Patents

Literature

34results about How to "Avoid affecting the effect of grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

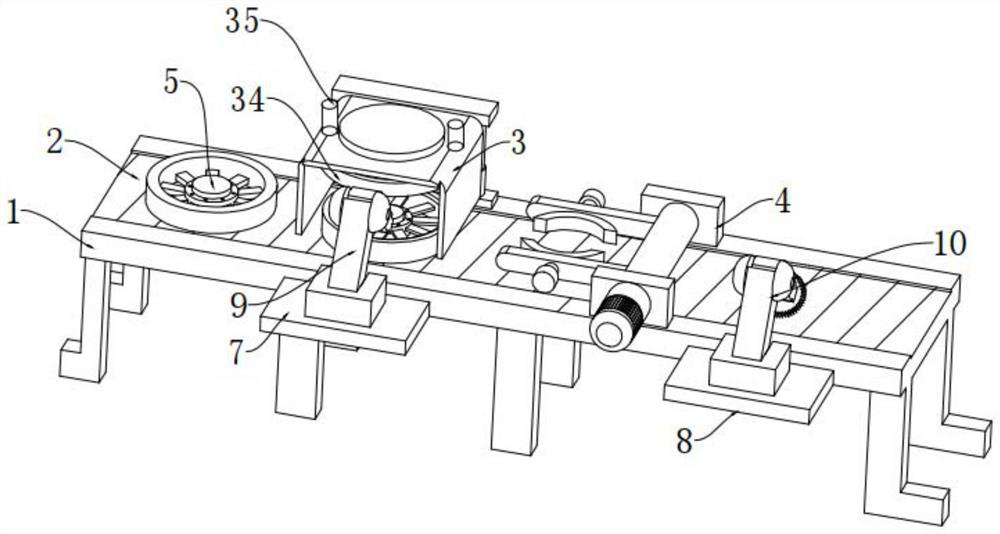

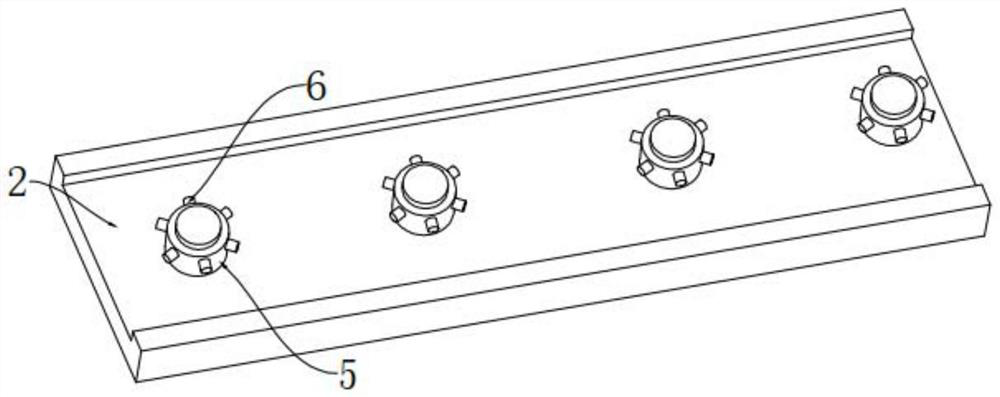

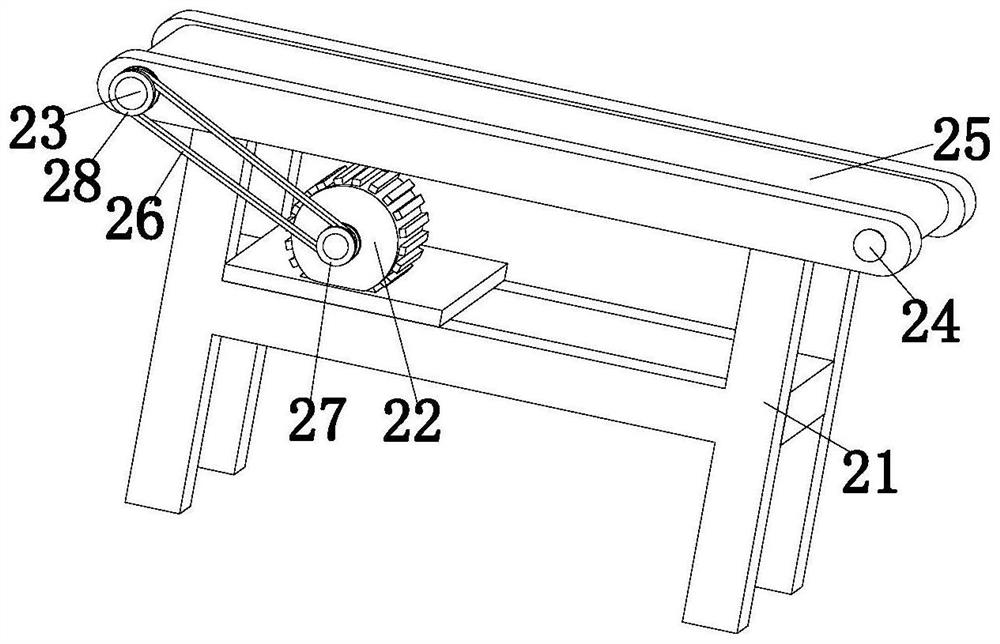

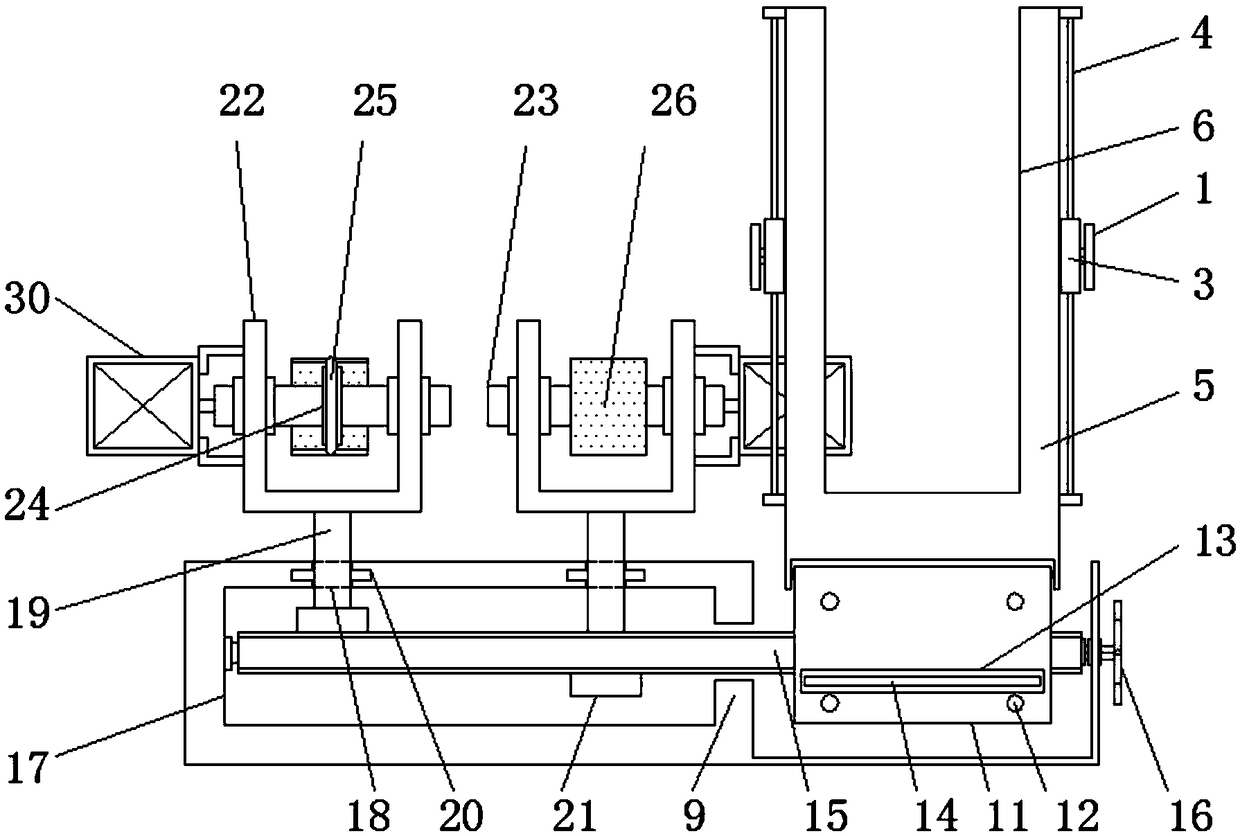

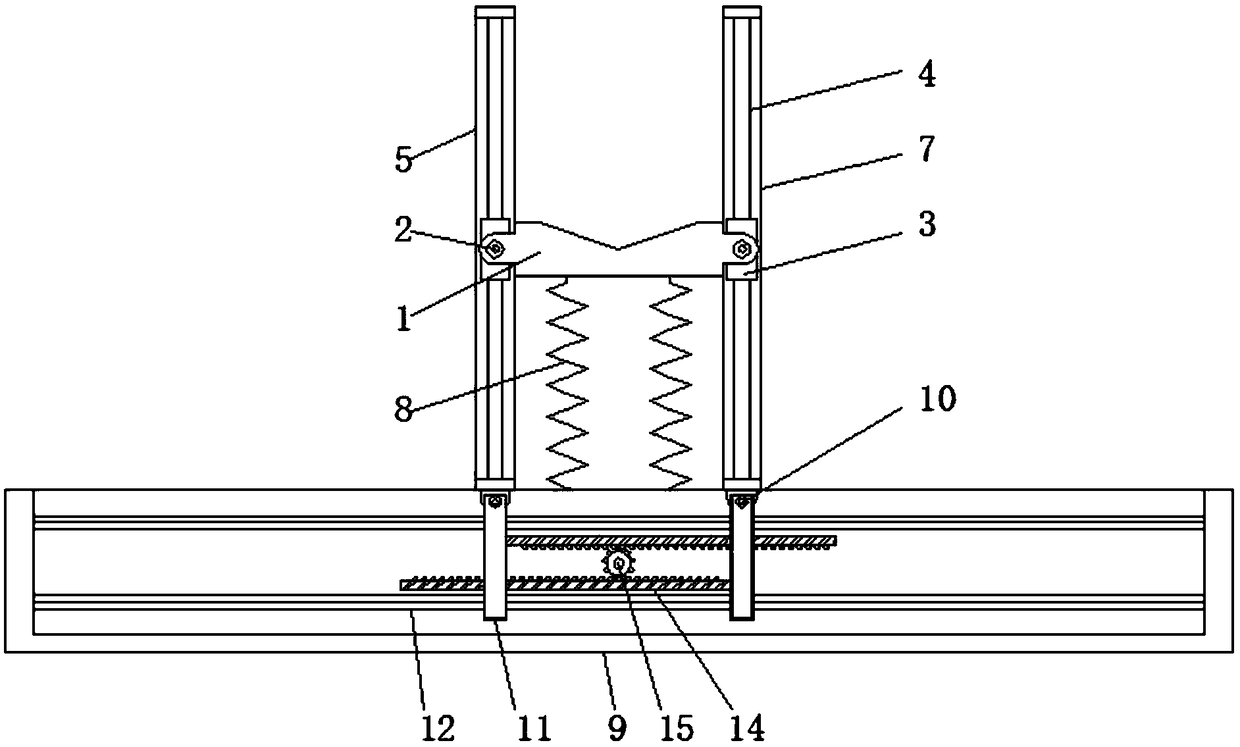

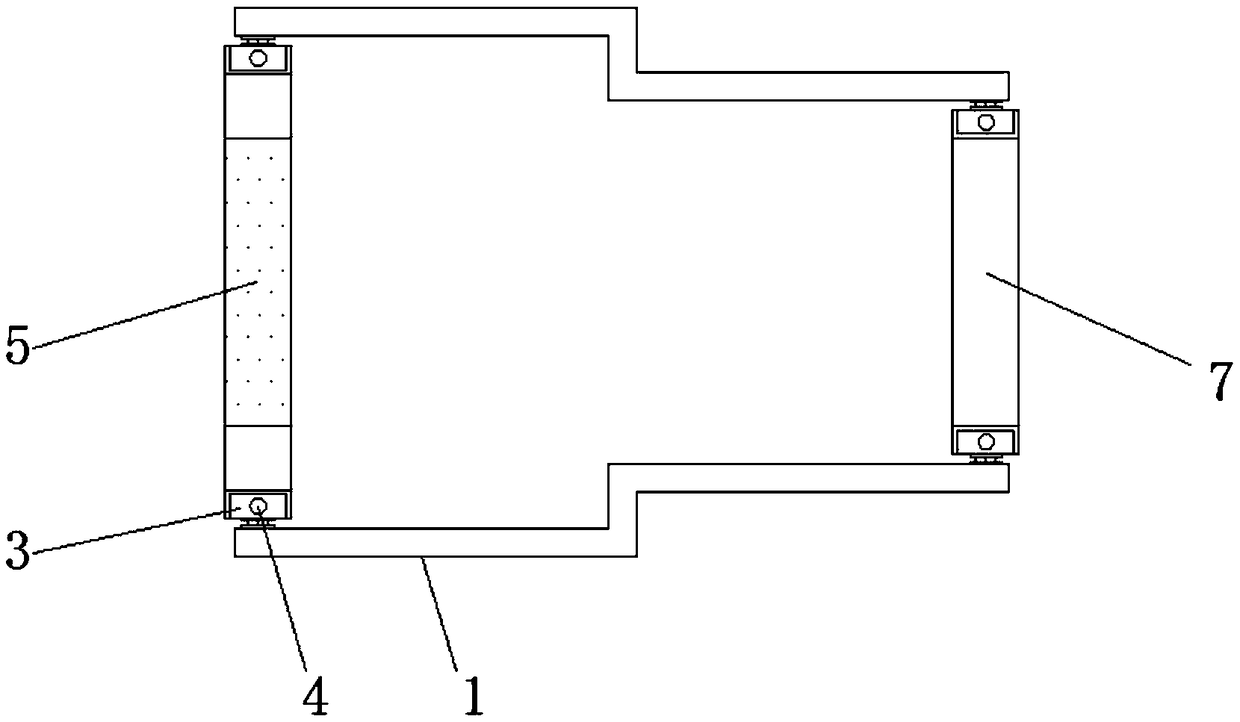

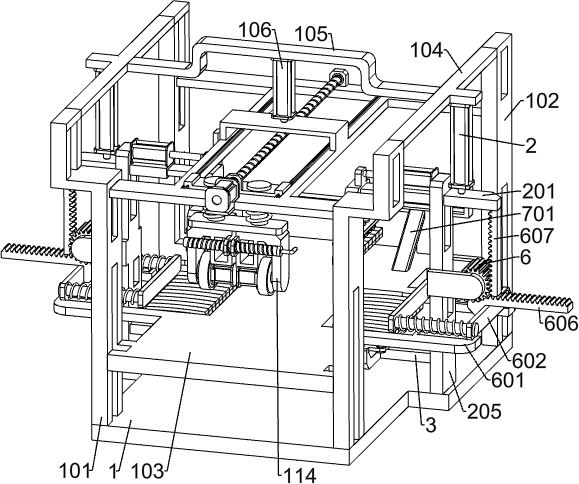

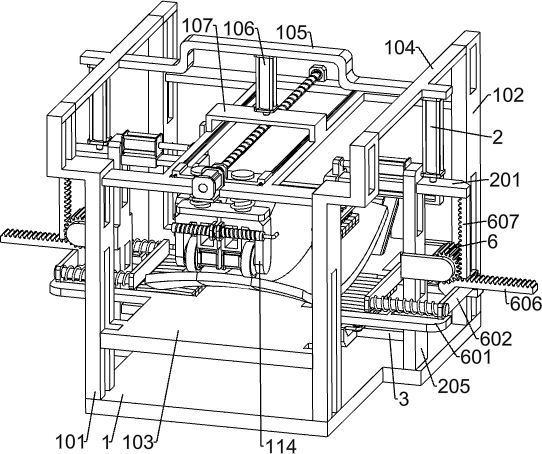

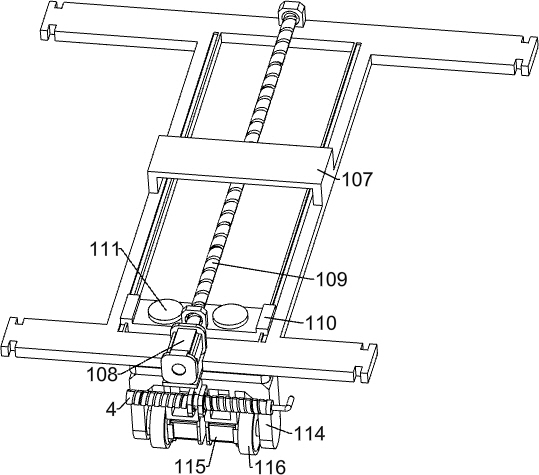

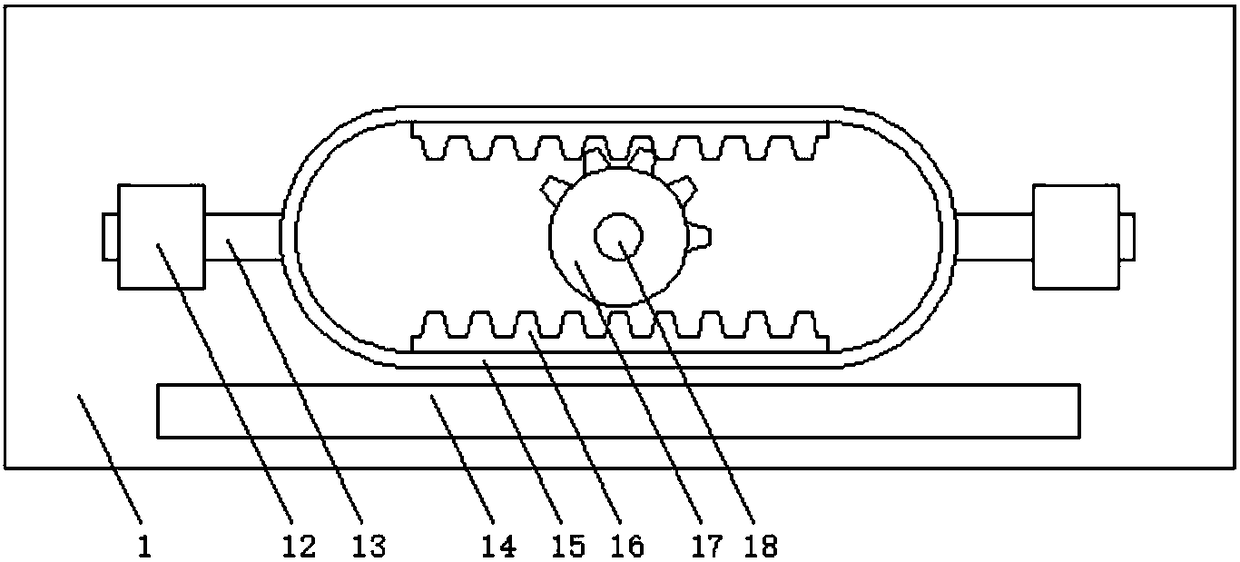

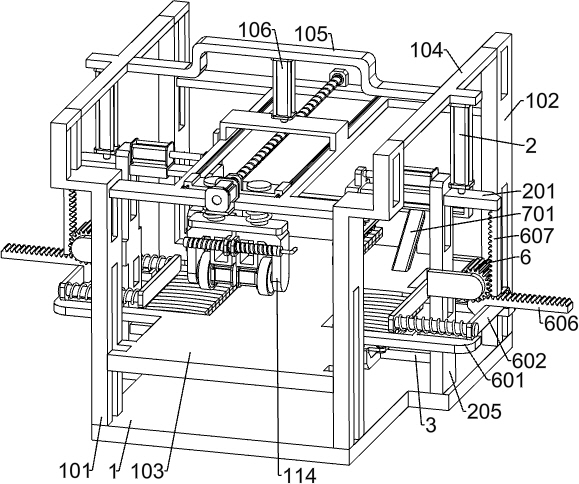

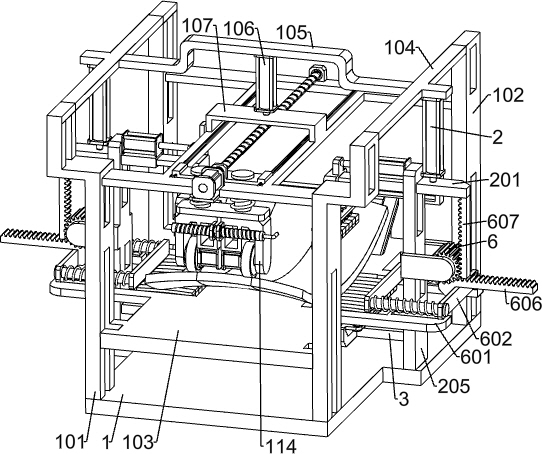

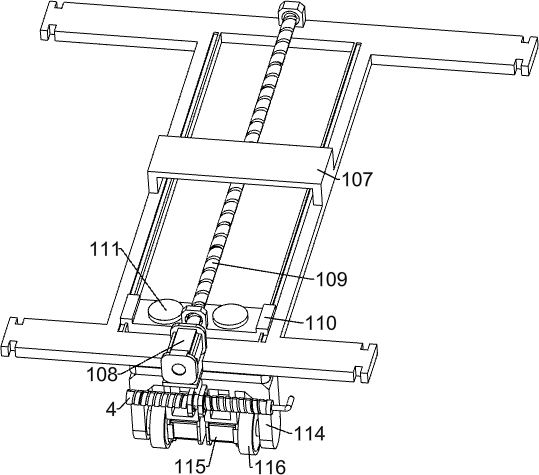

Rubber powder multi-stage grinding equipment

The invention relates to grinding equipment, in particular to rubber powder multi-stage grinding equipment and aims to achieve the technical effect of providing the rubber fine powder grinding equipment capable of performing multi-stage grinding and can reach the required specification. To achieve the technical effect, the rubber powder multi-stage grinding equipment comprises a grinding box, first bearing seats, a supporting rod, a motor, a first rotating rod, crushing cutters and the like; the middle of the inner side of the grinding box is connected with a filtering mesh, the upper portion of the left wall and the upper portion of the right wall of the grinding box are both connected with the first bearing seats, the first bearing seats are connected with the first rotating rod, and the first rotating rod penetrates through the first bearing seat on the right side; and the upper portion of the right side of the grinding box is connected with the supporting rod, and the bottom end of the supporting rod is provided with the motor. A collection mechanism is arranged in the first place, it can be convenient for workers to collect falling grinding powder, and belt wheels, a flat belt, second bearing seats, second rotating rods, grinding rolls and gears are also arranged.

