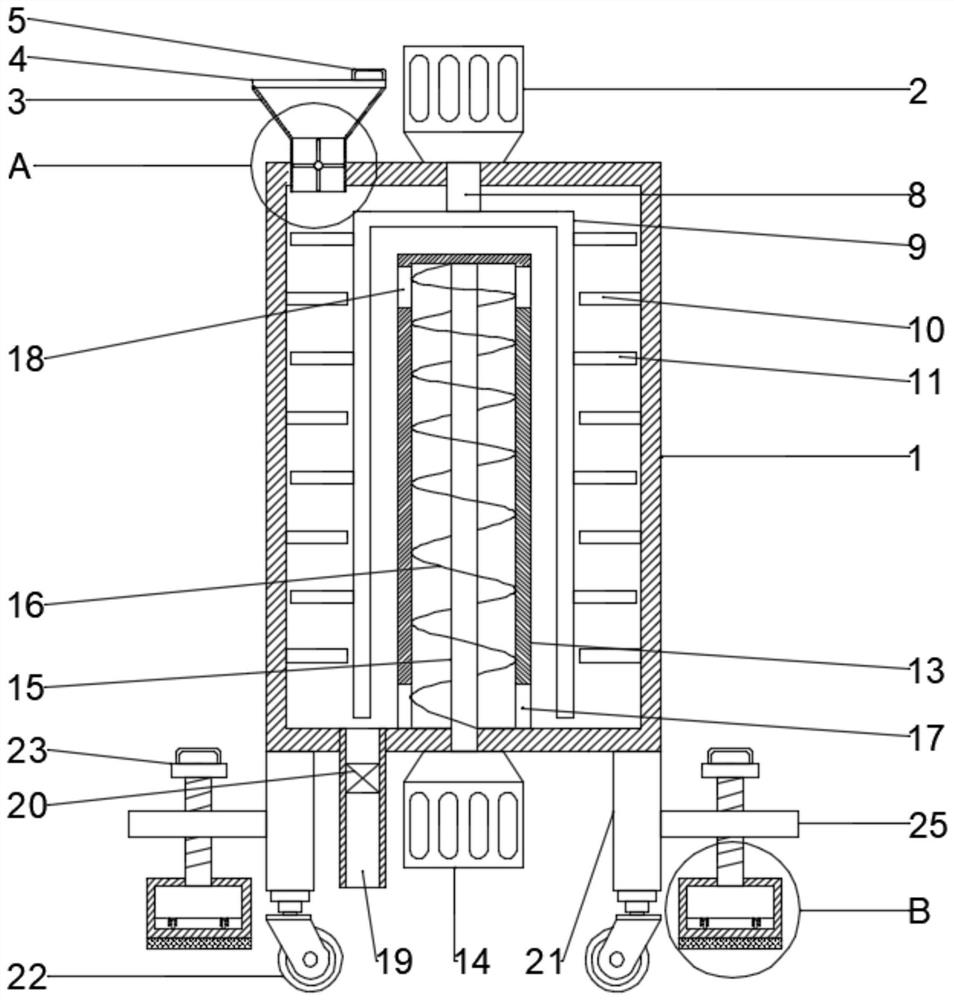

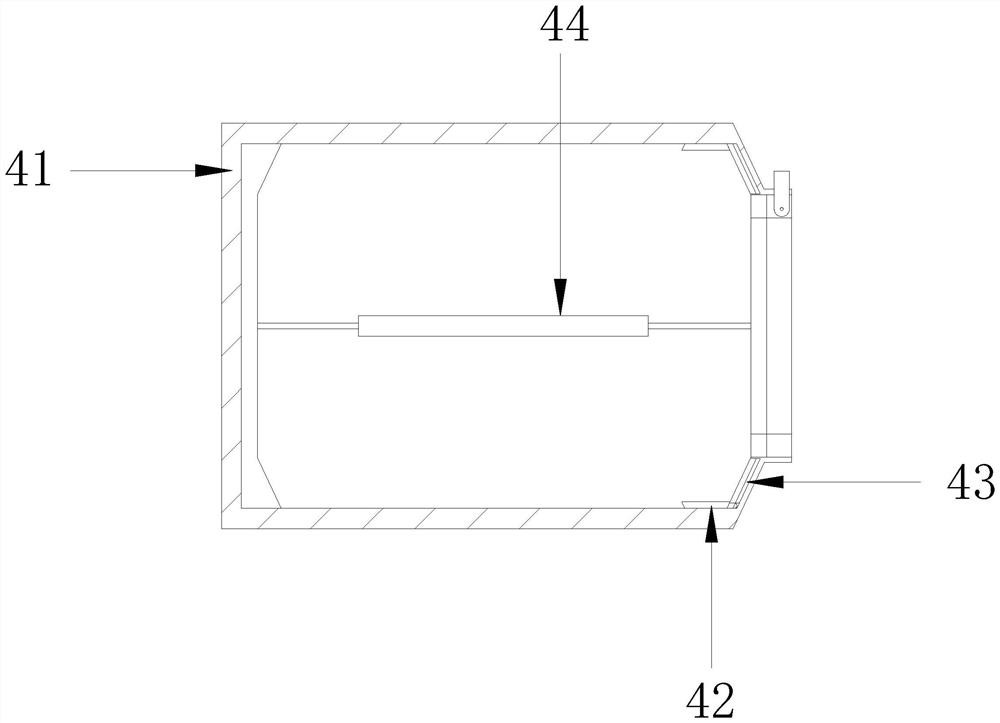

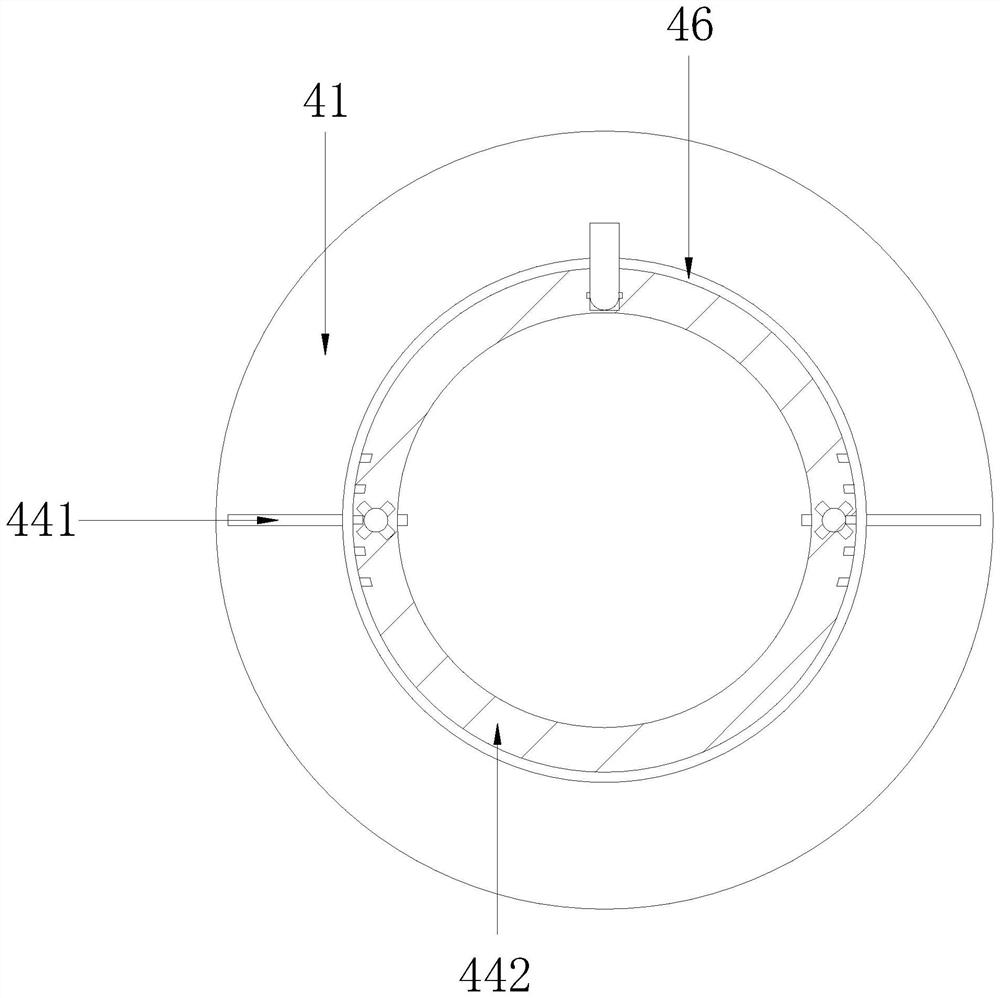

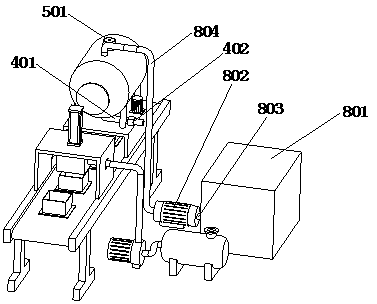

Feed stirring apparatus having drying function and used for animal husbandry

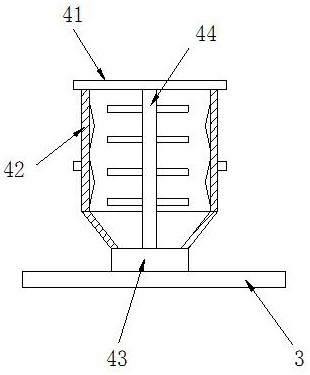

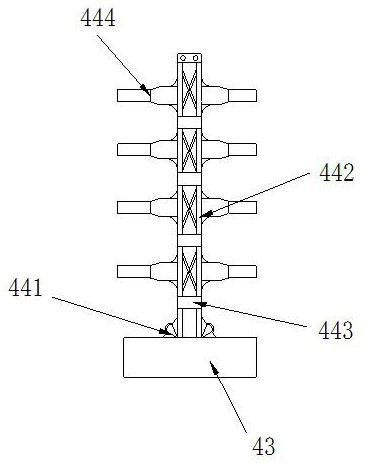

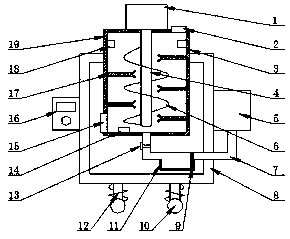

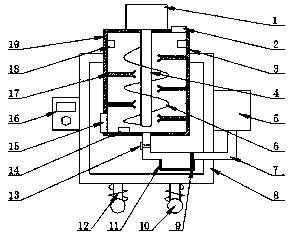

InactiveCN109550430AAffect the mixing effectImprove the mixing effectFeeding-stuffRotary stirring mixersEngineeringFodder

The invention belongs to the technical field of animal husbandry, and particularly to a feed stirring apparatus having drying function and used for animal husbandry. In the prior art, the stirring device has characteristics of simple structure and poor stirring effect, and cannot dry the feed. Based on the problems in the prior art, the technical scheme of the present invention comprises a base and a box body, wherein a material inlet is arranged at the central axis position of the top outer wall of the box body, a material feeding hopper is welded on the inner wall of the material inlet, theouter wall of one side of the material feeding hopper is connected to an adjusting valve through threads, a rotating motor is fixed on one side of the top outer wall of the box body through a bolt, both sides of the top outer wall of the box body are respectively provided with a first through hole and a first concave groove, and the inner walls of the first through hole and the first concave groove are rotatably connected to a first rotating shaft and a second rotating shaft respectively through a bearing. According to the present invention, through the mutual engaging between the arranged first gear and the arranged second gear, the rotating motor is started to drive the first rotating shaft and the second rotating shaft to rotate in opposite directions so as to effectively improve the stirring effect of the apparatus.

Owner:六安科创教育信息咨询有限公司

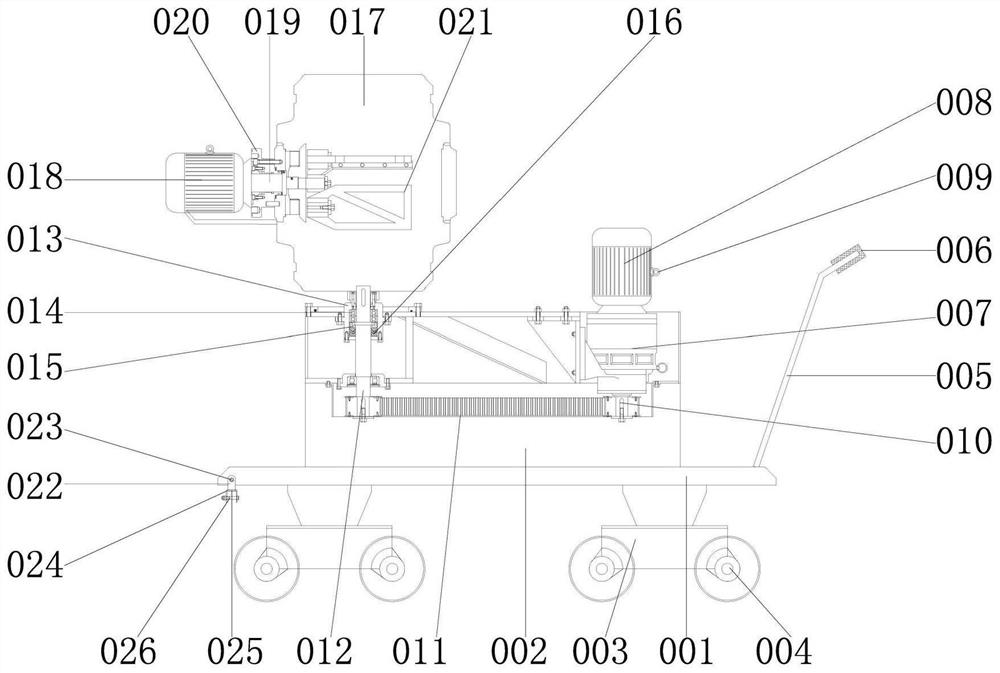

Energy-saving and environment-friendly mixing device of environment-friendly water-based paint

PendingCN108355537ATimely collectionAvoid wastingTransportation and packagingRotary stirring mixersWater basedEngineering

The invention discloses an energy-saving and environment-friendly mixing device of environment-friendly water-based paint. The device comprises universal wheels with brake pads, a movement base, a mixing case, a discharge pipe, a mechanical valve, a case cover, collecting covers, collecting pipes, collecting tanks, a stirring shaft, a coupler, a stirring motor, a reinforcement plate, a dismountable and replaceable stirring rod structure, water-based paint blending and purification hopper structures and water-based paint odor removal machine structures, wherein the universal wheels with the brake pads are mounted at four corners of the bottom of the movement base via bolts respectively. With the adoption of the case cover, the collecting covers, the collecting pipes and the collecting tanks, paint falling on the case cover or at a splashing part is timely collected; the waste is avoided; resources are saved; with the adoption of odor collecting bags, give-off prevention bags, odor suction pipes, fixing sheets, and bolt-nuts, an odor given off during paint mixing is timely collected; and the environment pollution can be avoided.

