Patents

Literature

36results about How to "Avoid affecting the mixing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

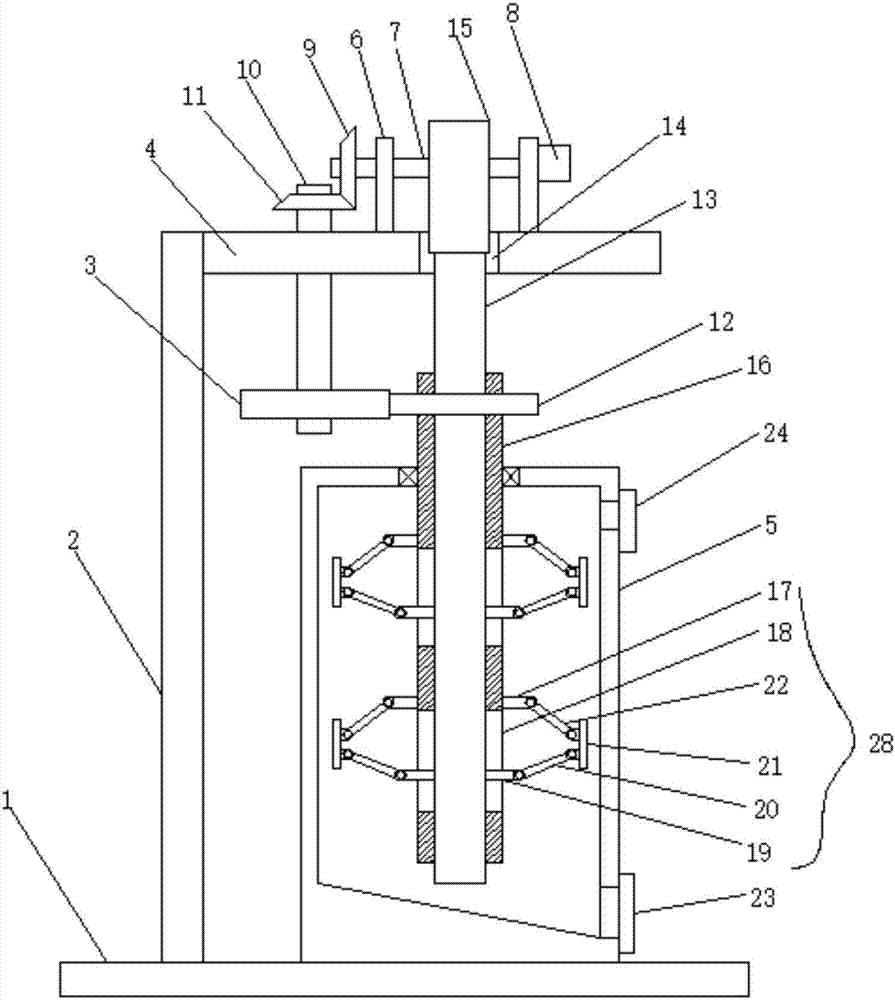

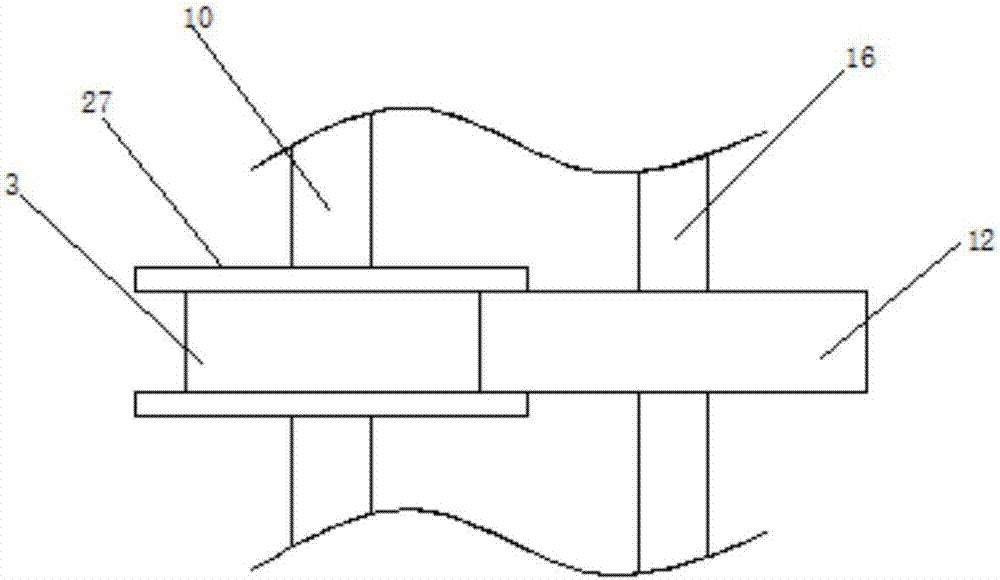

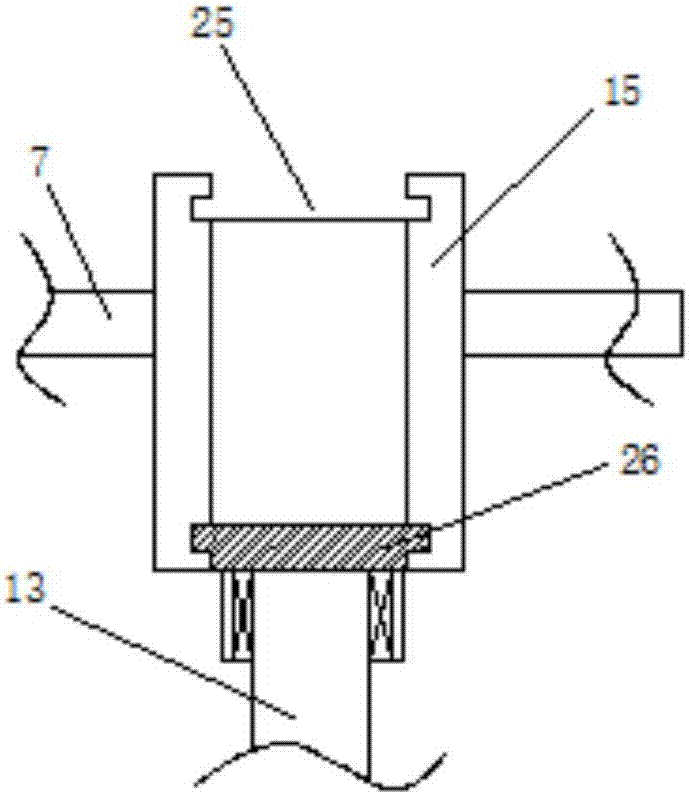

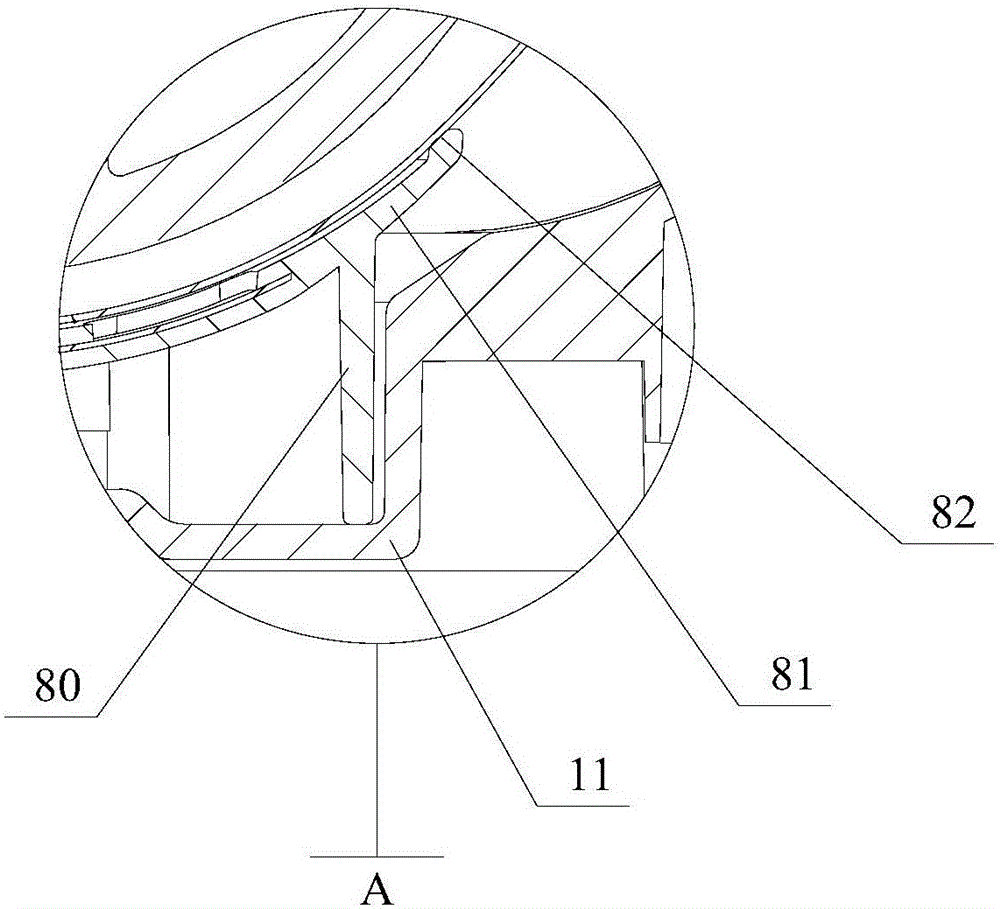

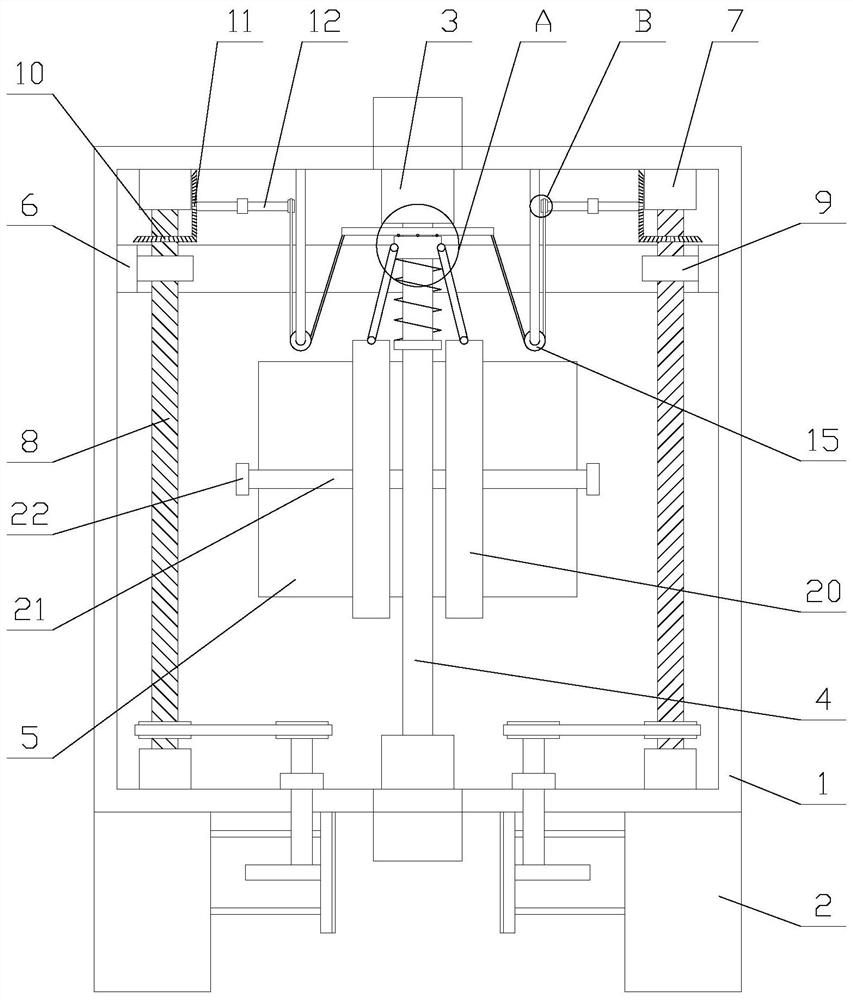

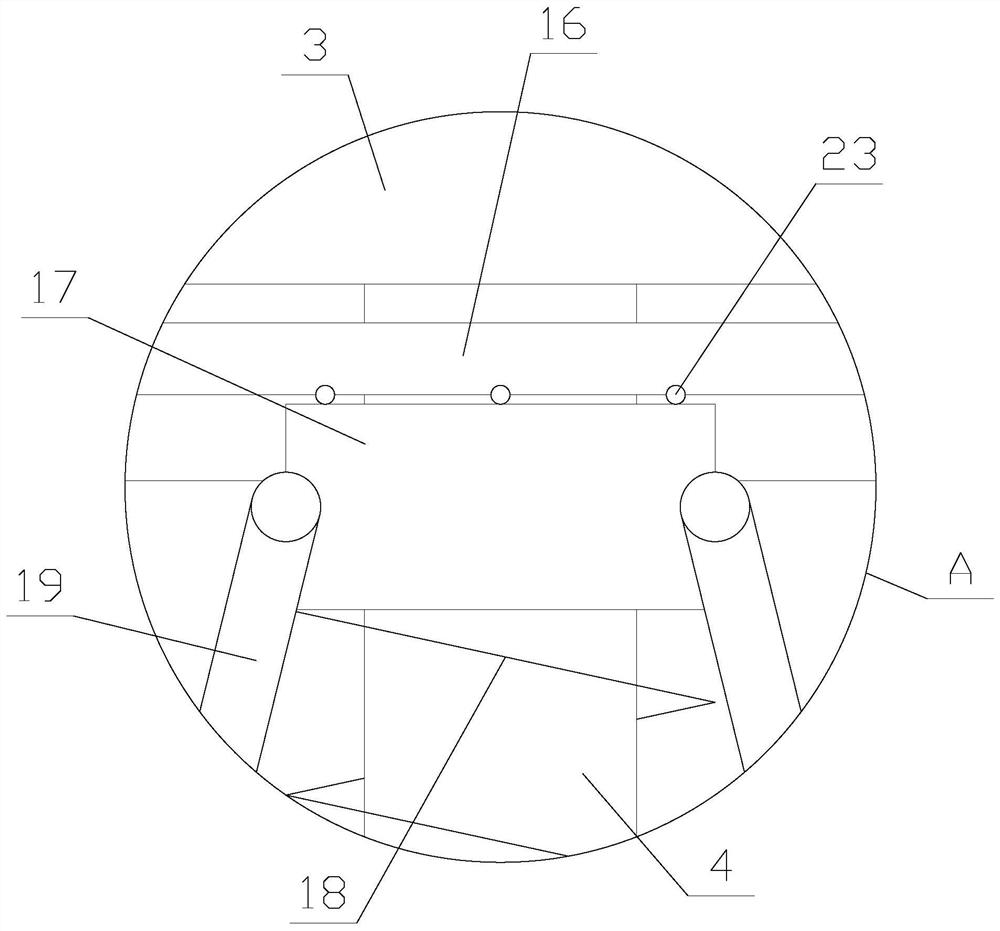

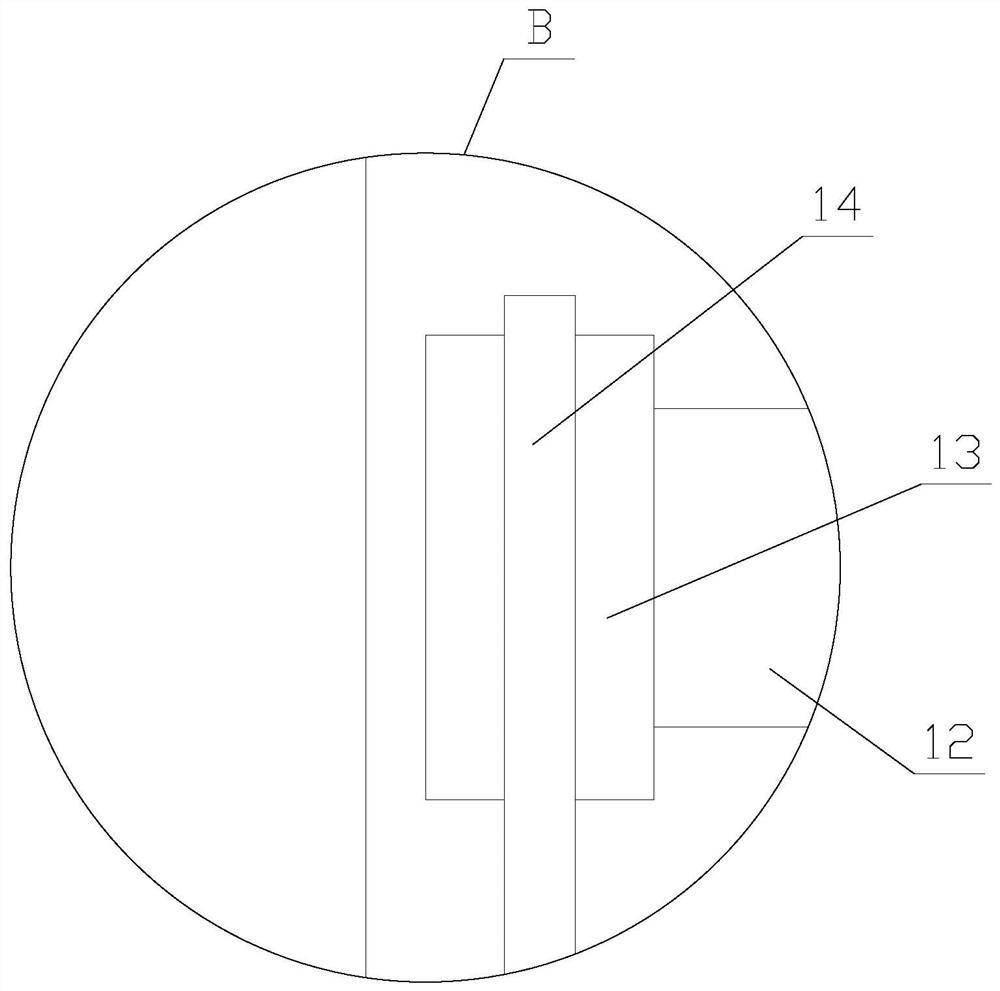

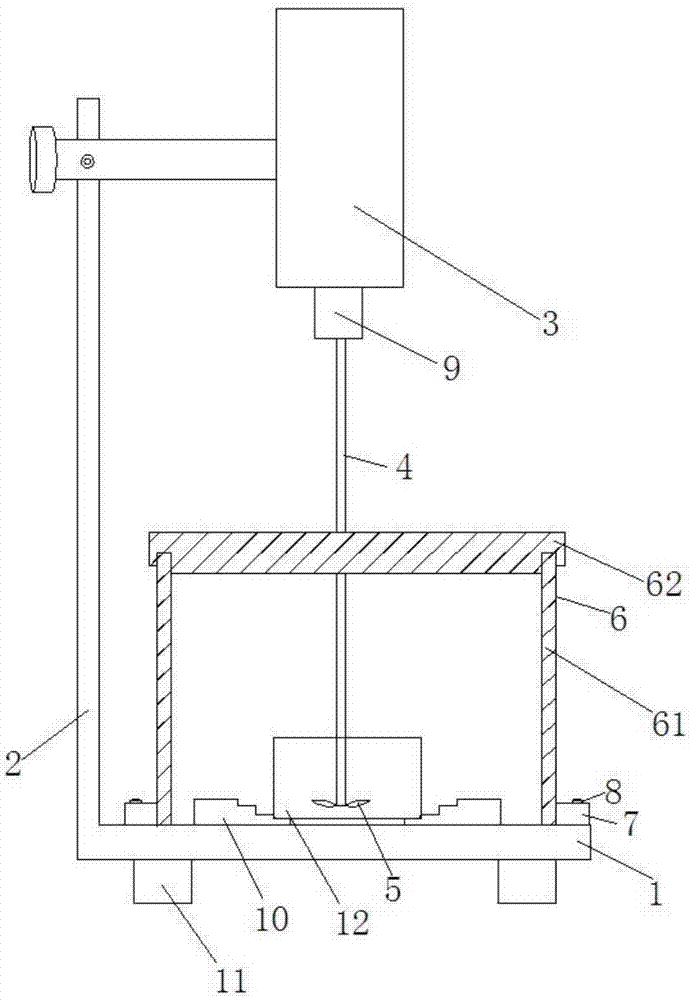

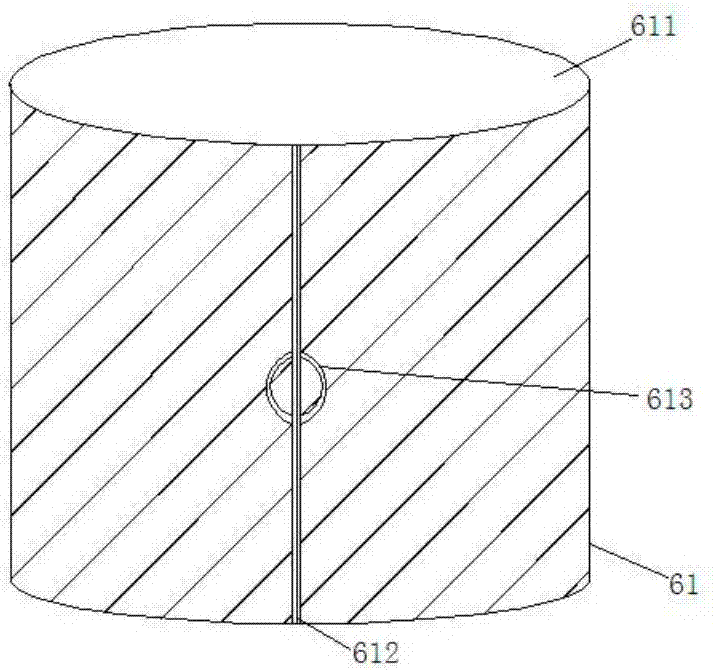

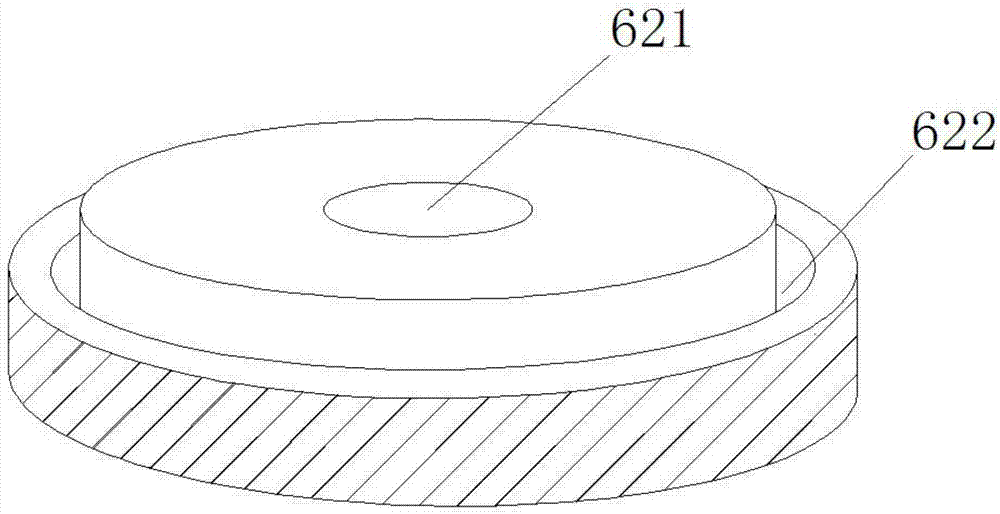

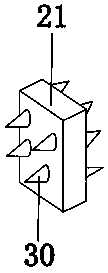

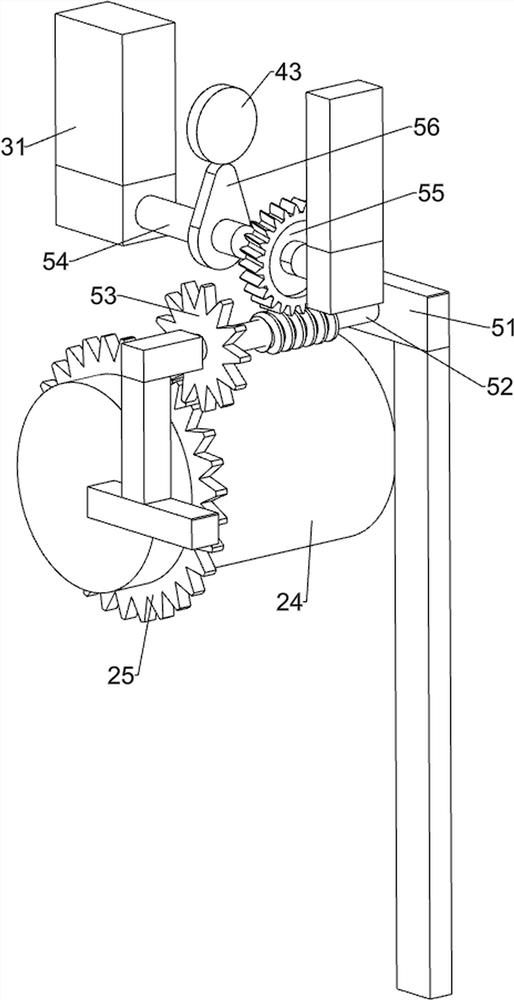

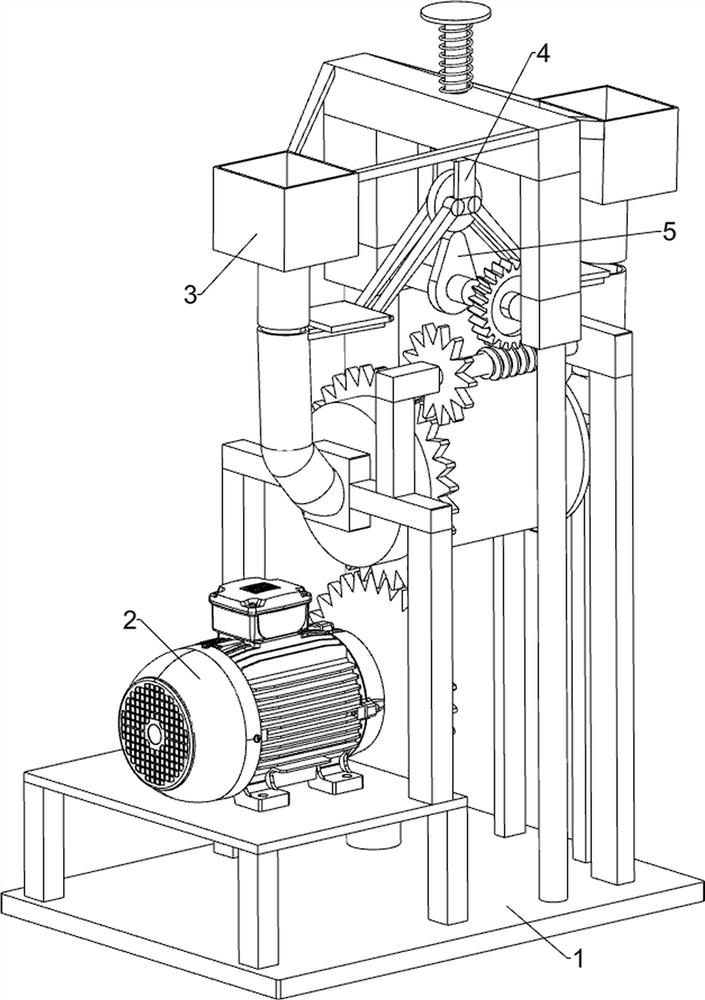

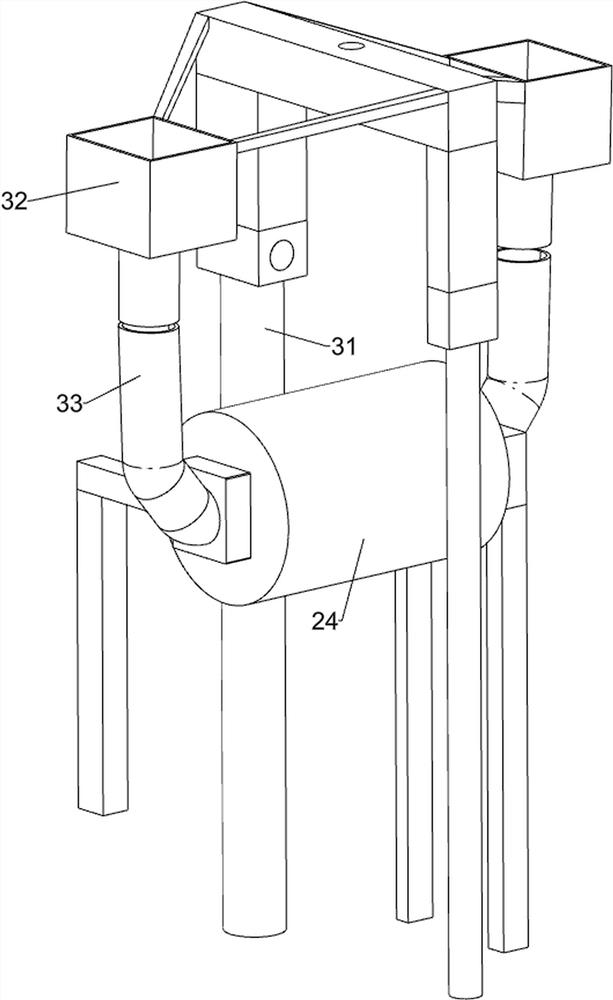

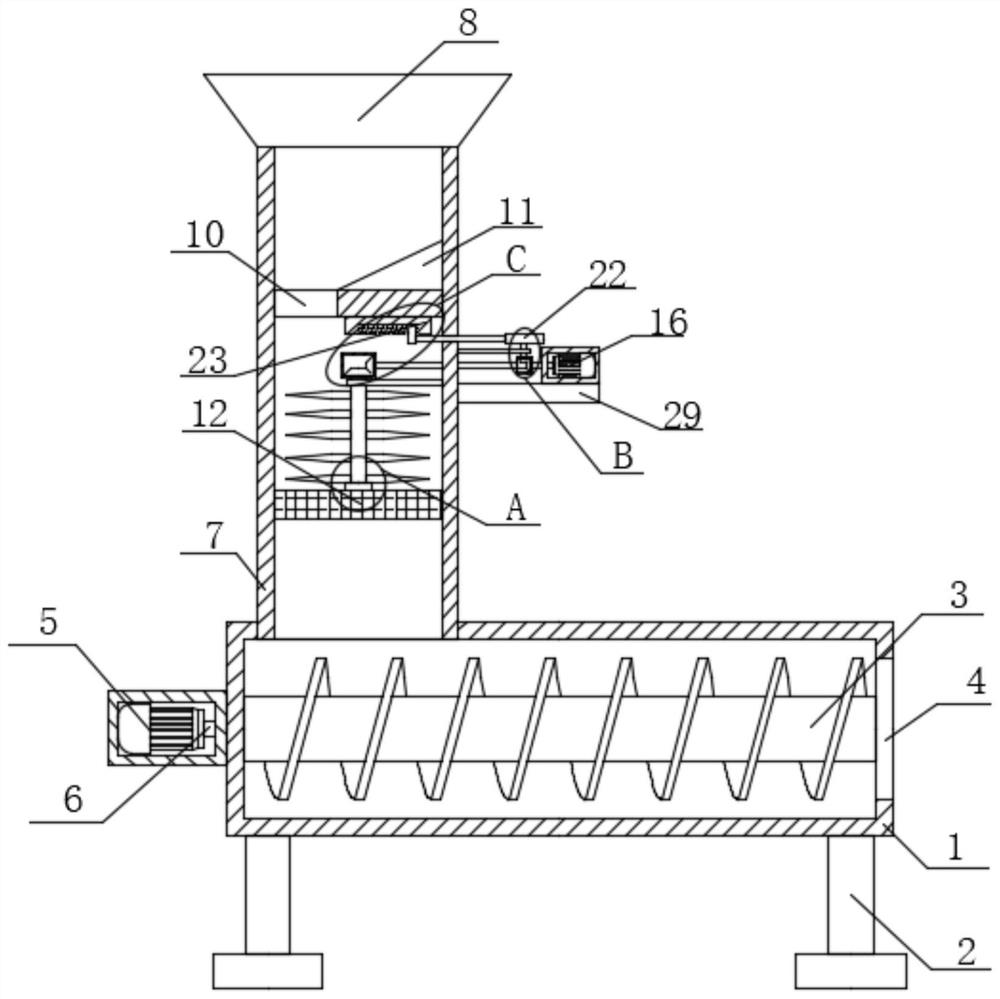

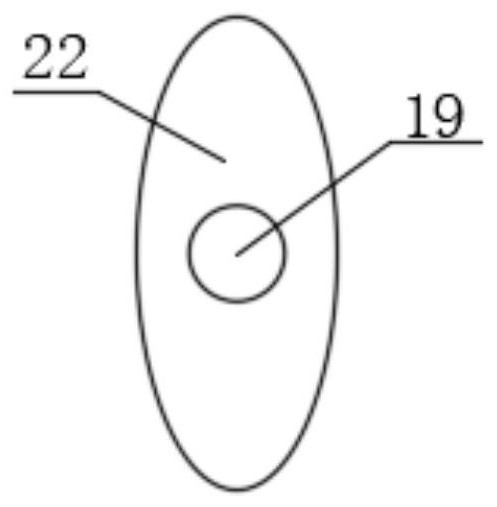

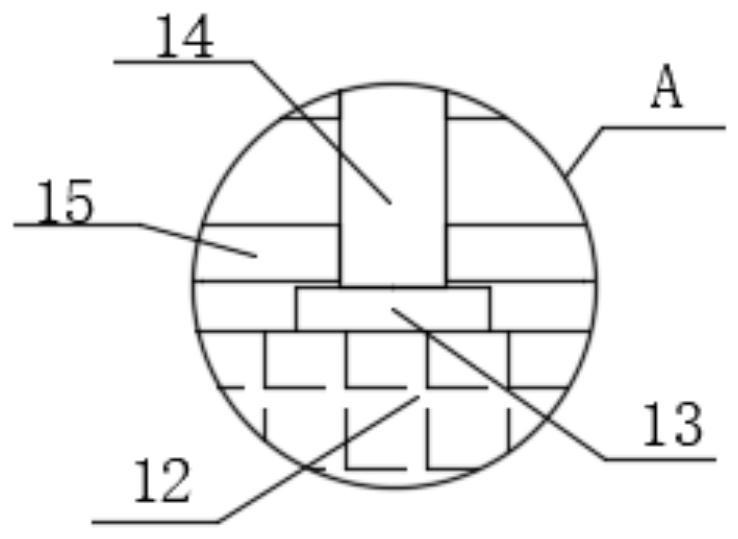

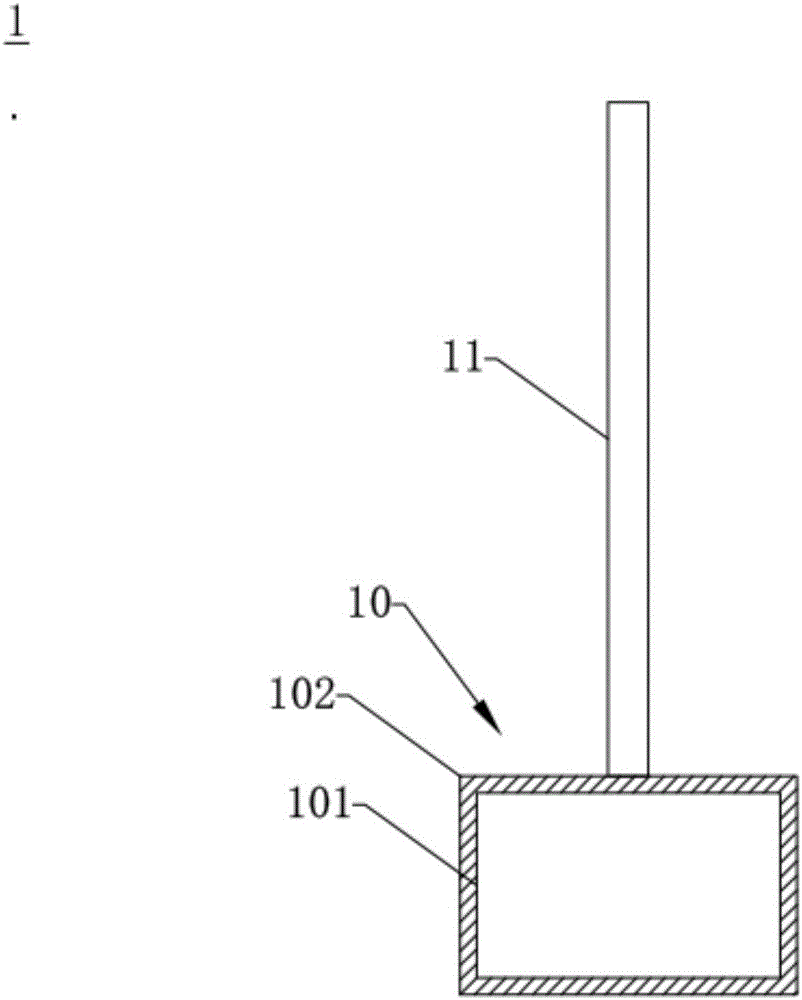

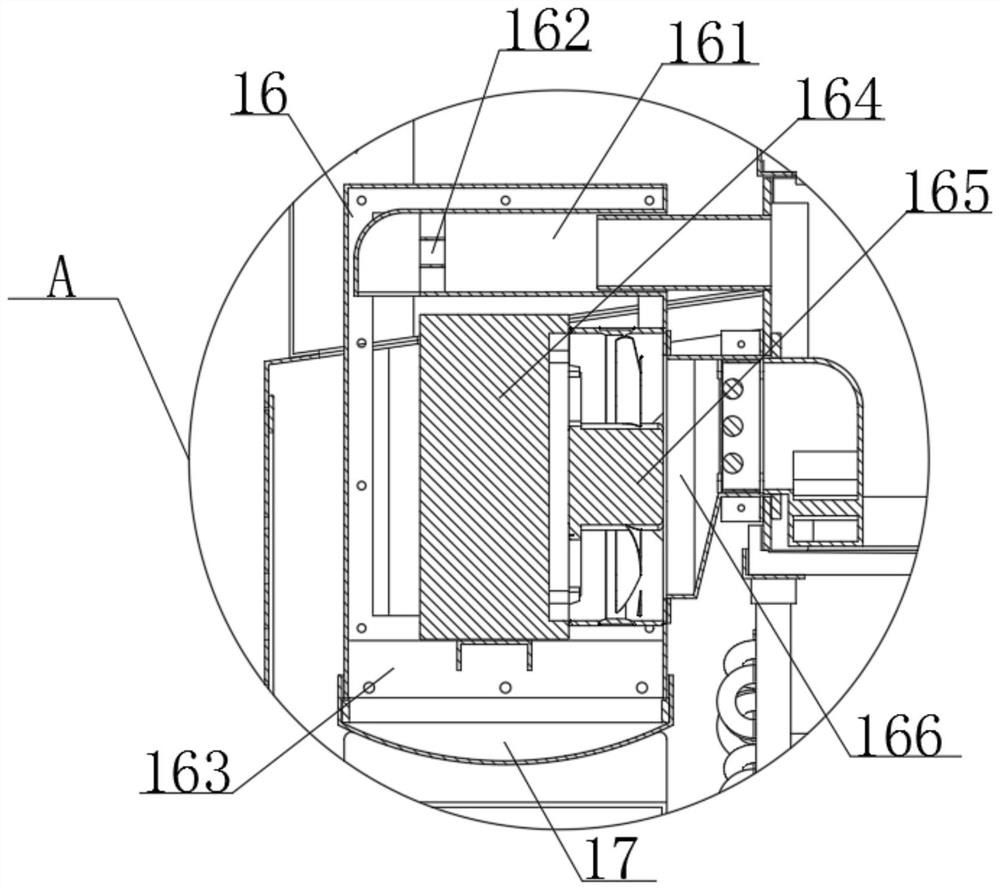

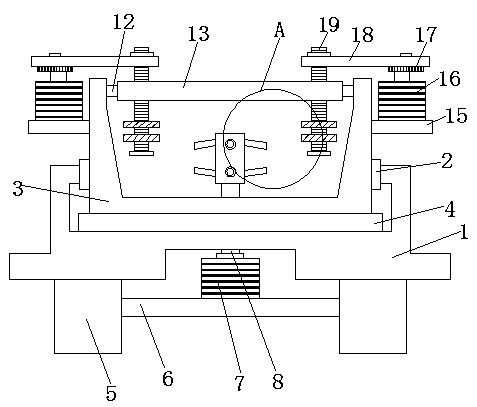

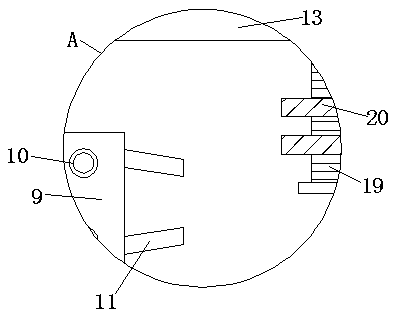

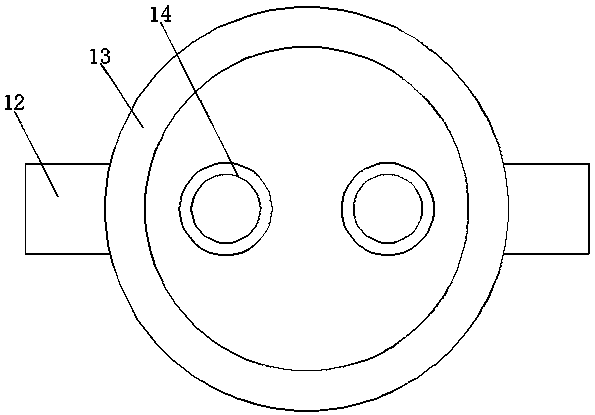

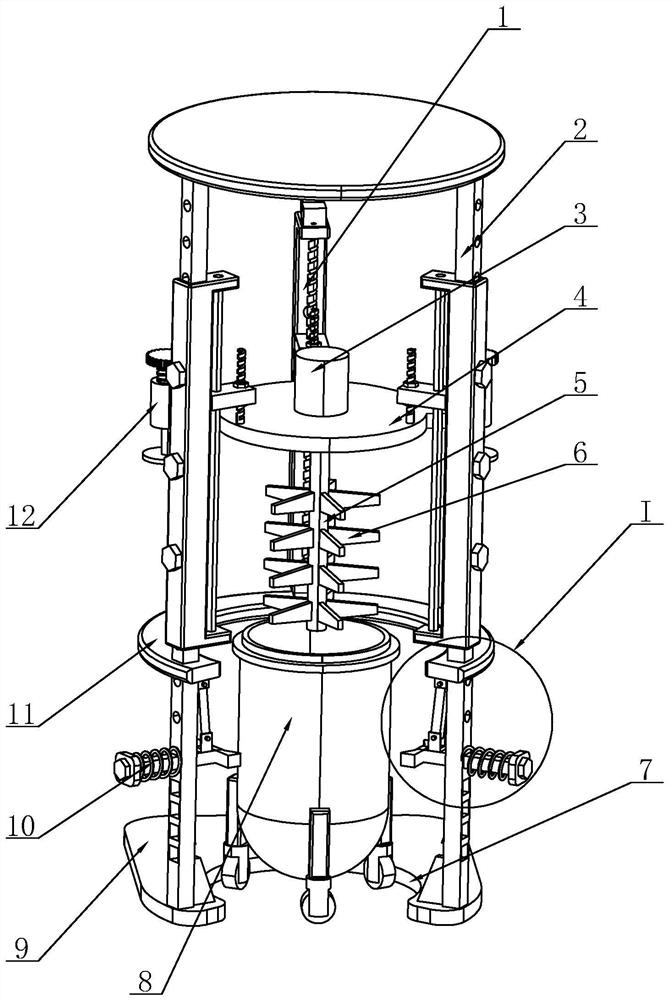

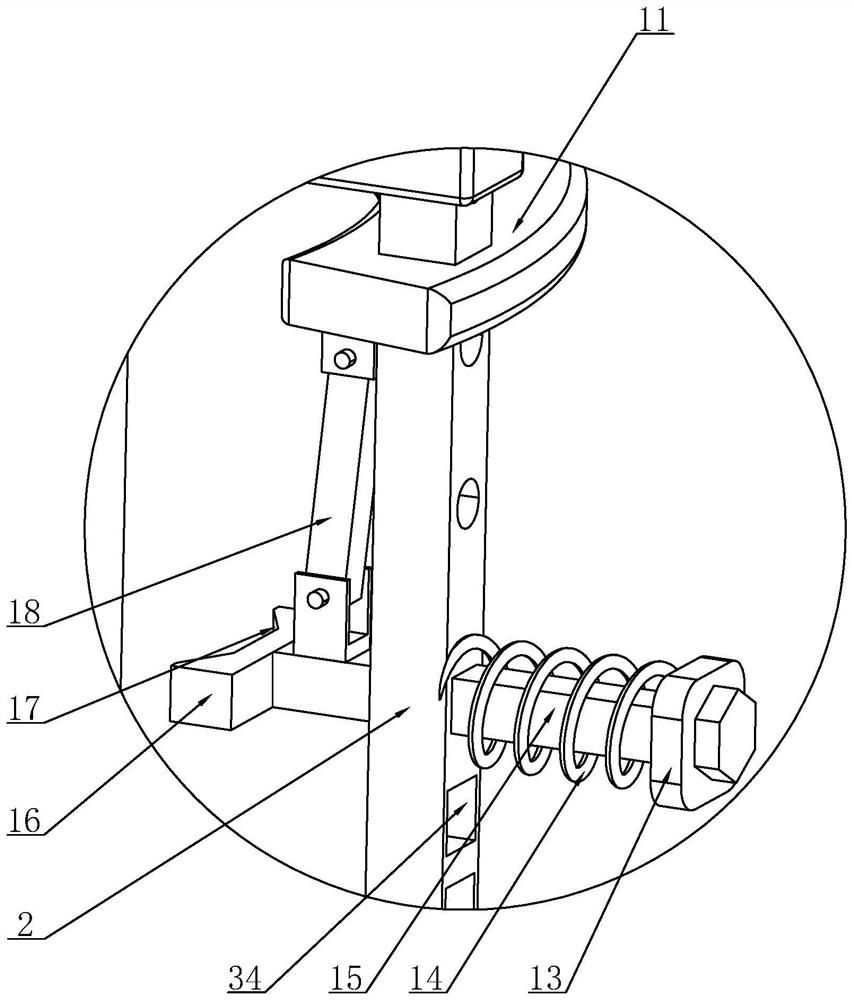

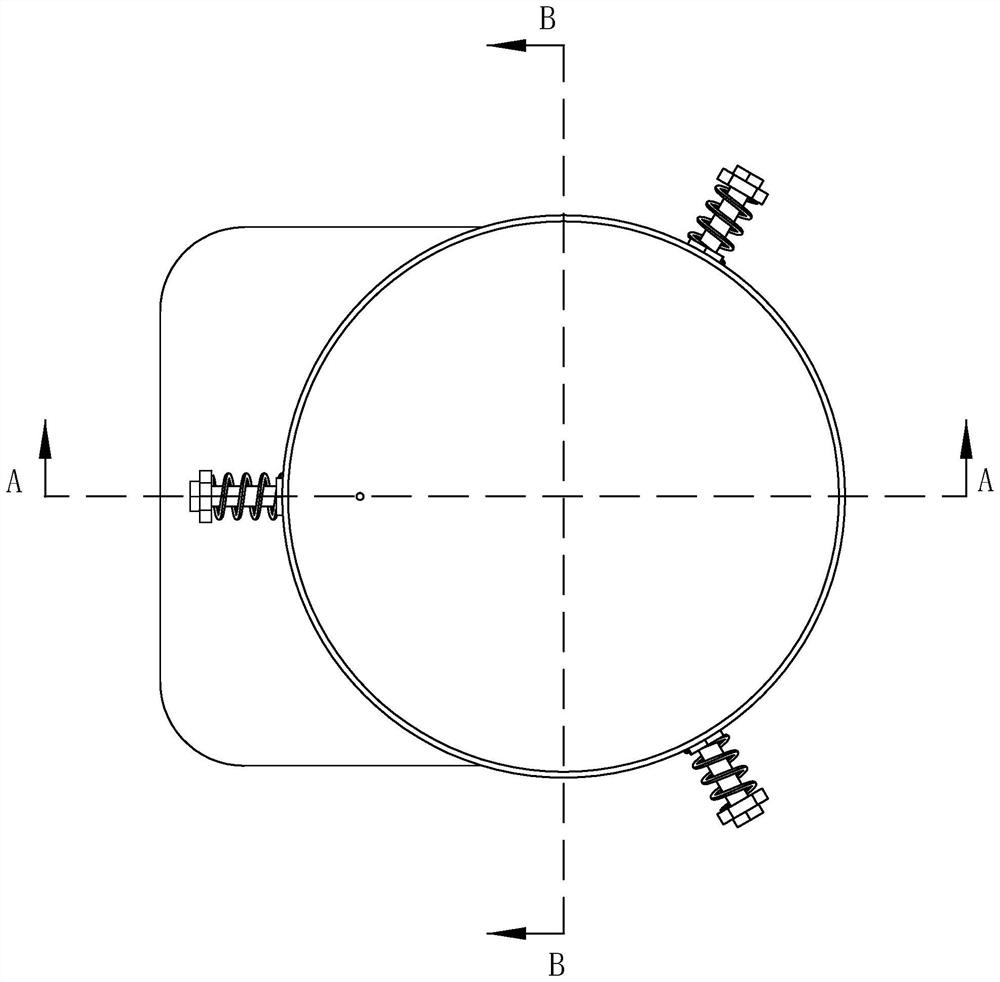

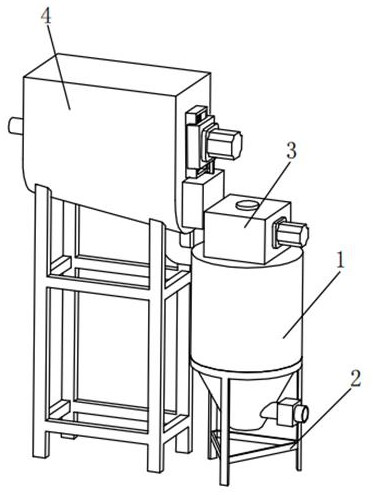

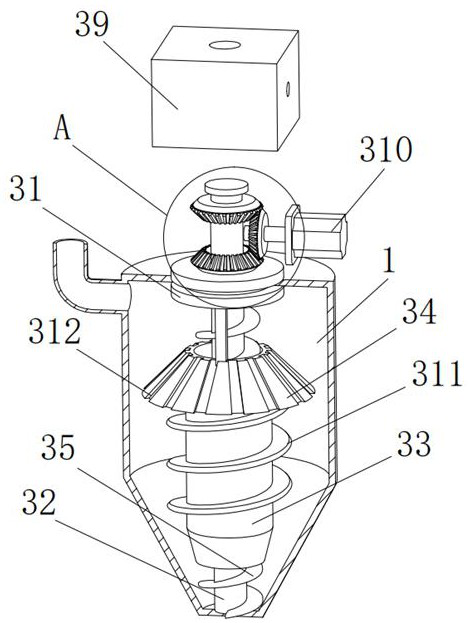

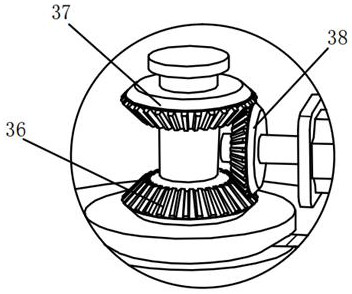

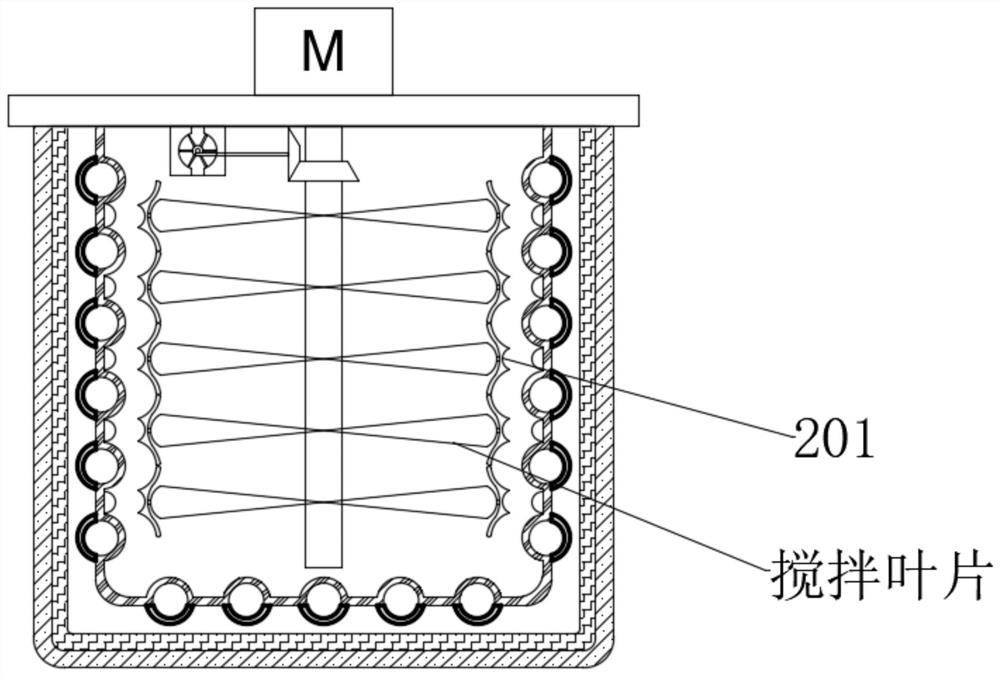

Chemical mixing device capable of stirring in continuous variable-diameter mode

InactiveCN107088376AAvoid affecting the mixing effectImprove stirring efficiencyRotary stirring mixersTransportation and packagingEngineeringDrive motor

The invention discloses a chemical mixing device capable of stirring in a continuous variable-diameter mode. The chemical mixing device comprises a bottom plate, a vertical plate, a top plate and a stirring barrel, wherein a support is arranged at the upper end of the top plate, a horizontal shaft is arranged on the support, further the horizontal shaft is movably connected with the support, one end of the horizontal shaft is connected with a driving motor arranged on the support, a vertically downward rotating shaft is in rotary connection with the top plate, the top end of the rotating shaft is connected with one end of the horizontal shaft through a gear mechanism, a vertical rod is vertically arranged in the stirring barrel, a rotary sleeve is arranged on the outer side of the vertical rod, the lower end of the rotating shaft is connected with the top end of the rotary sleeve through a transmission mechanism, at least two stirring assemblies are arranged on the rotary sleeve, the horizontal shaft is further provided with a cam, and the cam is connected with the vertical rod through a slide mechanism. The chemical mixing device disclosed by the invention is simple in structure, can stir in the continuous variable-diameter mode and has higher stirring efficiency and better stirring effect, and the stirring barrel can be cleaned.