Owner:NANTONG ELITE MARINE EQUIP & ENG INC JIANGSU

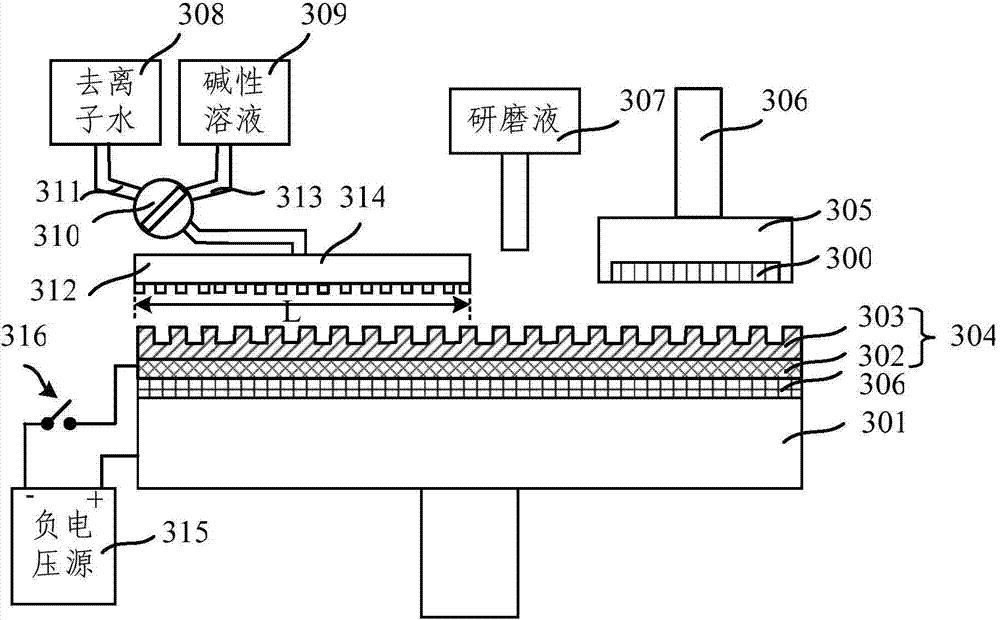

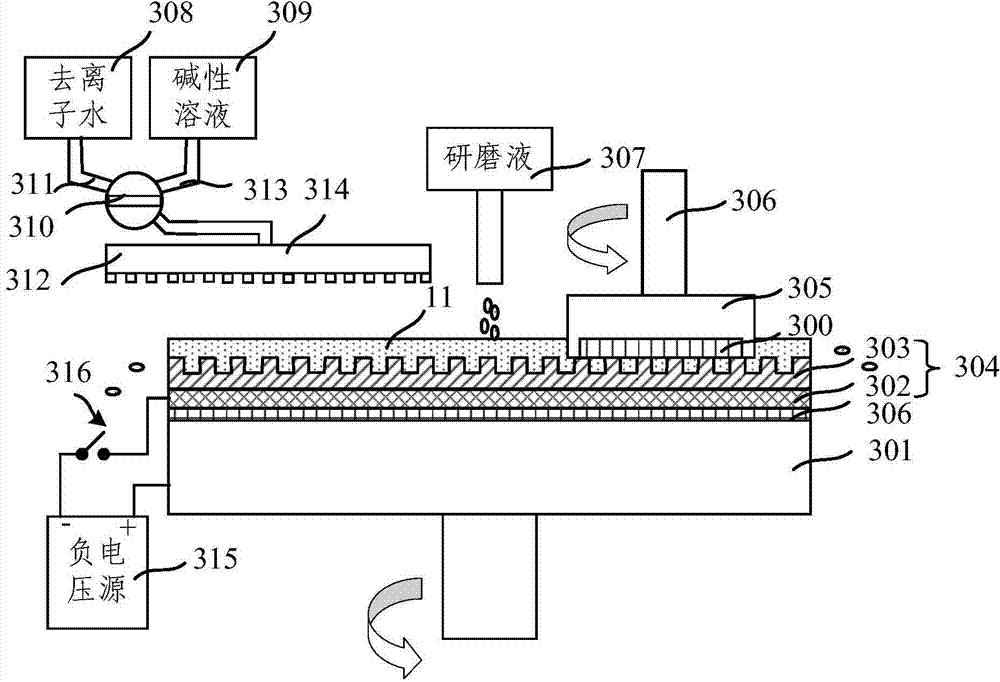

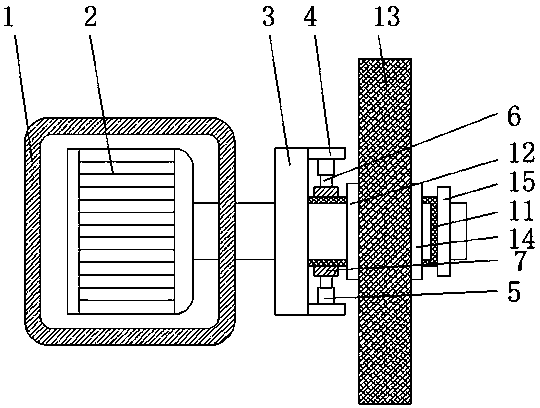

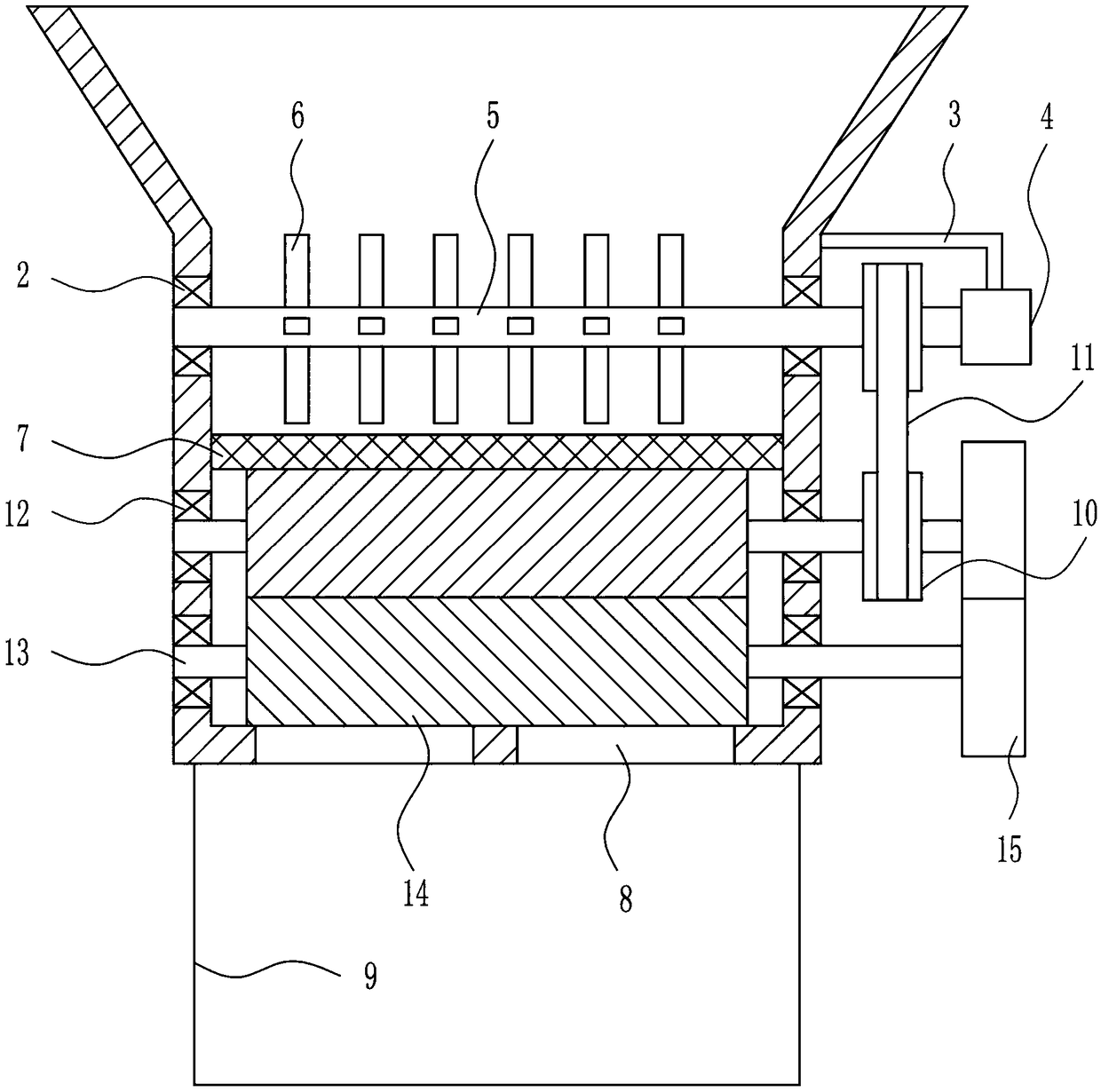

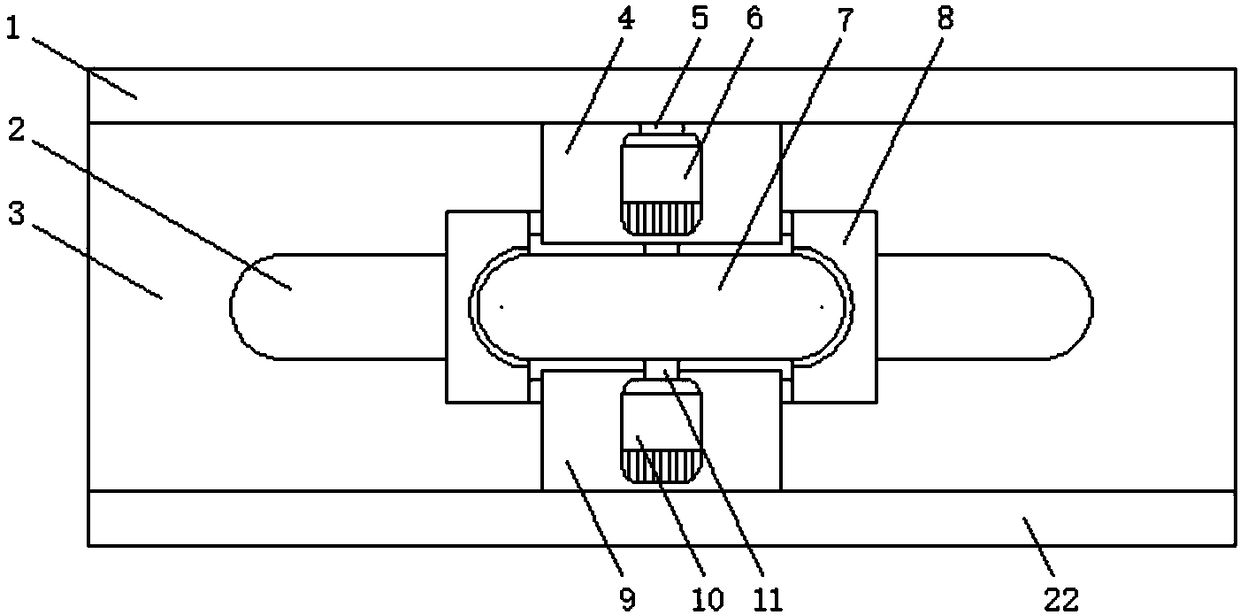

Chemical mechanical grinding device and chemical mechanical grinding method

ActiveCN104742007AIncrease repulsionAvoid condensationMachining electric circuitsAbrasion apparatusNegative powerEngineering

A chemical mechanical planarization (CMP) apparatus is provided. The CMP apparatus includes at least one platen; and a polishing pad disposed on the platen. The CMP apparatus also includes a polishing head disposed above the platen and configured to clamp a to-be-polished wafer; and a basic solution supply port disposed above the platen and configured to supply a basic solution onto a surface of the polishing pad. Further, the CMP apparatus includes a slurry arm disposed above the platen and configured to supply a polish slurry on the surface of the polishing pad; and a deionized water supply port configured to supply deionized water onto the surface of the polishing pad. Further, the CMP apparatus also includes a negative power source configured to apply a negative voltage onto the surface of the polishing pad.