Owner:ZHANGJIAGANG TIANYUAN PAINTING & COATING APPL

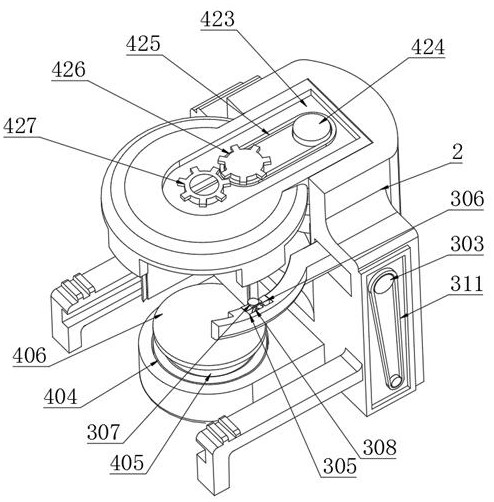

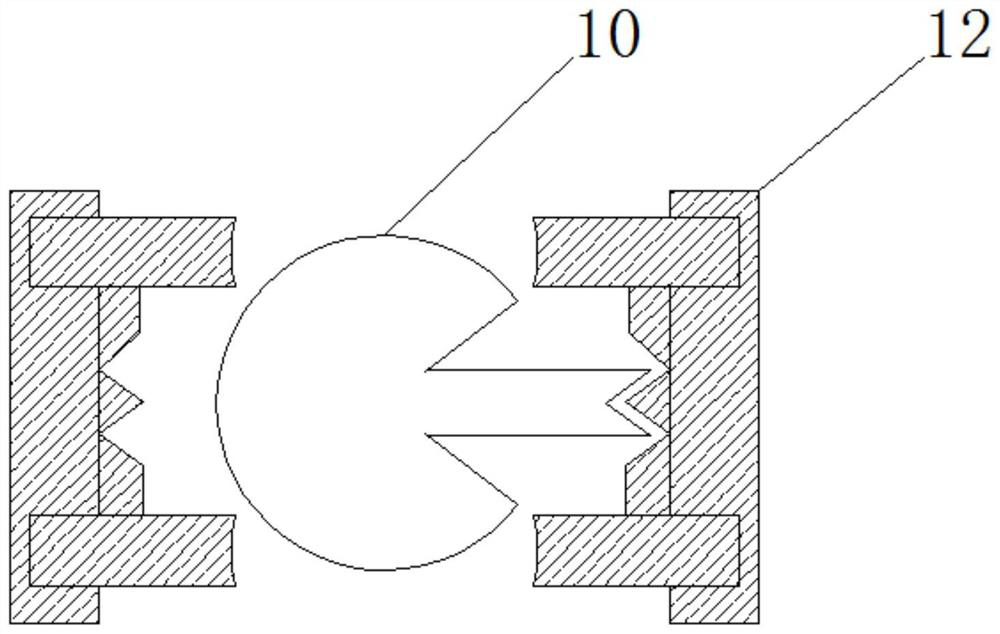

Stirring device for premixed mortar

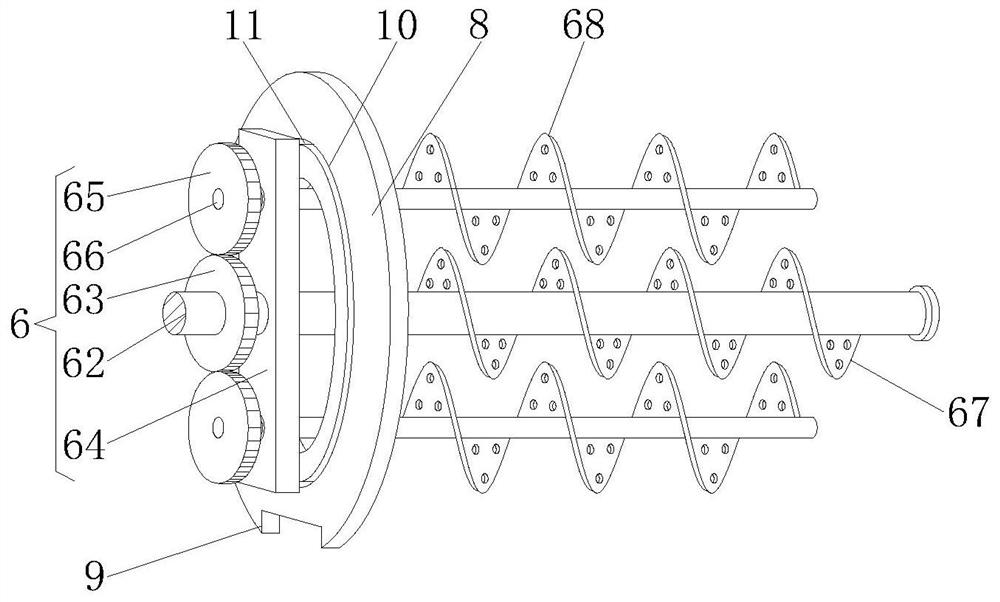

InactiveCN112936584AStir wellImprove work efficiencyDischarging apparatusCement mixing apparatusElectric machineGear wheel

The invention discloses a stirring device for premixed mortar. The technical solution of the stirring device is characterized by comprising a stirring bin and fixing frames located on the two sides of the stirring bin, wherein a controller and a rotating motor are arranged on the fixing frames, fixing shafts fixedly connected to the stirring bin in a bolt mode are arranged at the two ends of the stirring bin, the fixing shaft and the rotating motor are movably connected to each other through arrangement of a driven belt wheel, a driving belt and a driving belt wheel, at least three parallel stirring assemblies are arranged inside the stirring bin in a penetrating manner, fixing cover plates matching with the stirring bin are arranged on the two sides of the stirring bin, a stirring gear set and a stirring motor matching with the stirring gear set are arranged in the fixing cover plate on one side, the stirring motor drives the stirring assemblies to rotate through the stirring gear set, and the stirring bin and the stirring assemblies inside the stirring bin rotate independently and are driven by the rotating motor and the stirring motor correspondingly. The stirring device has the effects of simple structure, high working efficiency, uniform stirring and reliable mortar quality.

Owner:台州佳沃科技有限公司

Paint stirring equipment for preventing accumulation and retention

InactiveCN108144476AAffect the mixing effectIncrease contact areaTransportation and packagingRotary stirring mixersEngineering

The invention discloses paint stirring equipment for preventing accumulation and retention. The equipment comprises a tank, the top of the tank is provided with a material inlet pipe, a pipe opening of the material inlet pipe is provided with a valve, the top of the tank is provided with a motor, an output shaft of the motor is fixedly connected with a stirring shaft, the stirring shaft runs through an outer wall at the top of the tank and stretches into the tank, the outer walls of an upper side and a lower side of the stirring shaft are both fixedly connected with mounting rods, a fixed shaft is arranged between the mounting rods, two ends of the fixed shaft are fixedly connected on the mounting rod, the upper and lower outer walls of the fixed shaft are both fixedly connected with limiting blocks, a mobile pipe is arranged between the limiting blocks, the mobile pipe is sleeved on an outer wall of the fixed shaft, and an outer wall of the mobile pipe is fixedly connected with a plurality of stirring blades. The stirring blades are uniformly provided with material discharge holes, when the stirring blades are used for stirring, paint can pass in the material discharge holes and cannot retain on the stirring blades, so that the stirring effect of the stirring blades can be prevented from being influenced as residual paint adheres to the stirring blades after long-time stirring.

Owner:ANHUI MEILIN BUILDING MATERIAL

Multifunctional stirring device applied to food cooking

InactiveCN114849575AAvoid cloggingImprove cleanlinessRotary stirring mixersTransportation and packagingEngineeringCentrifugal force

The invention discloses a multifunctional stirring device applied to food cooking, the structure of the multifunctional stirring device comprises a raw material frame, a support, a stabilizing disc and a stirrer, raw materials can be classified and placed in the raw material frame, then the raw materials can be added into the stirrer to be stirred by driving a stirring shaft through a rotating machine, and in the stirring process, the raw materials can be uniformly stirred; a rotating shaft in a stirring shaft rotates and drives a stirring handle to rotate for stirring, during rotation, a cleaning ring also rotates along with the rotating shaft, centrifugal force is generated through rotation, then a centrifugal head protrudes outwards, a recycling frame is pulled, an upper ejection block is extruded, and a cleaning head opens opening pieces towards the two sides under the action of a clamping head; the rotating column is driven by the centrifugal force to rotate, shaking is generated through impact of the rolling balls in the rolling pipe, meanwhile, the centrifugal force can drive the centrifugal block to impact the fixing ring outwards, further shaking is generated, at the moment, peanut residues attached to the surface of the rotating column can be cleaned through shaking in cooperation with movement of the opening pieces, and the rotating column is prevented from being blocked.

Owner:青岛酒店管理职业技术学院

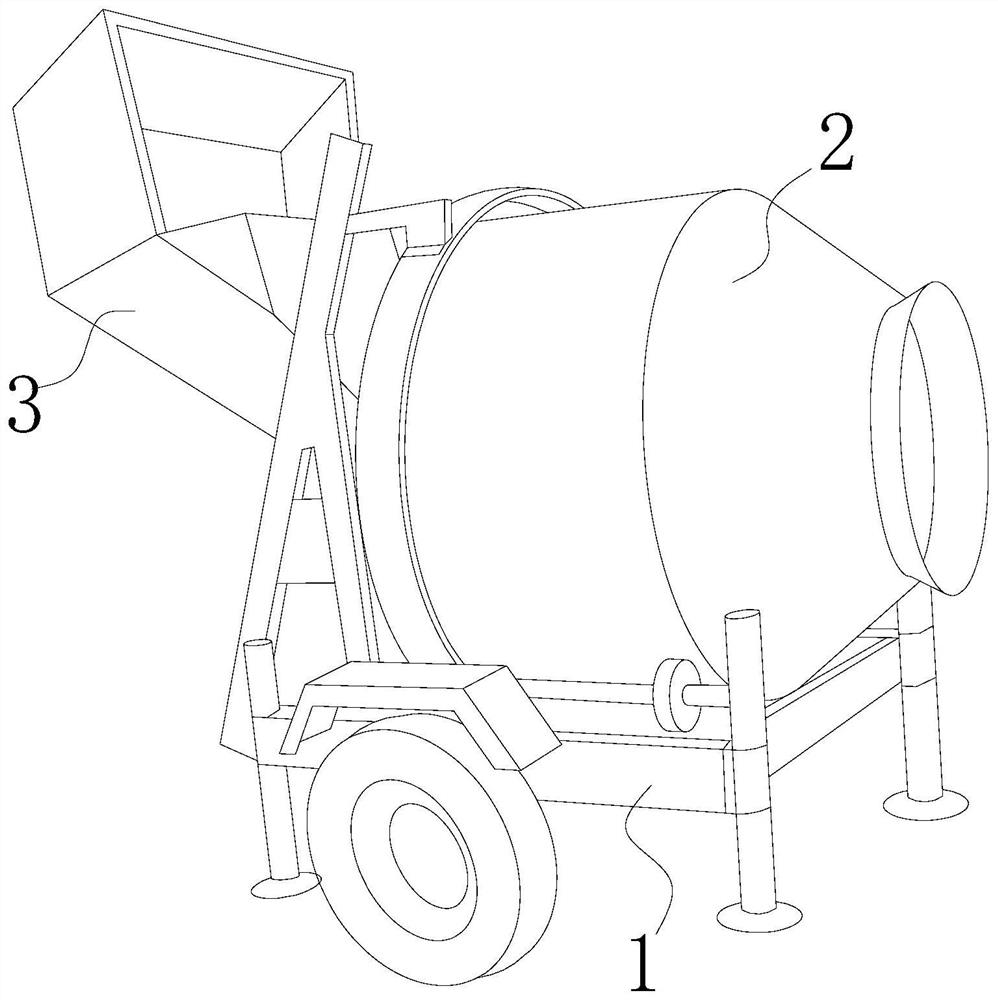

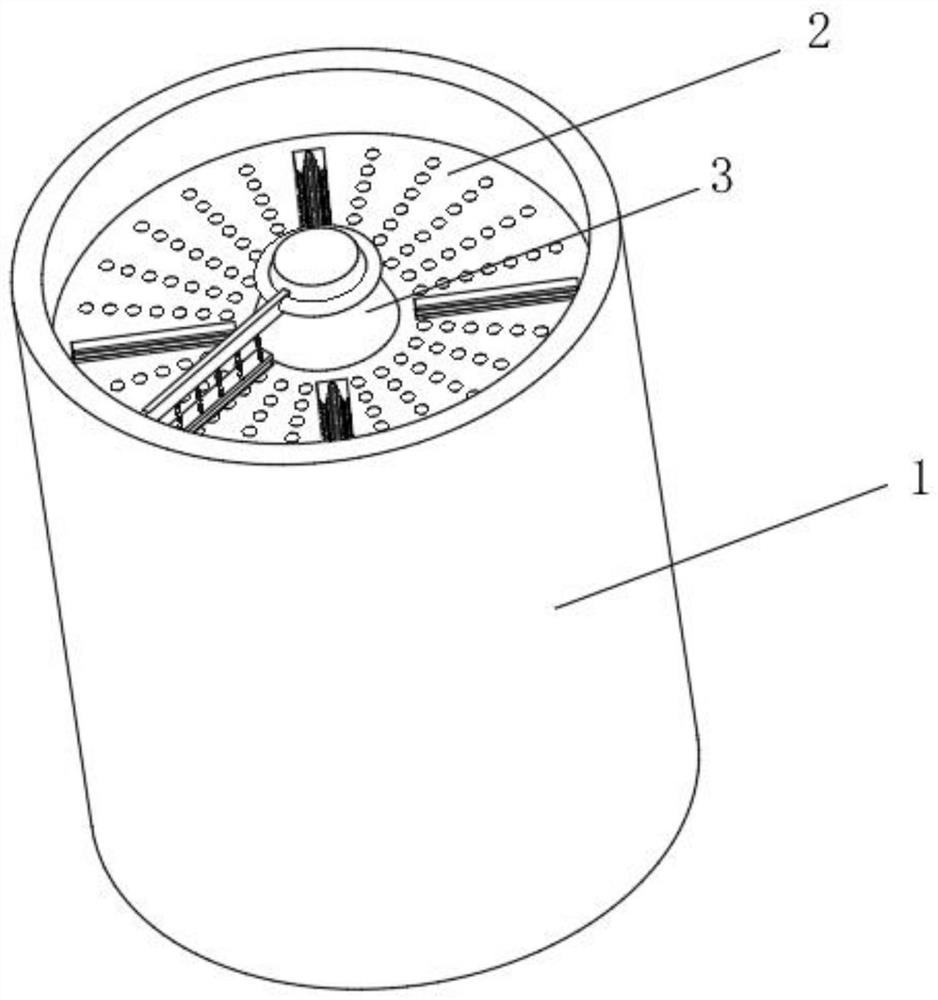

Convenient-to-discharge concrete mixer

InactiveCN113829507AStirring speed is fastImprove the mixing effectMixing operation control apparatusPretreatment controlStructural engineeringMechanical engineering

The invention belongs to the field of processing, and particularly relates to a convenient-to-discharge concrete mixer which comprises a support frame, wherein a stirring rod is arranged at the top of the support frame; the top of the support frame is movably connected with the top of the stirring rod; a stirring barrel is arranged at the bottom of the support frame; the bottom of the support frame is fixedly connected with the bottom of a stirring barrel; a water injection opening is formed in the bottom of the stirring barrel; a feeding barrel is arranged in the stirring barrel; the inner wall of the stirring barrel is fixedly connected with the outer surface of the feeding barrel; supporting columns are symmetrically arranged at the bottom of the feeding barrel; the bottom of the feeding barrel is fixedly connected with the tops of supporting columns; rotating mechanisms are arranged at the bottoms of the supporting columns; the axes of the supporting columns are fixedly connected with the outer surface of a stirring rod; a screw rod is arranged at the bottom of the stirring rod; the bottom of the stirring rod is fixedly connected with the top of the screw rod; a rotating paddle is arranged at the bottom of the screw rod; and the bottom of the screw rod is fixedly connected with the axis of the rotating paddle.