Owner:侯小芳

Water-based printing ink preparation method

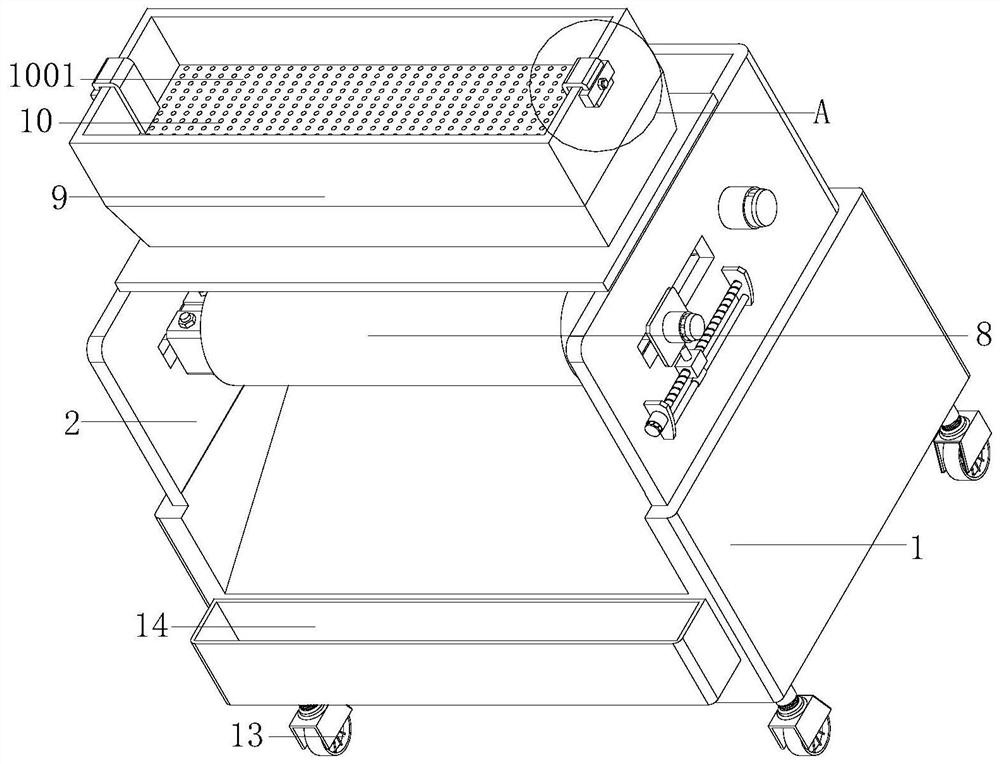

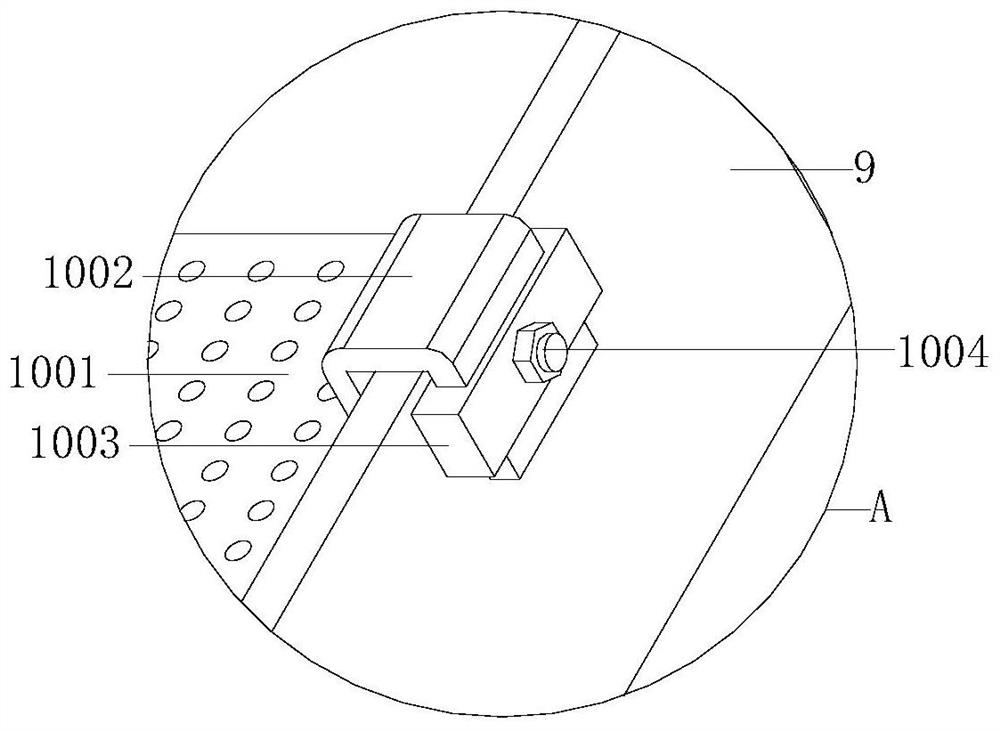

InactiveCN113134423AFine ink raw materialsEasy to stir and mixSievingScreeningPrinting inkGrinding mill

The invention relates to a water-based printing ink preparation method. A water-based printing ink preparation device is used. The water-based printing ink preparation device comprises a preparation box, a grinding mechanism, a screening mechanism, a scraping mechanism and a collecting box, the preparation box is of a rectangular structure, the grinding mechanism, the screening mechanism and the collecting box are sequentially arranged on the inner wall of the preparation box from top to bottom, and the scraping mechanism is arranged on the grinding mechanism. According to the method, the grinding mechanism can conduct double grinding on ink raw materials, so that the ground ink raw materials are finer, mixing and stirring of the ink raw materials are facilitated, the mixing stirring effect behind the ink raw materials is prevented from being influenced due to the fact that the grinding of the ink raw materials is not fine, meanwhile, the ink raw materials adhered to a first grinding roller and a second grinding roller on the grinding mechanism are scraped off by adopting the scraping mechanism, so that the adhered raw materials are prevented from influencing the grinding of a grinding roller, and therefore, the grinding effect of the grinding roller is not good.

Owner:有限会社林平

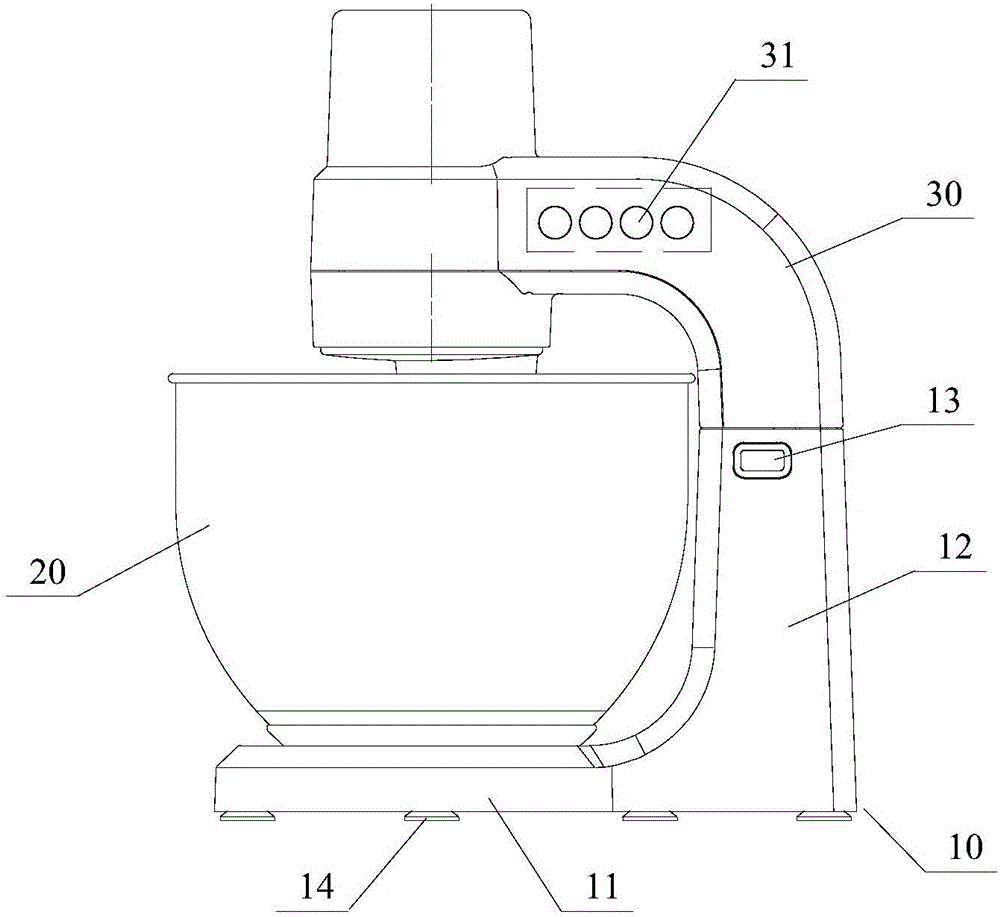

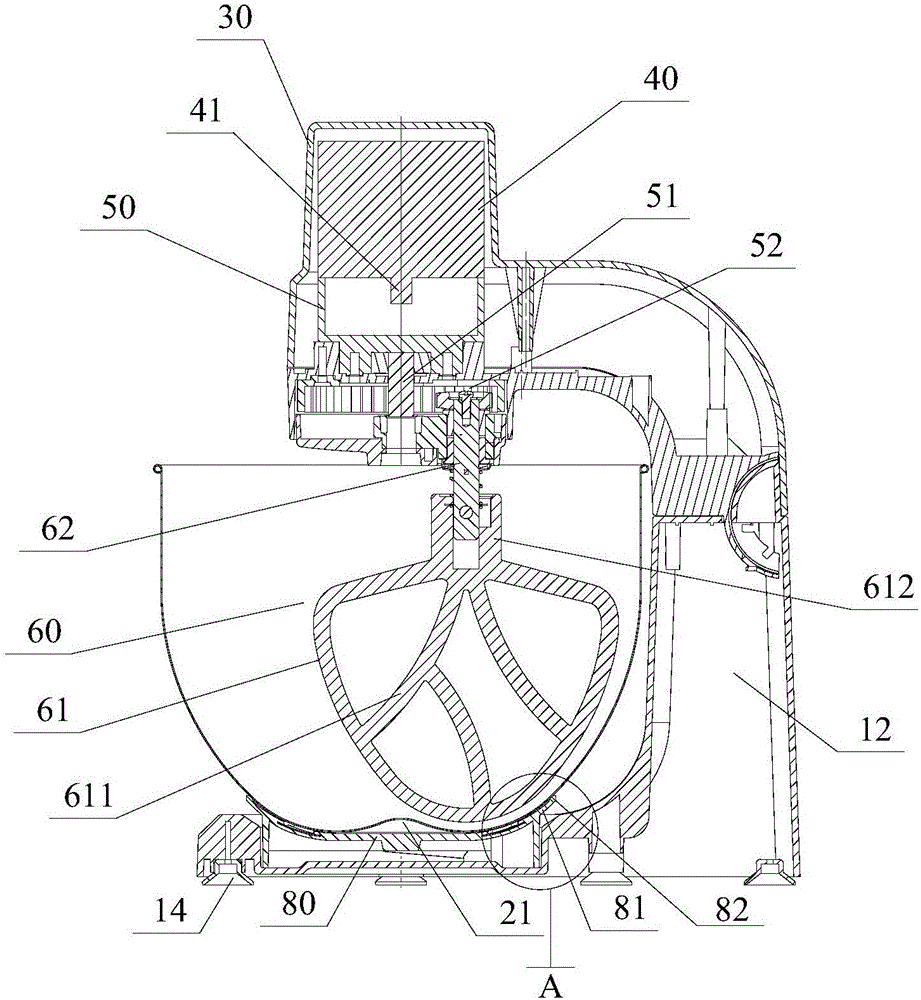

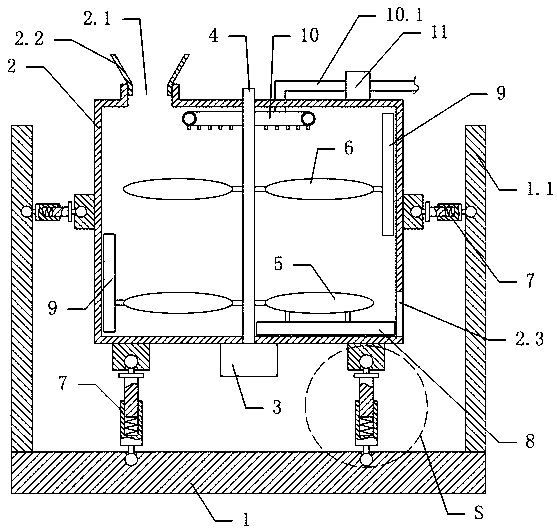

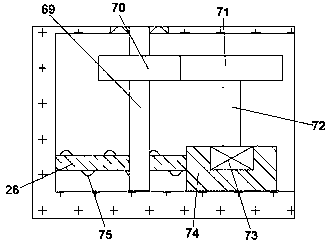

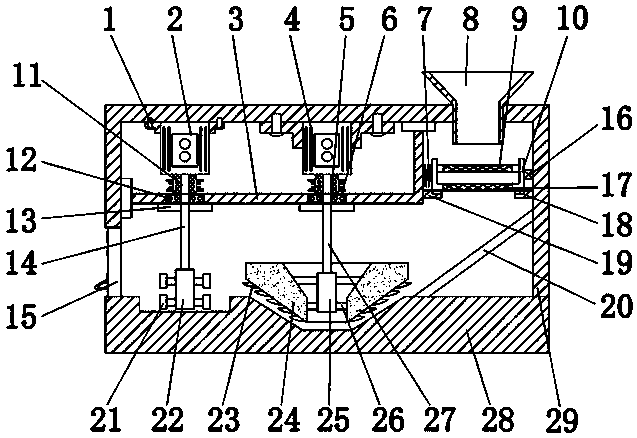

Vertical agitator

InactiveCN105832194AReduce in quantityReduce assembly errorsKitchen equipmentGear wheelReduction drive

The invention discloses a vertical agitator, which comprises a machine base which is composed of a base and a machine head, wherein a driving mechanism, which is used for driving an agitating component, is arranged in the machine head; the driving mechanism comprises a DC (direct current) motor which is arranged in a perpendicular mode, and a planetary gear reducer; the axle of a sun gear of the planetary gear reducer is connected to an output shaft of the DC motor, and one of planet gears of the planetary gear reducer is connected to the agitating component; and the output shaft of the DC motor and the axle of the sun gear are coaxially arranged with the center of an agitating bowl which is arranged on the base when used. The vertical agitator disclosed by the invention, with the adoption of the DC motor, is low in noise, low in energy consumption and high in torque; since the DC motor is arranged in the center of the agitating bowl in a perpendicular mode and power is directly outputted to the agitating component by virtue of the planetary gear reducer, the vertical agitator is short in transmission distance and compact in structure, and the overall dimensions of a finished product are greatly diminished; and by virtue of the planetary gear reducer, the number of product parts and assembling errors are reduced, and the service life of the finished product is prolonged.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

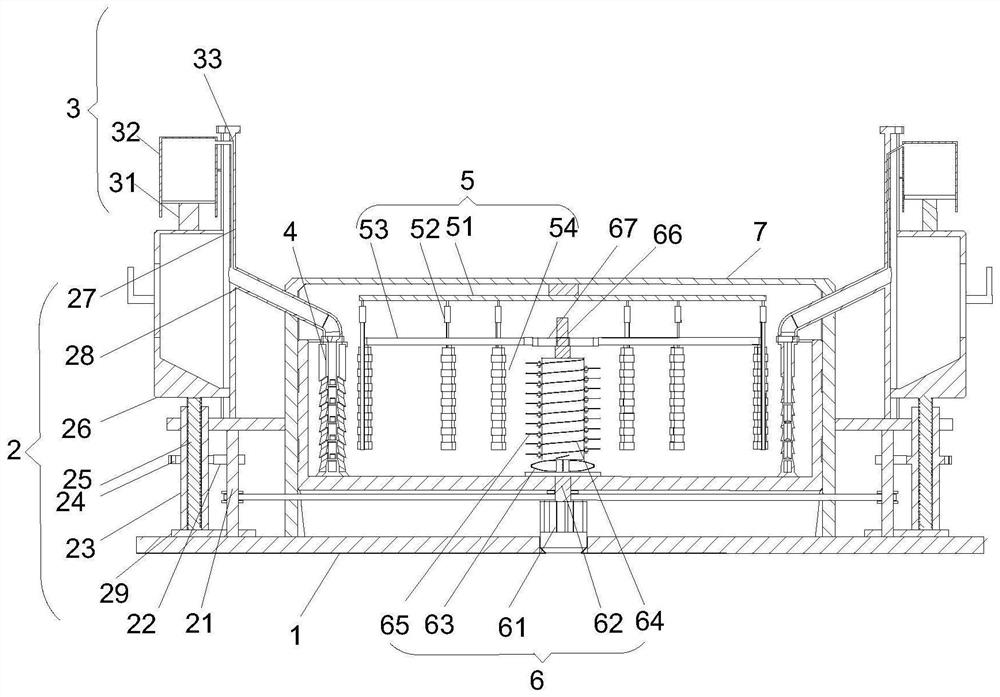

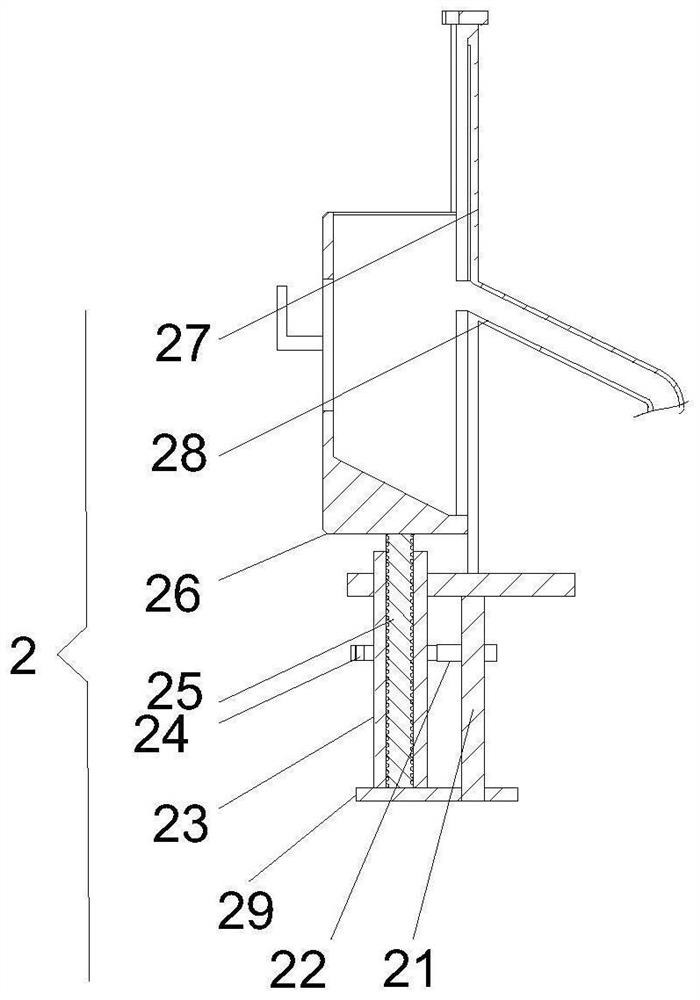

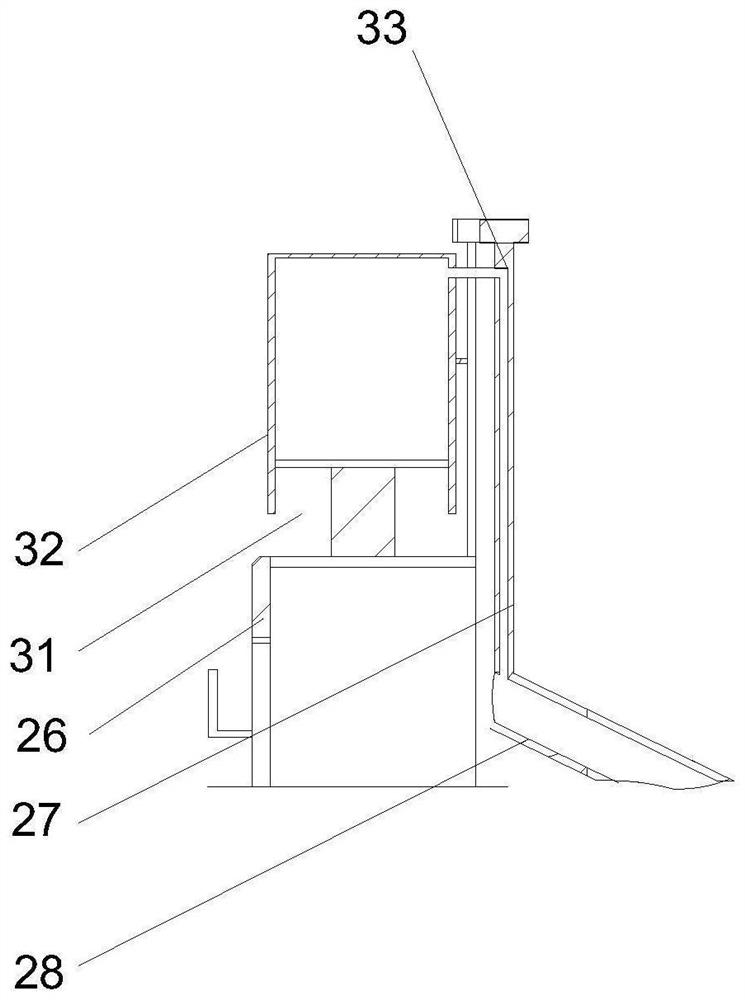

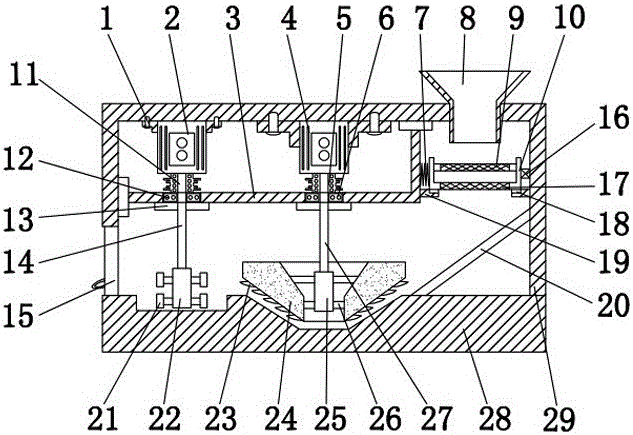

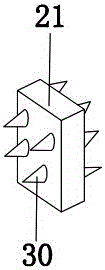

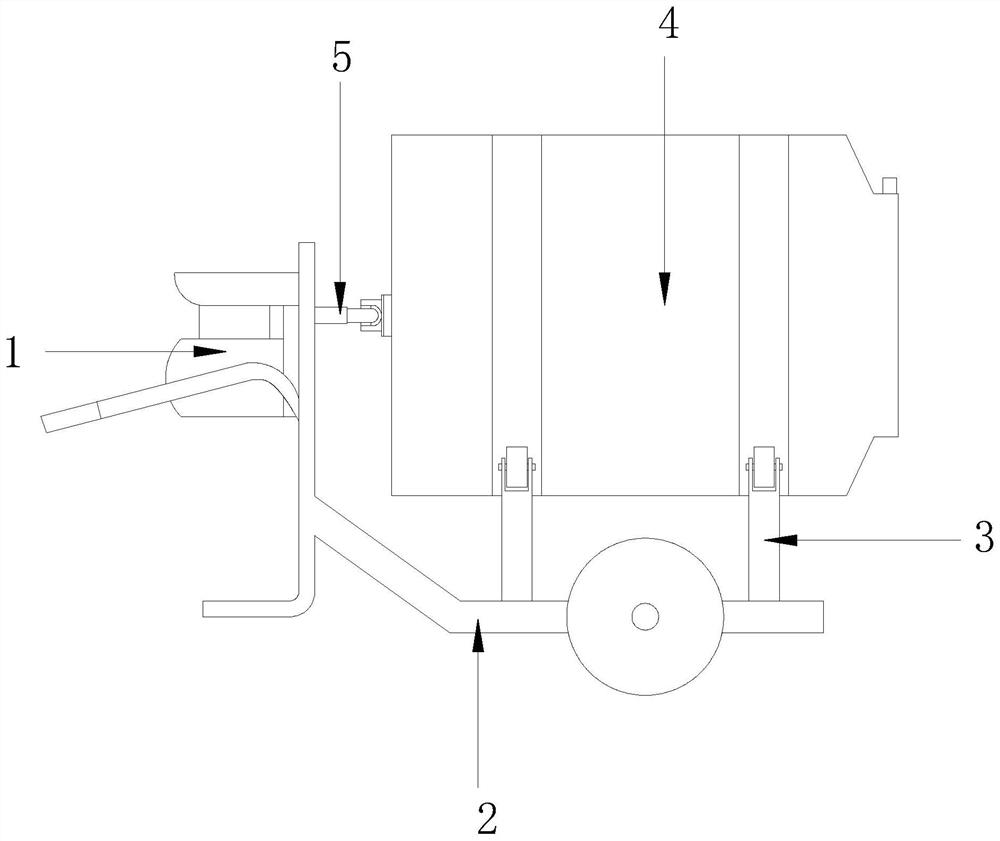

Mixing equipment for concrete production

InactiveCN111844436AAvoid affecting the mixing effectReduce loadDischarging apparatusCleaning using toolsElectric machineryStructural engineering

The invention relates to mixing equipment for concrete production. The mixing equipment for concrete production comprises a main body, a first motor, a first bearing, a stirring shaft, two stirring plates and two supporting blocks, and further comprises a cleaning mechanism and two vibrating mechanisms. The cleaning mechanism comprises a scraping plate, fixed plates, springs, a connecting block, aconnecting plate, two cleaning assemblies, two lifting assemblies and two driving assemblies. Each cleaning assembly comprises a cleaning plate and a hinge bar. Each vibrating mechanism comprises a transmission assembly, a rotary shaft, a second bearing, an eccentric wheel, a knocking plate and a plurality of elastic ropes. The mixing equipment for concrete production can clean the inner wall ofthe main body through the cleaning mechanism, prevents much concrete from solidifying on the inner wall of the main body and reducing the volume of the main body, thereby having no influence on the stirring effect. The mixing equipment achieves the function of knocking a discharge pipe through the vibrating mechanisms, vibrates concrete by vibrating the discharge pipe, thereby increasing the speedof the concrete passing through the discharge pipe, improving the discharge efficiency and reducing the blockage probability of the discharge pipe.