Owner:SEMICON MFG INT (BEIJING) CORP +1

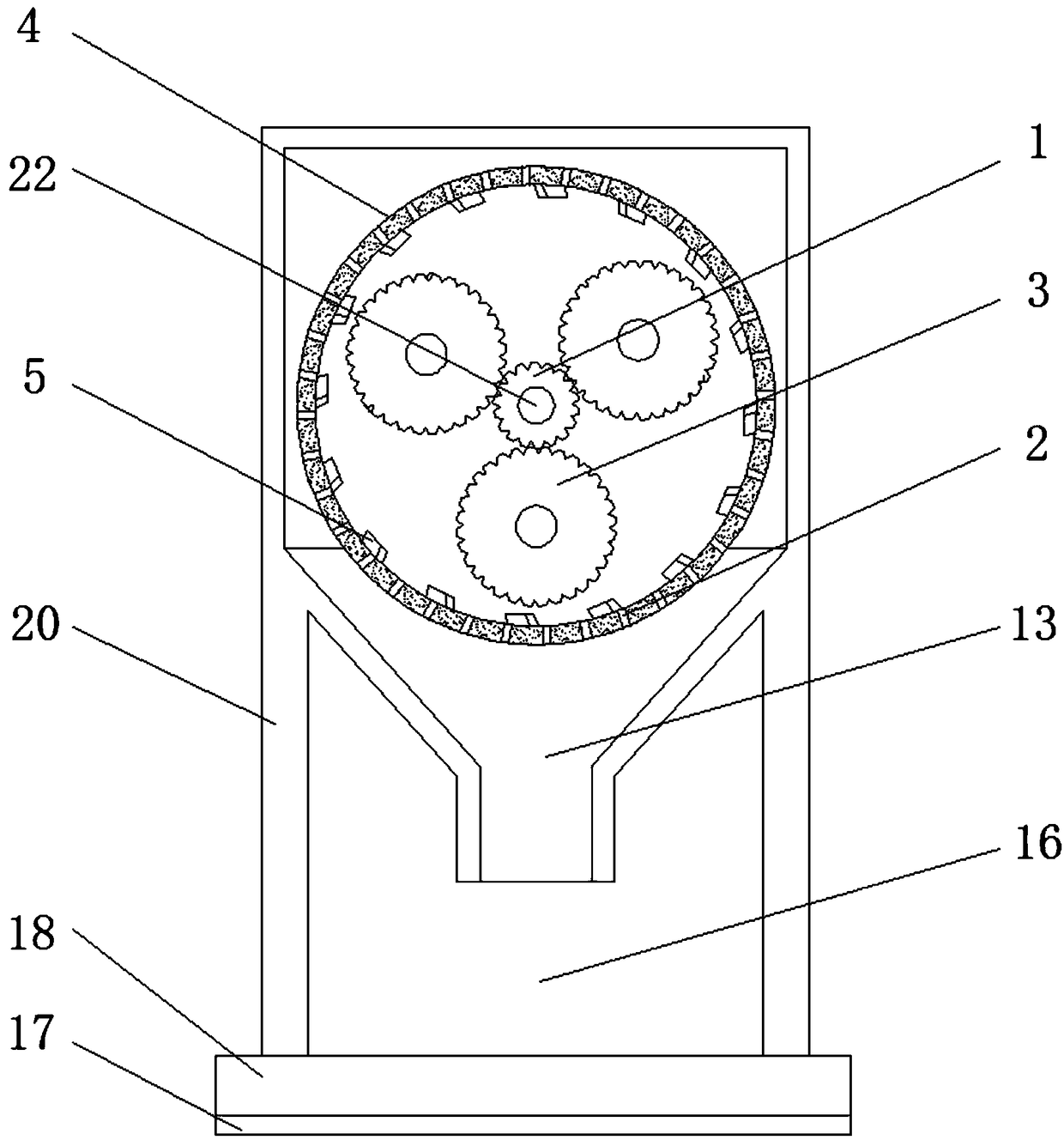

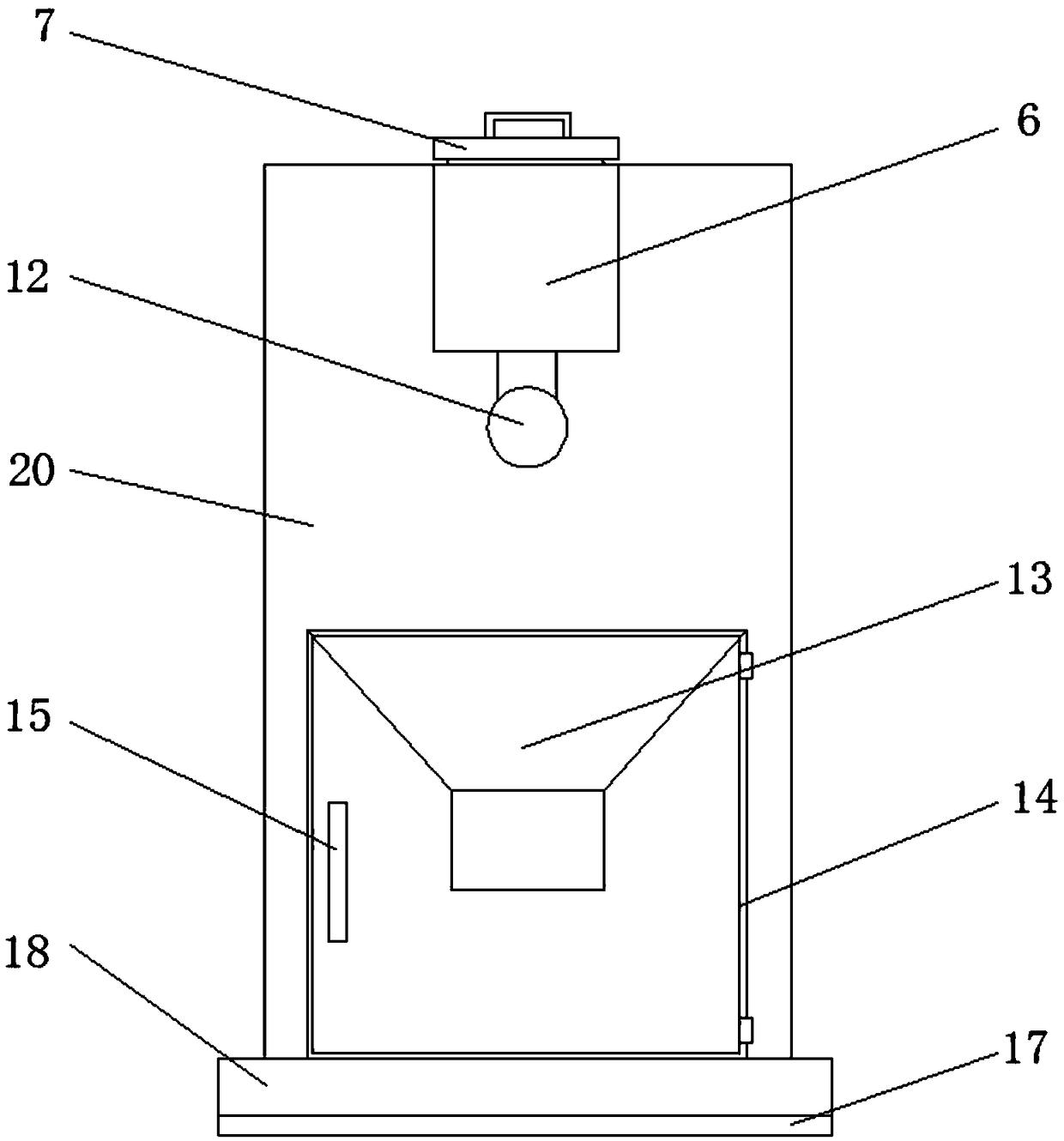

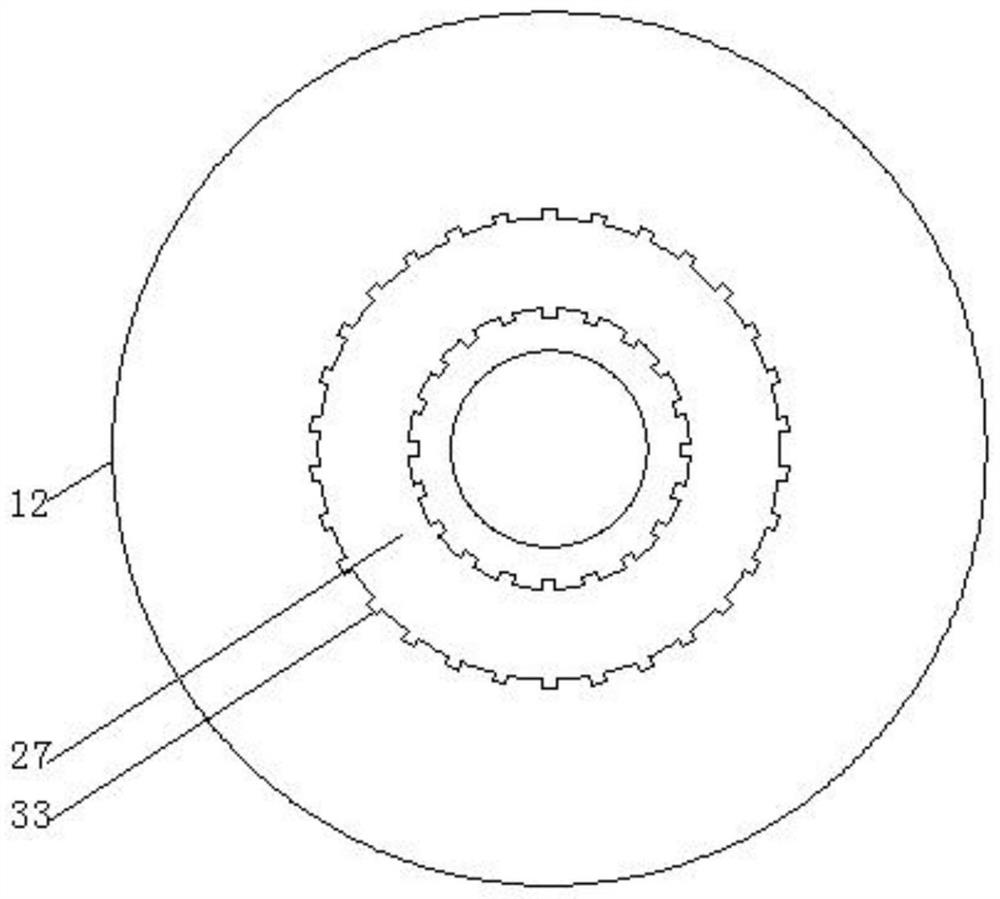

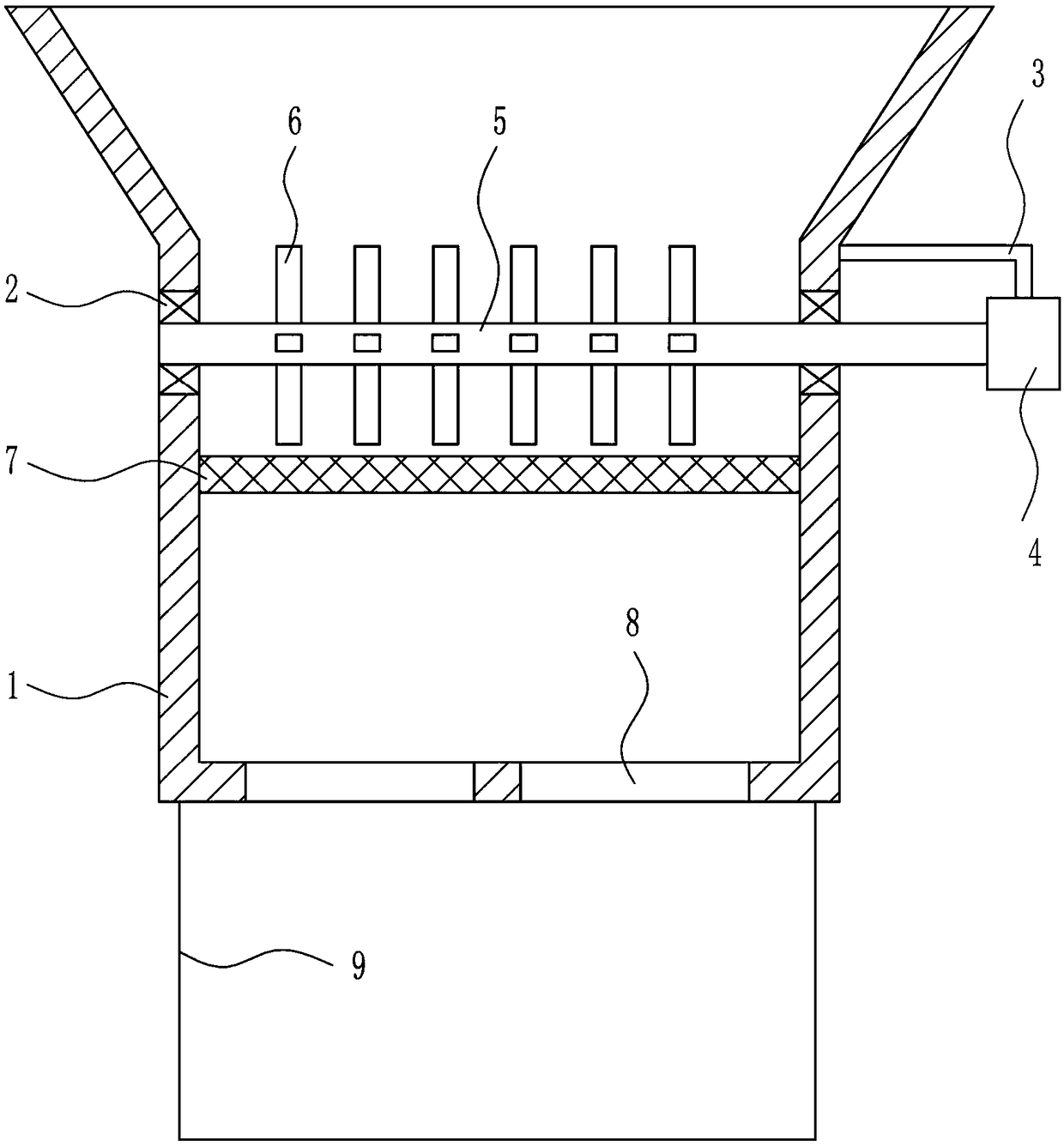

Efficient traditional Chinese medicine grinder capable of timely separating medicine powder

InactiveCN109261266AImprove work efficiencyImprove uniformityGrain treatmentsElectric machineryChinese herbology

The invention discloses an efficient traditional Chinese medicine grinder capable of timely separating medicine powder. The efficient traditional Chinese medicine grinder comprises a first grinding gear, a second grinding gear, a screen drum, a feeding hopper, a discharging groove, a base plate and a shell; the shell is welded to the top of the base plate; a motor is arranged at the top, on the inner side of the shell, of the base plate; a fixing plate is fixed to one side of the top end of the inner part of the shell; the screen drum is arranged between the fixing plate and the inner side wall of the shell; bearings are arranged between the two ends of the screen drum and the fixing plate and the inner side wall of the shell; and a fixing rod is fixed between the screen drum and the bearing close to one end of the fixing plate. According to the efficient traditional Chinese medicine grinder, the feeding hopper is arranged on one side of the top end of the outer side wall of the shell,a spiral stirring shaft extending to the lower part of the feeding hopper is fixed at one end of the fixing rod, so that medicinal materials are conveniently added, the spiral stirring shaft is driven to rotate in the grinding process of the medicinal materials, so that the medicinal materials are more uniformly added, in addition, the medicinal materials can be conveniently cut and crushed in the conveying process, a material conveying pipe is prevented from being blocked, and the grinding efficiency is improved.

Owner:侯红星

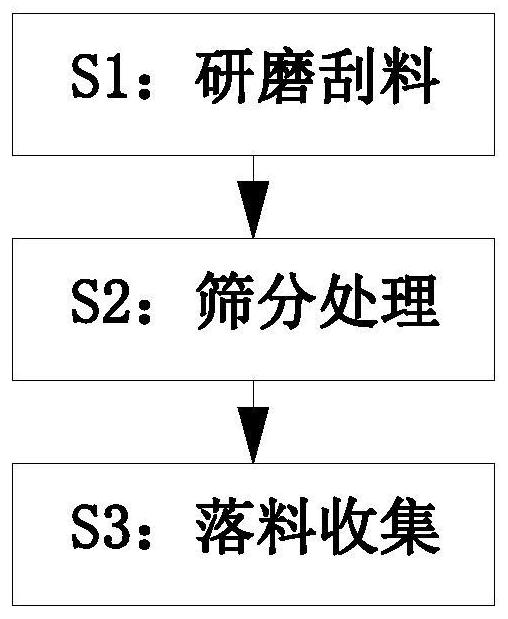

Water-based printing ink preparation method

InactiveCN113134423AFine ink raw materialsEasy to stir and mixSievingScreeningPrinting inkGrinding mill