Owner:吴铮

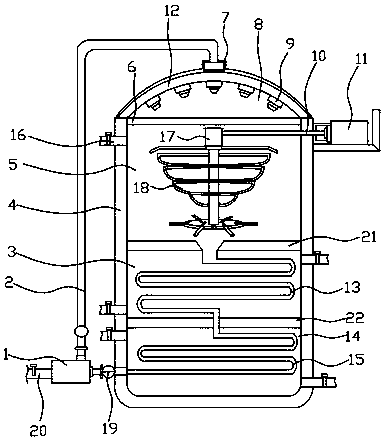

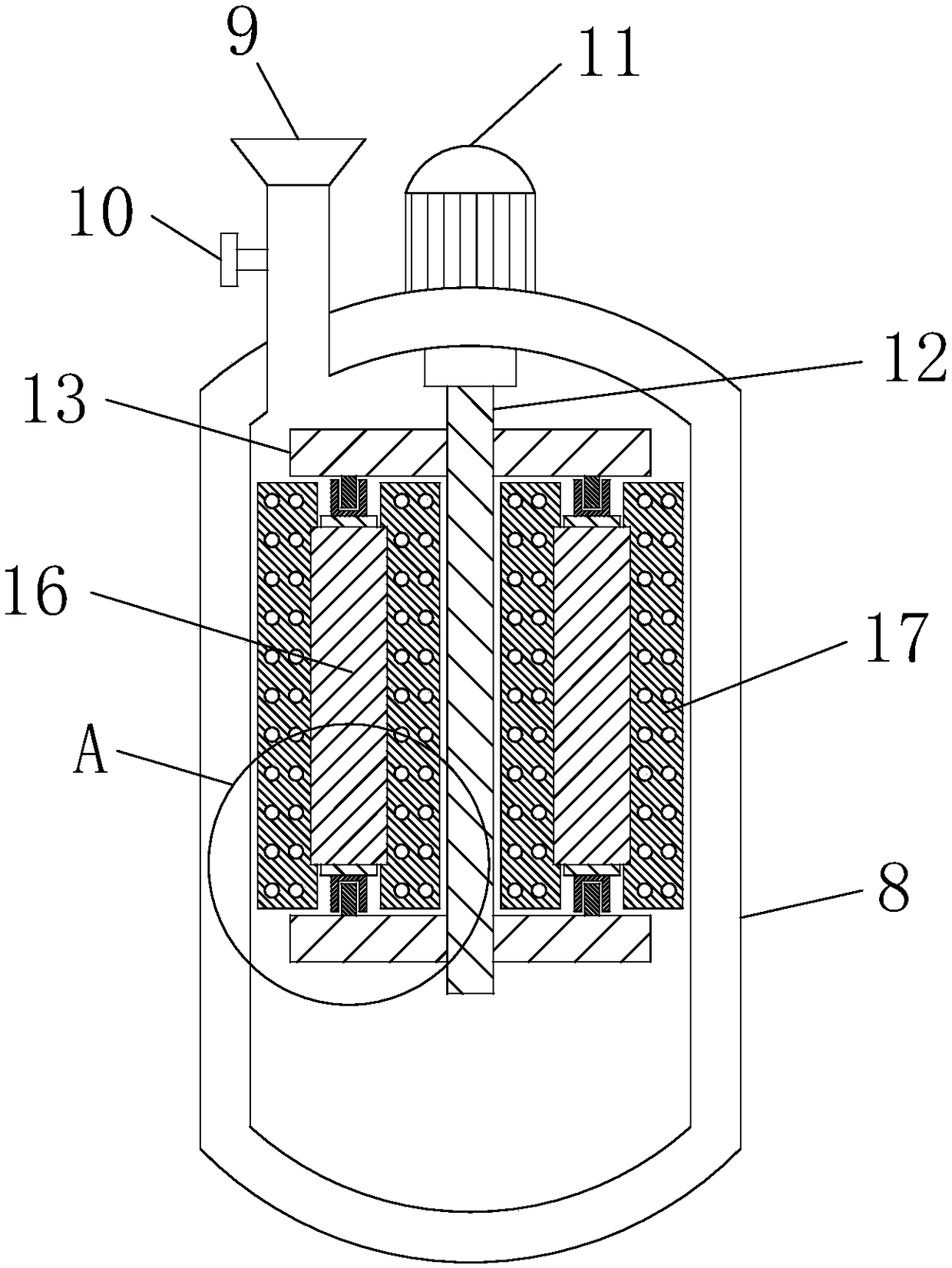

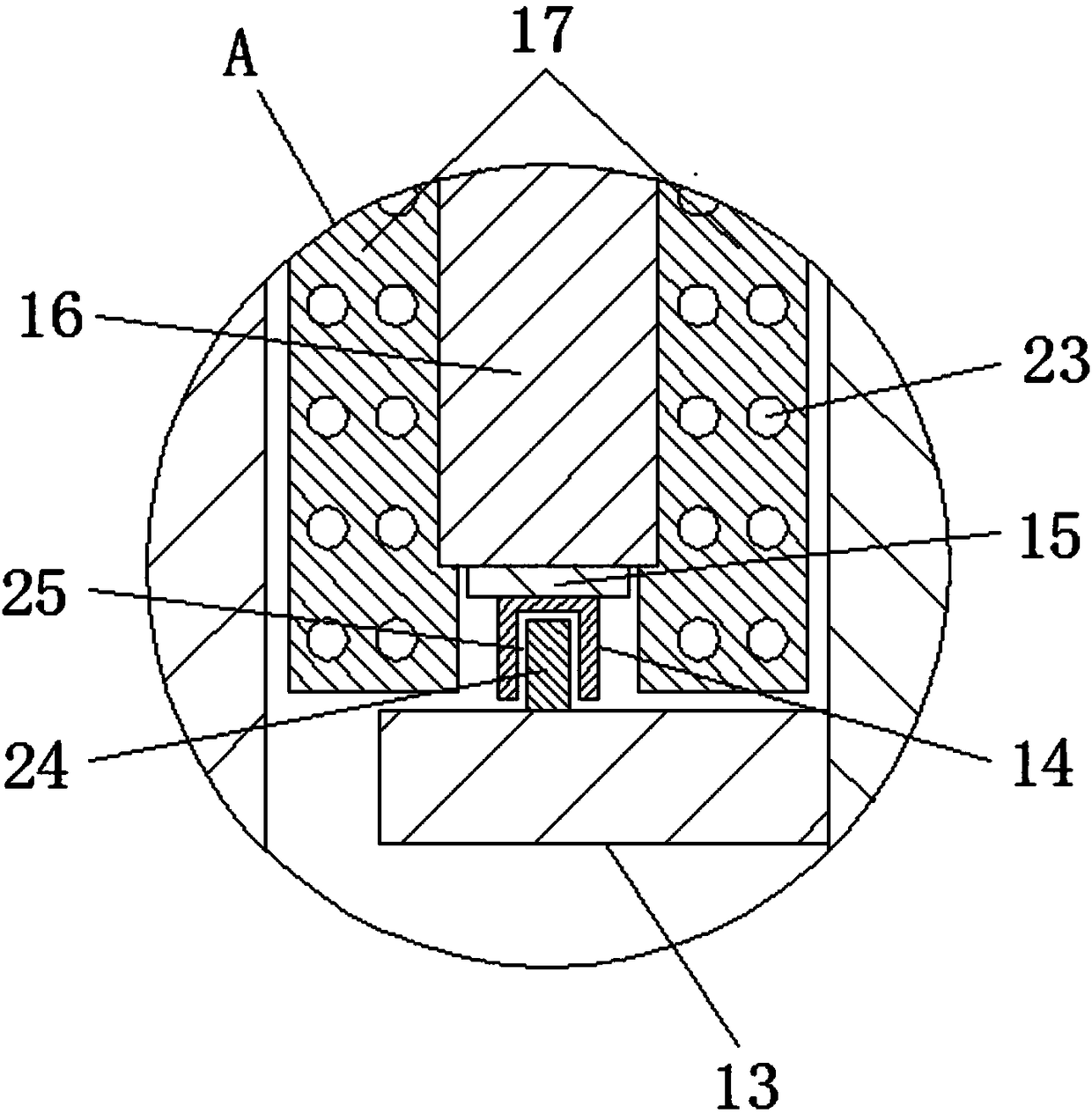

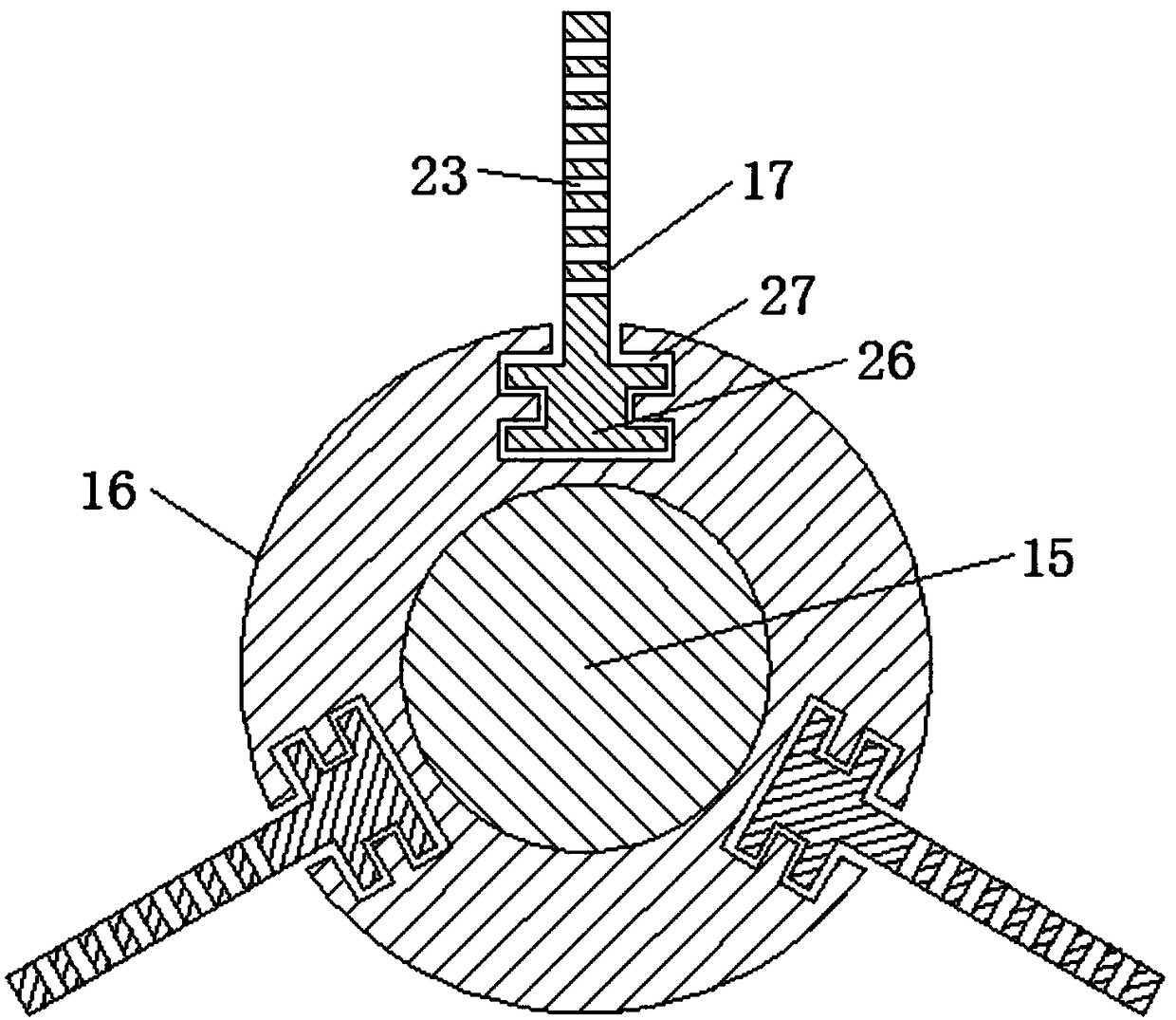

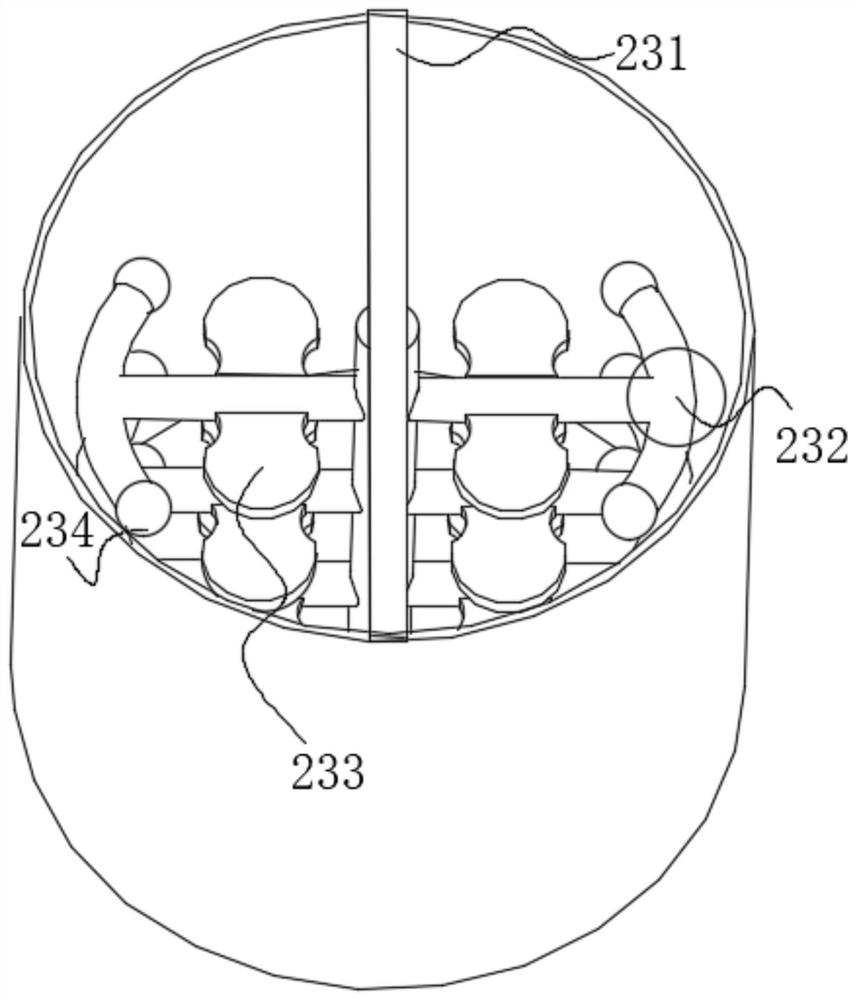

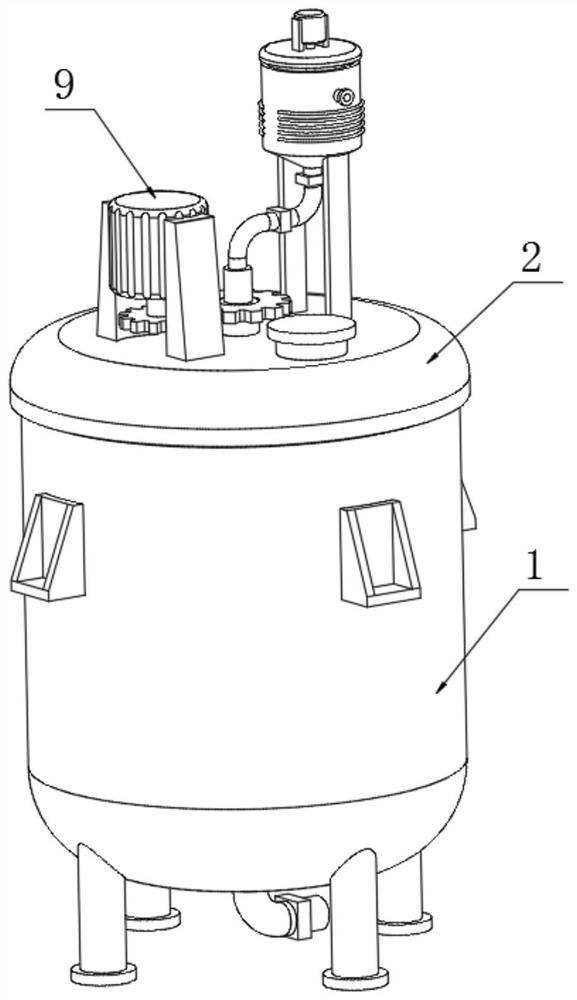

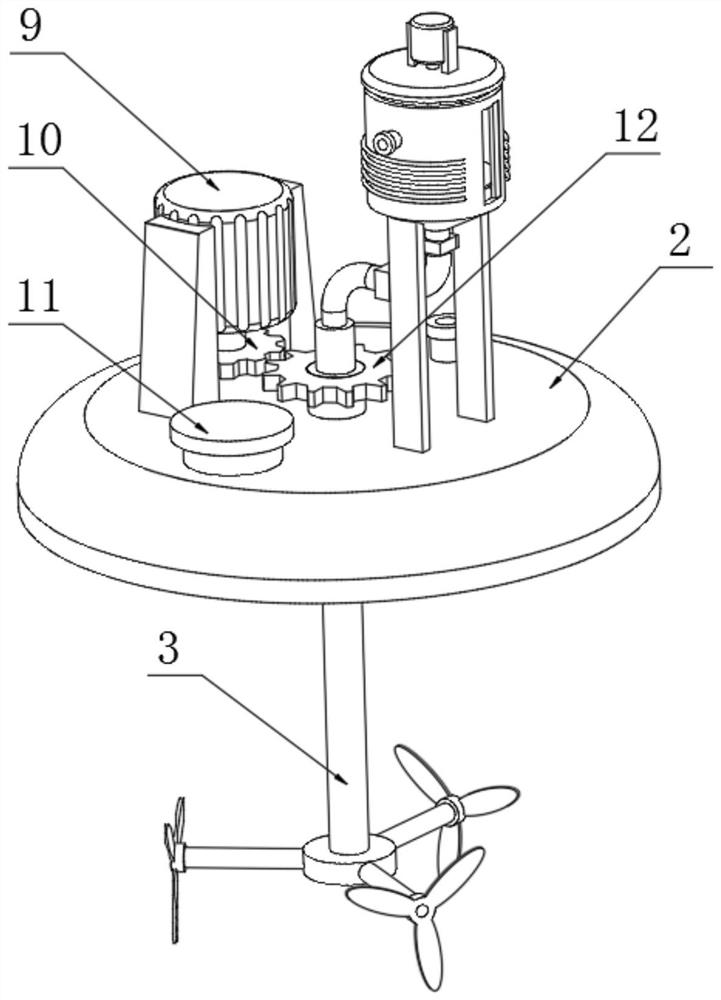

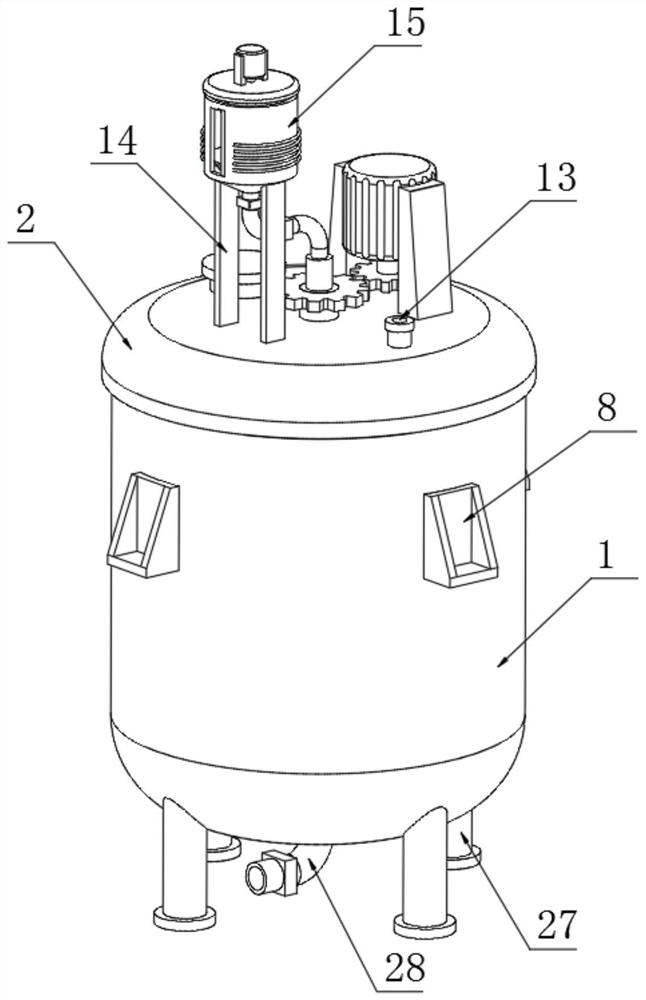

Dropwise adding reaction kettle for shoe glue

PendingCN113941292AStir wellLow costChemical/physical/physico-chemical stationary reactorsFeed devicesElectric machineryEngineering

