Turnover type stirring device with vibration reducing and buffering functions

A mixing device and mixing box technology, which is applied in cement mixing devices, clay preparation devices, springs/shock absorbers, etc., can solve problems such as vibration, damage, and affecting mixing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

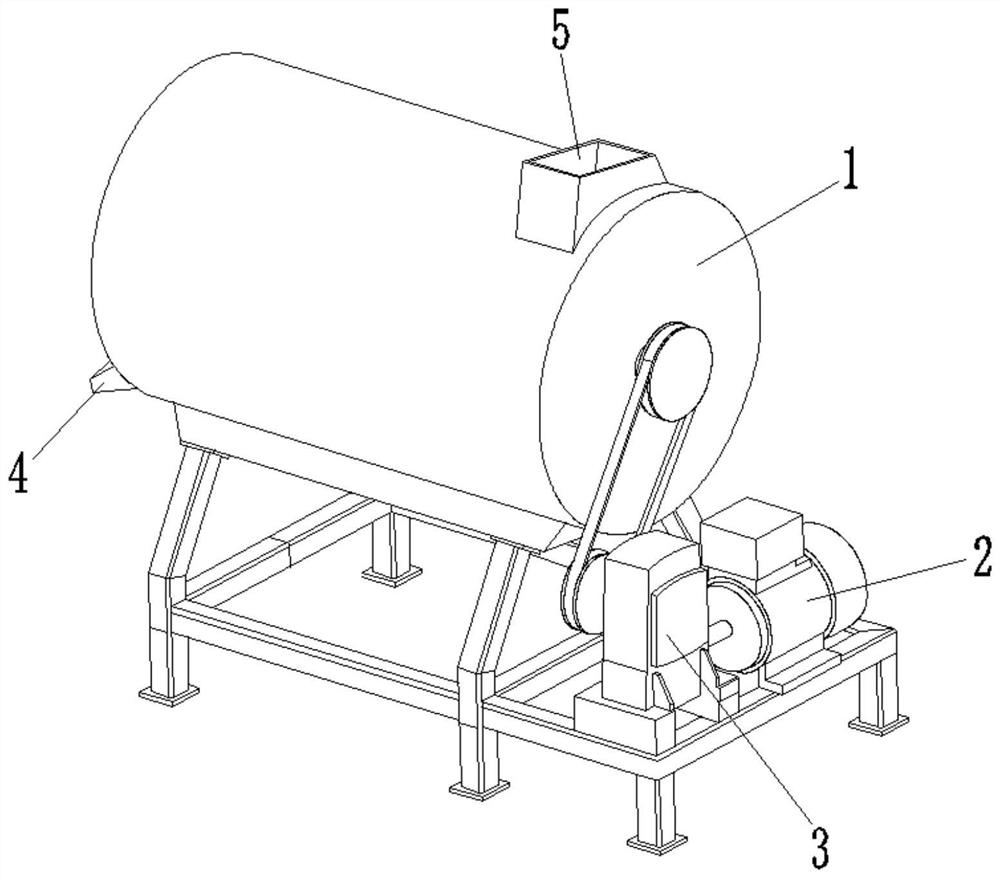

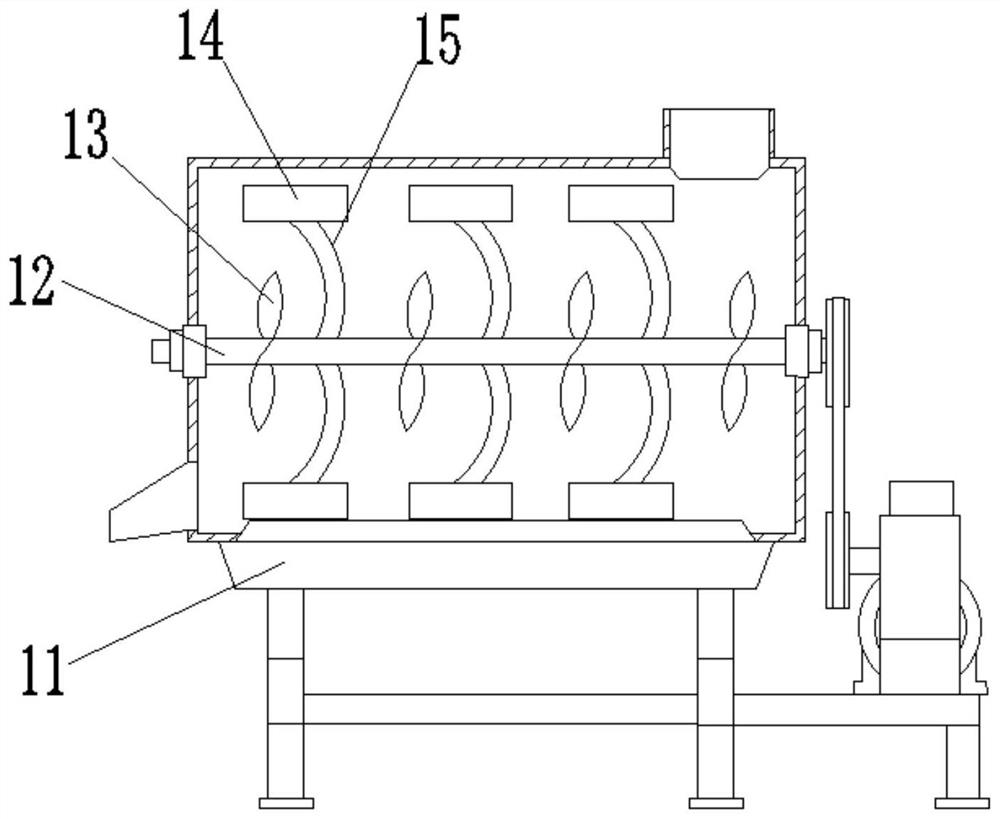

[0026] see Figure 1-4 :

[0027] The invention provides a technical solution: a tumbling stirring device with shock absorption and buffering, including a stirring box 1, a motor 2, a transmission mechanism 3, a material outlet 4 and a material inlet 5, and the motor 2 is arranged on the right side of the mixing box 1 side, the transmission mechanism 3 is set on the front of the motor 2, the discharge port 4 is set on the left side of the mixing box 1, the feeding port 5 is set on the right side of the top of the mixing box 1, the mixing box 1 includes a shock absorber 11, a rotating rod 12, a stirring box Blade 13, flap 14 and stirring rod 15, shock absorber 11 are installed on the bottom of stirring box 1, rotating rod 12 is arranged at the center of stirring case 1, stirring blade 13 is fixedly connected on the outer surface of rotating rod 12, and one end of stirring rod 15 is connected with The outer surface of the rotating rod 12 is fixedly connected, and the turning pl...