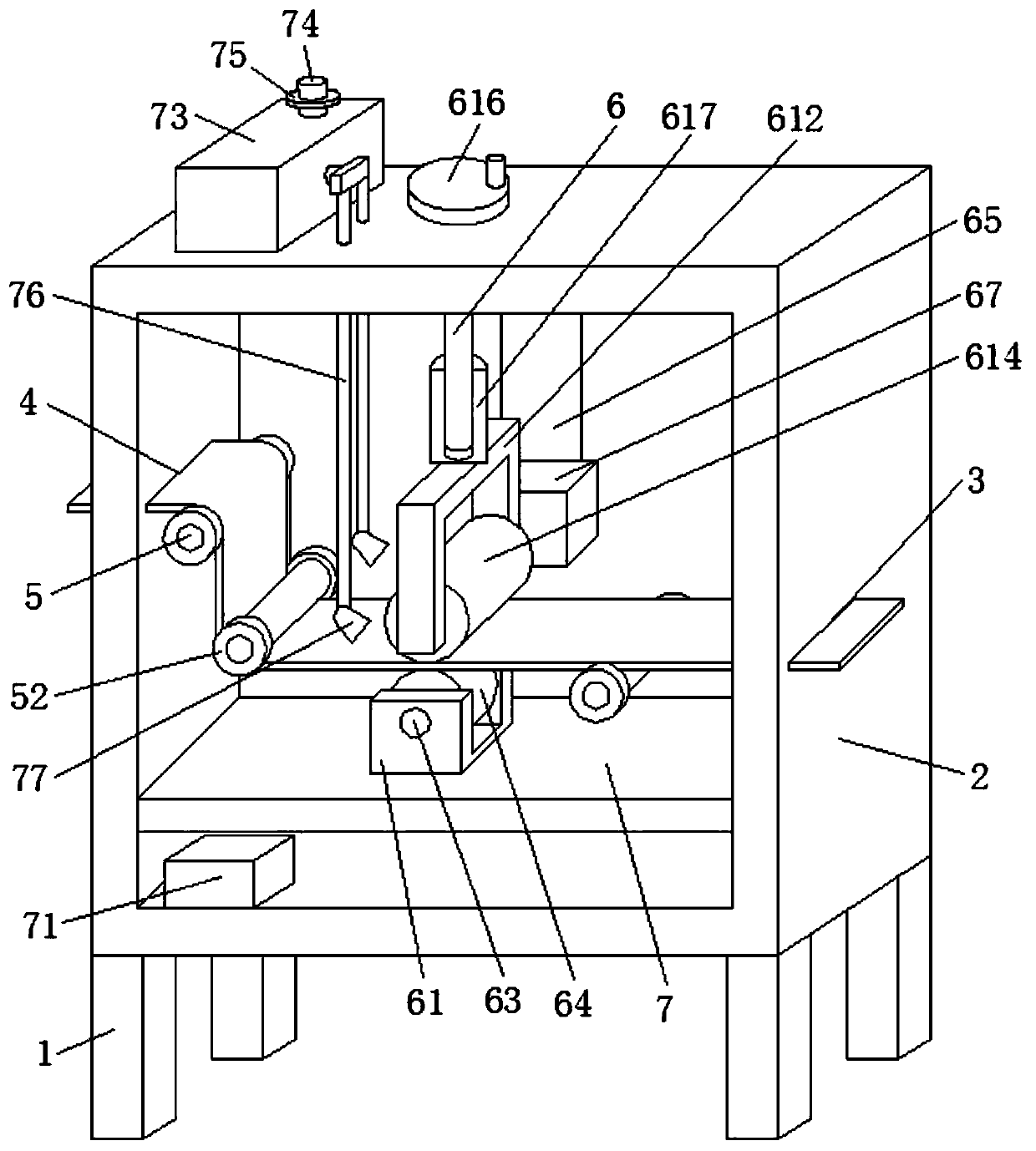

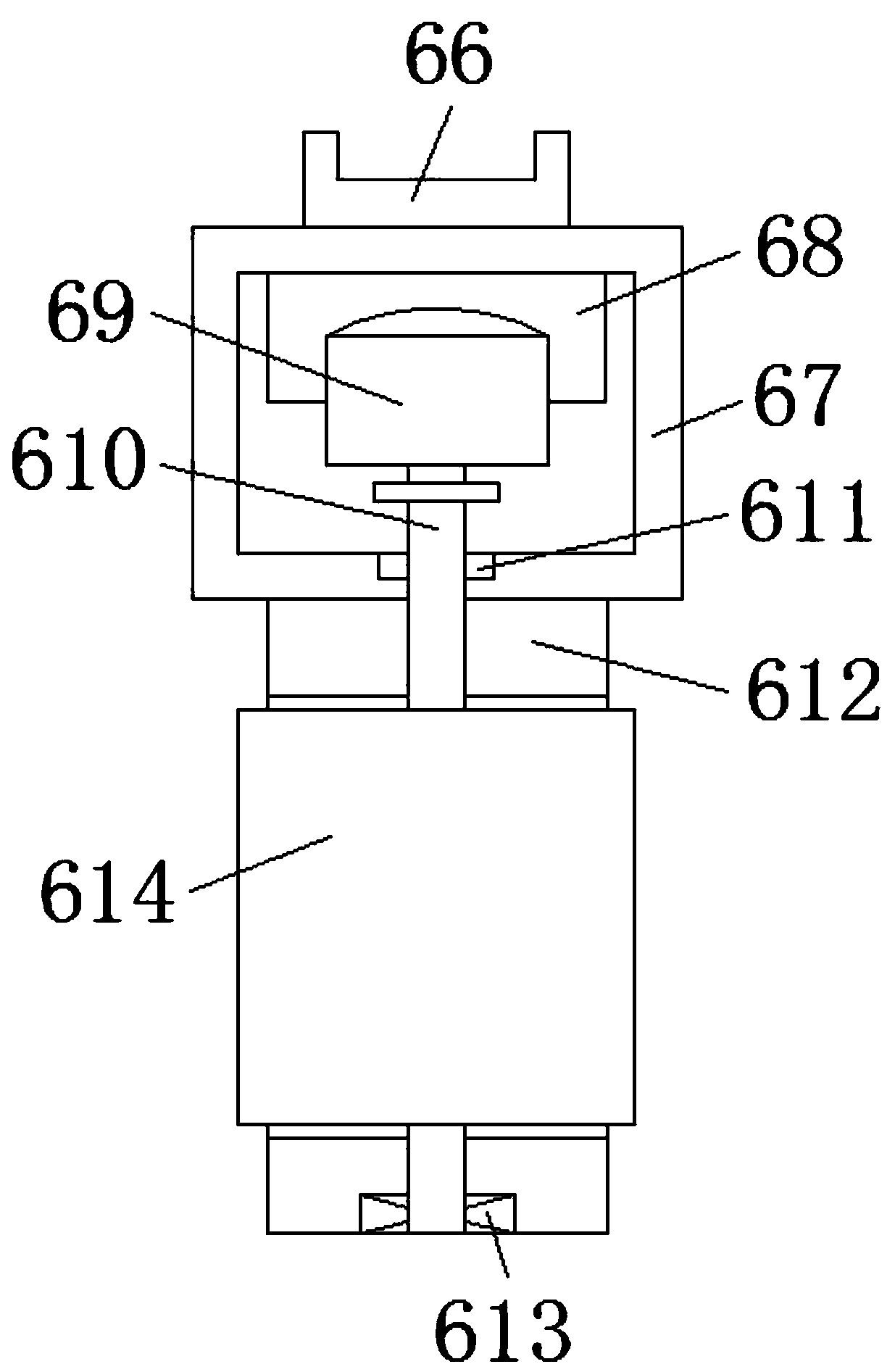

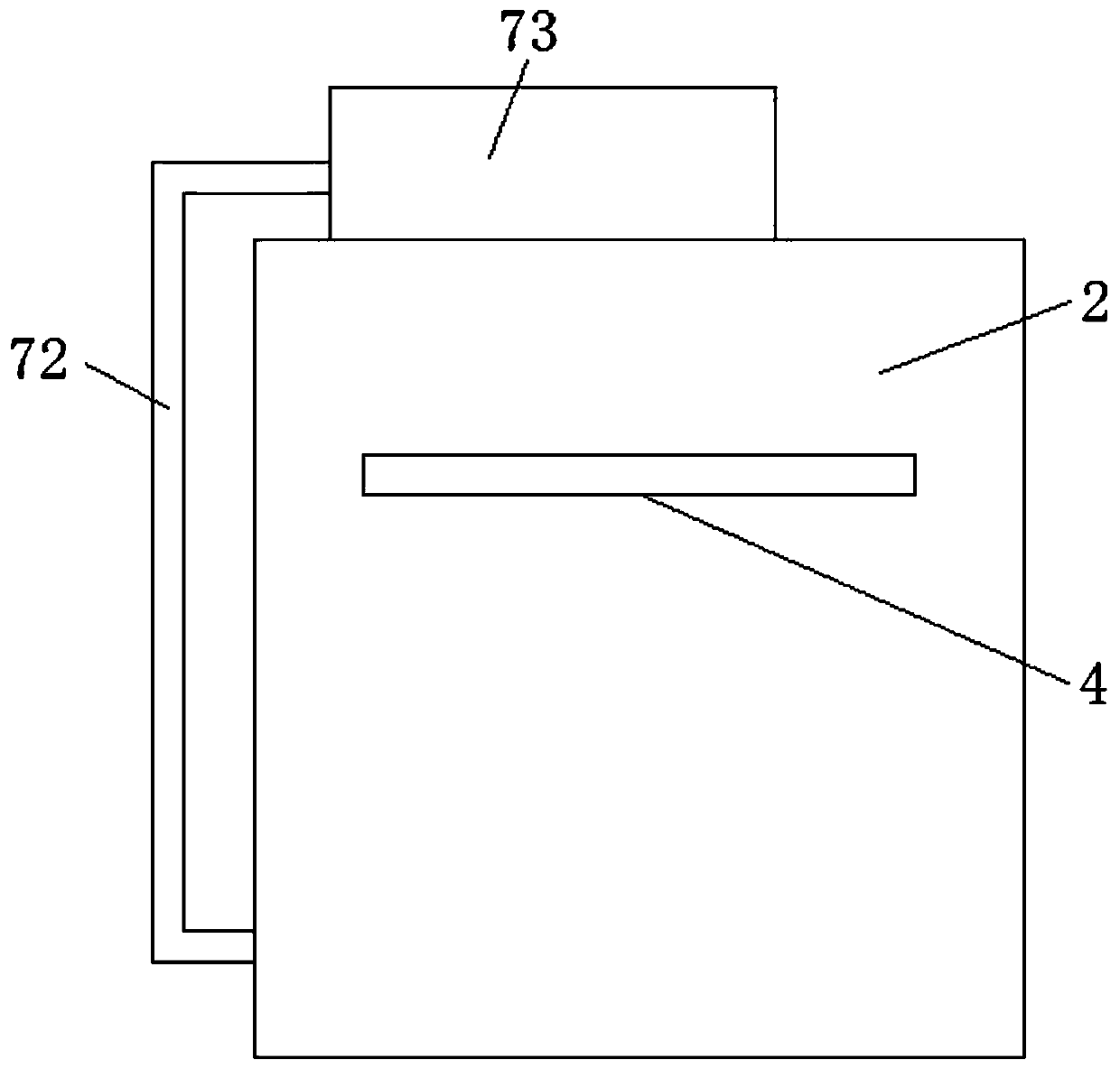

The invention relates to a water-based printing ink preparation method. A water-based printing ink preparation device is used. The water-based printing ink preparation device comprises a preparation box, a grinding mechanism, a screening mechanism, a scraping mechanism and a collecting box, the preparation box is of a rectangular structure, the grinding mechanism, the screening mechanism and the collecting box are sequentially arranged on the inner wall of the preparation box from top to bottom, and the scraping mechanism is arranged on the grinding mechanism. According to the method, the grinding mechanism can conduct double grinding on ink raw materials, so that the ground ink raw materials are finer, mixing and stirring of the ink raw materials are facilitated, the mixing stirring effect behind the ink raw materials is prevented from being influenced due to the fact that the grinding of the ink raw materials is not fine, meanwhile, the ink raw materials adhered to a first grinding roller and a second grinding roller on the grinding mechanism are scraped off by adopting the scraping mechanism, so that the adhered raw materials are prevented from influencing the grinding of a grinding roller, and therefore, the grinding effect of the grinding roller is not good.