Owner:佛山市尚峰高分子科技有限公司

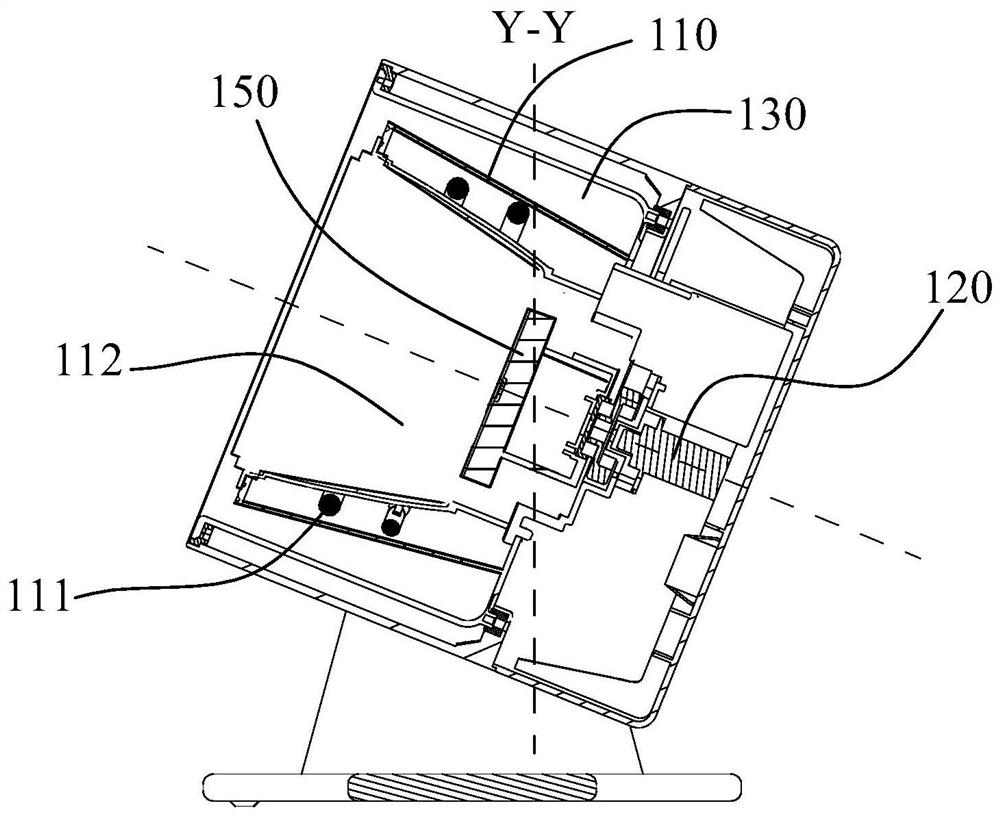

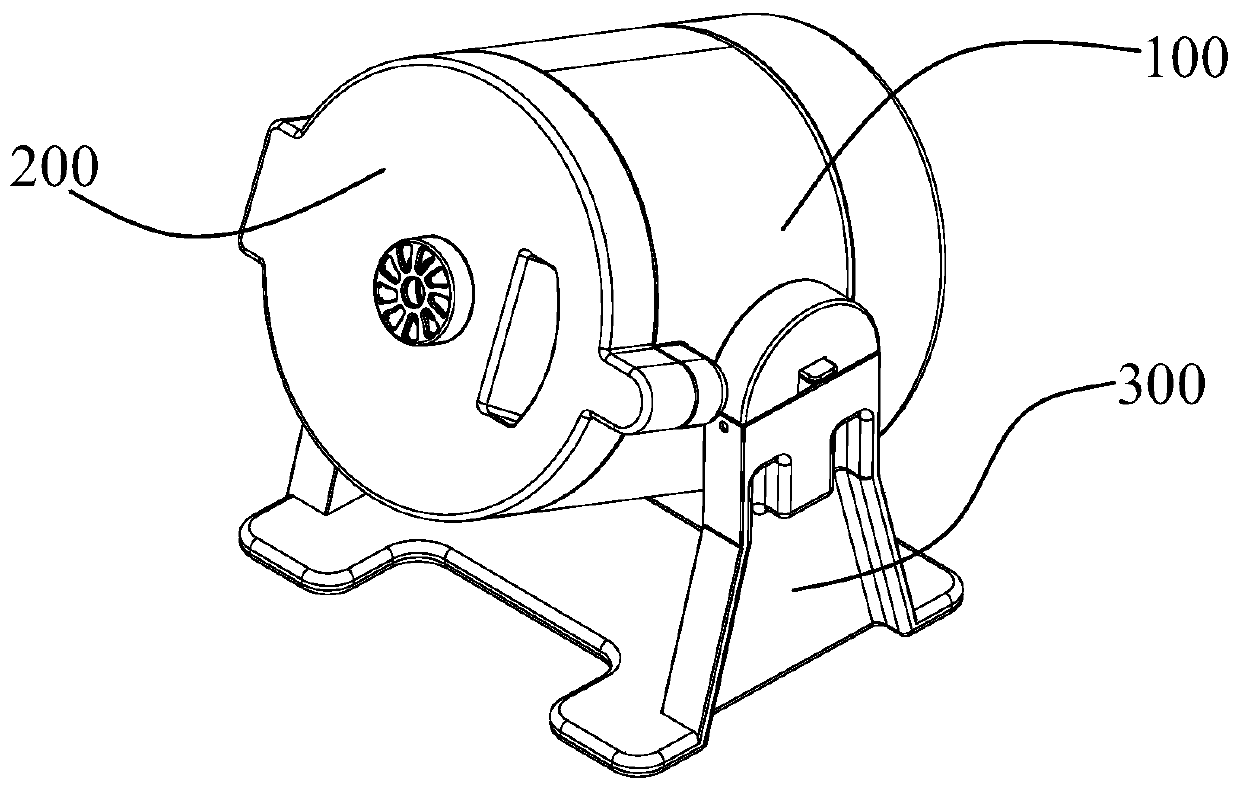

Aluminum foil box used for dish frying machine

ActiveCN111361860AIncrease surface areaAvoid burnsCooking vesselsContainers for heating foodEngineeringAluminum foil

The invention provides an aluminum foil box used for a dish frying machine. The aluminum foil box comprises a box body with an opening and a cover body for sealing the opening, wherein the aluminum foil box can be rotatably mounted in a heating cavity of the dish frying machine; the box body comprises a bottom wall and side walls; heat-absorbing rough surfaces formed by folds are arranged on the outer surfaces of the side walls; and the heat-absorbing rough surfaces absorb heat to heat food. According to the aluminum foil box adopting the technical scheme provided by the invention, the surfacearea of the aluminum foil box body is increased, so that more heat can be absorbed / stored in a cooking process, and therefore, cooking speed is increased, and cooking efficiency is improved.

Owner:JOYOUNG CO LTD

Concrete precast block production device

ActiveCN112873541AAffect the mixing effectPrevent solidificationCement mixing apparatusArchitectural engineeringStructural engineering

The invention discloses a concrete precast block production device. The concrete precast block production device structurally comprises a rack, a stirring barrel, a hopper and a swinging-off device; a stirring shaft, stirring blades and a magnet strip are arranged in the stirring barrel; the swinging-off device is arranged on the top faces of the stirring blades and composed of a pressed plate, an upper elastic column, a lower biting clamp, a pushing frame and a shock mechanism; the upper elastic column and the lower biting clamp abut against the bottom end of the pressed plate and the interiors of the stirring blades together; the pushing frame is fixedly connected to the arching end of the lower biting clamp; and the shock mechanism is arranged at the tail ends of the outer sides of the stirring blades. According to the concrete precast block production device, the swinging-off device is arranged on the upper end faces of the stirring blades, so that concrete stirred to the high position collides with the pressed plate in advance when falling onto the stirring blades, the pressed plate is driven by the lower biting clamp to be further pressed downwards, the pressed plate is driven by the lower biting clamp and the upper elastic column to bounce upwards, the pressed plate can shake up and down when being collided by the concrete, the concrete is shaken off as soon as possible, and the situation that the concrete is solidified on the stirring blades, and consequently the concrete stirring effect is affected is avoided.

Owner:四川开全新型材料科技有限公司

An aluminum foil box for cooking machine

ActiveCN111361860BIncrease surface areaAvoid burnsCooking vesselsContainers for heating foodEngineeringAluminum foil

Owner:JOYOUNG CO LTD

A concrete prefabricated block production equipment

ActiveCN112873541BAffect the mixing effectPrevent solidificationCement mixing apparatusClassical mechanicsStructural engineering

The invention discloses a concrete prefabricated block production equipment. Its structure comprises: a frame, a mixing bucket, a hopper, and a swinging device. The mixing bucket is provided with a mixing shaft, a mixing blade and a magnet strip, and the swinging device is arranged on the side of the mixing blade. On the top surface, the swinging device is composed of a pressure plate, an upper spring column, a lower clip, a push frame, and a shock mechanism. The upper spring column and the lower clip together abut against the bottom end of the pressure plate and the inside of the stirring blade. , the push frame is fixedly connected to the arched end of the lower bite clip, and the shock mechanism is arranged at the outer end of the mixing blade. In the present invention, a swinging device is provided on the upper end surface of the mixing blade, so that the concrete stirred to the high place is smashed to the ground. When the mixing blade goes up, it hits the pressure plate in advance, and the lower clip drives the pressure plate to further press down, and together with the upper spring column drives the pressure plate to bounce, so that the pressure plate will shake up and down when it is hit by concrete. Shake off the concrete as soon as possible to prevent the concrete from solidifying on the mixing blade and affect the concrete mixing effect.

Owner:四川开全新型材料科技有限公司

Powder coating dispersion machine

InactiveCN113648919APrevent powder accumulationEasy to installRotary stirring mixersMixer accessoriesEngineeringMechanical engineering

The invention discloses a powder coating dispersion machine which is characterized in that a stirring cavity is formed in a dispersing device main body, a sleeving inner frame is sleeved with the stirring cavity, a supporting frame is fixedly connected to the upper end face of the dispersing device main body, and a rotary stirring rod is rotatably connected to the middle of the supporting frame; the lower end face of the rotating stirring rod extends to the middle of the stirring cavity, a driving device is arranged on the upper end face of the rotating stirring rod, the sleeving inner frame comprises a sleeving inner frame body, the sleeving inner frame body is rotationally connected to the interior of the stirring cavity, and a rotating ring is rotationally connected to the upper end face of the sleeving inner frame body; the outer diameter of the rotating ring is matched with the inner diameter of the stirring cavity, a limiting rod is fixedly connected to the side end face of the rotating ring, a limiting groove matched with the limiting rod is formed in the upper portion of the dispersing device body, and a containing bag is clamped between the dispersing device body and the sleeving inner frame. The device has the effect of stirring thepowder coating, and the powder is prevented from solidifying and crusting on the inner wall of the container.

Owner:宁波高新区巴艺新材料科技有限公司

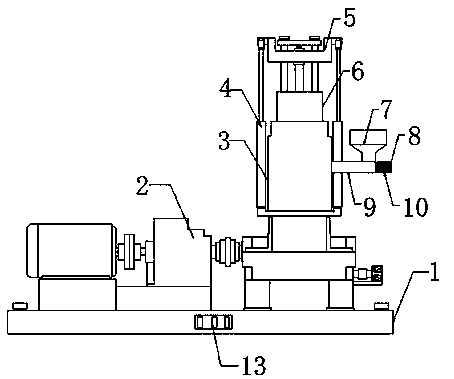

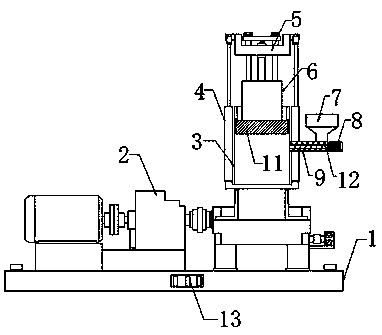

An infrared stealth material and production equipment for preparing the material

The invention discloses an infrared stealth material and production equipment for preparing the material, comprising a base frame, a support is fixedly connected to the top of one end of the base support, and a fixing mechanism is embedded in the support, and the fixing mechanism includes a support Plates, notches, screw rods, curved splints, grooves, movable blocks, guide wheels, support springs, slots, rotating rods, first belts, turntables, chutes, moving plates, universal wheels and fixed blocks, this The structure of the invention is scientific and reasonable, and it is safe and convenient to use. A fixing mechanism is set up. Through the cooperation of the screw rod, the turntable, the turn rod and the first belt, the curved splint is pushed to clamp and fix the mixing drum, which improves the stability of the mixing drum and avoids During the mixing process, the mixing drum is offset, which affects the mixing effect of the material and increases the quality of the mixed molding of the material. At the same time, the upper fixing plate and the lower fixing plate further fix the mixing drum, increasing the stability of the mixing drum.

Owner:YANGZHOUSRKLE INDAL

Preparation device and preparation method of steel fiber concrete pavement slab

InactiveCN112873552AAffect qualityEasy for primary mixingCement mixing apparatusGear wheelElectric machinery

The invention discloses a preparation device of a steel fiber concrete pavement slab. The preparation device comprises a box body, wherein supporting frames are bolted to two sides of the bottom of the box body; a feeding pipe is communicated with the left side of the top of the box body; a fixed plate is bolted to the left side of an inner cavity of the box body; a through groove is formed in the right side of the fixed plate; and a stirring mechanism is arranged in the inner cavity of the box body. According to the preparation device disclosed by the invention, a motor, a first stirring shaft, a first gear, a movable plate and a first stirring rotary blade are matched, so that a user can conveniently utilize the motor to drive the first stirring shaft and the first stirring rotary blade to carry out primary stirring on a plurality of types of raw materials; second gears, second stirring shafts and second stirring rotary blades are matched, so that the user can conveniently utilize the rotation of the movable plate to drive the two groups of second stirring shafts to rotate around the first stirring shaft; and meanwhile, the first gear is used for driving the two groups of second gears to rotate, so that the second stirring shafts and the second stirring rotary blades are driven to rotate at the same time, and furthermore, the plurality of types of raw materials are sufficiently mixed and stirred.

Owner:中铁十一局集团第五工程有限公司

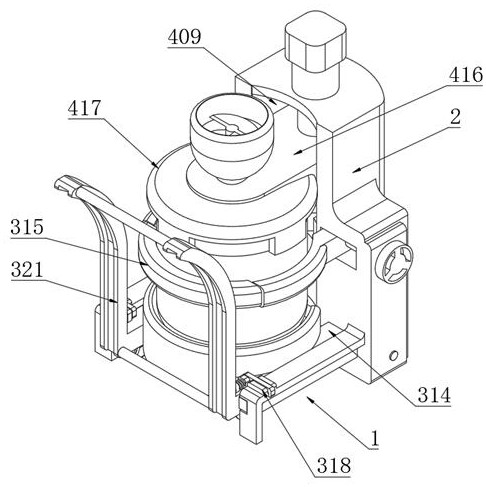

A stirring and grinding device for bulk cosmetic raw material particles

ActiveCN112024085BTo achieve the effect of periodic positive and negativeAffect the mixing effectRotary stirring mixersTransportation and packagingGear wheelReciprocating motion

The invention relates to the technical field of cosmetic processing, and discloses a stirring and grinding device for bulk cosmetic raw material particles, including a support frame, a motor is fixedly connected to the bottom of the support frame, and a movable rod is connected to the top key of the motor. The inner walls on both sides of the support frame are fixedly connected with fixed blocks, the top inner wall of the fixed block is fixedly connected with a stirring tank, the bottom of the fixed block is provided with a chute, and the inside of the chute is inserted with a gear bar. The bottom of the gear bar is fixedly connected with an arc-shaped frame, and the front of the gear bar is meshed with gears. The stirring and grinding device for bulk cosmetic raw material particles drives the small racks on both sides to reciprocate back and forth through the runner, and is used in conjunction with the push rod, piston and grinding plate, so as to achieve the crushing effect on the bulk damp cosmetic raw material. The uniform mixing degree of different cosmetic raw materials is improved, and the quality of cosmetics is further improved.