Owner:王小娟

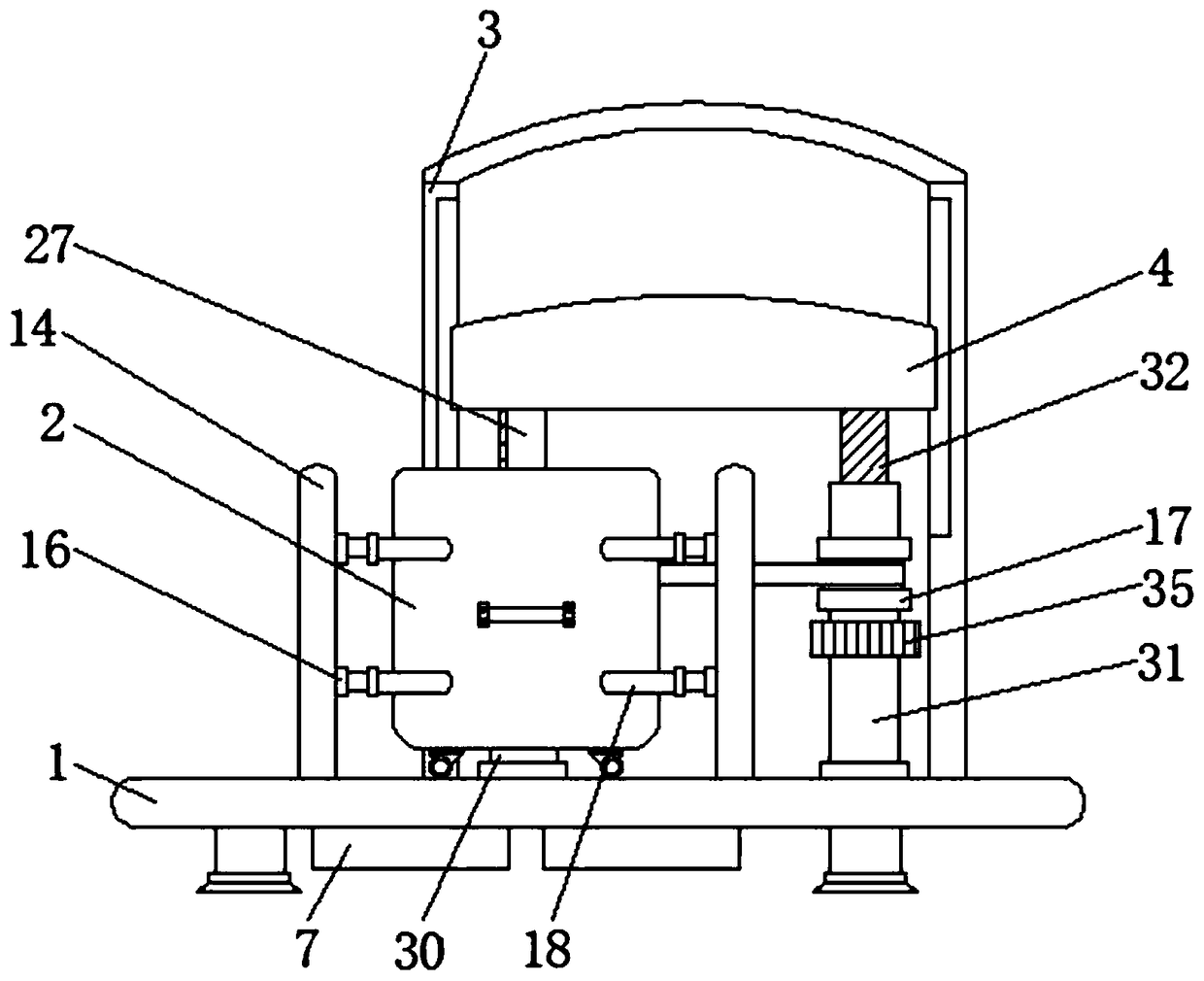

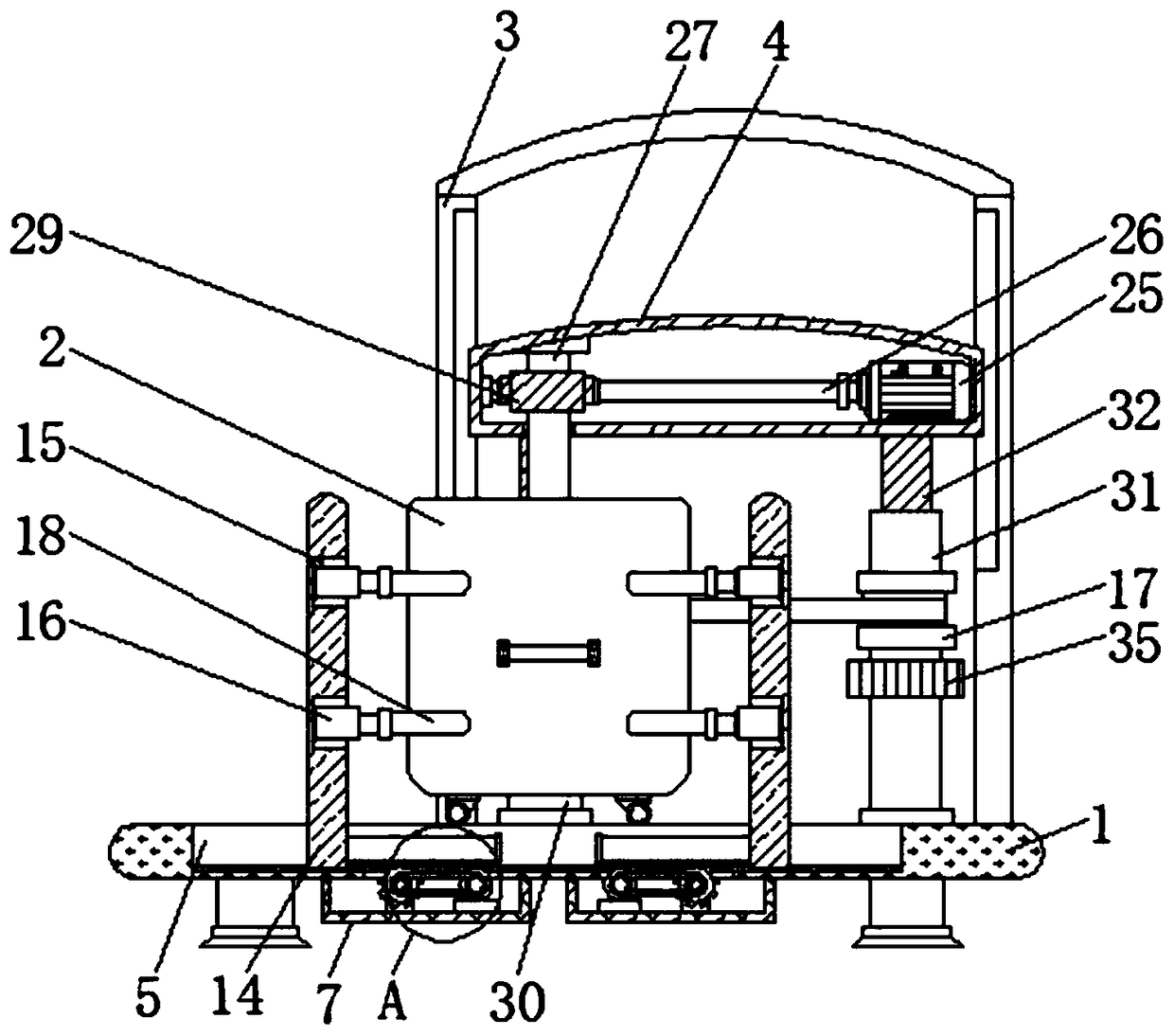

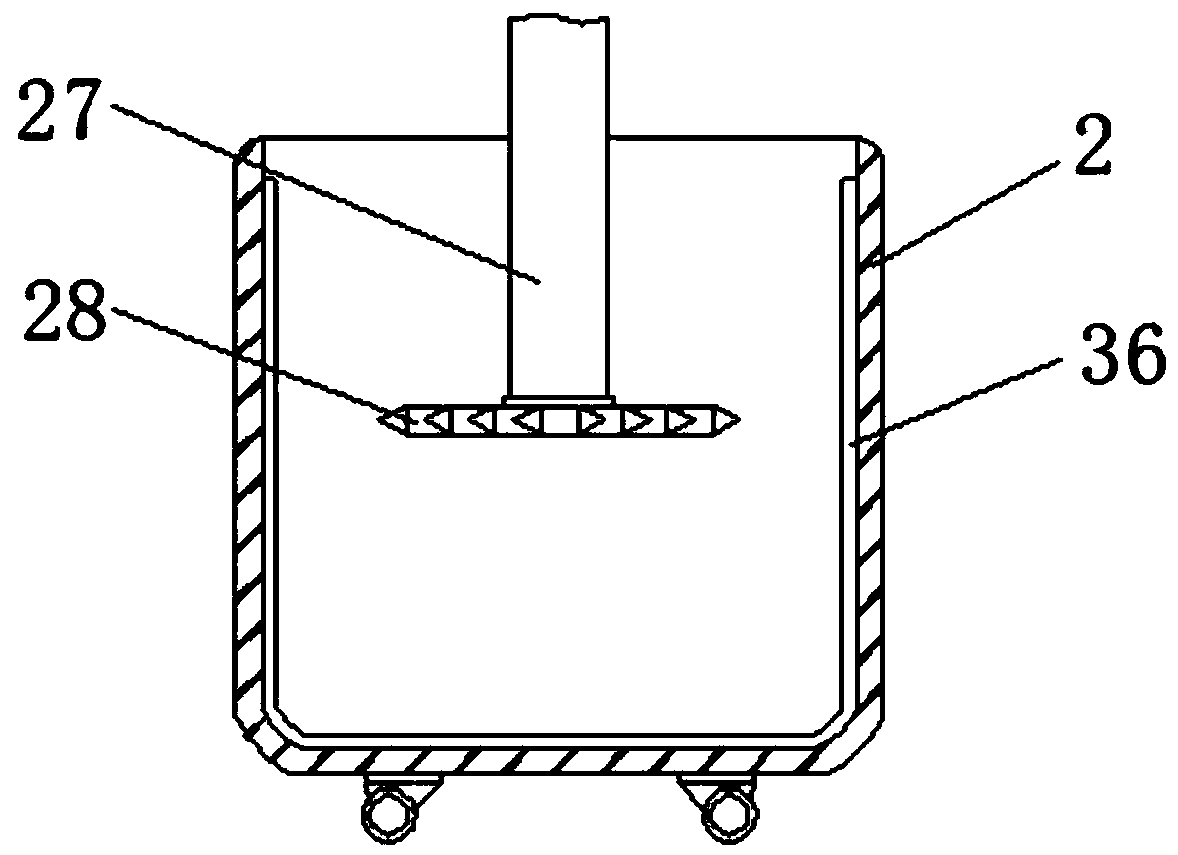

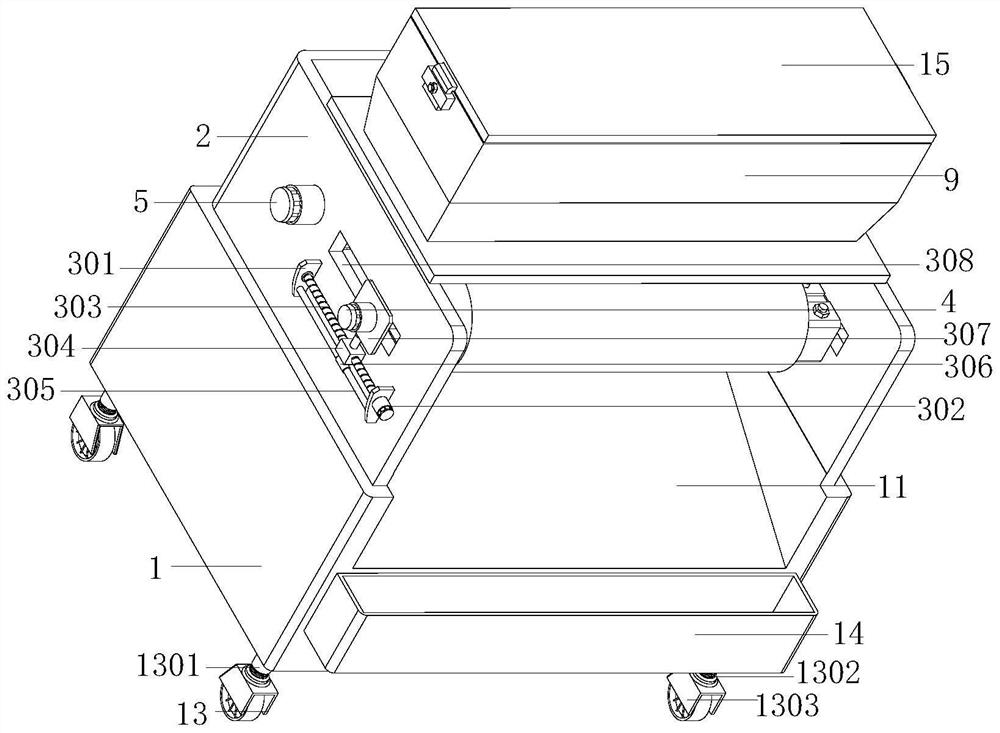

Positioning device for paint high speed dispersing machine

PendingCN109126615AAvoid wastingAvoid affecting the discharge workRotary stirring mixersTransportation and packagingFixed framePulp and paper industry

The invention discloses a positioning device for a paint high speed dispersing machine. The positioning device for the paint high speed dispersing machine comprises a bottom plate and a stirring bucket; an anti-sticking layer is fixedly connected to the internal wall of the stirring bucket; supporting frames are fixedly connected to the two sides of the top of the bottom plate; a rectangular box is slidingly connected between one opposite sides of the two supporting frames; a fixing groove is formed in the top of the bottom plate; fixing frames are fixedly connected to the two sides of the bottom of the bottom plate; first motors are fixedly connected to one sides of the bottoms of the internal walls of the fixing frames through connecting blocks; and first belt wheels are fixedly connected to one ends of output shafts of the first motors. The invention relates to the technical field of paint production equipment. The positioning device for the paint high speed dispersing machine, disclosed by the invention, has the advantages that the stirring bucket can be effectively positioned while paint is mixed and dispersed to prevent the stirring bucket from moving to affect the stirring effect of the stirring bucket during the high-speed rotation of a dispersing disc; and meanwhile, the positioning device can automatically adjust the size of the stirring bucket, so that the practicability of the positioning device is enhanced.

Owner:湖北三雷德化工有限公司

Cement mixer

InactiveCN107756639APrevent affecting the subsequent stirring effectAvoid affecting the mixing effectCement mixing apparatusEngineeringAbsorption effect

The invention provides a cement mixer which comprises a base, a mixing drum, a motor, a rotation shaft, upper mixing blades and lower mixing blades. A feeding port and a feeding hopper are formed in the top of the mixing drum, and a discharging port and a sealing door are arranged at the root of the side wall of the mixing drum. A plurality of shock absorbers are connected between the bottom of the mixing drum and the base, and the two ends of each shock absorber are connected with the mixing drum and the base through spherical pairs. A plurality of stand columns are uniformly arranged on thebase along the circumferential direction of the mixing drum, a shock absorber is connected between each stand column and the side wall of the mixing drum, and the two ends of the shock absorber is connected with the mixing drum and the stand column through the spherical pairs. Two lower mixing blades are arranged, and the lower mixing blades are fixed to the lower part of the rotation shaft. The lower side of one lower mixing blade is connected with a lower scraper, and a vertical scraper is arranged at the end part of the other lower mixing blade. Two upper mixing blades are arranged, the upper mixing blades can move up and down along the rotation shaft, and a vertical scraper is arranged at the end part of one upper mixing blade. The cement mixer can prevent materials from remaining on the inner wall of the stirring drum, has a good shock absorption effect, and cannot generate the phenomenon that the mixing blades are idle.