Embodiment 2

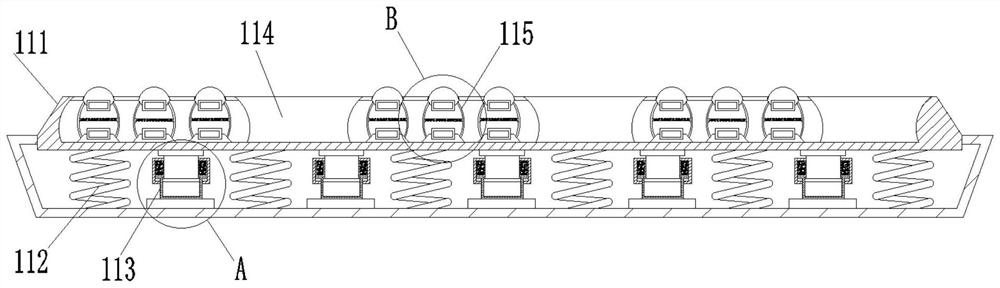

[0031] see Figure 5-7 :

[0032] The buffer seat 114 includes a top plate c1, a shrapnel c2, a return spring c3 and an elastic ball c4. The top plate c1 is arranged on the top of the buffer seat 114, the elastic ball c4 is arranged at the inner center of the buffer seat 114, and the shrapnel c2 and the return spring c3 are fixedly connected on the elastic The top and bottom of the ball c4, the top of the upper shrapnel c2 and the top of the return spring c3 are fixedly connected to the bottom of the top plate c1, and the bottom of the lower shrapnel c2 and the bottom of the return spring c3 are fixedly connected to the bottom of the inner wall of the buffer seat 114. By setting the buffer seat 114 is because the force generated by the material falling after tumbling will cause the top plate c1 to press the shrapnel c2 and the return spring c3 to be pressed and deformed, and then the elastic ball c4 absorbs and compresses the force and then bounces out, which can simply buffer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com