Owner:湖南秦湘九州生物科技股份有限公司

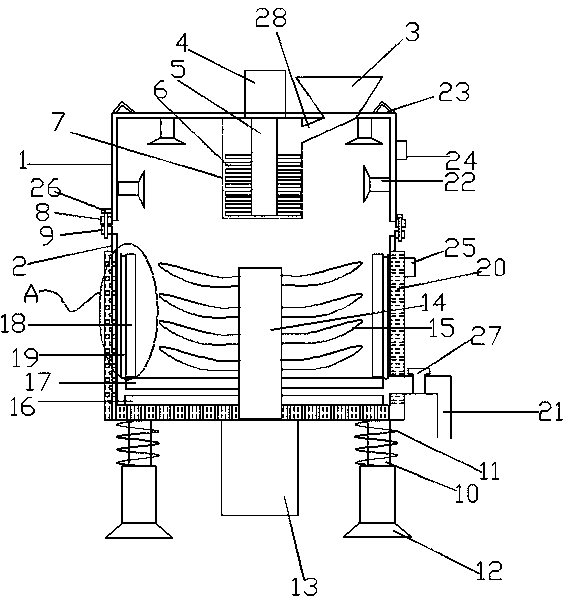

Ceramic soil stirring equipment with good stirring effect

InactiveCN109834836AStir fully and evenlyAffect the mixing effectCement mixing apparatusSpiral bladeHoneycomb

The invention discloses ceramic soil stirring equipment with good stirring effect. The ceramic soil stirring equipment comprises a rotating motor, a top cover, a stirring tank, a rotating shaft, a storage tank, a spiral blade, a sealing pipe, a supporting frame, a filter screen, universal wheels, a collecting tank, damping springs, an electromagnetic valve, a gravity sensor, a bottom cover, a control panel, a stirring blade, a cabin wall vibrator, a honeycomb acoustic board, an alarm and a PLC, wherein the damping springs are correspondingly arranged at the bottom of the supporting frame, theuniversal wheels are arranged at the bottom of the damping spring, the control panel is arranged on one side of the supporting frame, the alarm and the PLC are arranged in the control panel, the otherside of the supporting frame is provided with the storage tank, the stirring tank is connected with the storage tank through the sealing pipe, the sealing pipe is provided with the electromagnetic valve, one side of the sealing pipe is provided with the collecting tank, and the inner wall of one side of the collecting tank is provided with the filter screen. The ceramic soil stirring equipment has the characteristics of being good in stirring effect and high in practicability.

Owner:唐建华

Novel medical mixing device

InactiveCN112237869AImprove work efficiencyExtended service lifeRotating receptacle mixersTransportation and packagingElectric machineryEngineering

The invention discloses a novel medical mixing device which comprises a bottom plate, a box body is mounted on the upper surface of the bottom plate, the lower surface of the box body is connected with the upper surface of the bottom plate, a wheel carrier is mounted on the lower surface of the bottom plate, the upper surface of the wheel carrier is connected with the lower surface of the bottom plate, and rolling wheels are mounted on the inner wall of the wheel carrier. The outer walls of the rolling wheels are movably connected with the inner walls of the wheel carriers, and a push handle is mounted on the upper surface of the bottom plate. According to the novel medical mixing device, through cooperation of a first motor, a first rotating shaft, a rotating rod and a belt, under the action of the box body, the first motor is an alternating current servo motor, the stirring efficiency is improved, and under the action of a second motor, a second rotating shaft and a stirring paddle,the second motor is an alternating current servo motor; the rotating speed of the motor is adjusted by adjusting the power generated by current passing through the motor, the rotating speed of the second rotating shaft is adjusted by adjusting the rotating speed of the motor, and the device is suitable for application and popularization.

Owner:诸暨市新鑫弹簧有限公司

Bean mixing and stirring equipment

InactiveCN112675736AAffect the mixing effectImprove the mixing effectRotary stirring mixersMixer accessoriesSpiral bladeElectric machine

Disclosed bean mixing and stirring equipment comprises a box body, a feeding opening is formed in one side of the top end of the box body, a first motor is fixedly connected to the center of the upper surface of the top of the box body, and a first transmission rod is fixedly connected to the output end of the first motor, penetrates through the top of the box body and is rotationally connected with the box body; an n-shaped rod is fixedly connected to the lower surface of the first transmission rod, second stirring rods are fixedly connected to the two sides of the n-shaped rod, a first stirring rod is fixedly connected to the inner wall of the box body, a second motor is fixedly connected to the center of the lower surface of the bottom of the box body, and a second transmission rod is fixedly connected to the output end of the second motor, penetrates through the bottom of the box body and is rotationally connected with the box body; and the upper surface of the second transmission rod is rotationally connected with the top of a fixing frame, spiral blades are fixedly connected to the circumferential surface of the second transmission rod, a lower inlet is formed in the bottom end of the fixing frame, an upper outlet is formed in the top end of the fixing frame, and a discharging pipe is arranged on one side of the bottom of the box body. The equipment is novel in structure, convenient to operate, good in stirring and mixing effect and more sufficient in mixing.