Owner:FOSHAN GAOMING YANGHE METAL MATERIAL PROFESSIONALTOWN TECH INNOVATION CENT

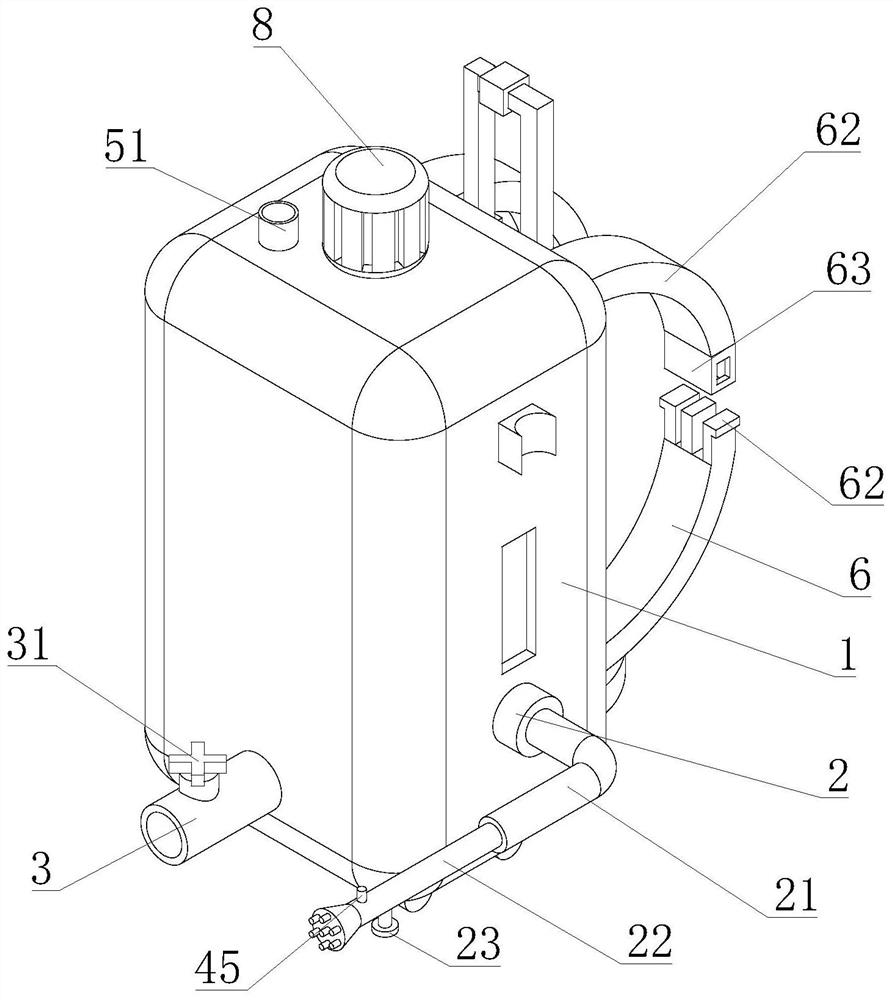

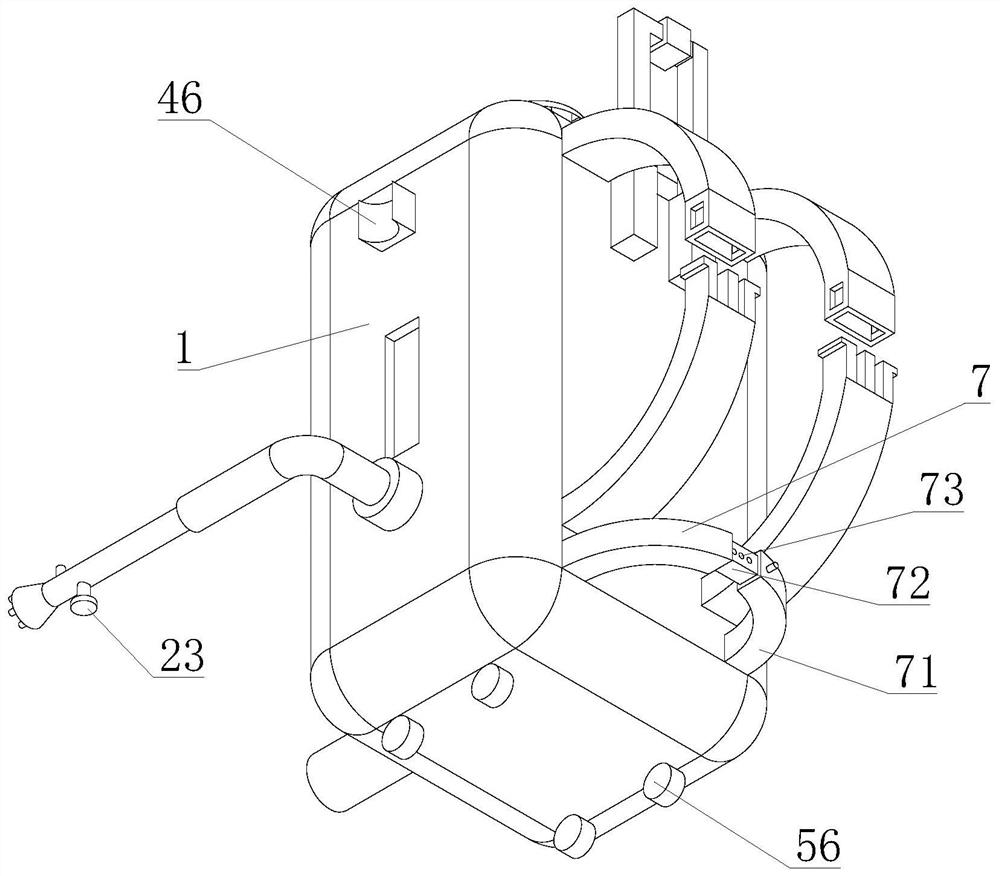

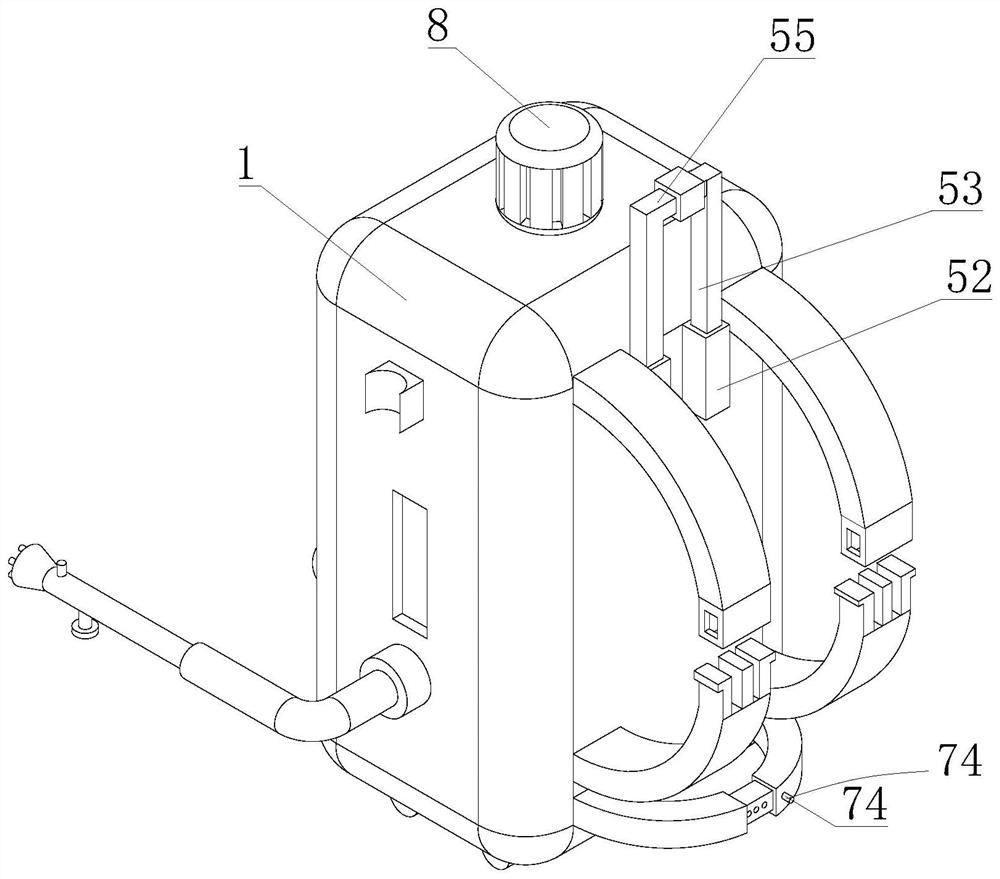

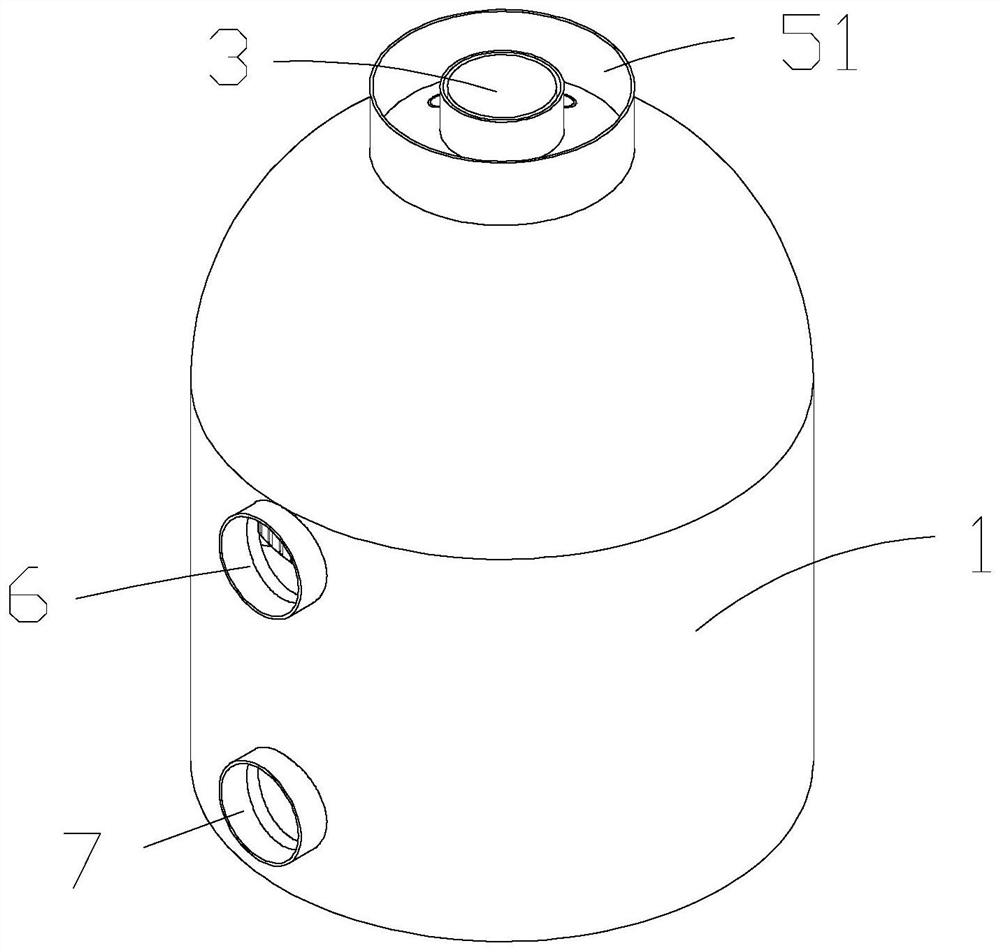

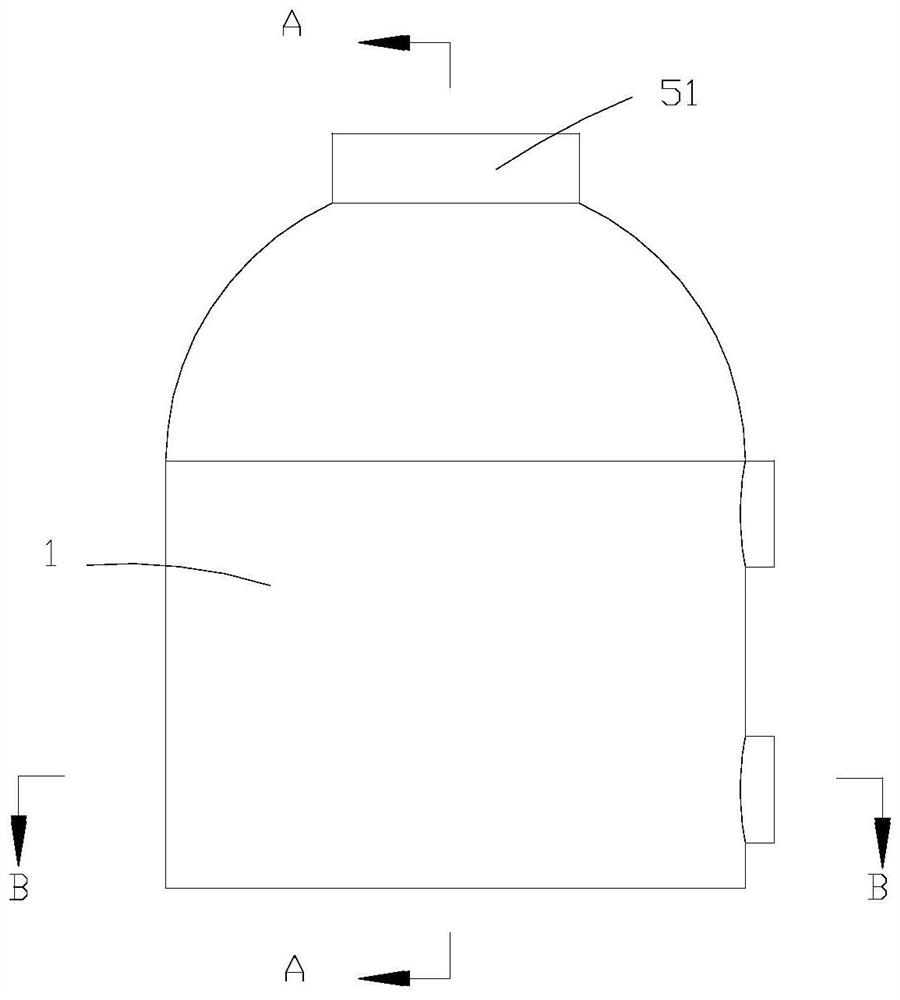

Detection equipment for rare earth hydroxide during washing

ActiveCN112657456AEasy to stir and mix workAvoid affecting the mixing effectRotary stirring mixersPreparing sample for investigationPhysical chemistryChemical engineering

The invention relates to detection equipment, in particular to detection equipment for rare earth hydroxide during washing. The technical problem to be solved is to provide the rare earth hydroxide washing time detection equipment which can uniformly mix mined rare earth and then neutralize the mined rare earth according to conditions. Rare earth hydroxide washing detection equipment comprises: a support, wherein a mixing mechanism is arranged at the top of the support; and an inspection mechanism which is arranged on the inspection mechanism and the mixing mechanism. By arranging the mixing mechanism, rare earth to be detected can be conveniently stirred and mixed; and the acid-base value of the rare earth can be detected through the arranged inspection mechanism, and then the neutralizer is added according to the acid-base value to be stirred again until the acid-base value of the rare earth is qualified and available.

Owner:FUJIAN ZIJIN MINING & METALLURGY TESTING TECH

High-safety pesticide spraying equipment for preventing and treating forest diseases and insect pests

InactiveCN112314576AAvoid shockAffect qualityTransportation and packagingRotary stirring mixersAnimal scienceEngineering

The invention discloses high-safety pesticide spraying equipment for preventing and treating forest diseases and insect pests, and relates to the technical field of pesticide spraying equipment. The equipment comprises a medicine storage box, a medicine inlet pipe and a driving motor are fixedly connected to the upper surface of the medicine storage box, a connecting rod is rotatably connected tothe output end of the driving motor, the output end of the driving motor penetrates through the upper surface of the medicine storage box, a plurality of rotating rods are arrayed on the peripheral side face of the connecting rod, and the ends of the rotating rods are fixedly connected with stirring blades. One side face of the medicine storage box is fixedly connected with a main strap and an auxiliary strap, one end of the main strap is fixedly connected with a buckle, and one end of the auxiliary strap is fixedly connected with a connecting strap. By arranging the driving motor, the drivingmotor rotates to drive the connecting rod and the stirring blades to rotate, pesticides can be fully stirred in water, the situation that the quality of the pesticide is affected due to uneven stirring is prevented, by arranging a clamping groove and the buckle, the buckle can be clamped in the clamping groove, and the main strap can be fixed to the auxiliary strap. The main strap and the auxiliary strap are matched with each other and are completely fixed on the back of a user.

Owner:宣晓永

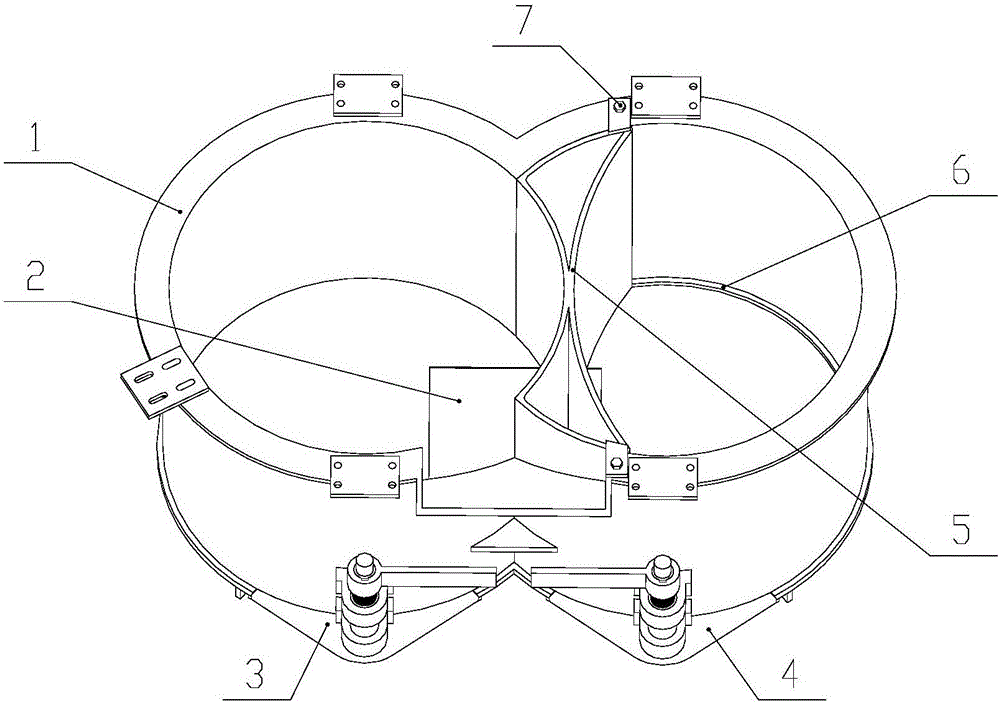

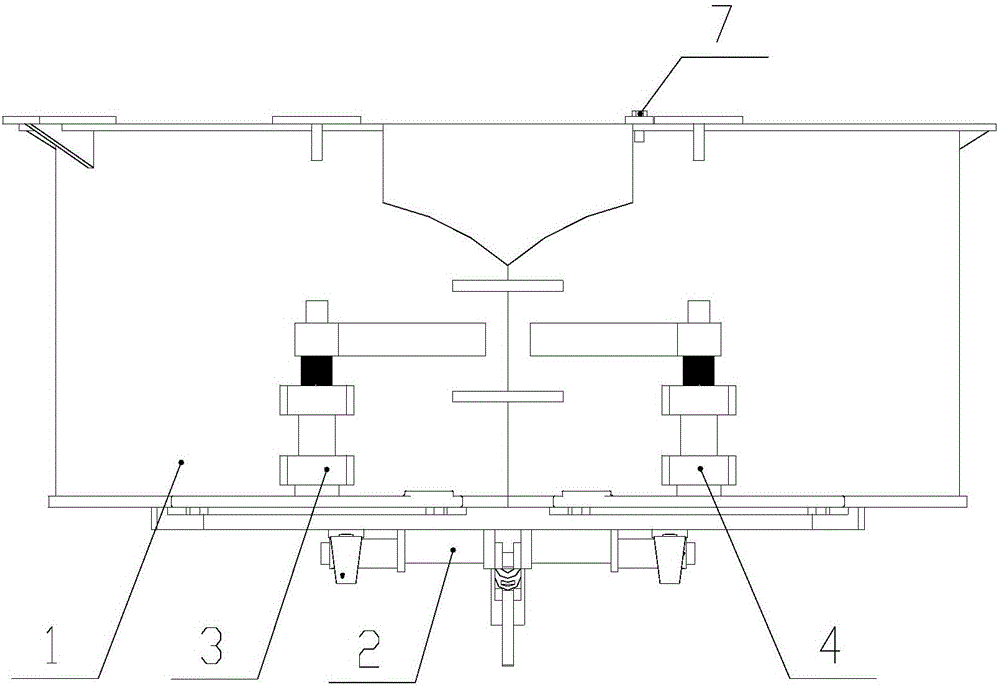

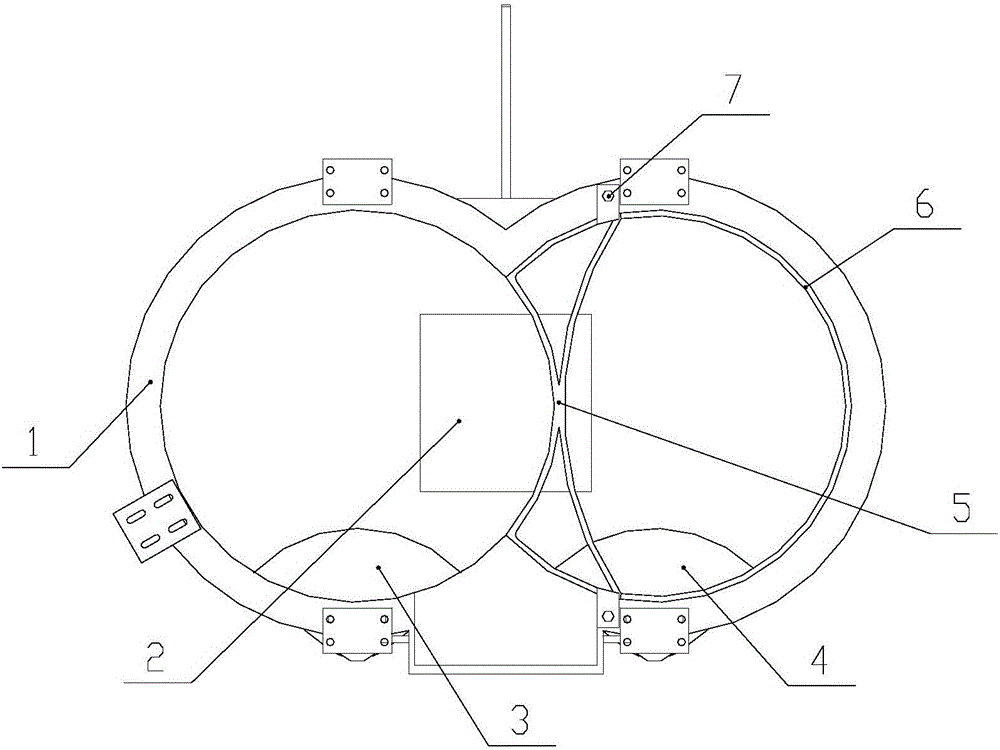

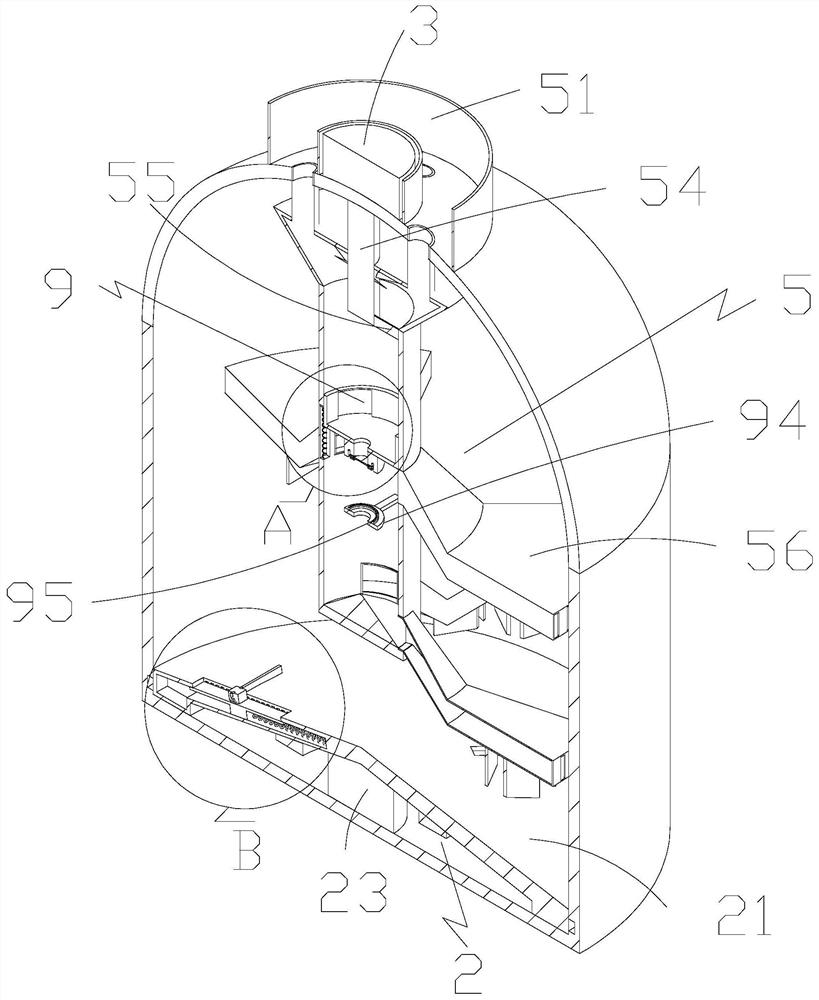

Vertical variable-volume mixing barrel

InactiveCN106738330AChange the effective working volumeIncrease profitCement mixing apparatusEngineeringElectrical and Electronics engineering

The invention discloses a vertical variable-volume mixing barrel which comprises a double-barrel type mixing barrel body. A detachable single-barrel partition plate is arranged between two barrel bodies of the mixing barrel body. A main discharging door is arranged in the center of the bottom of the mixing barrel. A left discharging door and a right discharging door are arranged on one side of the bottom of the mixing barrel. According to the vertical variable-volume mixing barrel, the effective working volume of the mixing barrel can be changed, and switching of the double-barrel mixing condition and the single-barrel mixing condition can be achieved.

Owner:德通智能科技股份有限公司

Paint mixing, stirring and collecting device

InactiveCN111085128AWell mixedStir wellRotary stirring mixersTransportation and packagingMechanical engineeringEngineering

Owner:YUYAO FEIGE AUTOMATION TECH CO LTD

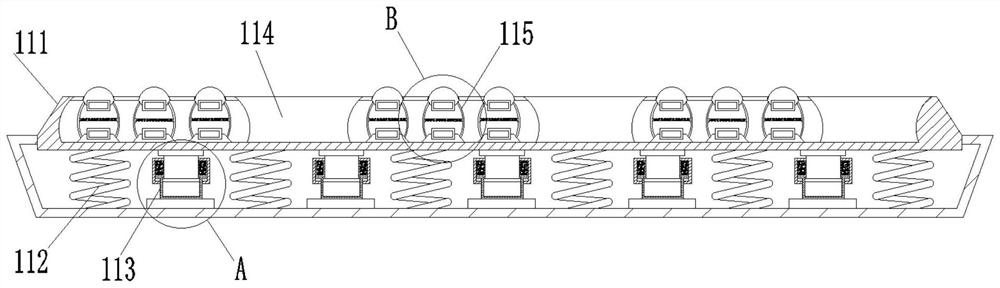

Turnover type stirring device with vibration reducing and buffering functions

InactiveCN113370390AAvoid damageSolve the problem of shock absorption and bufferingVibration dampersNon-rotating vibration suppressionElectric machineEngineering

The invention discloses a turnover type stirring device with vibration reducing and buffering functions. The turnover type stirring device comprises a stirring box, a motor, a transmission mechanism, a discharging port and a feeding port, wherein the motor is arranged on the right side of the stirring box, the transmission mechanism is arranged on the front face of the motor, the discharging port is formed in the left side of the stirring box, the feeding port is formed in the right side of the top of the stirring box, the stirring box comprises a vibration reducing base, a rotating rod, stirring blades, a turning plate and a stirring rod, the vibration reducing base is installed at the bottom of the stirring box, the rotating rod is arranged at the center position of the stirring box, and the stirring blades are fixedly connected to the outer surface of the rotating rod. According to the turnover type stirring device, through arrangement of a buffering base, a top plate can press an elastic sheet and a reset spring to be pressed and deformed due to the force generated by falling of a material after turning, then the force is absorbed and compressed through an elastic ball and then rebounded out, so that the impact force can be simply buffered, and meanwhile the material can leave the outer surface of the top plate due to the rebounded force, and the material can be prevented from being attached to the top.