Owner:有限会社林平

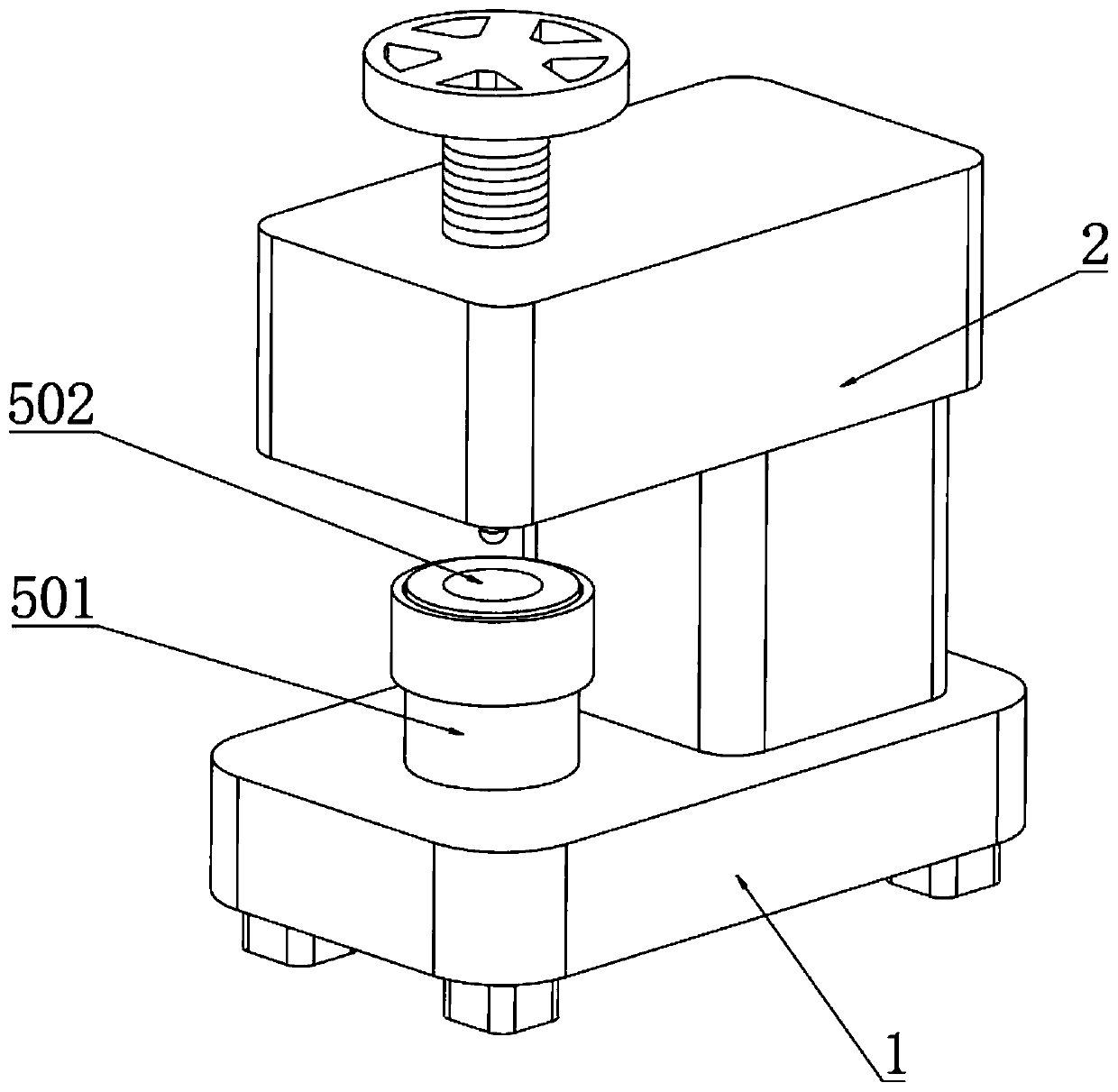

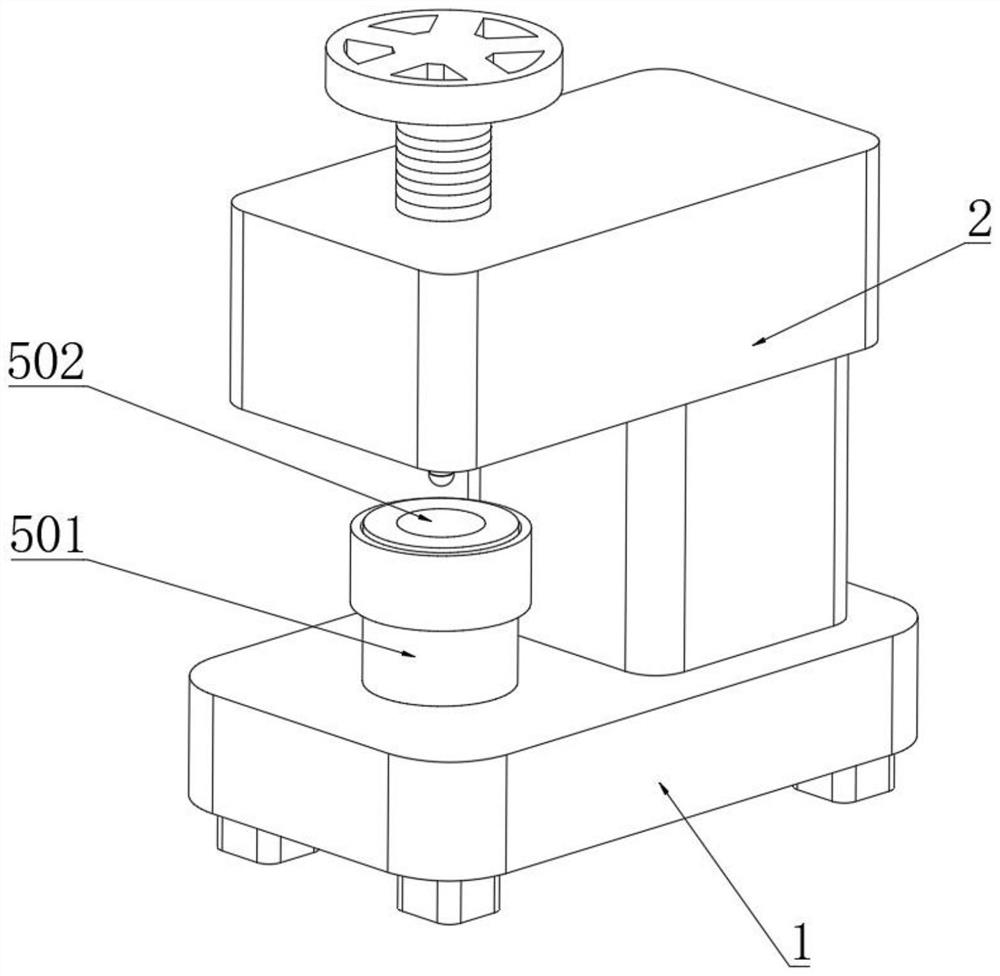

Anti-loss molecular biology experimental sample grinder

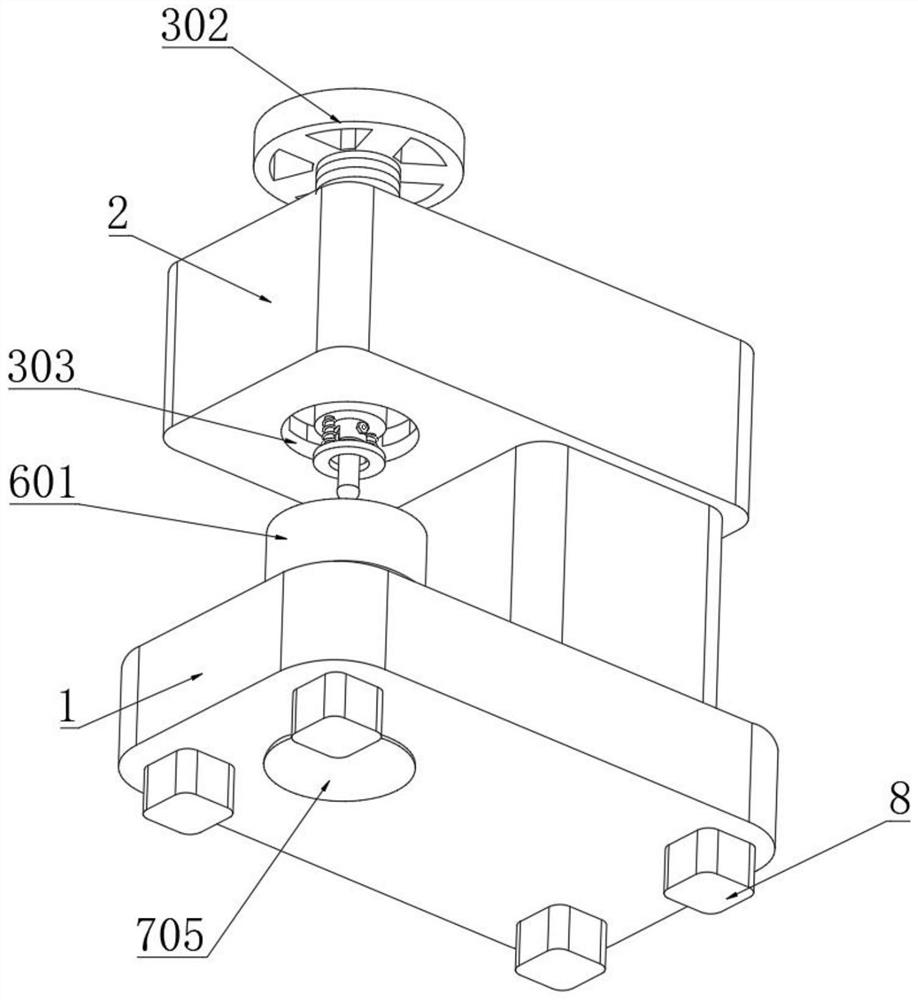

ActiveCN111530536AScientific and reasonable structureEasy to useGrain treatmentsRotational axisElectric machine

The invention discloses an anti-loss molecular biology experimental sample grinder. The anti-loss molecular biology experimental sample grinder comprises a base. A supporting frame is fixedly connected with the lateral side of the top end of the base. A lifting mechanism is movably connected with the lateral side of the top end of the supporting frame. The lifting mechanism comprises a rotating rod, a rotary disc, a round groove, a slide groove, a slider, a fixed base, rotating motor and a rotating shaft base. The rotating rod is screwed in and rotationally connected with the top end of the supporting frame. The rotary disc is cast at the top end of the rotating rod. The anti-loss molecular biology experimental sample grinder is scientific and reasonable in structure and safe and convenient to use; and the lifting mechanism is arranged and the rotary disc is rotated to drive the rotating rod to rotate, and the fixed base is pushed to slide up and down along the round groove through thecooperation of the slide groove and the slider, so that the heights of the fixed base, the rotating motor and the rotating shaft base are adjusted, then the gap between a grinding rod and a grindingpipe is adjusted according to needs, the grinding effect is improved, and biological experimental samples can be ground more sufficiently.

Owner:QINGDAO AGRI UNIV

Grinding material and grinding tool device for grinding

PendingCN108406587AImprove the fixed effectImprove replacement efficiencyGrinding wheel securing apparatusEngineeringMachine parts

The invention relates to the technical field of processing equipment and discloses a grinding material and grinding tool device for grinding. The grinding material and grinding tool device for grinding comprises a protective shell, wherein a motor is fixedly mounted in the bottom of an inner cavity of the protective shell; the output shaft of the motor penetrates through the protective shell and extends out of the protective shell; the output shaft of the motor is movably connected to the connection part of the protective shell; a fixed plate is fixedly mounted on the output shaft of the motorin a sleeving manner; and a limiting plate is fixedly mounted on the side face of the fixed plate. According to the grinding material and grinding tool device for grinding, a ring of protective layeris arranged around the motor by matching the protective shell with the motor, to prevent flying chips generated by a grinding sheet and grinding mechanical parts in the grinding process from enteringthe motor in the flying process to affect the service life of the motor which is used for a long time. By matching the fixed plate and the limiting plate, a limiting barrel is prevented from fallingfrom the limiting plate in the rotating process.