Owner:赣州康瑞农产品有限公司

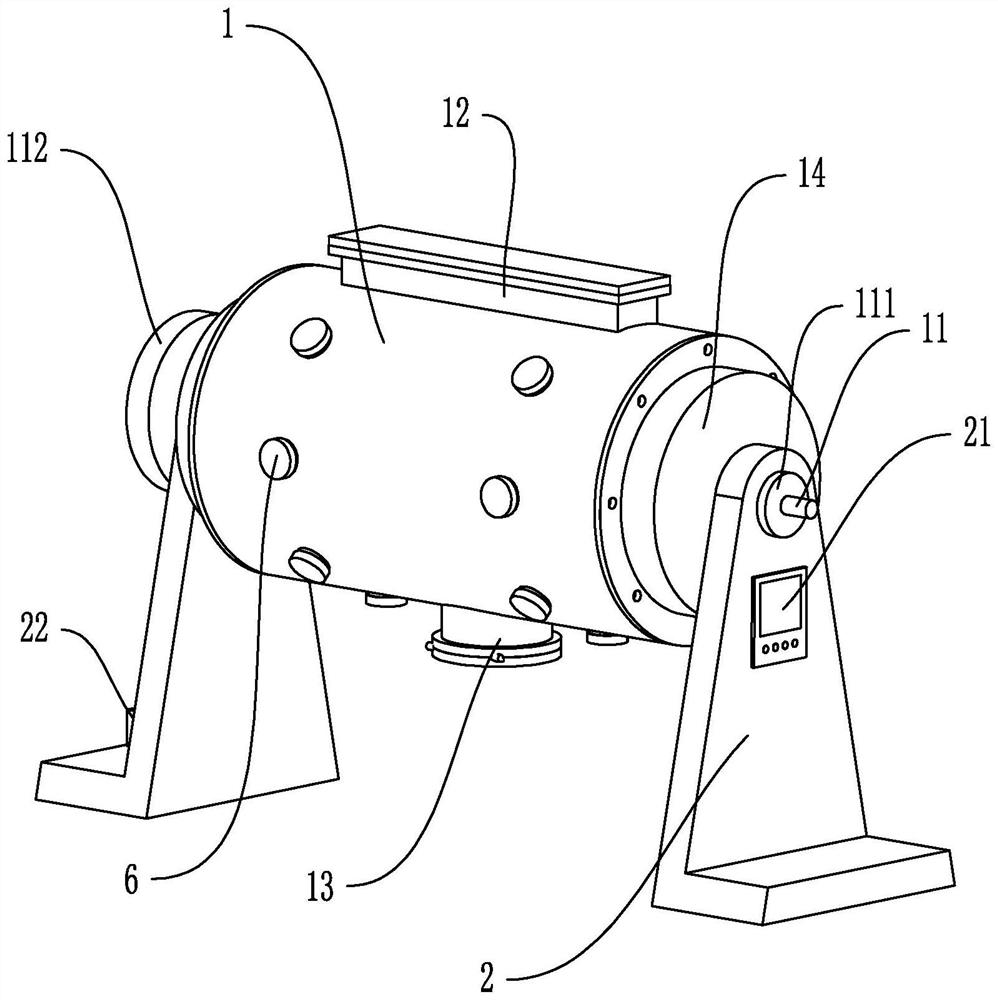

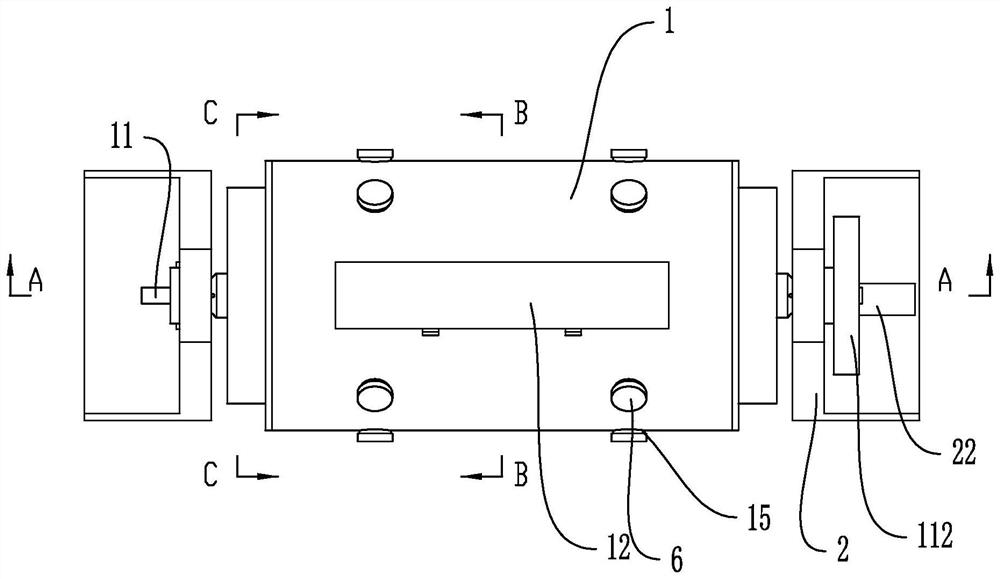

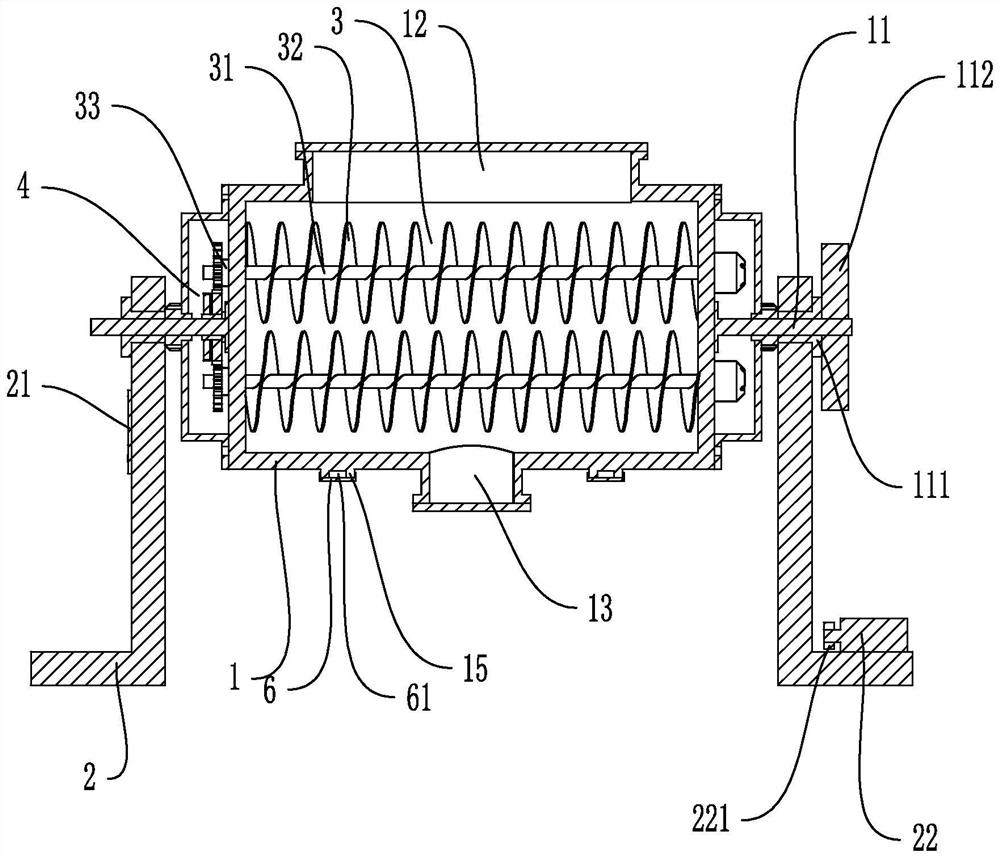

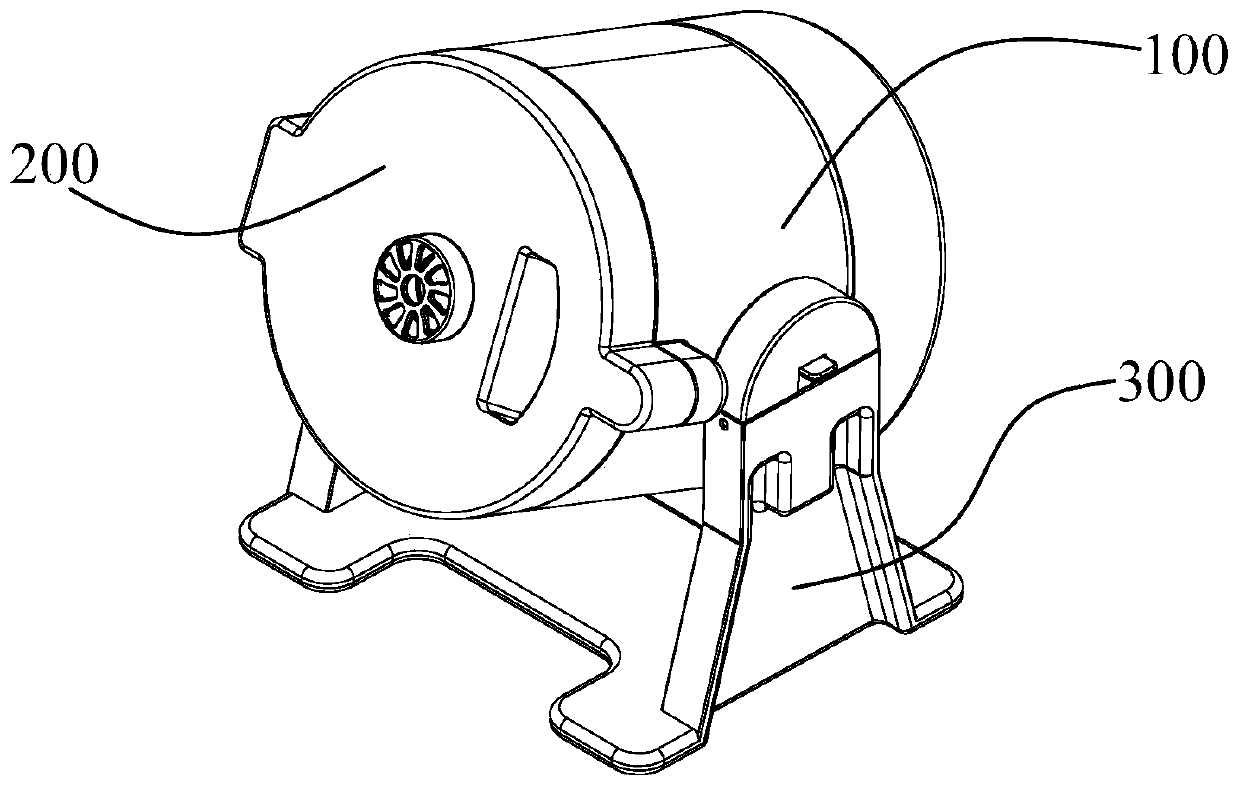

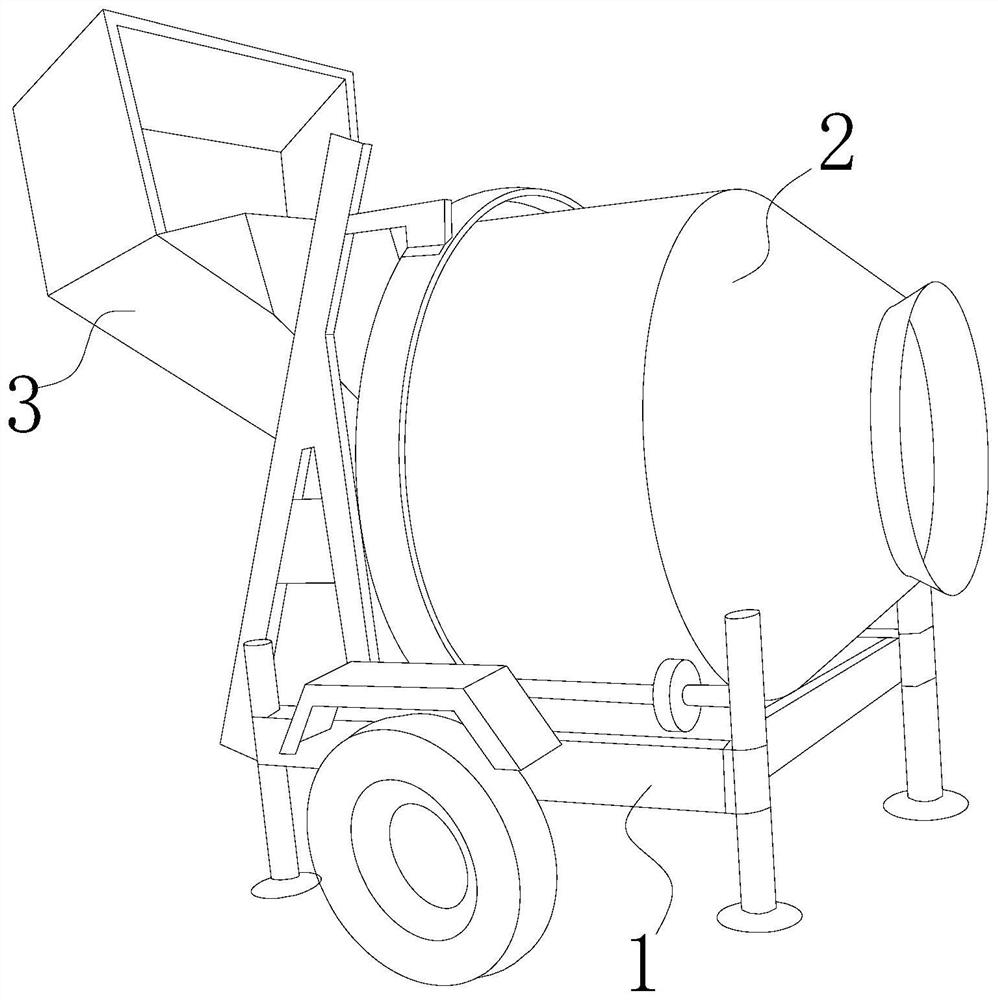

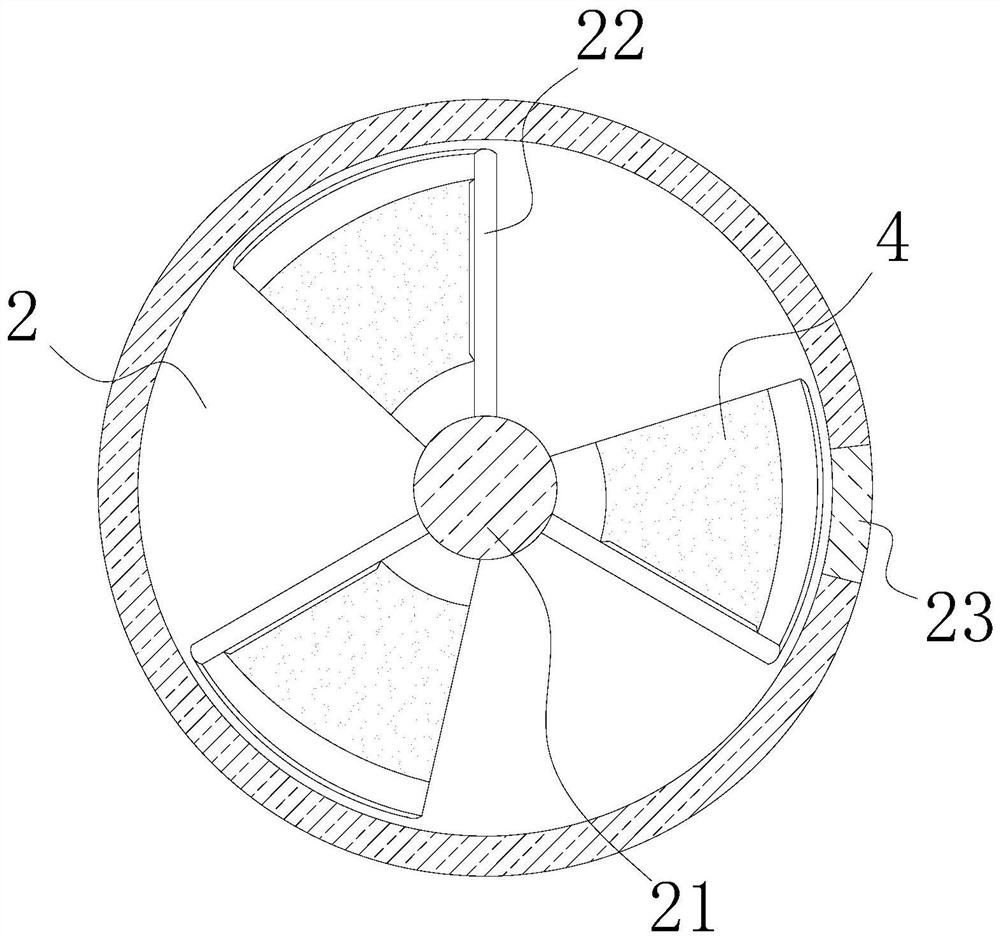

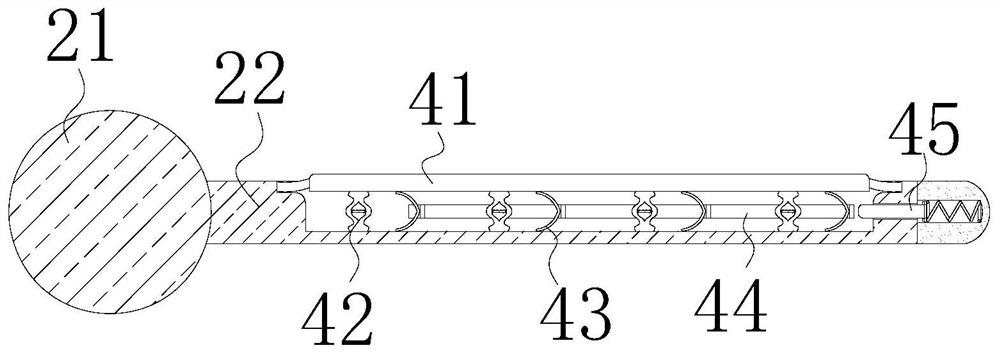

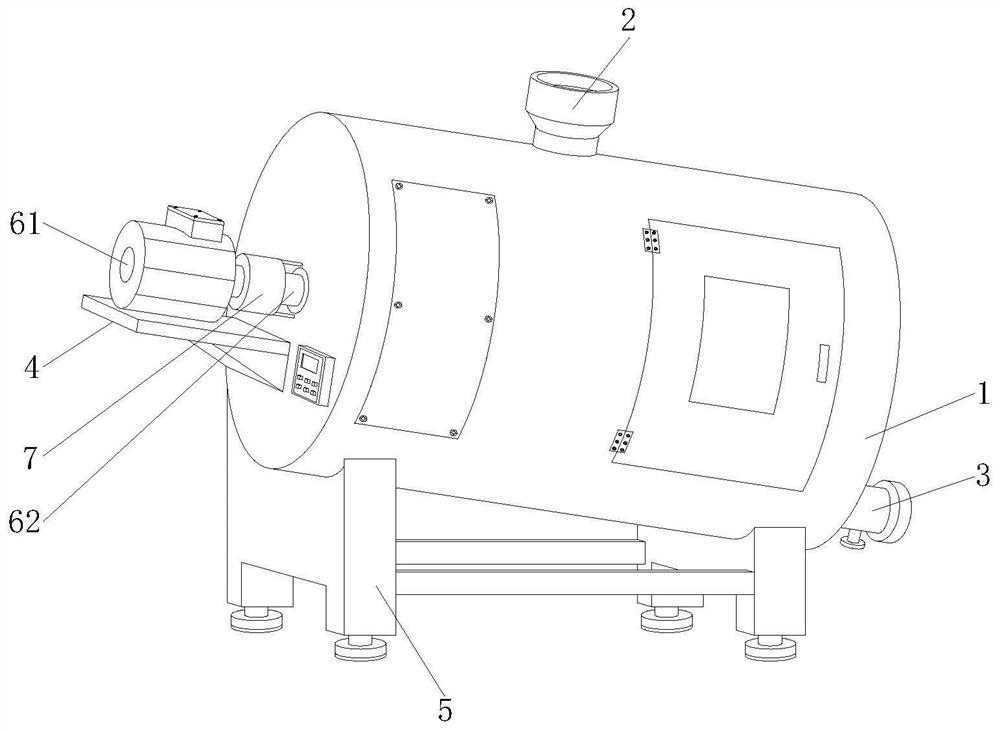

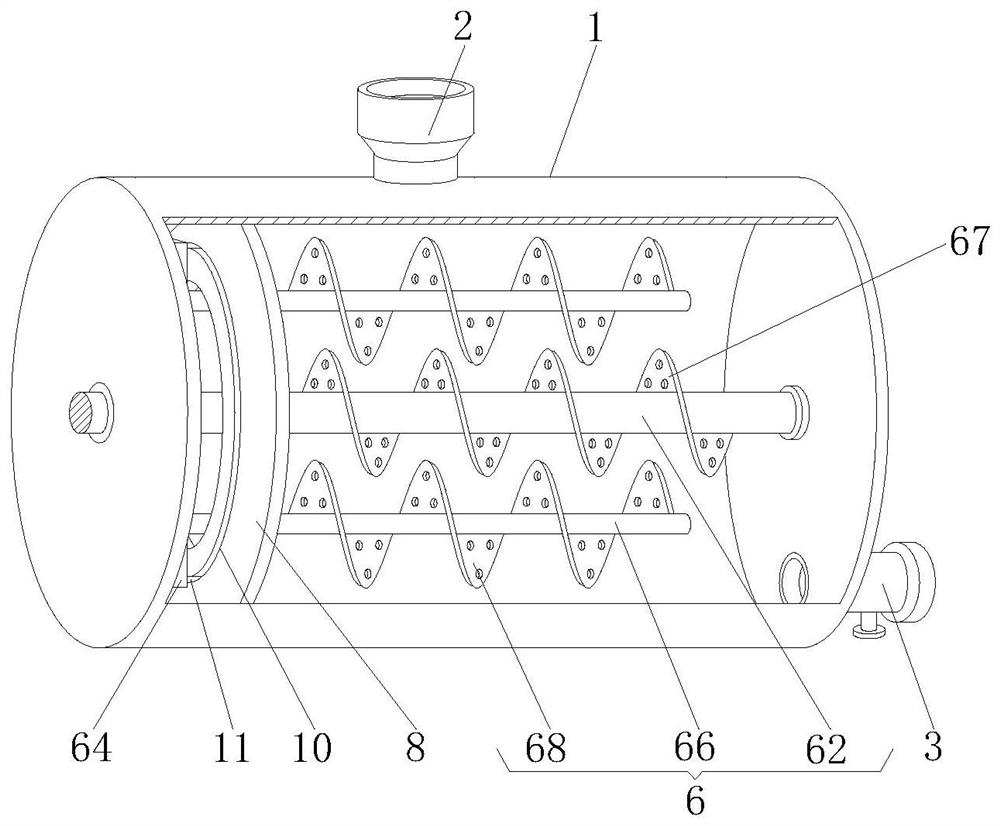

A drum concrete mixer

ActiveCN113320015BPrevent hardeningAvoid affecting the mixing effectSolid waste managementDischarging apparatusGear wheelArchitectural engineering

The invention discloses a drum-type concrete mixer, which relates to the technical field of construction machinery. The rack roller is movably matched with the drum, and a universal shaft is installed on one side of the drum. The beneficial effects of the present invention are: the present invention is set by the combination of the movable ring and the stirring assembly, and the rack ring in the movable ring is rotated to make the rack move in a circle. Drive the gear to rotate, so that the longer side of the mixing blade is turned inward, so that the entire mixing assembly can be pulled out, and the groove disc pushes the concrete remaining on the cylinder wall to the material port from the inside, preventing the remaining concrete from hardening on the cylinder wall. After the mixing assembly is pulled out, the entire mixing assembly can be washed to prevent the hardening of the concrete from affecting the rotation of the movable ring and preventing the concrete from blocking the through holes on the mixing blade to affect the mixing effect.

Owner:河北盛烯耐火材料有限公司

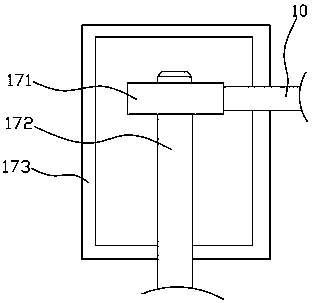

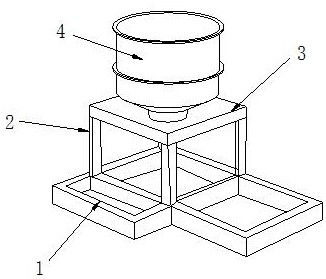

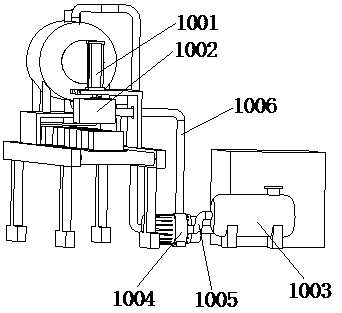

Continuous sludge hydrothermal treatment reaction kettle device

ActiveCN114380480AAffect the effect of heat treatmentAffect the mixing effectSievingSludge treatment by de-watering/drying/thickeningSludgeEnvironmental geology

The invention provides a continuous sludge hydrothermal treatment reaction kettle device, and relates to the technical field of sludge treatment. The continuous sludge hydrothermal treatment reaction kettle device comprises a shell, the shell comprises a sludge pumping mechanism, the sludge pumping mechanism comprises a discharge pipe fixedly connected to the bottom end of the shell, a cylinder is fixedly connected to the middle of the inner bottom end of the discharge pipe, a reset spring and an extrusion mechanism are fixedly connected to the outer bottom end of the cylinder, and the extrusion mechanism comprises a connecting through pipe arranged in the shell; steam pipes are evenly and fixedly connected to the front side and the rear side of the side, away from the middle of the shell, of the connecting through pipe, a filter plate is arranged between the steam pipes, the filter plate and the connecting through pipe are fixedly connected, and extrusion bags are fixedly connected to the top end and the bottom end of each steam pipe. The problem that excessive sludge solidified on the inner wall of the sludge discharge pipeline of the reaction kettle affects discharge of the sludge in the reaction kettle is solved.