Owner:曹福全

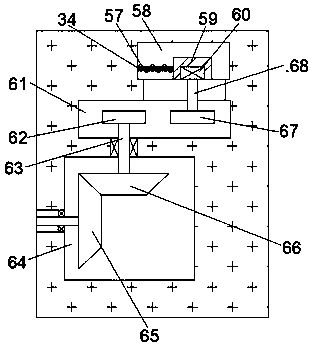

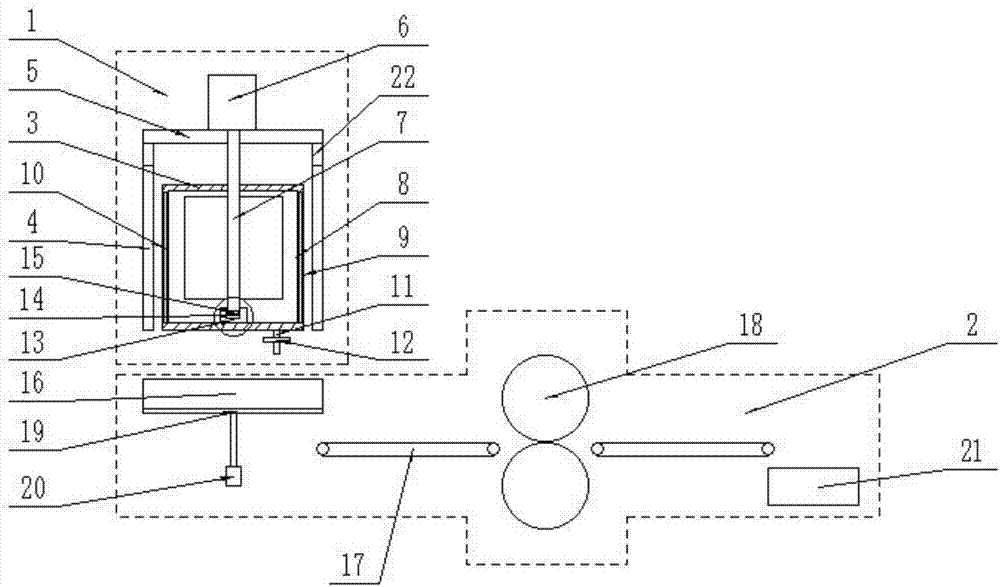

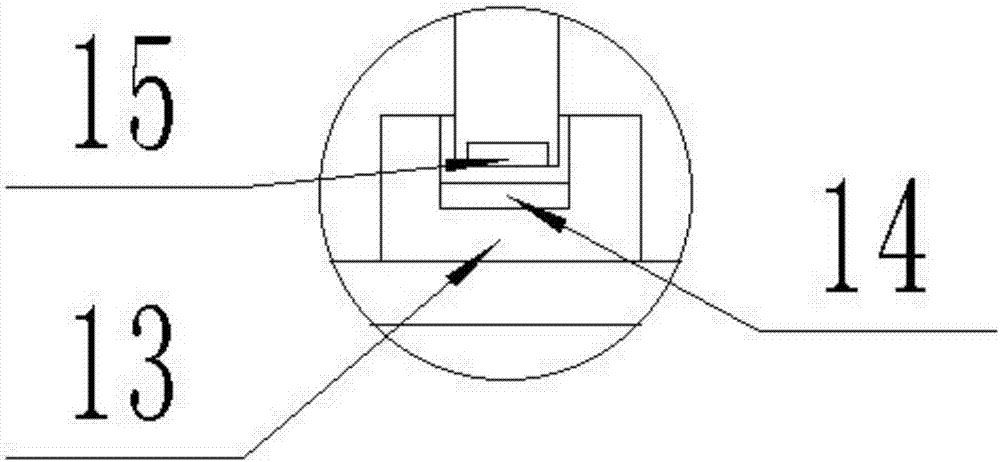

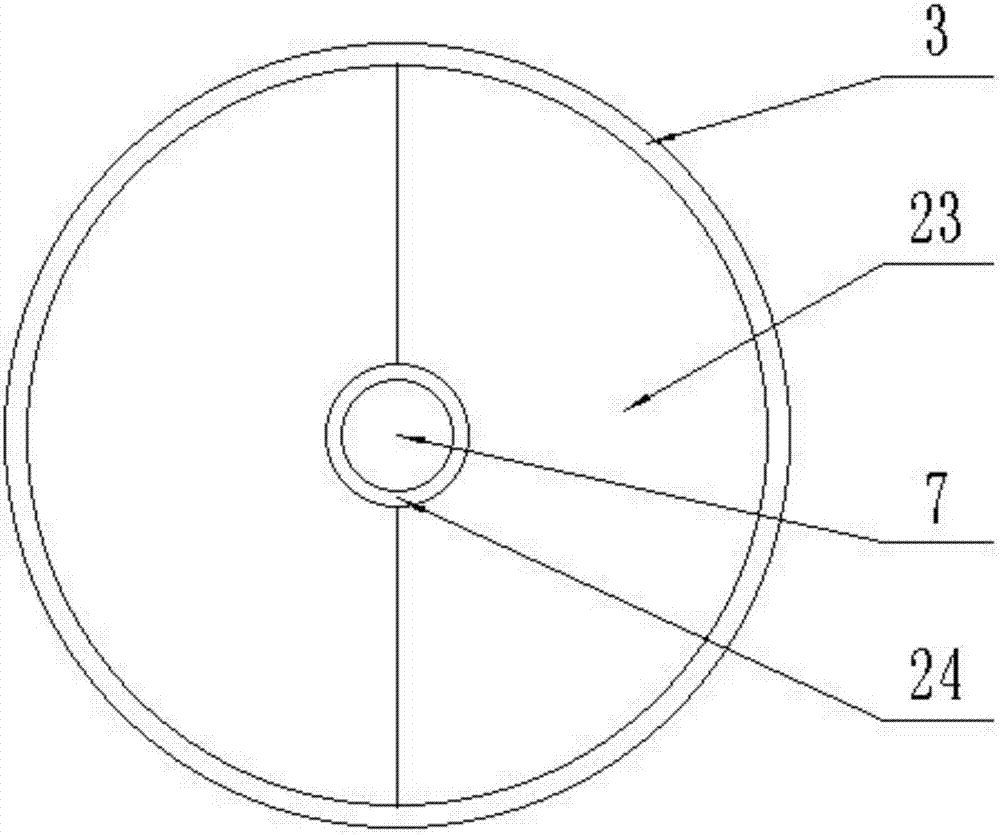

Production equipment of acidic activated nutritive chewing gum and production method of chewing gum

InactiveCN106974057AAvoid direct contactAvoid affecting the mixing effectChewing gumChewing gumMagnet

The invention discloses an acid activated nutritional chewing gum production equipment and a chewing gum production method, comprising a raw material mixing and heating device and a cooling and rolling device. The raw material mixing and heating device consists of a heating tank, four brackets arranged outside the heating tank, and a The stage at the top of the bracket, the motor arranged on the stage, and the stirrer connected to the rotating end of the motor are composed. The heating tank is provided with an inner wall and an outer wall, and an electric heating wire is arranged between the inner wall and the outer wall. The lower part of the heating tank is provided with a discharge port, the discharge port is provided with a solenoid valve, the inner bottom of the heating tank is provided with a support seat, the support seat is provided with a No. 1 magnet, and the lower end of the agitator is provided with a No. 2 magnet , the lower end of the agitator is installed in the support seat. The beneficial effect of the present invention is that it can avoid direct contact between the shaft end of the agitator and the support base, reduce wear and avoid shaking caused by wear to affect the stirring effect.

Owner:许非凡

Electric stirrer

InactiveCN107875915ADoes not affect normal usePrevent splashRotary stirring mixersTransportation and packagingElectric machineryEngineering

The invention discloses an electric stirrer which comprises a base, wherein a bracket is arranged on the base; a motor is arranged on the top of the bracket and detachably connected with a stirring shaft; the stirring shaft is connected with a stirring paddle; the electric stirrer further comprises a protecting hood; the protecting hood comprises a protecting hood body and a protective cover; theprotecting hood body is arranged on the base; an opening is formed in the upper part of the protecting hood body; a through hole allowing the stirring shaft to penetrate is formed in the protective cover; the through hole is in clearance fit with the stirring shaft; and an annular groove is formed in the bottom of the protective cover and matched with the opening. The electric stirrer disclosed bythe invention is provided with the protective cover, so that the condition that reactants in the protecting hood splash to threaten safety of laboratory personnel or pollutants drop into the reactants to pollute the reactants can be avoided.

Owner:河南大松仪器设备有限公司

A rotary mixing and milling device for producing refractory materials

ActiveCN106269134BMeet production needsAvoid affecting the mixing effectTransportation and packagingRotary stirring mixersRefractoryEngineering

The invention discloses a rotary milling device for producing refractory materials, which comprises a base, a casing is fixedly installed on the top of the base, a top plate is fixedly installed on the left side of the top of the casing, and the bottom of the first rotating rod A rotating head is fixedly installed at the end of the rotating head, the outer wall of the rotating head is equipped with a stirring frame plate, the bottom end of the second rotating rod is equipped with a turntable, the outer side of the turntable is provided with a roller milling platform, and the roller milling platform The outer wall is equipped with a spinning ring. The rotary mixing and milling device used to produce refractory materials, through the cooperation of the stirring frame plate, the roller milling table and the base, the second rotating rod drives the turret and the roller milling table to rotate, and the materials are rolled through the cooperation of the roller milling table and the base Grinding, the first rotating rod drives the rotor and the stirring frame to rotate the material during the mixing and grinding process to avoid partial compaction of the material during the mixing and grinding process resulting in uneven mixing and grinding, which meets the production needs of the refractory material industry.

Owner:CHANGXING MINGTIAN FURNACE CHARGE

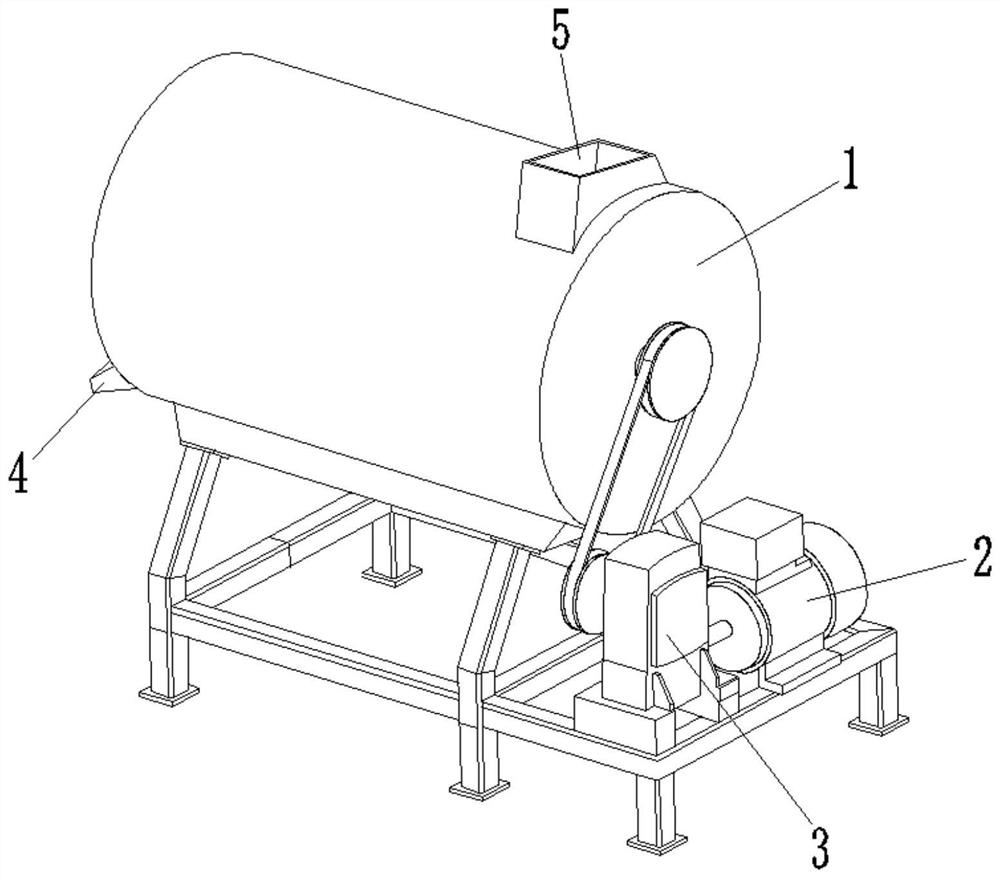

Mixed coating stirring device

PendingCN112892319AEasy to operateAvoid blockingRotating receptacle mixersTransportation and packagingElectric machineEngineering

The invention relates to a stirring device, in particular to a mixed coating stirring device. The technical problem to be solved by the invention is to provide the mixed coating stirring device capable of achieving automatic and uniform stirring. The mixed coating stirring device comprises: a support frame; a mixing assembly, which is mounted on the support frame; and a blanking assembly, which is installed on the support frame. By controlling a speed reducing motor, a rotating drum automatically rotates and stirs, the operation is simple and convenient, and the device can be used for mass production; the stirring device is provided with a blocking assembly, so that a storage frame can be prevented from being blocked, coating in the storage frame cannot completely flow into a rotary drum to be stirred, and the situation that the stirring effect is affected due to excessive feeding is effectively prevented; the device is provided with an automatic switch assembly, so that the device can achieve automatic and uniform blanking, the coating is stirred more uniformly, meanwhile, the device can performing blanking without manually controlling the blocking assembly, and manpower is saved.

Owner:熊建平

Test reaction capsule

PendingCN108444802AIncrease the lengthIncrease detection reaction timePreparing sample for investigationMaterial analysis by optical meansFeeding tubeReaction chamber

The invention relates to a test reaction capsule, which comprises a rotating disc, a reaction chamber arranged on the rotating disc and two or more feeding tubes communicated with the reaction chamber. The inner wall of the reaction chamber is in circular arc transition. According to the invention, the reaction chamber is arranged on the rotating disc, the centrifugal force generated by rotating of the rotating disc can mix liquid in the reaction chamber, the circular arc transition inner wall of the reaction chamber can effectively prevent accumulation of liquid in the corner from affecting the blending effect, the mixing is more uniform and the detection accuracy is guaranteed.

Owner:SHIJIAZHUANG HIPRO BIOTECH

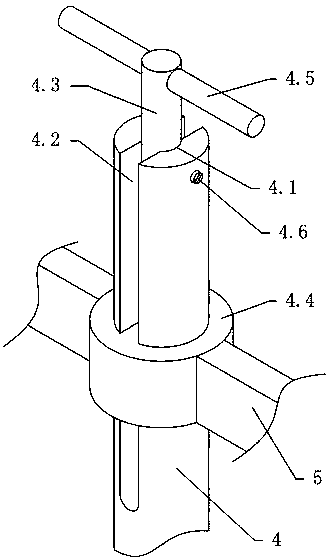

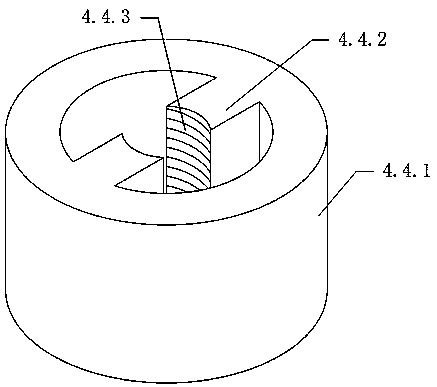

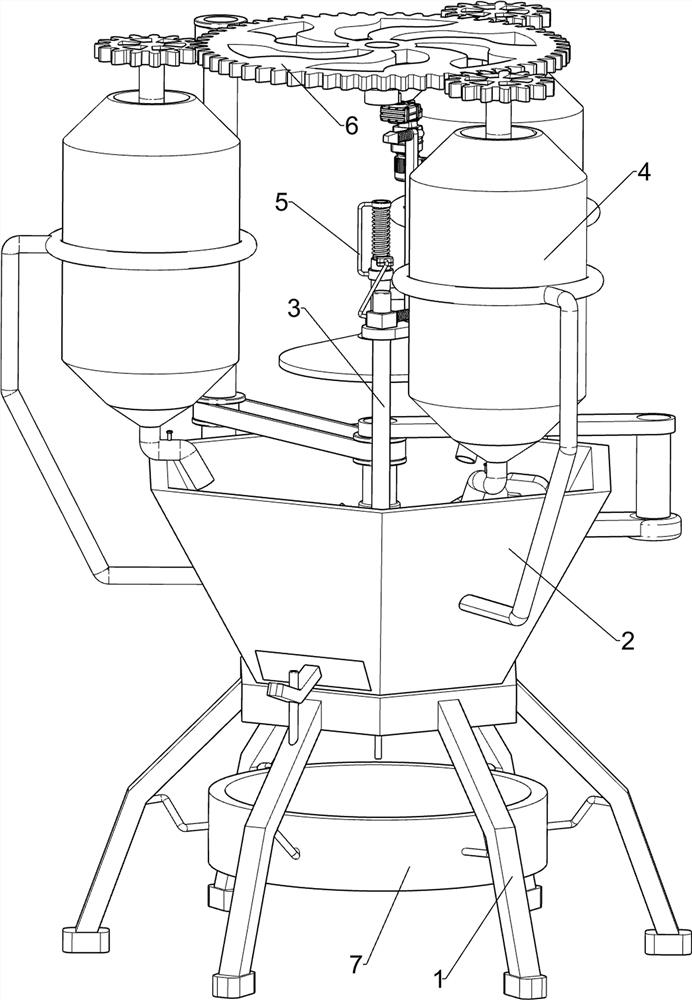

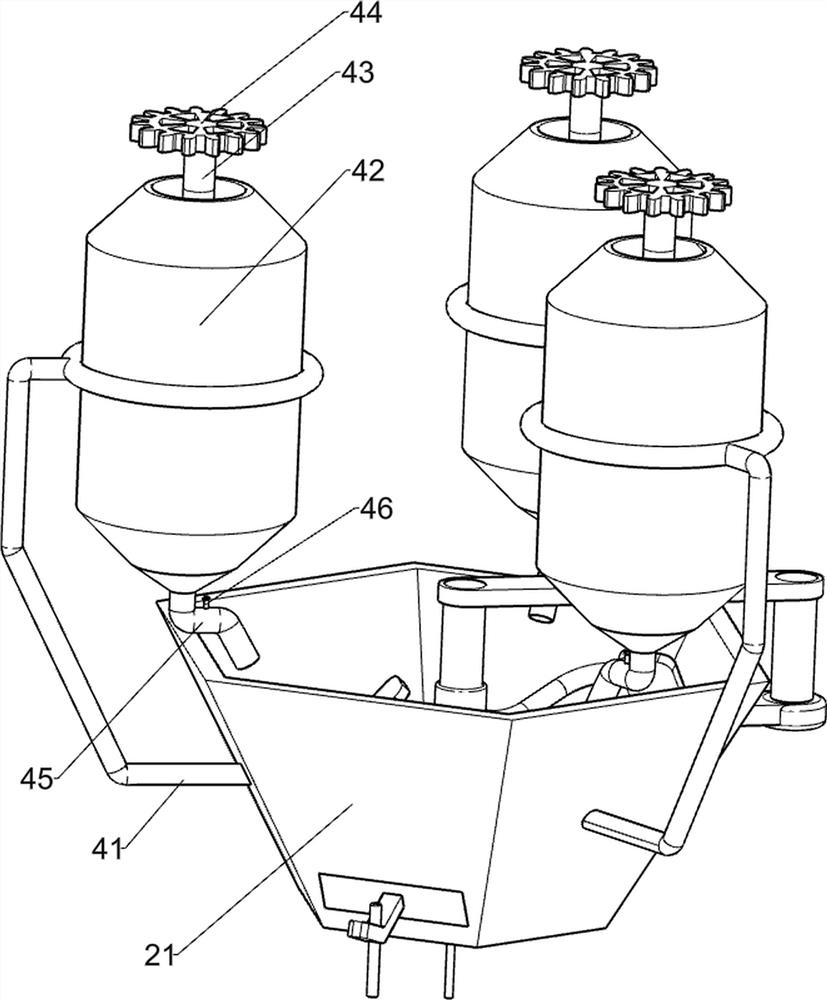

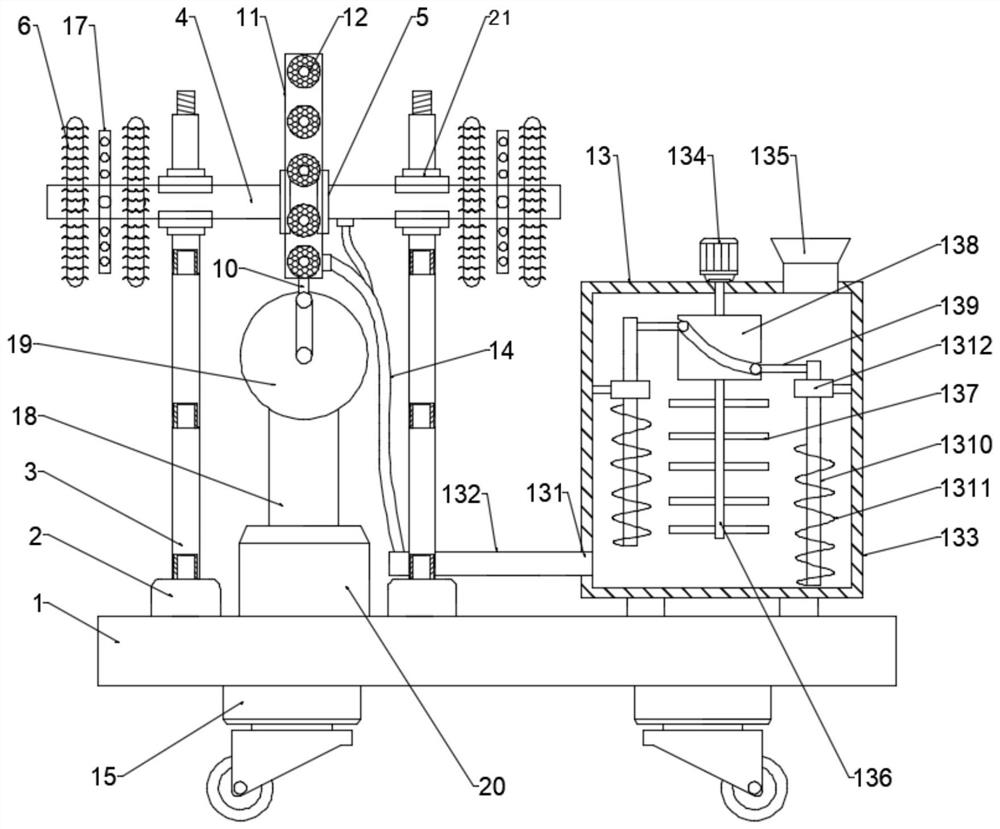

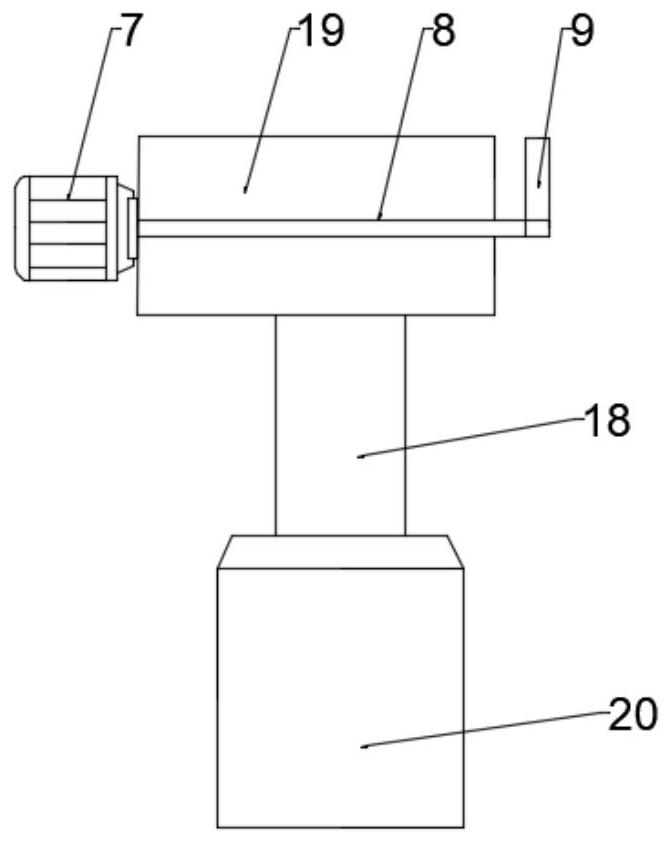

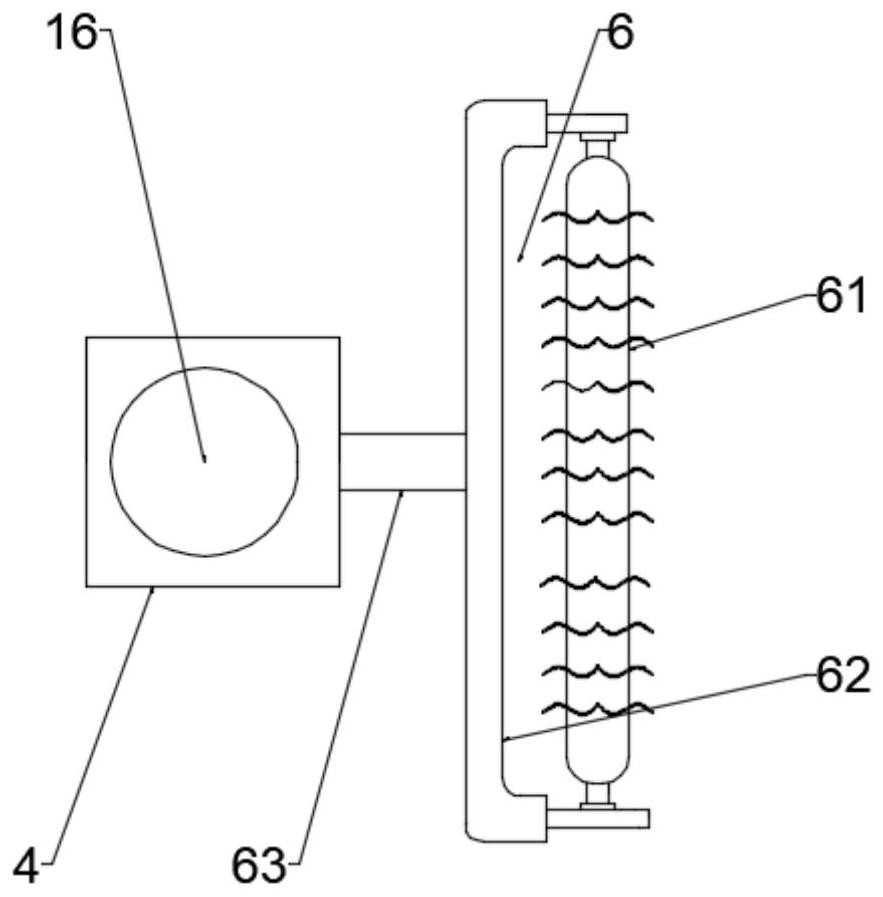

Waterproof coating stirring and mixing preparation system and preparation process

InactiveCN114797647AAccurate transmissionAvoid stickingRotary stirring mixersMixing methodsEngineeringMechanical engineering

The invention relates to the technical field of coating preparation, in particular to a waterproof coating stirring and mixing preparation system and process, feeding devices are fixedly mounted at the two ends of the upper surface of a base, air pressure devices are fixedly mounted at the tops of the feeding devices, and a rotating device is fixedly mounted in the center of the base; a stirring device is fixedly mounted at the top end of the rotating device, a stirring tank body is fixedly mounted at the position, located on the outer side of the rotating device, of the upper surface of the base, and layered material pouring pipes are fixedly mounted at the positions, located on the two sides of the rotating device, in the stirring tank body. According to the powder and liquid mixing device, powder and liquid can be repeatedly and dispersedly poured into the mixing tank according to the proportion, the powder and the liquid can be more sufficiently contacted, meanwhile, the feeding proportion of the powder and the powder liquid is more accurate, particles or solids formed due to insufficient contact of the powder and the powder liquid in the mixing tank can be cut, and the powder and the liquid can be uniformly mixed. The powder and the powder liquid are in full contact, the quality of the waterproof coating is improved, and the problem that the powder and the powder liquid flow in the conveying pipe can be solved.

Owner:刘会安

Rotary mixing and grinding device for producing fireproof material

ActiveCN106269134AMeet production needsAvoid affecting the mixing effectRotary stirring mixersTransportation and packagingRefractoryEngineering

The invention discloses a rotary mixing and grinding device for producing a fireproof material. The device comprises a base, wherein a housing is fixedly mounted at the top end of the base; a top plate is fixedly mounted on the left side of the top end of the housing; a rotary head is fixedly mounted at the bottom end of a second rotary rod; stirring frame plates are mounted on the outer wall of the rotary head; a rotating stand is mounted at the bottom end of a second rotary rod; rolling and grinding tables are arranged on the outer sides of the rotating stand; and a material rotating ring is mounted on the outer wall of each of the rolling and grinding tables. According to the rotary mixing and grinding device for producing the fireproof material disclosed by the invention, by matching the stirring frame plates, the rolling and grinding tables and the base, the second rotary rod drives the rotating stand and the rolling and grinding tables to rotate; the material is rolled and ground by matching the rolling and grinding tables with the base; the first rotary rod drives the rotary head and the stirring frame plates to rotate to stir the material in the mixing and grinding process, so that the material is prevented from being unevenly mixed and ground as the part of the material is compacted, and the production demand in a fireproof material industry is satisfied.