Owner:FORTURE TOOLS CO LTD

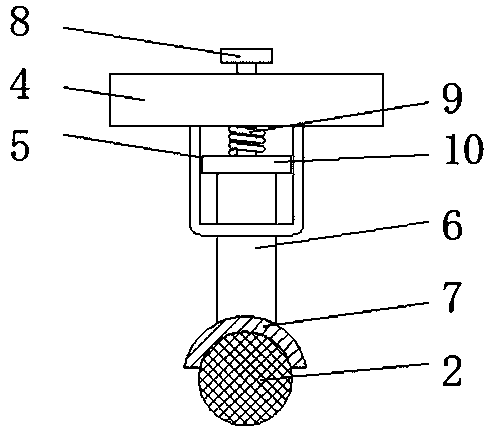

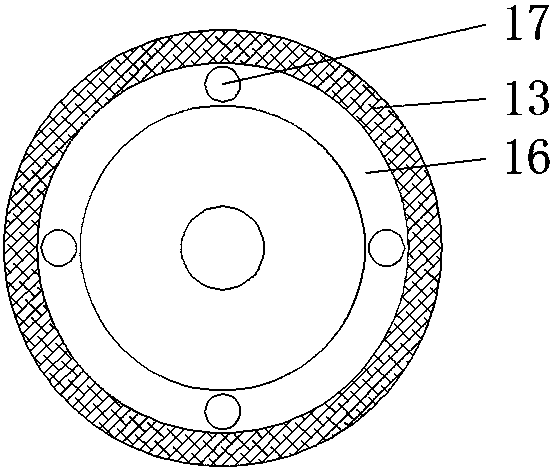

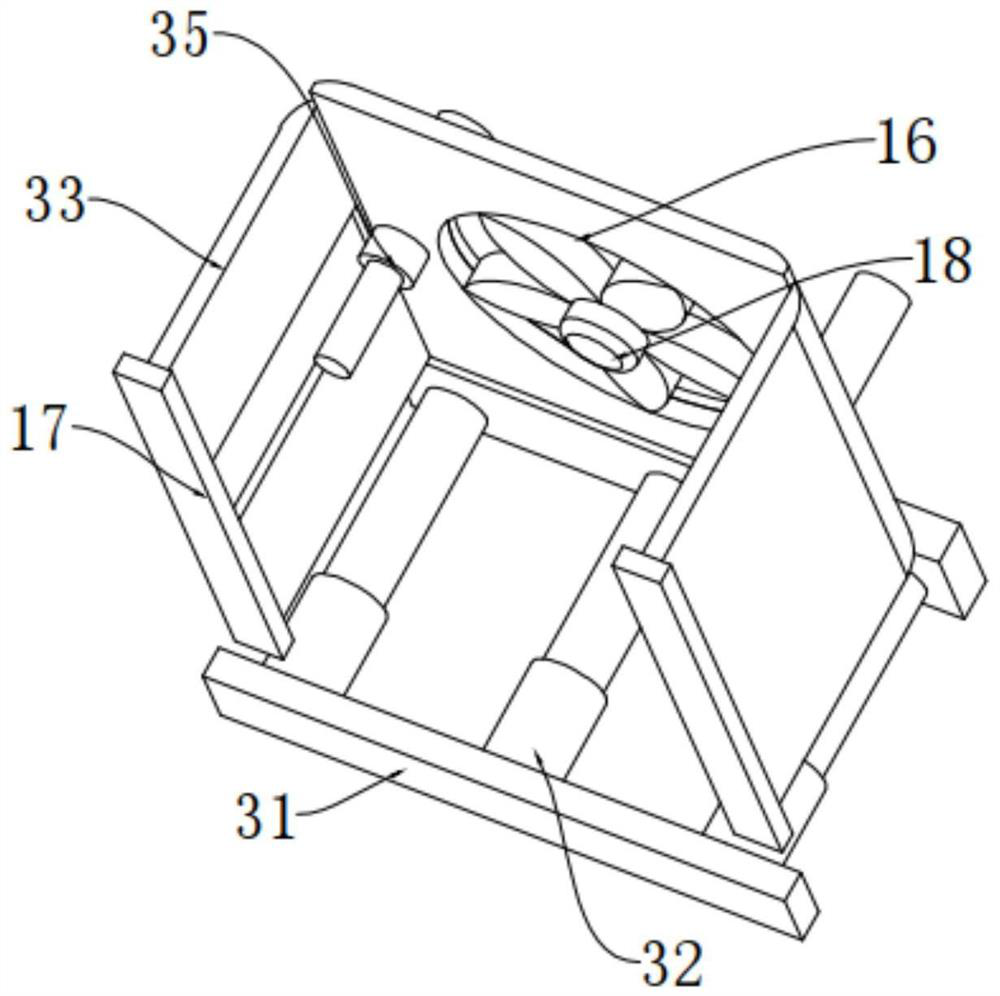

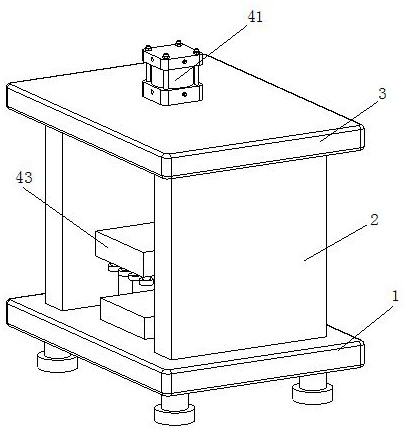

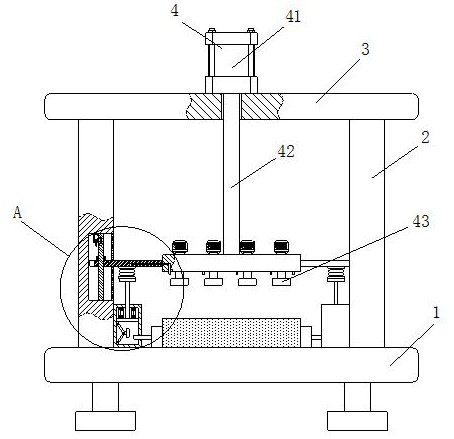

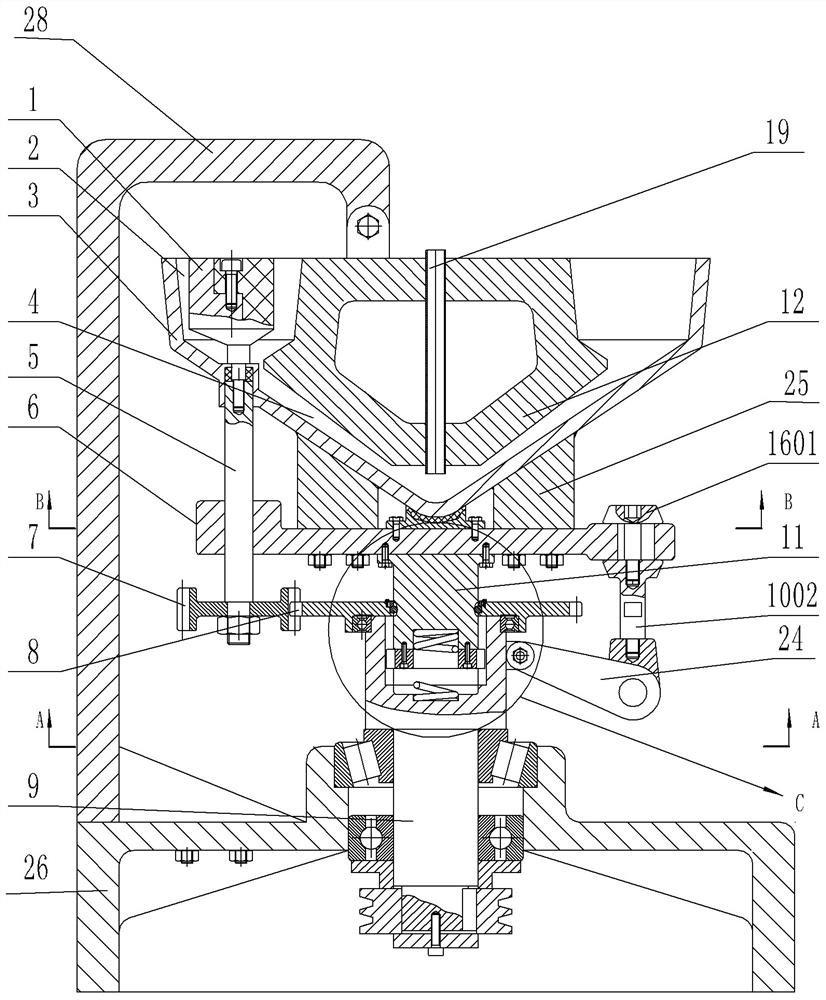

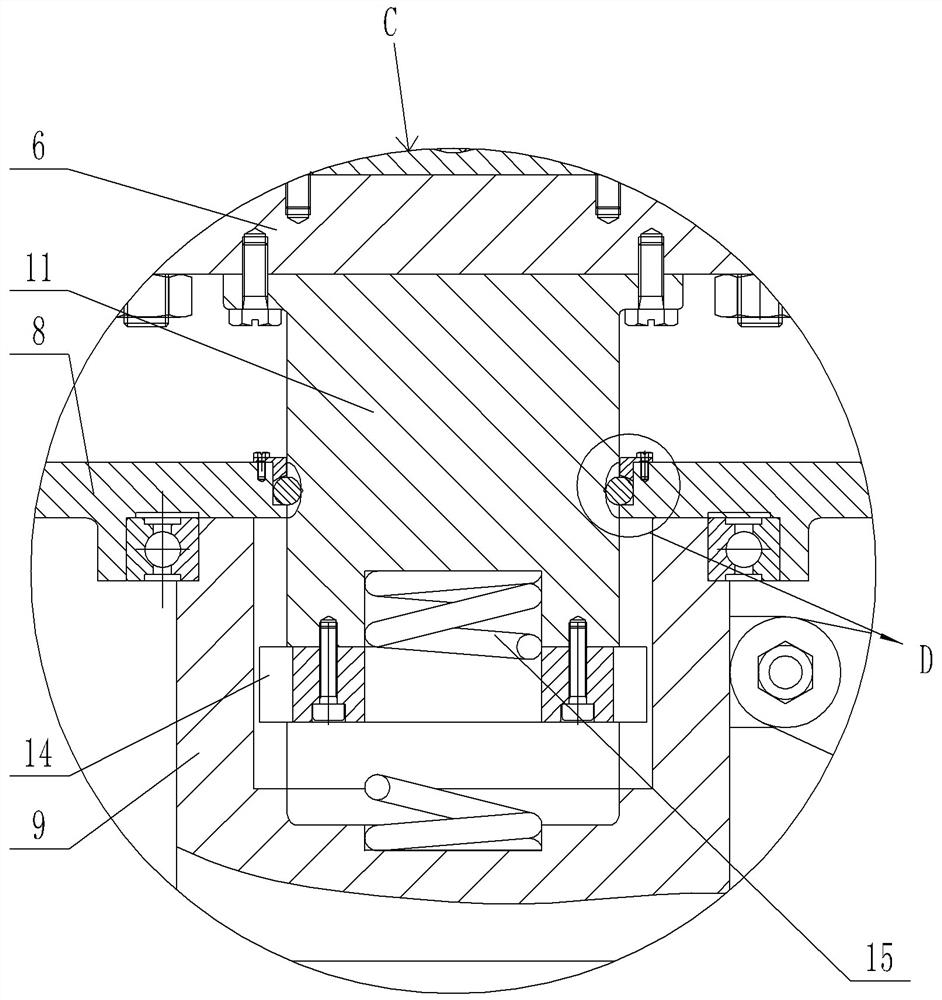

Turning over tool for accurate grinding of automobile gearbox transmission gear

PendingCN112091790APractical to useAvoid affecting the effect of grindingGrinding carriagesGrinding drivesGear wheelElectric machinery

The invention relates to the technical field of automobile gearbox transmission gears, and discloses a turning over tool for accurate grinding of an automobile gearbox transmission gear. The turning over tool comprises a fixing frame plate, an turning over grinding mechanism is arranged inside the fixing frame plate, and the turning over grinding mechanism comprises a fixing column, a motor, a motor shaft, a first bearing, a connecting rod, a first fixing cylinder, a partition plate, a clamping block and a first spring. According to the turning over tool, by arranging a first spring, a first fixing rod, a second bearing and second fixing blocks in the first fixing cylinder, gears of different sizes can be placed between the two second fixing blocks by using the first spring and the first fixing rod, therefore the gears of different sizes can be clamped and ground, and the second fixing blocks can be rotated through the second bearing, so that the second fixing blocks are turned over, accurate grinding and rough grinding are switched according to the grinding requirement for switching, and in addition, the side faces of the gears can be ground through the second grinding blocks on the first fixing cylinder.

Owner:济南健嵘精密机械有限公司

Electric vehicle wheel hub end cover polishing table

InactiveCN114260766AEasy to handlePlay a clamping effectRevolution surface grinding machinesGrinding drivesStructural engineeringMachine

The invention relates to the technical field of hub grinding equipment, in particular to an electric vehicle hub end cover grinding table which comprises a rack, a conveying belt, a positioning protection device and a turnover mechanism, the conveying belt is located above the rack, and a plurality of electric lifting columns capable of penetrating through hub center shaft holes are evenly and horizontally arranged on the conveying belt; a plurality of recycling rods capable of freely stretching out and drawing back are circumferentially distributed on the side wall, close to the top end, of the electric lifting column, a first side supporting table and a second side supporting table are arranged on one side of the rack, a first grinding machine is arranged on the first side supporting table, and a second grinding machine is arranged on the second side supporting table; the positioning protection device is installed on the portion, corresponding to the first grinding machine in position, of the machine frame, and the turnover mechanism is arranged on one side of the positioning protection device and arranged on the portion, between the first grinding machine and the second grinding machine, of the machine frame. And the hub on the grinding table can be automatically positioned, and chippings can be prevented from being splashed down to other hubs.

Owner:XUZHOU XIAOQIANG WHEEL TECH CO LTD

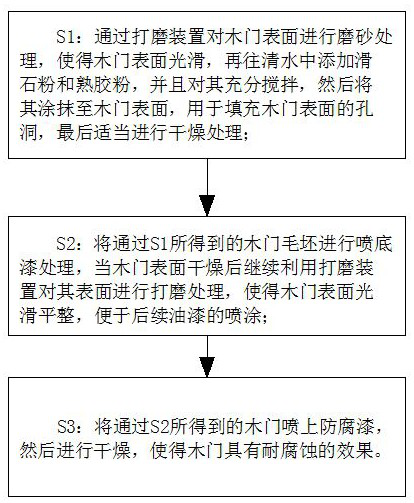

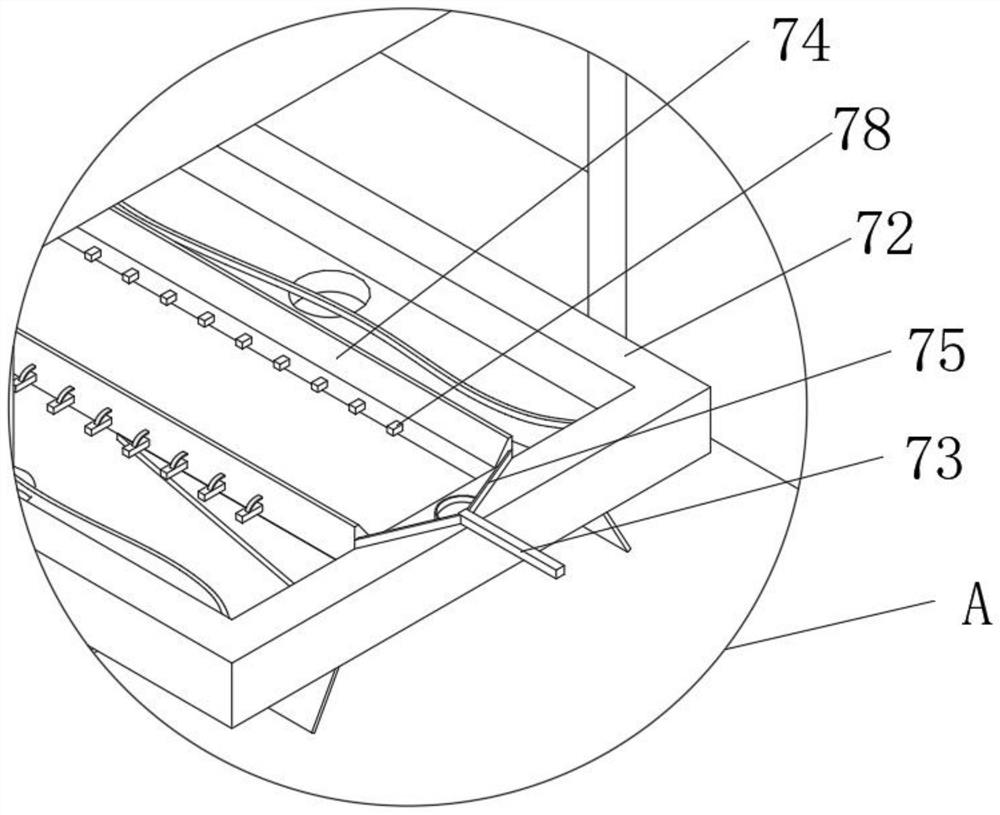

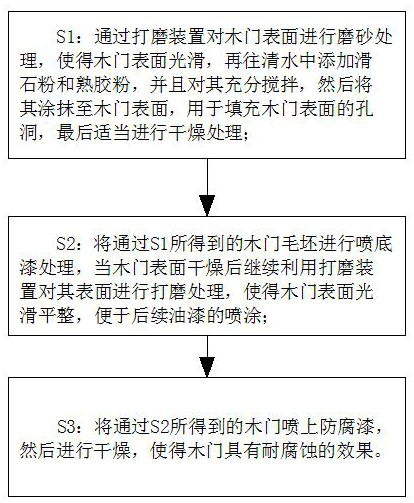

Process for machining corrosion-resistant wooden door and device thereof

ActiveCN112720123ASmooth slidingImprove stabilityGrinding drivesSpecial surfacesCorrosion resistantPolishing

The invention belongs to the field of wooden door machining and manufacturing, and in particular relates to a process for machining a corrosion-resistant wooden door and a device thereof. The process comprises the steps: S1, conducting frosting treatment on a surface of the wooden door by using a polishing device, wherein the surface of the wooden door is smooth, then adding talc powder and cured rubber powder into clean water and fully stirring the same, then smearing the mixture to the surface of the wooden door for filling a hole in the surface of the wooden door, and finally, conducting drying properly; S2, spraying a primer to a wooden door blank prepared in the S1, and polishing the surface of the wooden door by using the polishing device continuously after the surface of the wooden door is dried, wherein the surface of the wooden door is smooth and level and it is convenient to spray paint subsequently; and S3, spraying an anti-corrosion paint to the wooden door obtained in the S3, and then drying the wooden door, wherein the wooden door has a corrosion-resistant effect. The polishing device in the S1 and S2 comprises a worktable, a supporting plate, a cover plate and a polishing unit. The process is good in wooden door polishing effect.

Owner:浙江瀚霖门业有限公司

Grinding device adjustable in grinding distance

InactiveCN108177052AAffectAffect accuracyGrinding wheel securing apparatusGrinding carriagesGear wheelEngineering

The invention relates to the technical field of grinding equipment, and discloses a grinding device adjustable in grinding distance. The grinding device comprises grinding equipment, two supporting legs are fixedly installed at the bottom of the grinding equipment and symmetrically distributed at the bottom of the grinding equipment, a first connecting rod is movably connected to the side wall ofan inner cavity of the grinding equipment, one end of the first connecting rod is fixedly connected with a fixing gear, and outer teeth of the fixing gear are meshed with a chain. According to the grinding device adjustable in grinding distance, through the cooperation of the grinding equipment and the supporting legs, when the equipment is used for grinding objects, the situation is avoided thatthe grinding precision and effect are influenced since the equipment vibrates during grinding and displaces from an original position; through the cooperation of the first connecting rod and the fixing gear, the fixing gear is fixed in the grinding equipment; through the cooperation of a handle and the chain, a positing gear and the fixing gear are in matched transmission with a rotating wheel.

Owner:姜慧 +1

Continuous mold for hardware punching

PendingCN110202055AEasy to take outAvoid bondingShaping toolsGrinding work supportsPunchingEngineering

The invention discloses a continuous mold for hardware punching. The continuous mold for hardware punching comprises a punching mold, a bottom cabinet and a cutting rack. Mounting plates are welded totwo sides of the top of the bottom cabinet through supporting rods, a penetrating air cylinder is fixedly mounted on the tops of the mounting plates, a motor is fixedly mounted on the side, far awayfrom the air cylinder, of the top of the mounting plate, the cutting rack is fixedly mounted at the bottom of the mounting plate through a bolt, a buffer rack is mounted on the top of the bottom cabinet through a bolt, a punching mold is fixedly mounted on one side of the top of the buffer rack, and a fixing rack is fixedly mounted on one side of the punching mold. The continuous mold is providedwith a reset rack, so that a trough plate of the mold is reset, the punched mold is taken out conveniently, and a workpiece is prevented from being adhered to the trough plate of the punching mold, sothat the punching efficiency of the device is improved effectively. The workpiece can be polished through a mounted polishing disc, so that staff does not need to polish with additional equipment, sothat the functionality of the continuous mold is increased and the practicality of the continuous mold is improved.