Owner:南通展望科技资讯有限公司

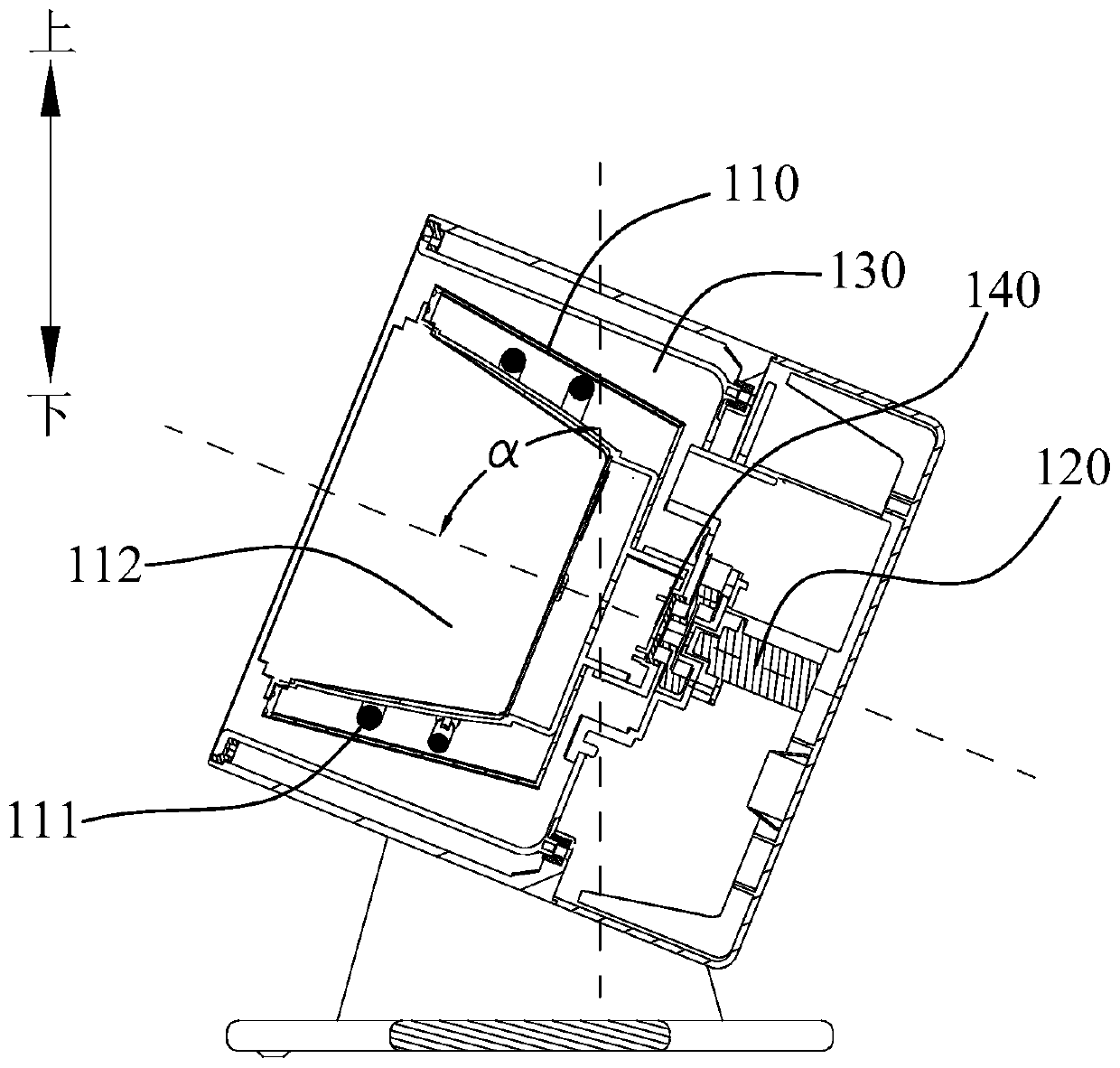

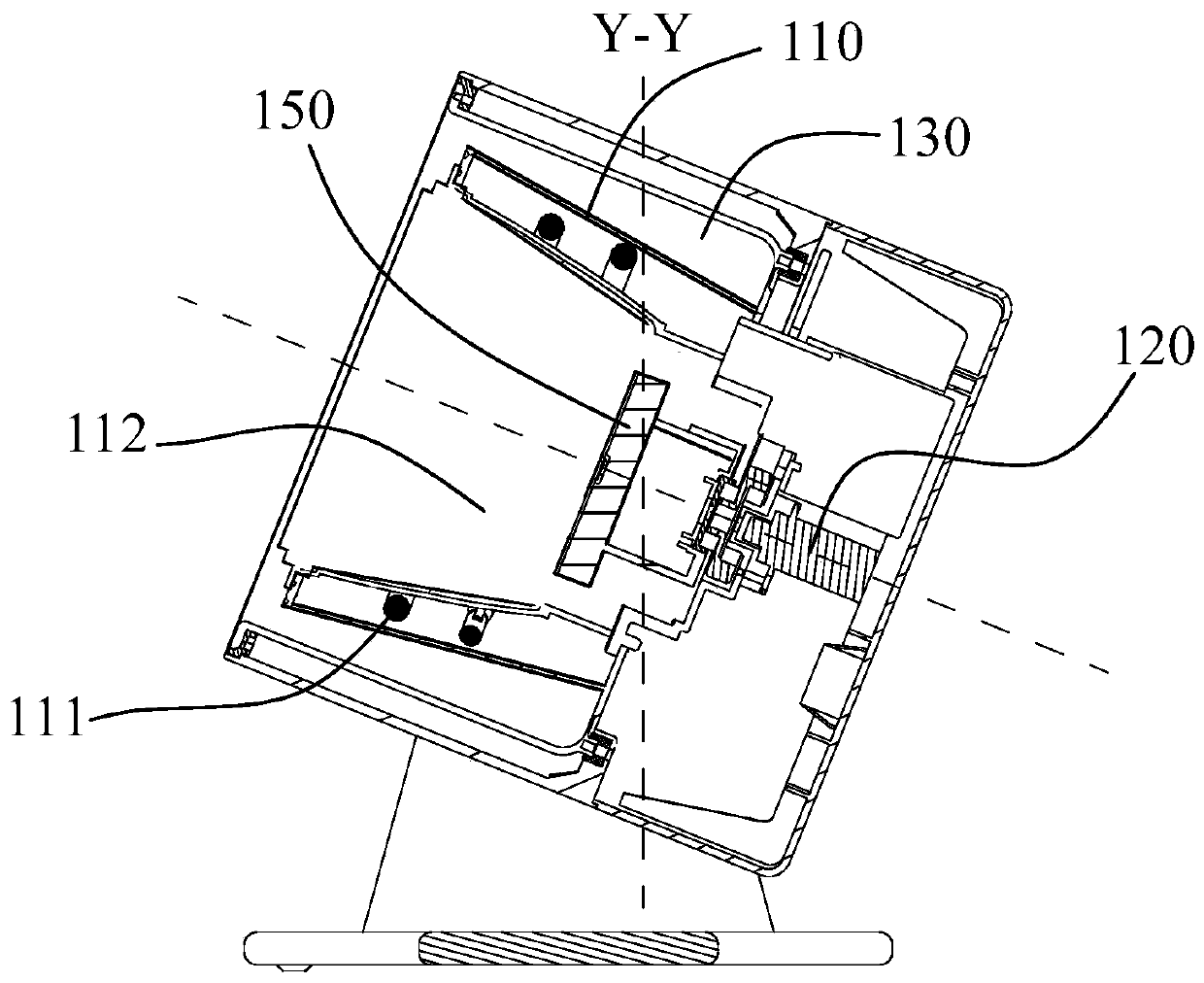

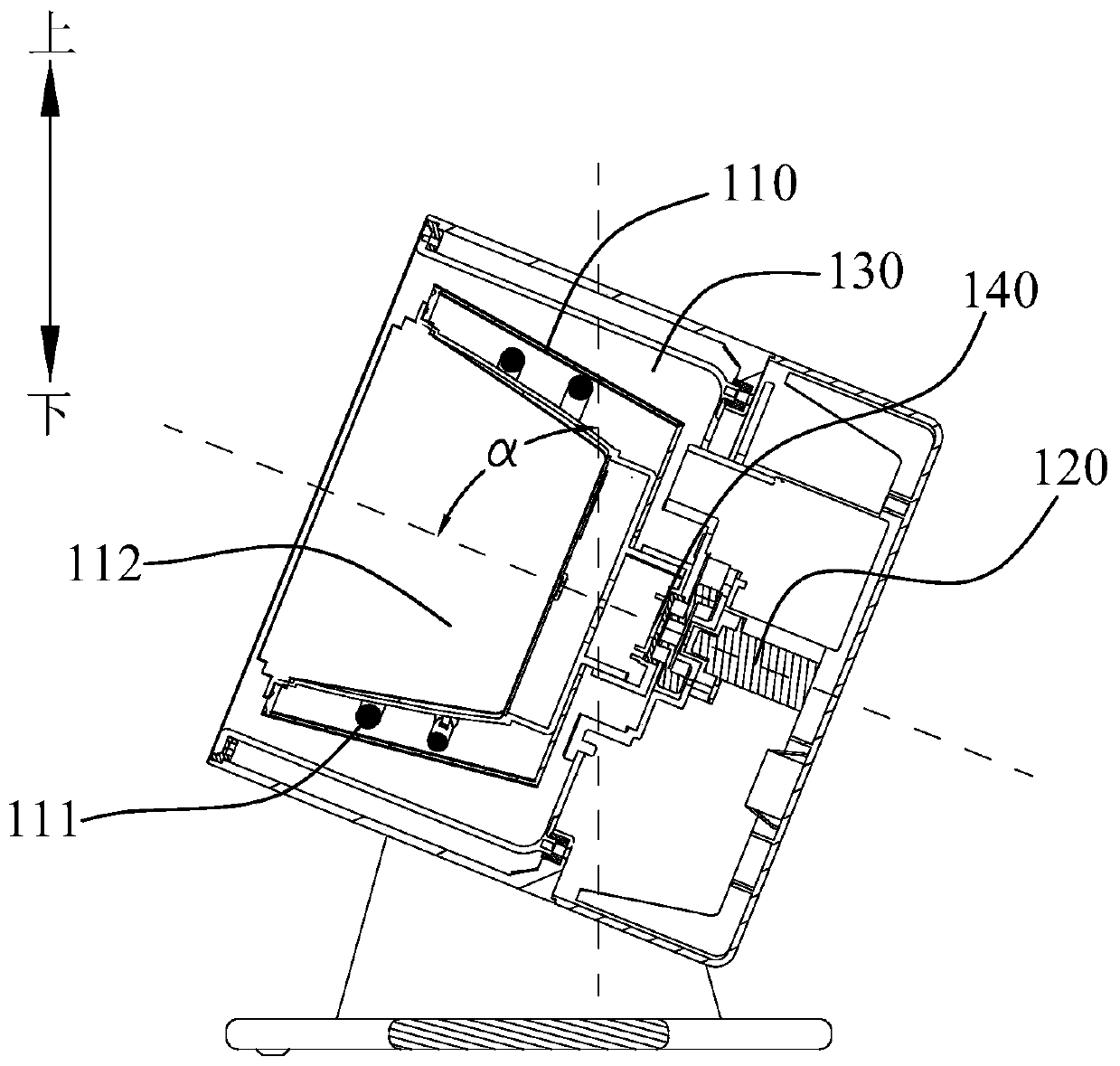

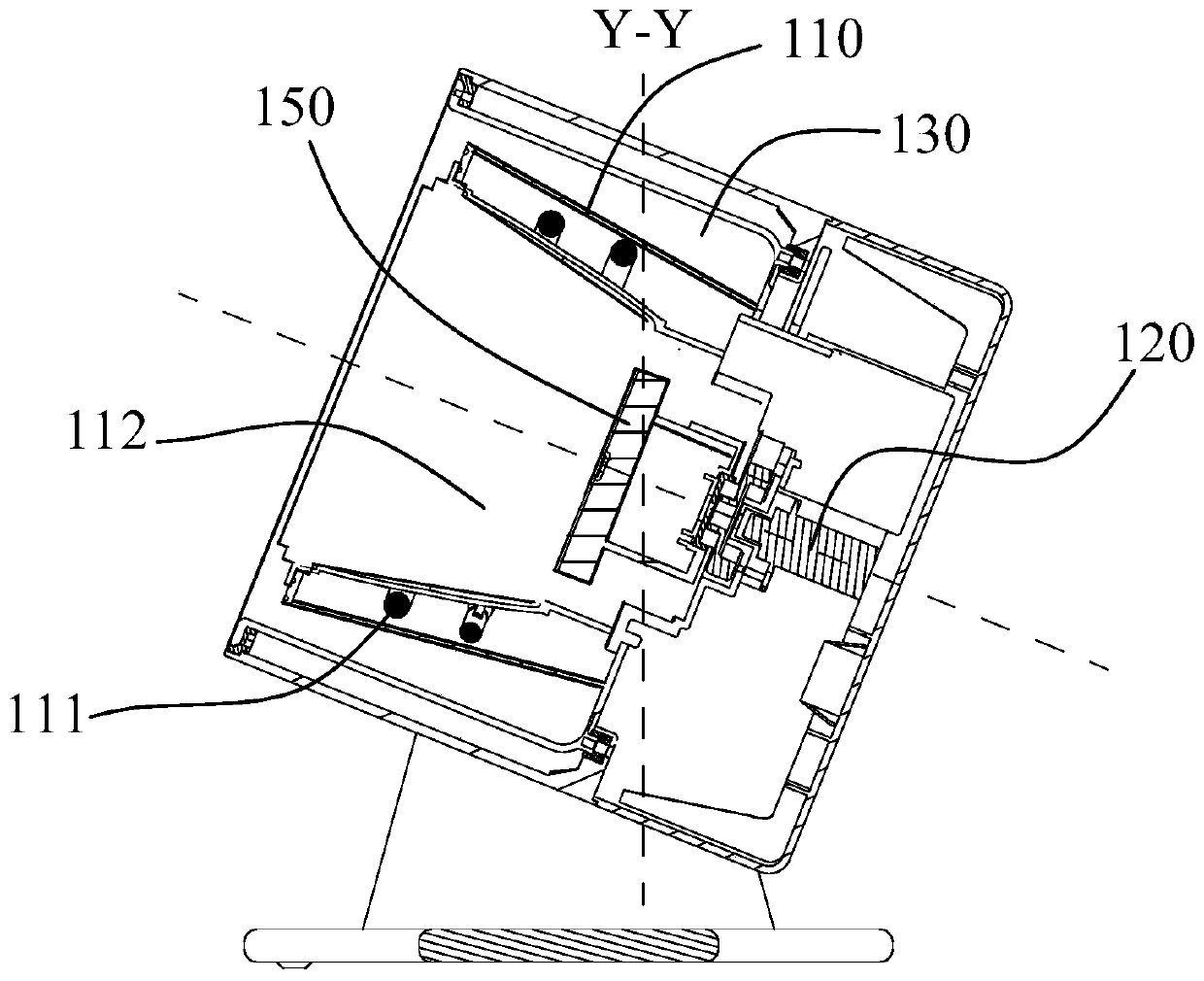

Automatic cooker

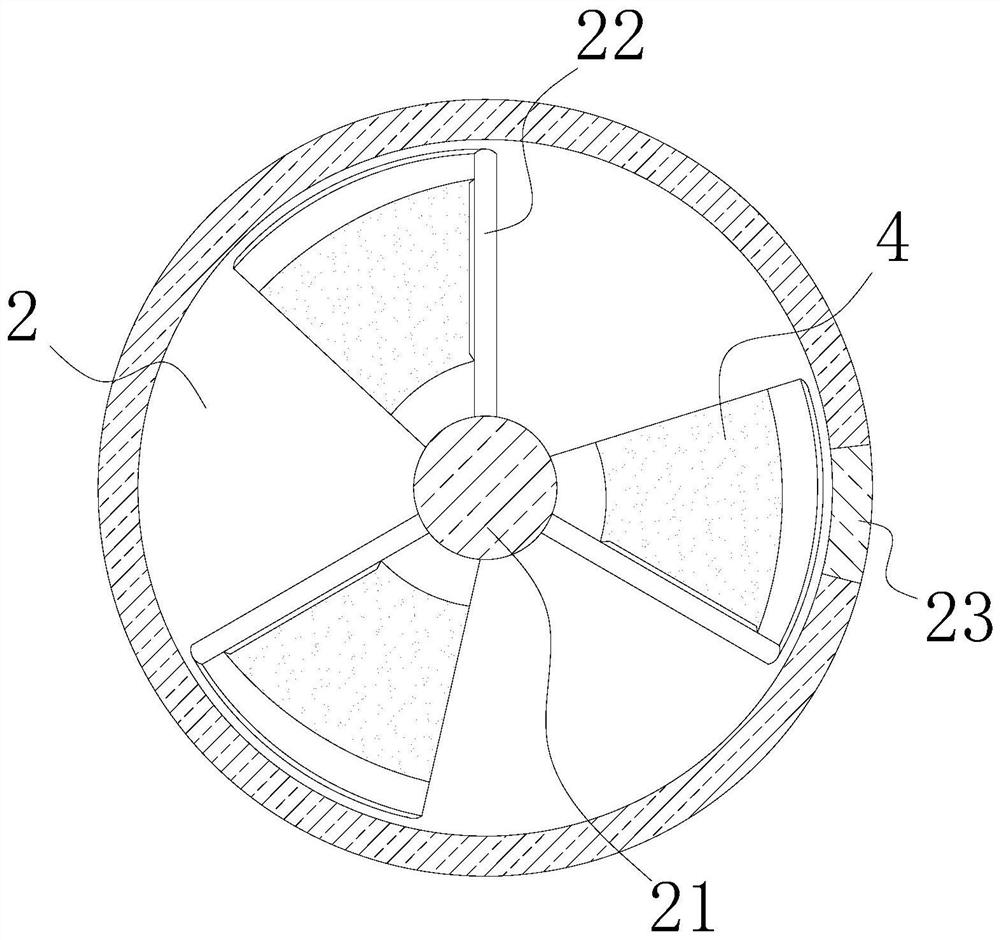

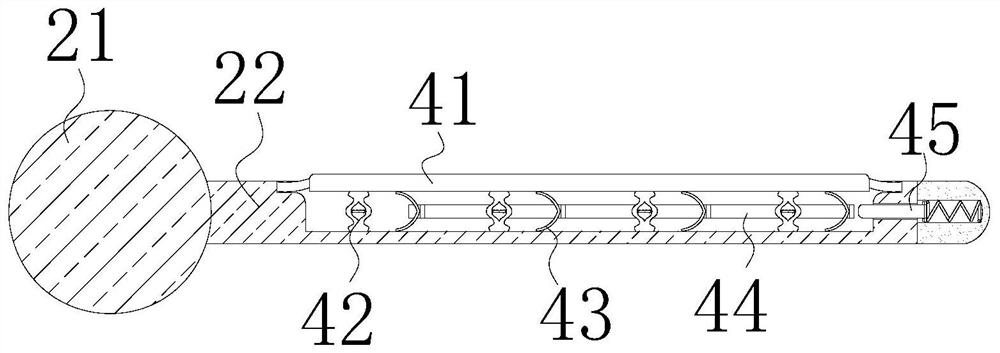

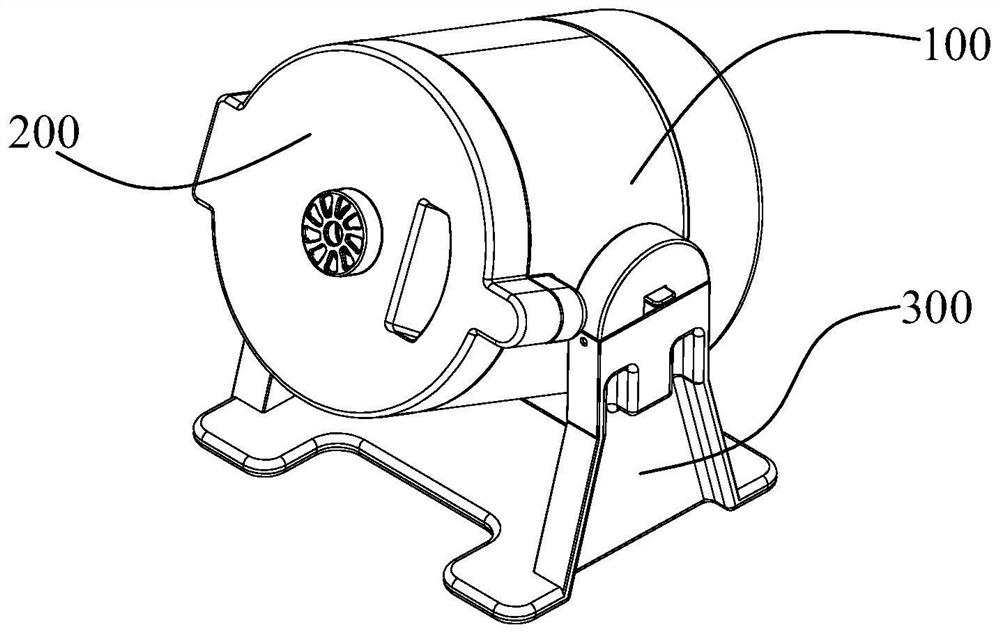

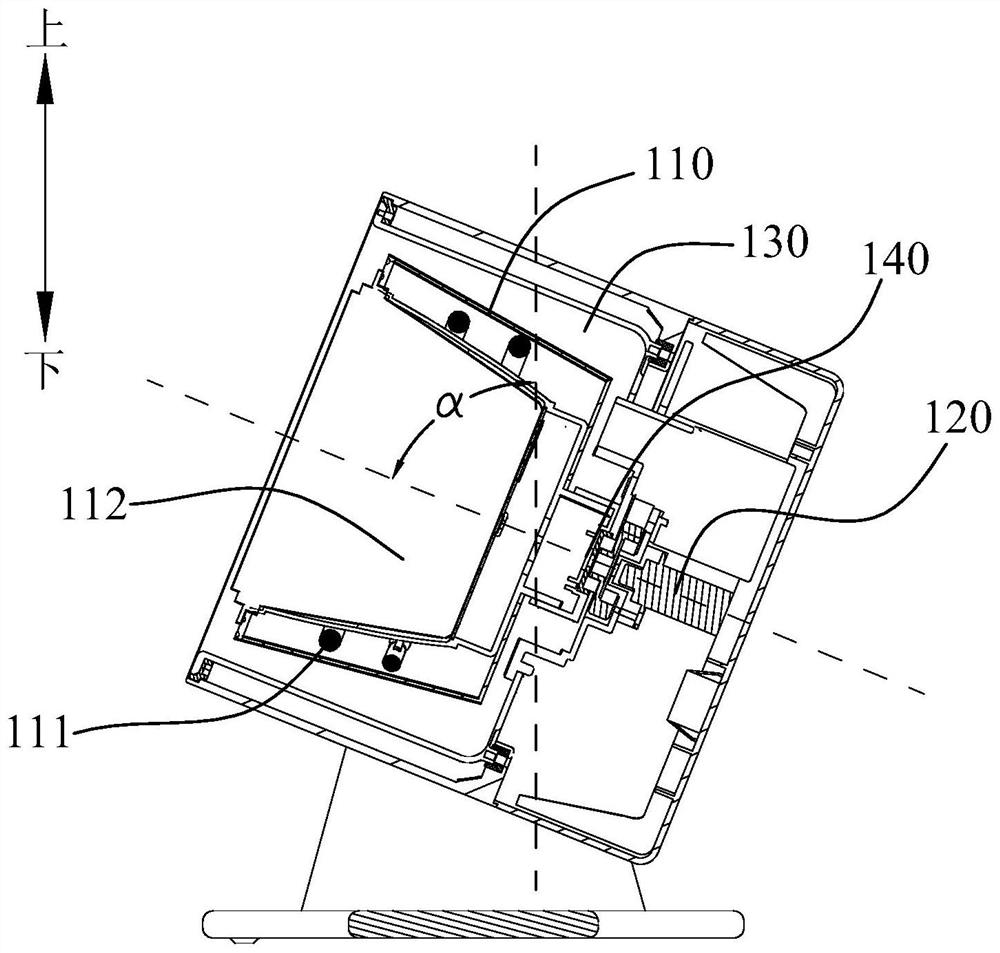

InactiveCN111358273APrevent slippingImprove Stir-Fry MixingVessels with intergral heatingCooking vessel constructionsElectric machineryFood material

The invention provides a cooker comprising a heating cavity for mounting an aluminum foil box and a motor, wherein the aluminum foil box comprises a box body and a cover body, the box body is providedwith a bottom wall and a side wall, the motor drives the aluminum foil box to rotate so that a stirring rough surface formed by wrinkles on the inner surface of the side wall can drive food materialsto be stir-fried, and the included angle between the rotating center axis of the aluminum foil box and the axis perpendicular to the horizontal plane ranges from 0 degree to 75 degrees. By the adoption of the technical scheme, the contact friction force between food materials in the aluminum foil box and the stirring rough surface is increased, the aluminum foil box can drive the food materials to turn over in the rotary stir-frying process, meanwhile, the food materials can be prevented from adhering to the side wall, and the stir-frying mixing effect of the food materials is improved.

Owner:JOYOUNG CO LTD

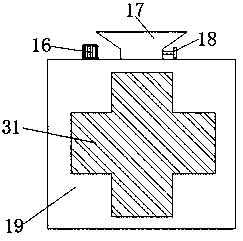

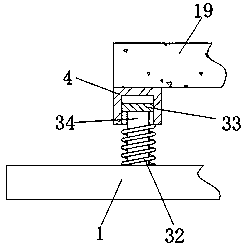

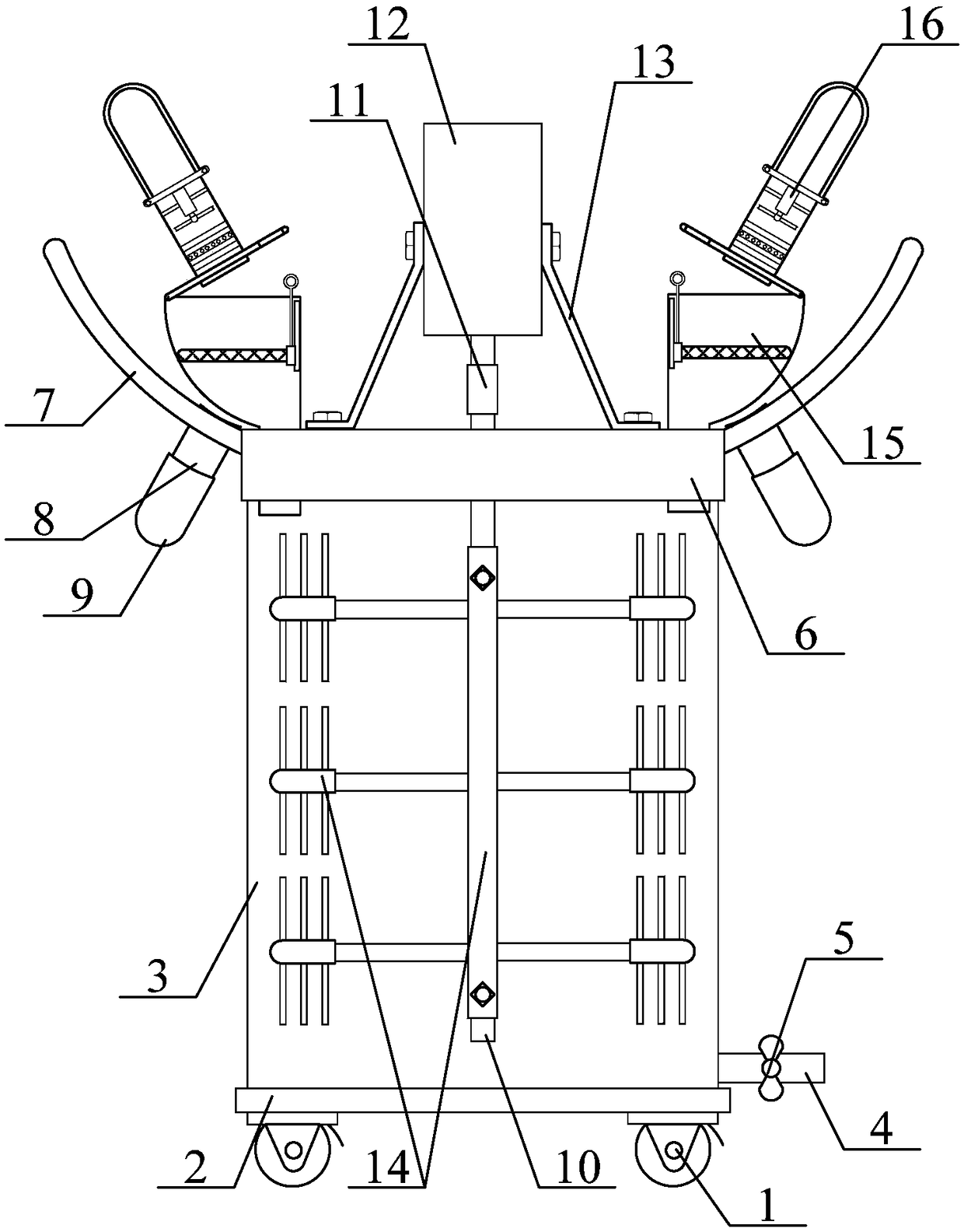

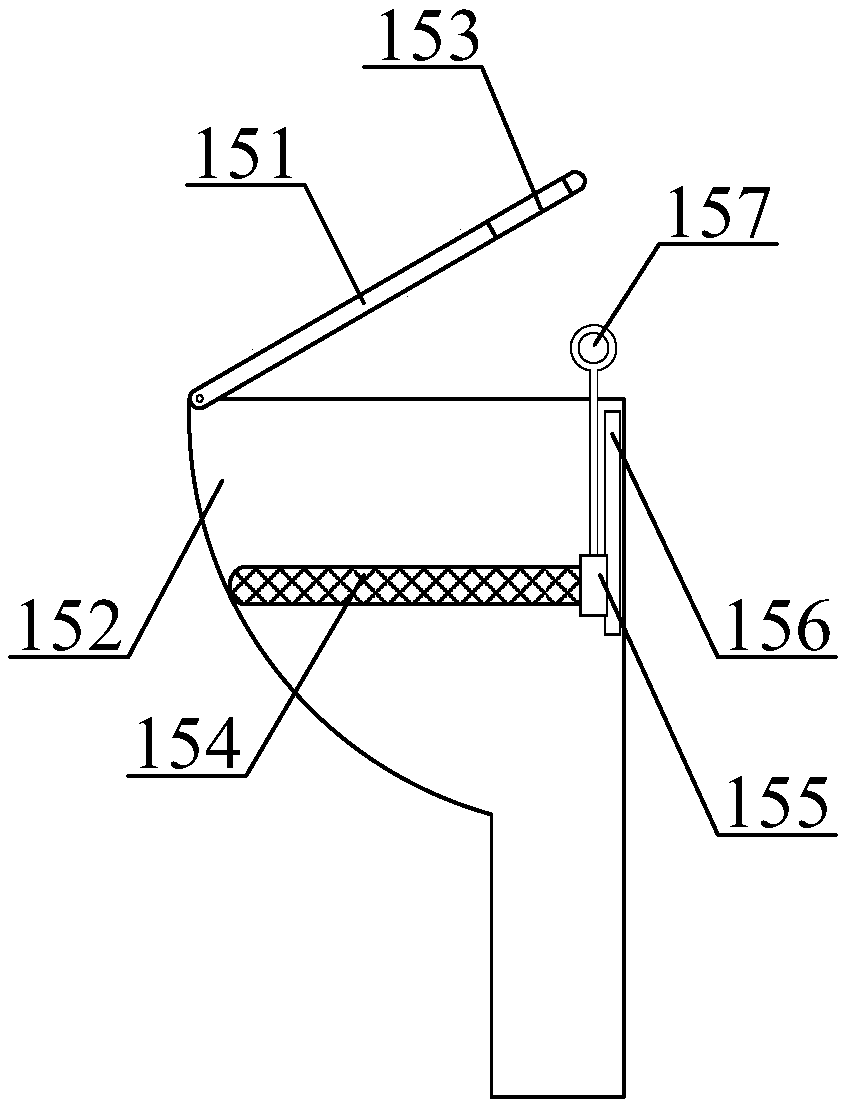

Environmental-friendly feeding device of tire internal mixer

The invention discloses an environmental-friendly feeding device of a tire internal mixer. The environmental-friendly feeding device of the tire internal mixer comprises a base, wherein an internal mixer body is fixedly arranged at the top end of the base; a feed inlet is formed in the top end of the internal mixer body; a charging barrel is fixedly arranged at the top end of the feed inlet; electric hydraulic cylinders are fixedly arranged on two side outer walls of the charging barrel; the telescopic ends of the two electric hydraulic cylinders are fixedly connected with two sides of the bottom end of a cross plate; a push rod is fixedly arranged in the middle of the bottom end of the cross plate; and a push plate is fixedly arranged at the bottom end of the push rod. According to the environmental-friendly feeding device of the tire internal mixer provided by the invention, a drive motor drives a packing auger rod to rotate, so that uniform loading is conveniently realized, and theoccurrence of the phenomenon that the nonuniformity of loading influences a mixing effect of the internal mixer is avoided; and the arranged electric hydraulic cylinders stretch out and draw back to drive the push rod to move up and down, and the push rod moves up and down so as to conveniently press a material entering the charging barrel into the internal mixer so as to mix the material, so thatthe occurrence of the phenomenon that tire rubber blocks the feed inlet so as to influence mixing is avoided.