Owner:CHANGXING MINGTIAN FURNACE CHARGE

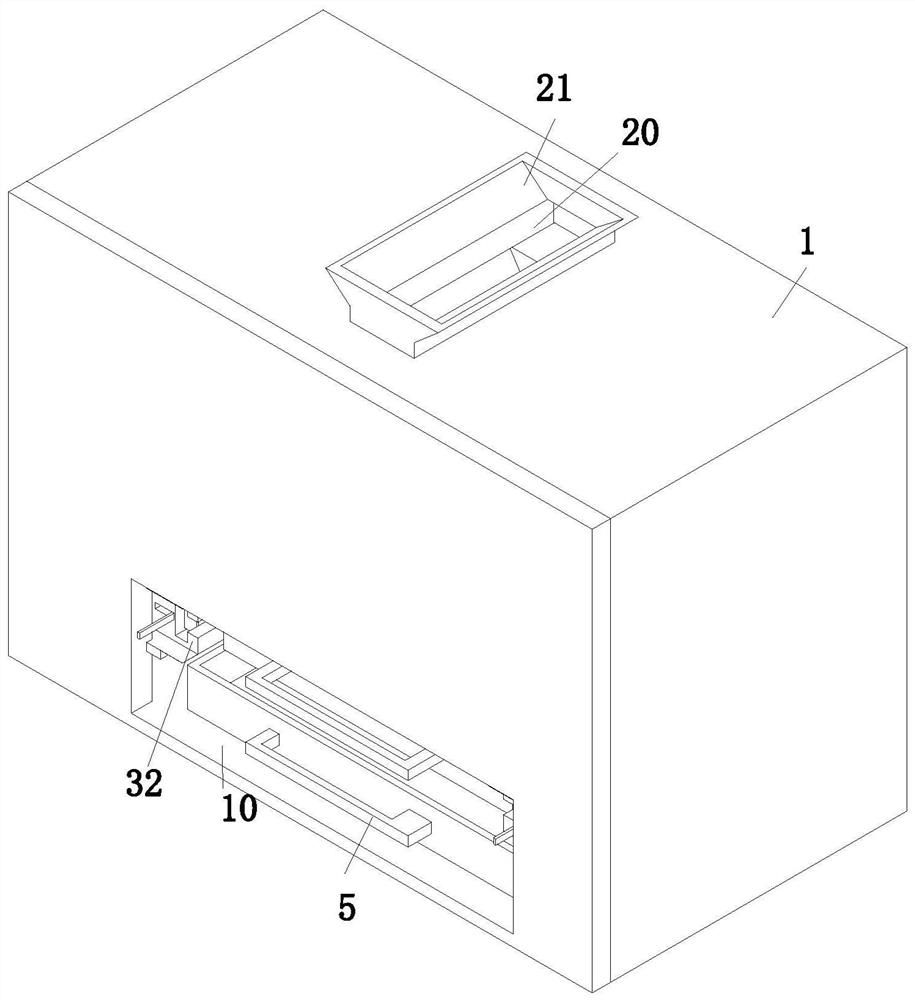

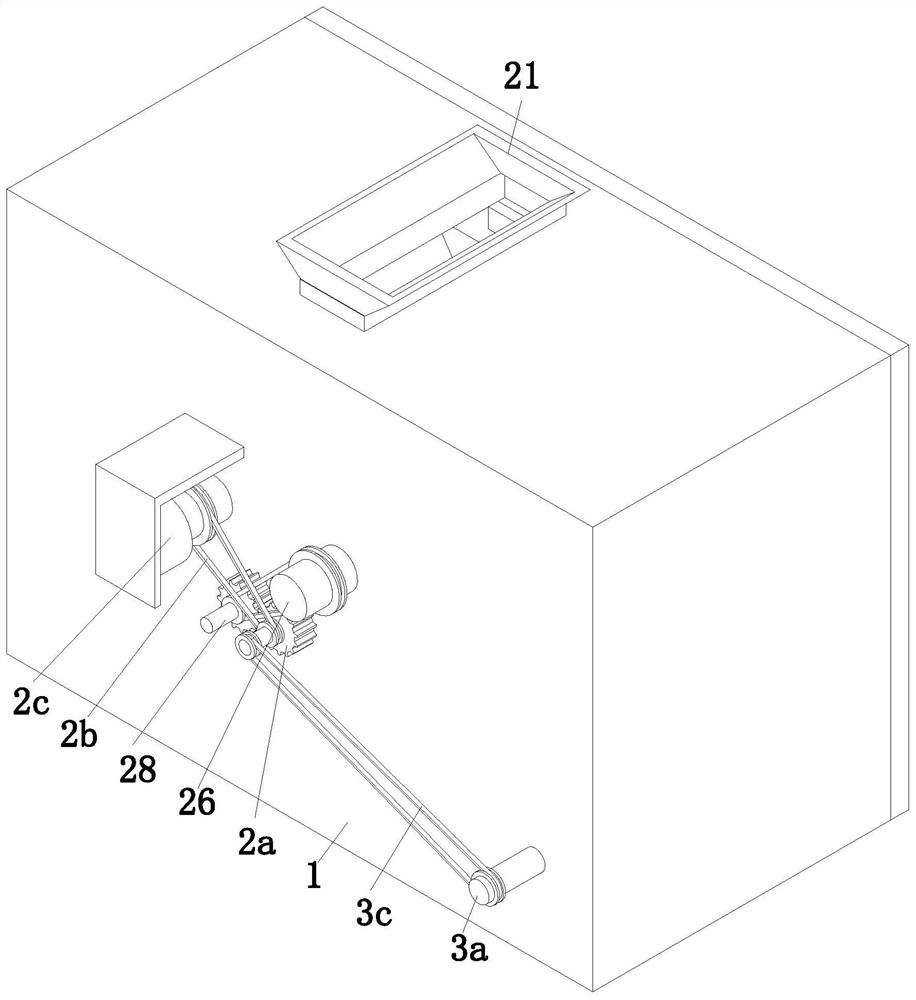

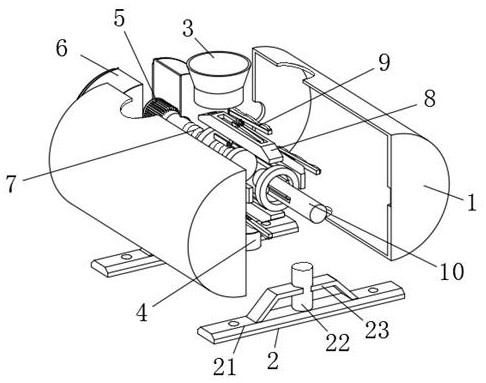

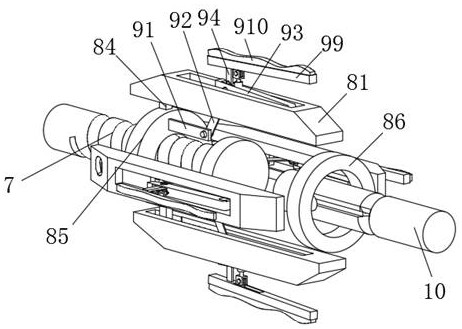

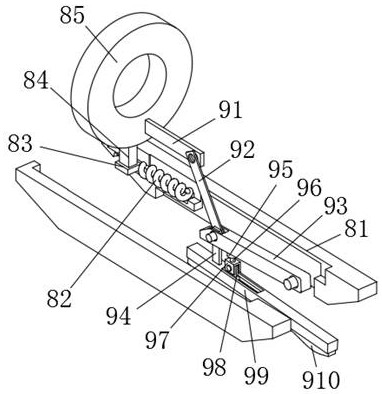

Enhanced rubber extrusion feeding device

The invention belongs to the technical field of feeding devices, particularly relates to an enhanced rubber extrusion feeding device, and aims at solving the problems that in an existing rubber production device, intermittent feeding by workers is often needed according to production requirements, the workload is greatly improved, manual operation is inconvenient, materials are prone to caking due to accumulation and the working efficiency is greatly reduced. According to the scheme, the device comprises a box body, two supports are symmetrically and fixedly installed at the bottom of the box body, an extrusion screw is rotatably installed in the box body, a discharging hole is formed in one side of the box body, a first driving motor is fixedly installed on the other side of the box body, a driving shaft is fixedly installed on an output shaft of the first driving motor, and the end, away from the output shaft of the first driving motor, of the driving shaft is fixedly connected with the extrusion screw. According to the device, manual operation is avoided, time and labor are saved, accumulation and caking of materials are avoided, the discharging amount is controlled, and the production efficiency and quality of rubber are effectively improved.

Owner:台州耘智科技有限公司

Stirring device for aluminum alloy smelting and manufacturing method of stirring device

InactiveCN106191484AHigh melting pointHigh strengthMixersMetallic material coating processesTitaniumSilicon

The invention discloses a stirring device for aluminum alloy smelting. The stirring device comprises a stirring body, wherein the stirring body comprises an iron matrix and a cladding layer coating the outer surface of the iron matrix, and the cladding layer is made of a titanium-silicon compound. The cladding layer of the stirring device is formed on the iron matrix in a laser cladding manner and can be well combined with the iron matrix, so that the stirring device has the good characteristics of high-temperature resistance and corrosion resistance after long-time usage.

Owner:ASIA PACIFIC LIGHT ALLOY NANTONG TECH

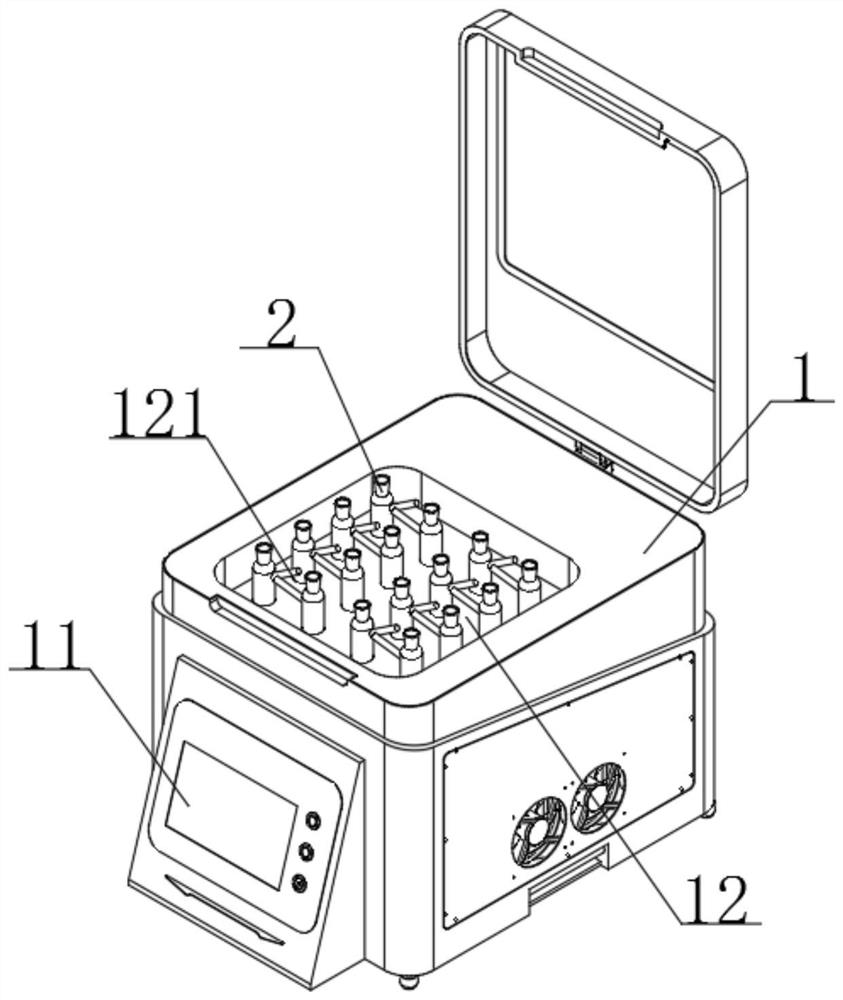

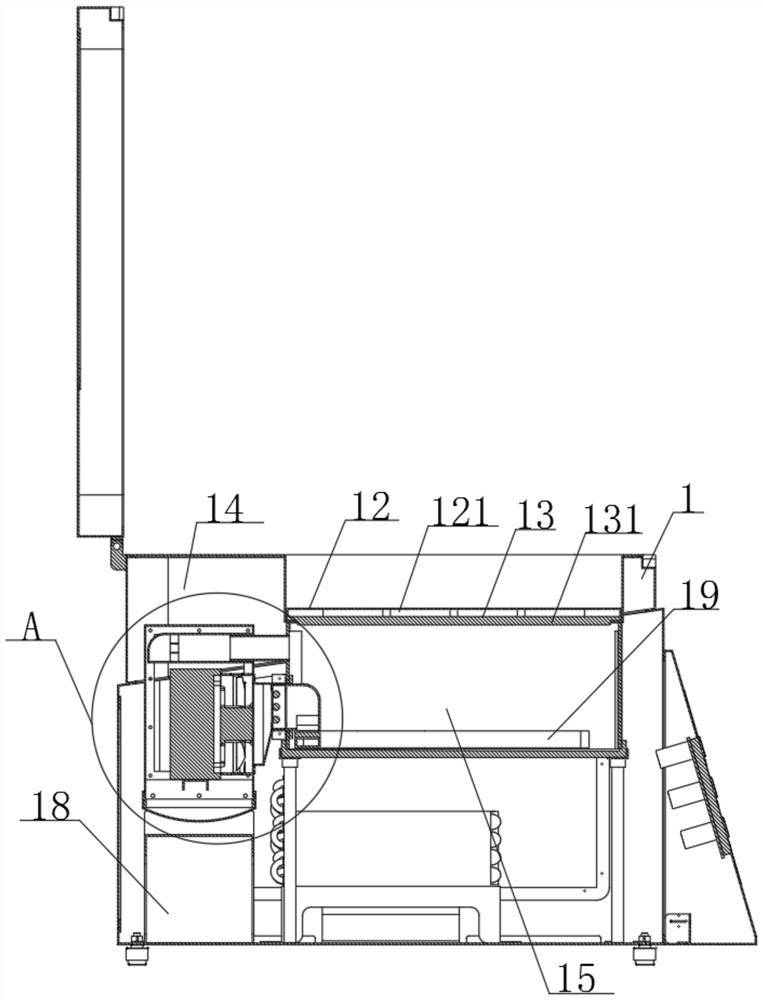

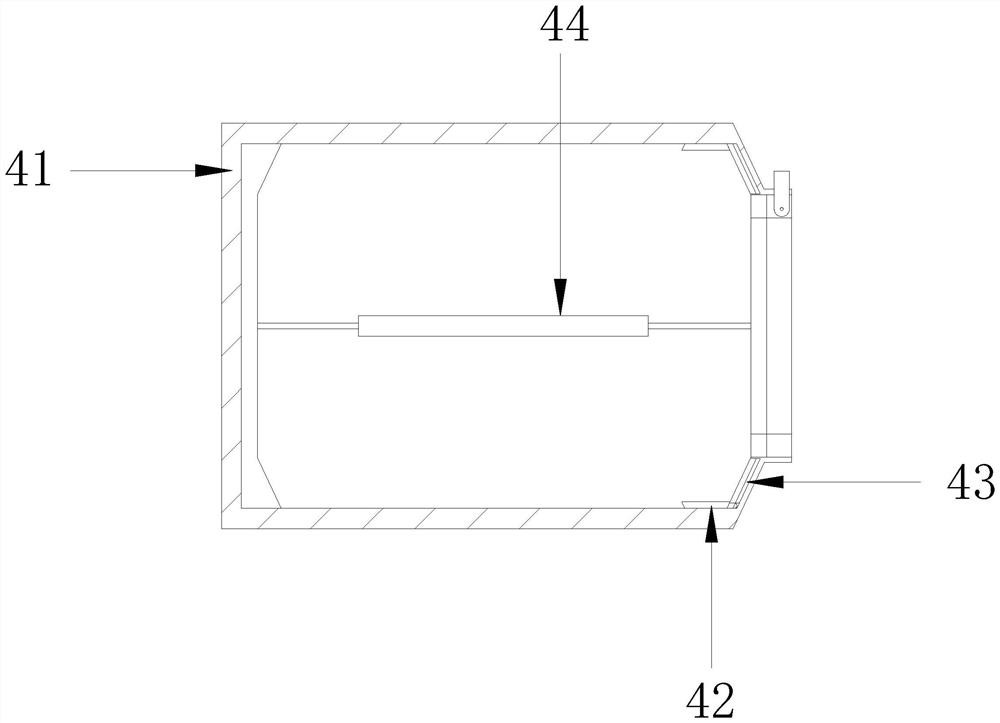

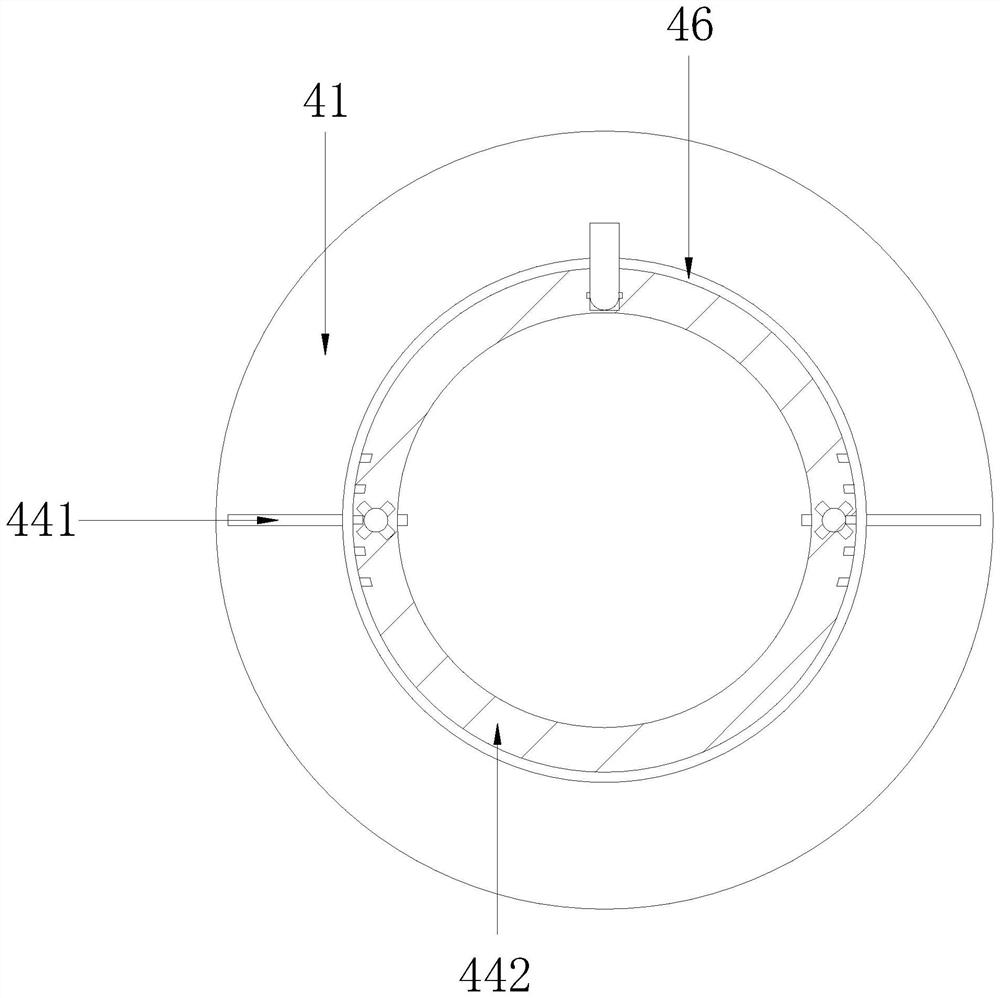

Photocatalytic device and refrigeration type reaction box adopting same

PendingCN114713160ASolve the problem that the sinking bottom affects the lightStable lightingEnergy based chemical/physical/physico-chemical processesRefrigerationPhoto catalysis

A first cavity is formed in the position, close to a sealing cover, of an inner cavity of a box body, a second cavity is formed in the position, located on the right side of the first cavity, of the inner cavity of the box body, an evaporation box is connected to an inner cavity of the first cavity in a clamped mode, and the evaporation box is connected with a photocatalytic device. A compressor is fixedly installed in an inner cavity of the evaporation box, a cooling fan is rotationally connected to the right side of the compressor, a second air duct is fixedly installed on a bottom plate of an inner cavity of a second cavity, a heating piece frame is jointly communicated between the second air duct and the evaporation box, and a plurality of ventilation openings are formed in the upper end of the second air duct at equal intervals; the temperature in the cavity is stabilized, a reaction temperature system is kept, and the accuracy of a reaction experiment is ensured.

Owner:安徽科幂仪器有限公司

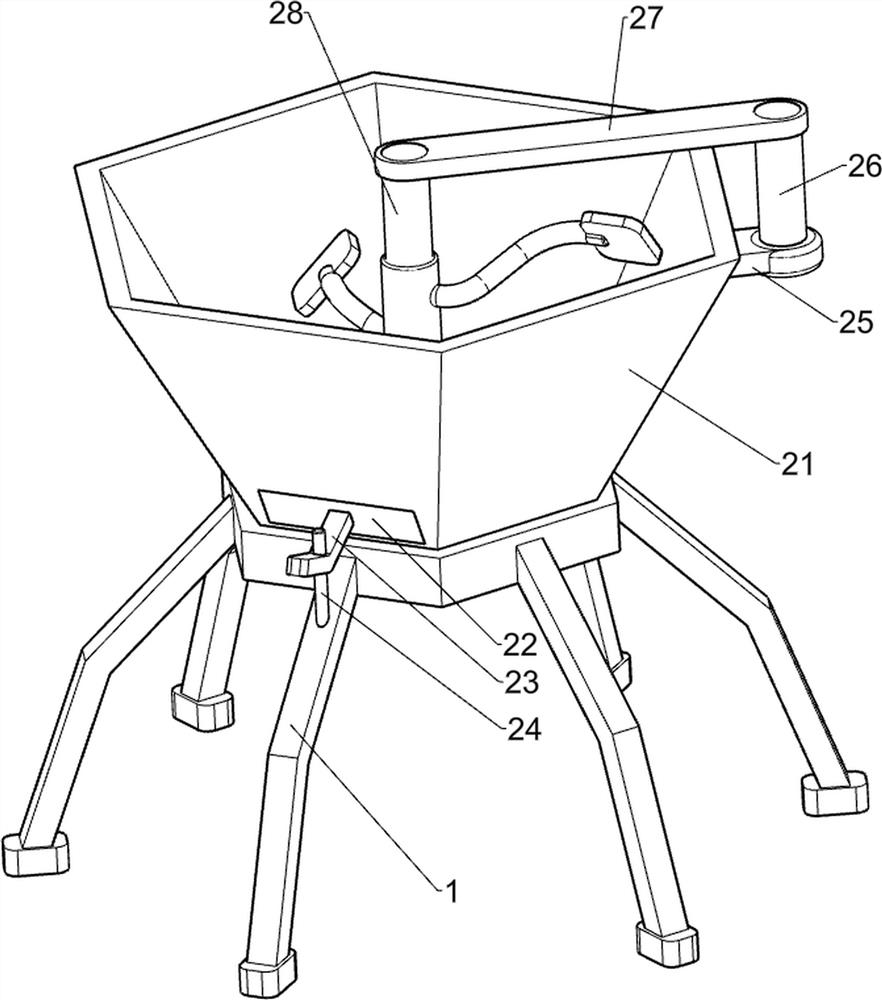

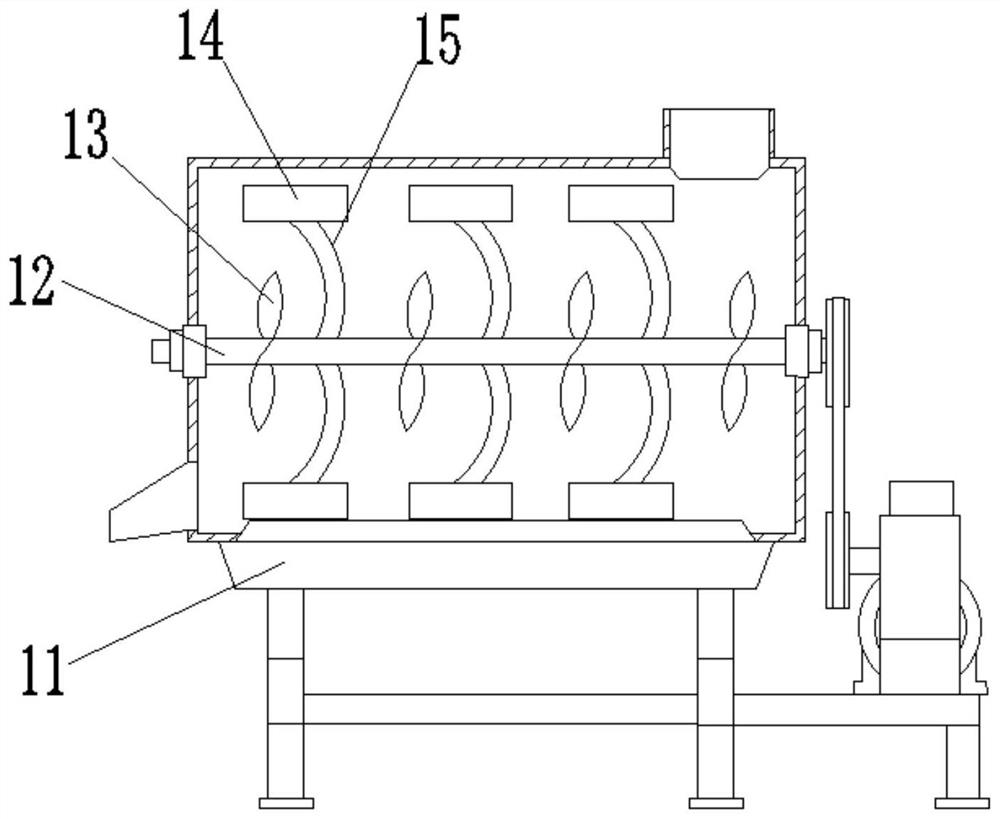

Sand blender with efficient mixing function for core sand

InactiveCN107737870AEfficient stirring functionImprove the mixing effectMould handling/dressing devicesArchitectural engineeringSand casting

The invention relates to the technical field of core sand casting equipment, and discloses a sand blender with an efficient mixing function for core sand. The sand blender comprises a support platform, wherein positioning seats are fixedly connected to both sides of the top of the support platform respectively, the two positioning seats are fixedly connected to both sides of the outer surface of asand mixing tank respectively, baffles are fixedly connected to both sides of the top of the outer surface of the sand mixing tank respectively, second motors are fixedly connected to the tops of thetwo baffles respectively, eccentric wheels are fixedly connected to one end of the tops of output shafts of the two second motors respectively, the tops of the eccentric wheels are engaged with one side of the bottoms of hinge plates, and mixing shafts are connected to inner cavities of one end of the hinge plates in a penetrating mode. According to the sand blender with the efficient mixing function for the core sand, the second motors, the eccentric wheels, the hinge plates, the mixing shafts and mixing blades are matched, so that the eccentric wheels are driven to rotate by the second motors, the hinge plates can be driven to rotate irregularly when the eccentric wheels rotate, and the mixing effect on mixed sand can be greatly increased by centrifugal force generated by irregular rotation.