Owner:DOUBLE COIN GRP JIANGSU TIRE

Organic fertilizer production equipment

InactiveCN110433686AAffect the mixing effectReduce the difficulty of cleaningTransportation and packagingRotary stirring mixersAgricultural engineeringOrganic manure

The invention discloses organic fertilizer production equipment, and belongs to the technical field of fertilizer production. The equipment comprises a conveying belt, a first U-shaped plate, a secondU-shaped plate, a fertilizer stirring tank, a feeding port, a material discharge pipe, a stirring heating assembly, a water conveying assembly, a material discharge assembly, a drying assembly, foursupporting legs and a plurality of placing boxes, wherein the first U-shaped plate and the second U-shaped plate are arranged on the conveying belt, the fertilizer stirring tank is horizontally arranged above the first U-shaped plate, the feeding port is arranged on the top portion of the fertilizer stirring tank, the material discharge pipe is arranged on the bottom portion the fertilizer stirring tank, the stirring heating assembly is arranged in the fertilizer stirring tank, the water conveying assembly is arranged beside the conveying belt, the material discharge assembly is arranged in the first U-shaped plate, the drying assembly is arranged in the second U-shaped plate, and the plurality of the placing boxes are arranged on the conveying belt at equal intervals. In the prior art, asmall of organic fertilizers remain, such that the inner wall of the box is required to be manually cleaned, the cleaning difficulty is high, and the cleaning efficiency is low. According to the present invention, the problem in the prior art can be solved.

Owner:于玮

Mixing device for producing full-body-color PVC (polyvinyl chloride) wood-plastic decorative material

The invention relates to the technical field of wood-plastic decoration, and discloses a full-body-color PVC wood-plastic decorative material production mixing device which comprises a barrel body, a supporting device is arranged in the barrel body, a rotating device is arranged above the supporting device, the supporting device comprises a supporting plate, the outer surface of the supporting plate is fixedly connected with the inner wall of the barrel body, and the outer surface of the supporting plate is fixedly connected with the inner wall of the barrel body. A first open groove is formed in the supporting plate, and a dispersing mechanism is arranged in the first open groove. According to the invention, mixed ingredients to be added are placed above the supporting plate, so that raw materials can uniformly fall down through leaking holes formed in the supporting plate and the first open groove by moving the rotating frame, and the raw materials are conveniently mixed; when too many raw materials are accumulated on the supporting plate, part of the raw materials can flow out after making contact with the scattering plate through the third open groove, it can be guaranteed that the raw materials are caked, the raw materials can flow out through the open holes and the fourth open groove in the third open groove, and the raw materials can better fall into the barrel body to be mixed.

Owner:ANHUI KOJO NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com