Owner:李广连

Dye stirring device

PendingCN114471228AAvoid affecting the mixing effectEasy to take outRotary stirring mixersTransportation and packagingPhysicsElectric machinery

The invention discloses a dye stirring device, which comprises: a bottom plate, which is provided with a cylinder inlet groove; the supporting frame comprises three supporting rods fixed to the bottom plate, and the three supporting rods are evenly distributed around the axis circumference of the cylinder entering groove; the number of the clamping assemblies is three, the three clamping assemblies are connected to the three corresponding supporting rods respectively, each clamping assembly comprises a clamping rod, each supporting rod is provided with a clamping sliding groove allowing the clamping rod of the corresponding clamping assembly to penetrate through, and the clamping rods can transversely move relative to the clamping sliding grooves; the supporting rod can move towards or away from the dye cylinder body to clamp or loosen the dye cylinder body; a driving motor is fixed on the cover plate, a stirring shaft is fixed on a rotating shaft of the driving motor, and stirring blades are fixed on the stirring shaft; the lifting device is used for driving the cover plate to move up and down, and the stirring blades are inserted into or moved out of the dye vat body. The dye vat body can be fastened and then stirred, and the stirring effect is good.

Owner:绍兴东龙针纺织印染有限公司

Mixing equipment for production of fluorinated silicone rubber and use method of mixing equipment

The invention belongs to the technical field of rubber production and processing, and particularly relates to mixing equipment for fluorosilicone rubber production and a using method thereof.The mixing equipment comprises a device body, a mounting plate is fixed to the top of the device body, an adjusting mechanism is arranged on one side of the mounting plate, and a first motor is mounted on one side of the adjusting mechanism; a first motor is mounted on one side of the mounting plate, a second motor is mounted on one side of the mounting plate, the output shaft ends of the first motor and the second motor are both connected with dismounting mechanisms, a fixed roller and a mixing roller are slidably arranged in the two dismounting mechanisms respectively, and the fixed roller is in bearing rotation with the inner wall of the mounting plate. A third motor is turned on, the third motor drives a threaded rod to rotate, the threaded rod and a threaded block rotate in a threaded mode, and a limiting rod is slidably connected with a sleeve, so that the threaded block is driven to move left and right, a first motor and a mixing roller move along with the first motor, and a gap between a fixed roller and the mixing roller can be adjusted according to actual conditions; the mixing effect is enhanced.

Owner:南京宏匡硅材料有限公司

Processing technology of melt-blown non-woven fabric

InactiveCN113005637AStir wellFully heatedFilament forming substance formingRotary stirring mixersYarnPolymer science

The invention discloses a processing technology of a melt-blown non-woven fabric. The processing technology comprises the following steps: a, crushing, specifically, crushing a polypropylene raw material; b, stirring, specifically, putting the raw materials into a stirrer, adding a thermal toughening agent, and stirring; c, carrying out spinning treatment, specifically, carrying out spinning treatment on a molten mixture; and d, processing, specifically, processing fiber yarns prepared in the step c to obtain a melt-blown fiber layer, wherein the stirrer in the step b comprises a main body, a heating device, a motor, a stirring roller, a stirring device, a feeding hole and a discharging hole. The raw materials are uniformly heated through the heating device, and the raw materials are prevented from sticking into the main body during melting to affect the stirring effect; the uniformity of the bottom of the mixture is improved through a stirring plate, and the stirring effect is further improved, so that the product quality is improved; and the stirring device realizes heating and mixing of the thermal toughening agent, so that the thermal toughening agent is directly mixed in the mixture in the stirring process, the stirring effect is improved, and the product quality is further improved.

Owner:金艺炜

Efficient stirring bin with inner wall residue scraping structure for feed production

ActiveCN111921399AStir wellImprove mixing efficiencyFood processingRotary stirring mixersElectric machineEngineering

Owner:岳阳宏泰饲料科技有限公司

Mixing equipment for plastic colorant processing

ActiveCN113477128BAvoid technical problems that reduce productivityEvenly mixedShaking/oscillating/vibrating mixersRotary stirring mixersMechanical engineeringMixing tank

The invention discloses a mixing equipment for plastic colorant processing, which relates to the technical field of mixing equipment, including a mixing tank, a mixing bracket, a mixing part and a feeding part, and the mixing tank is arranged on a mixing At the top of the bracket, the mixing part is arranged in the mixing tank, and the feeding part is arranged on one side of the mixing tank. When the present invention works, the feeding part transports the materials into the mixing tank, and then the materials Falling to the bottom of the mixing tank, the mixing column rotates at this time, and the material is transported to the top of the mixing tube through the first mixing blade, and then the material slides down to the bottom of the mixing tank again along the distribution plate at the top of the mixing tube , working reciprocatingly in turn, the materials at the bottom of the mixing tank will be evenly transported to the top and then fall down, and the materials will be mixed evenly, which can drive all the materials to move, avoiding the technical problem of low working efficiency of the mixing equipment in the prior art.

Owner:LAIZHOU GLASS FIBER REINFORCED PLASTICS PRODS

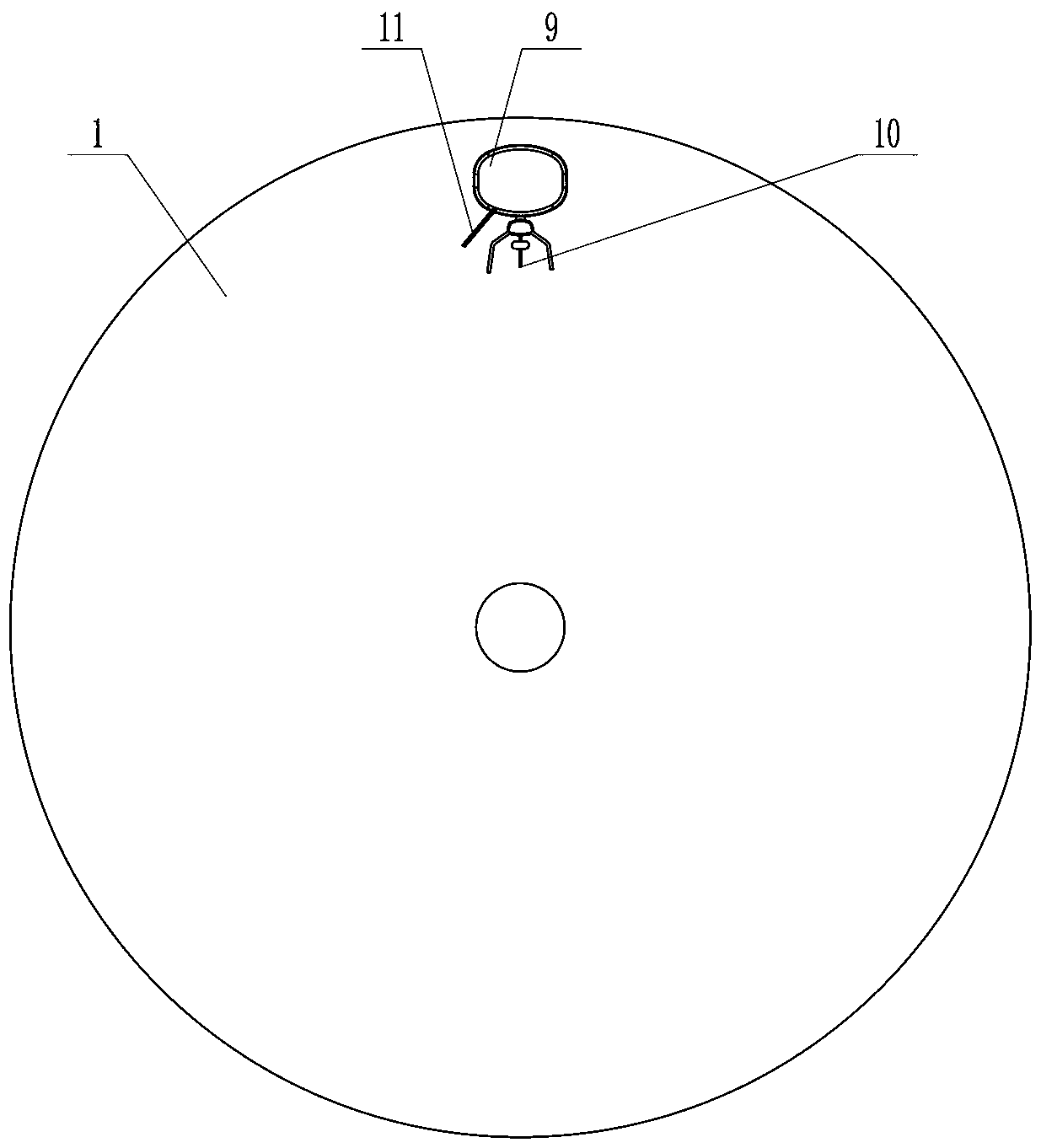

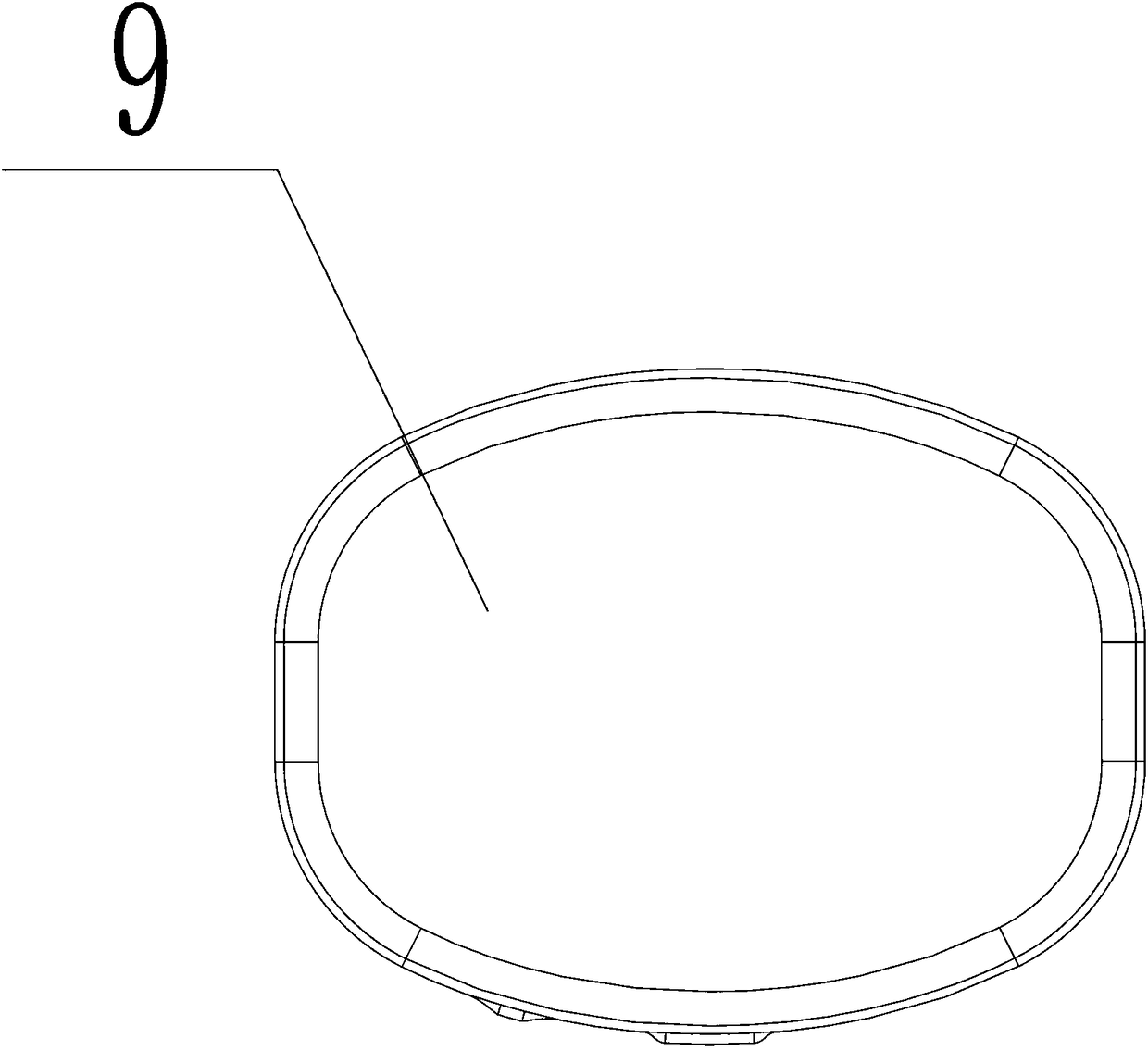

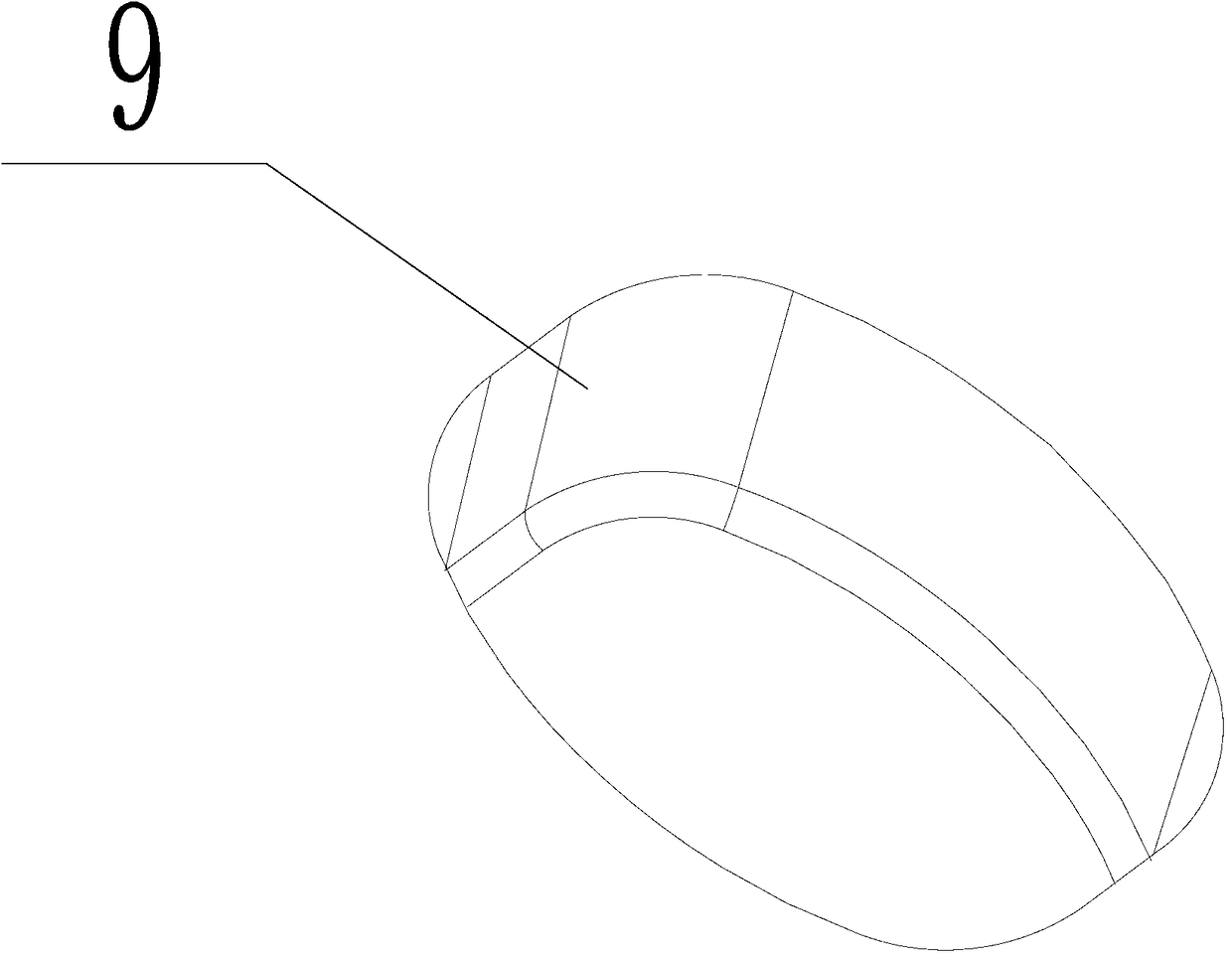

A drum concrete mixer

ActiveCN113320015BPrevent hardeningAvoid affecting the mixing effectSolid waste managementDischarging apparatusGear wheelArchitectural engineering

The invention discloses a drum-type concrete mixer, which relates to the technical field of construction machinery. The rack roller is movably matched with the drum, and a universal shaft is installed on one side of the drum. The beneficial effects of the present invention are: the present invention is set by the combination of the movable ring and the stirring assembly, and the rack ring in the movable ring is rotated to make the rack move in a circle. Drive the gear to rotate, so that the longer side of the mixing blade is turned inward, so that the entire mixing assembly can be pulled out, and the groove disc pushes the concrete remaining on the cylinder wall to the material port from the inside, preventing the remaining concrete from hardening on the cylinder wall. After the mixing assembly is pulled out, the entire mixing assembly can be washed to prevent the hardening of the concrete from affecting the rotation of the movable ring and preventing the concrete from blocking the through holes on the mixing blade to affect the mixing effect.

Owner:河北盛烯耐火材料有限公司

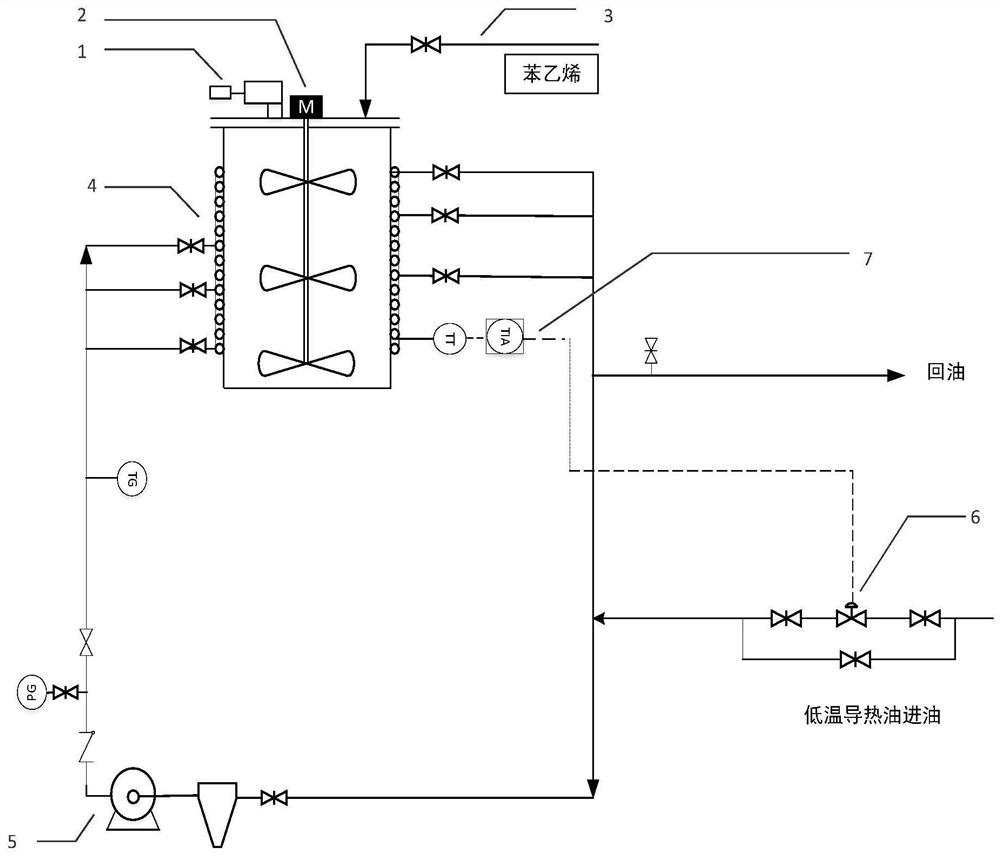

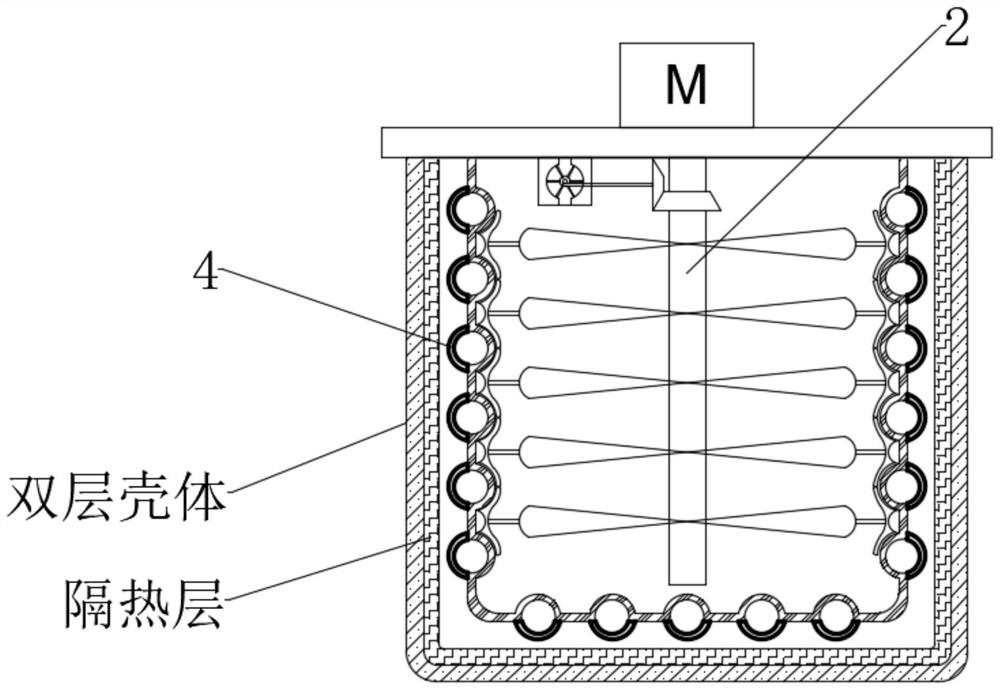

Temperature-controllable rubber dissolving tank

ActiveCN113441021AImprove rubber dissolution ratePrevent self-aggregationRotary stirring mixersPlastic recyclingComposite materialPolymer chemistry

The invention discloses a temperature-controllable rubber dissolving tank, belonging to the field of resin production equipment. According to the temperature-controllable rubber dissolving tank, a jacket is additionally arranged on an existing rubber dissolving tank and is filled with heat conduction oil; the heat conduction oil is circulated through an additionally arranged circulating pump, and low-temperature hot oil (80 DEG C) is quantitatively added into an inlet of the circulating pump through a regulating valve to control the temperature of the jacket, so the temperature of a rubber solution can be accurately controlled; and thus, an optimal dissolving temperature can be set according to different rubber varieties, a rubber dissolving speed can be increased, self-polymerization of styrene can be avoided, full-load stable operation of the device is ensured, the influence of the environment temperature (especially in cold winter) on the rubber dissolving speed is effectively eliminated. In addition, by improving the shape of the inner shell of the dissolving tank, the inner shell and the jacket form a closed system, so on one hand, heat conduction efficiency can be effectively improved and a dissolving speed is further increased, and on the other hand, rubber can be effectively prevented from being hung on a wall to affect stirring effect.

Owner:宁波利万新材料有限公司

Paint spraying mechanical equipment

InactiveCN111997320AEvenly paintedIncrease the areaBuilding constructionsMechanical equipmentBrush device

The invention relates to the field of building machines, in particular to paint spraying mechanical equipment. The paint spraying mechanical equipment comprises a pedestal. Two supporting bases are installed on one side of the upper portion of the pedestal. Sliding rails are arranged above the supporting bases. A first sliding plate is in clamping connection to the sliding rails in a sliding mode.A clamping connection base is arranged at the center of the first sliding plate. First brushing devices are symmetrically installed on the left side and the right side of the clamping connection base. A second brushing device is arranged on a second sliding plate, and the second sliding plate is in clamping connection with the clamping connection base in a sliding mode. A stirring device is arranged on one side of the supporting bases. A hose communicates with the lower portion of the first sliding plate and the lower portion of the second sliding plate. The paint spraying mechanical equipment is high in degree of automation and easy to operate, the spraying efficiency and spraying effect can be greatly improved and the paint spraying mechanical equipment can be widely applied and popularized.

Owner:孙支发

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com