Owner:张家港市云宸汽车零部件有限公司

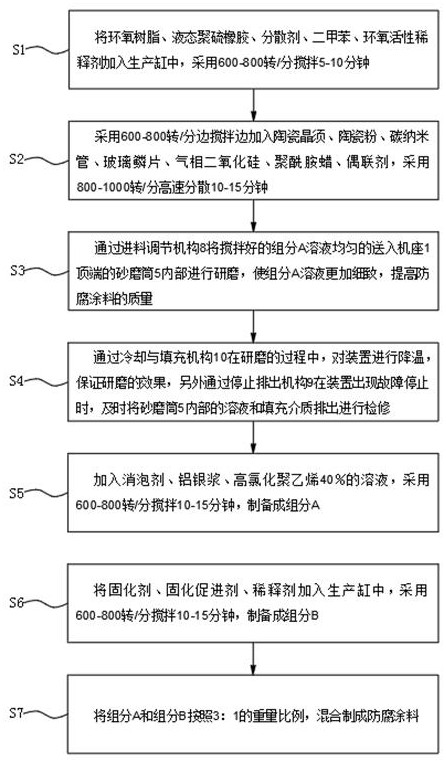

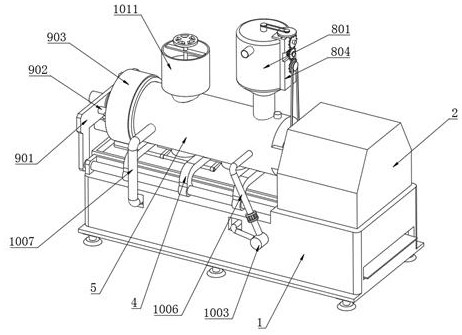

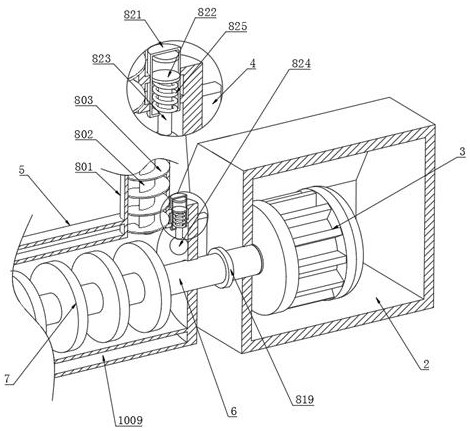

Flexible ceramic heavy anti-corrosion coating and preparation method thereof

InactiveCN113480917AScientific and reasonable structureEasy to useMixer accessoriesAnti-corrosive paintsXylylenePolyamide

The invention discloses a preparation method of a flexible ceramic heavy anti-corrosion coating, which comprises the following steps of: S1, adding epoxy resin, liquid polysulfide rubber, a dispersing agent, xylene and an epoxy active diluent into a production cylinder, and stirring for 5-10 minutes at the speed of 600-800 revolutions per minute; and S2, adding ceramic whiskers, ceramic powder, carbon nanotubes, glass flakes, fumed silica, polyamide wax and a coupling agent while stirring at the speed of 600-800 revolutions per minute, and dispersing at the high speed of 800-1000 revolutions per minute for 10-15 minutes. According to the invention, the structure is scientific and reasonable, the use is safe and convenient. The liquid polysulfide rubber and the high chlorinated polyethylene are adopted, the epoxy resin is modified by the curing reaction of the epoxy resin and a phenolic aldehyde amine curing agent, and the obtained coating has characteristics of good flexibility and good corrosion resistance under the action of the ceramic whisker and the carbon nanotubes. Meanwhile, the glass flakes further improve the corrosion resistance of the coating, and the ceramic powder and the whiskers effectively improve the corrosion resistance of the coating and improve the impact resistance of the coating.

Owner:NANJING YUSONG MATERIAL TECH CO LTD

Polishing device in cosmetic bag production and using method thereof

PendingCN110846444ATo achieve the effect of guiding limitAvoid affecting the effect of grindingSkins/hides/leather/fur manufacturing apparatusLeather surface mechanical treatmentEngineeringMechanical engineering

The invention belongs to the technical field of cosmetic bag equipment, and particularly relates to a polishing device in cosmetic bag production and a using method thereof. The polishing device in the cosmetic bag production and the using method thereof involves supporting legs, a grinding box is fixedly connected to the tops of the supporting legs, a feeding port and a discharging port are formed in the surfaces of the two sides of the polishing box correspondingly, the inner wall of the feeding port and the inner wall of the discharging port are in sliding plugging connection with the surface of cosmetic bag leather, a moving and guiding device is arranged inside the polishing box, and the moving and guiding device comprises a guiding shaft. According to the polishing device in the cosmetic bag production and the using method thereof, a dust cleaning and impurity removing device is arranged at the inner bottom of the polishing box, the dust cleaning and impurity removing device comprises a filtering plate, and the surface of the filtering plate is fixedly connected with the inner wall of the grinding box, so that the purposes that the surface of the cosmetic bag is cleaned and impurities or dust is ground when the grinding is conducted by using water and the grinding effect can be enhanced by adopting a water grinding technology as well are achieved, and the cosmetic bag canbe smooth and bright.

Owner:安徽百川纳包装制品有限公司

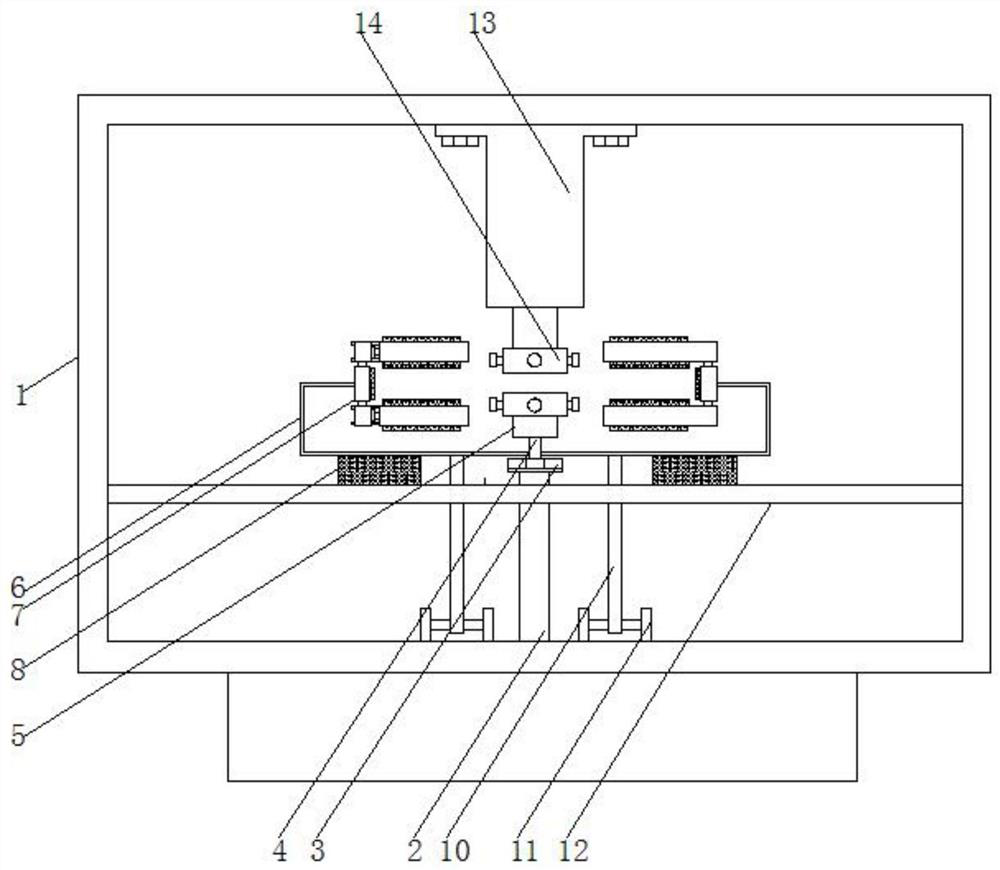

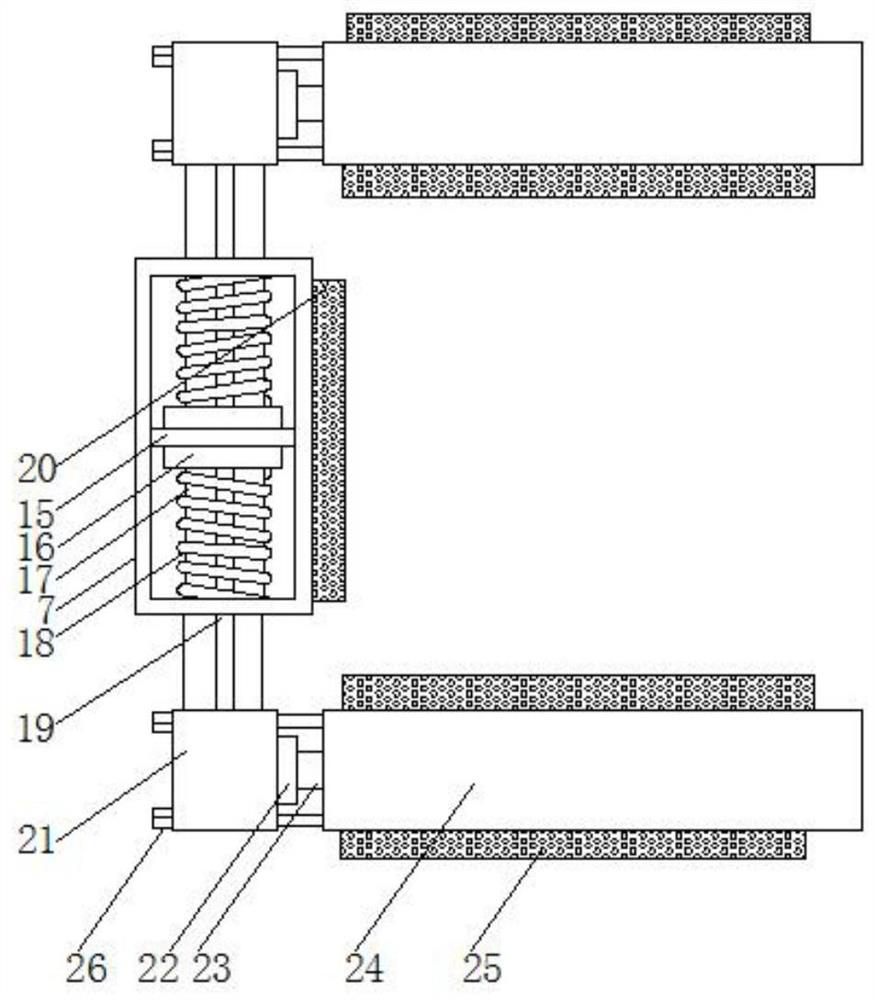

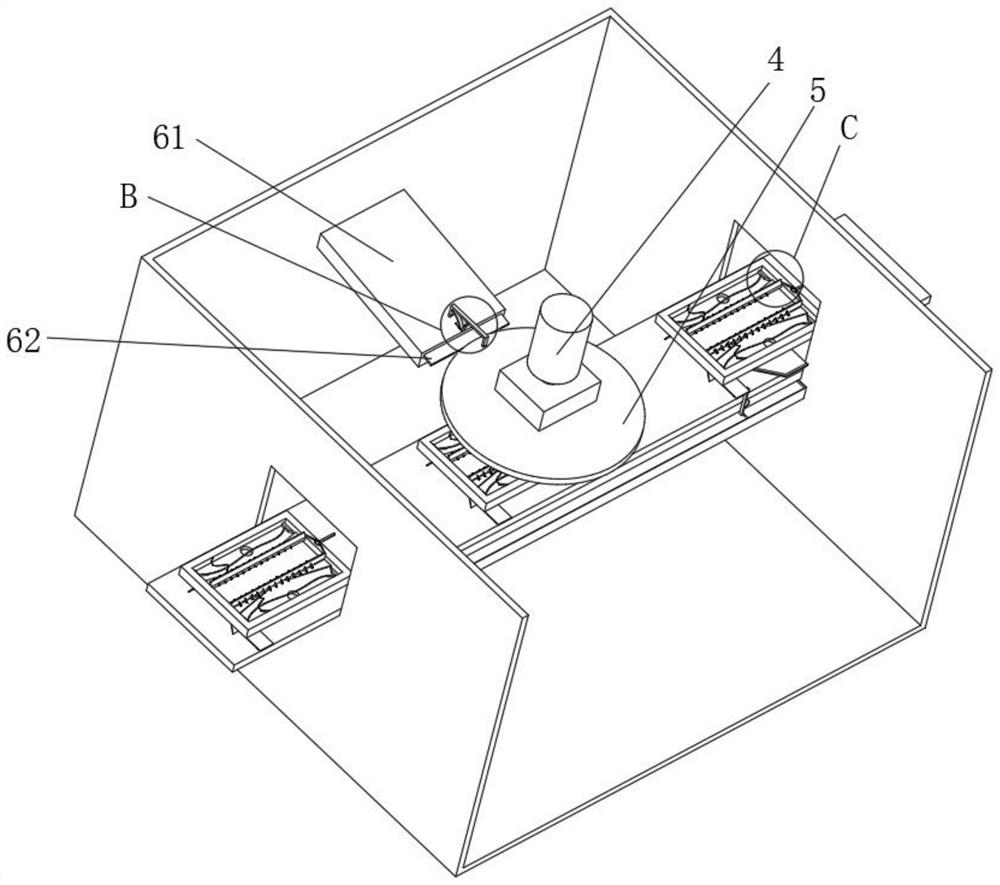

A grinding device for relay skeleton processing

Owner:HUANGSHAN WANGRONG ELECTRONICS

Polishing device for machining of relay framework

The invention discloses a polishing device for machining of a relay framework, and belongs to the technical field of machining of relays. The polishing device comprises two fixing assemblies, a conveying assembly, rotary polishing assemblies, an overturning assembly and a dust collection assembly. The two fixing assemblies are respectively fixedly arranged above the conveying assembly. The rotarypolishing assemblies are fixedly arranged on two sides of the conveying assembly, and the work ends of the rotary polishing assemblies are located above the conveying assembly. The overturning assembly is fixedly arranged beside one end of the conveying assembly. The dust collection assembly is fixedly arranged on one side of the conveying assembly and arranged on the inner sides of the rotary polishing assemblies. Through cooperation of the above assemblies, the polishing efficiency and effect are improved, and harm caused by scrap iron generated in the manual polishing process to the body ofa worker is avoided.

Owner:HUANGSHAN WANGRONG ELECTRONICS

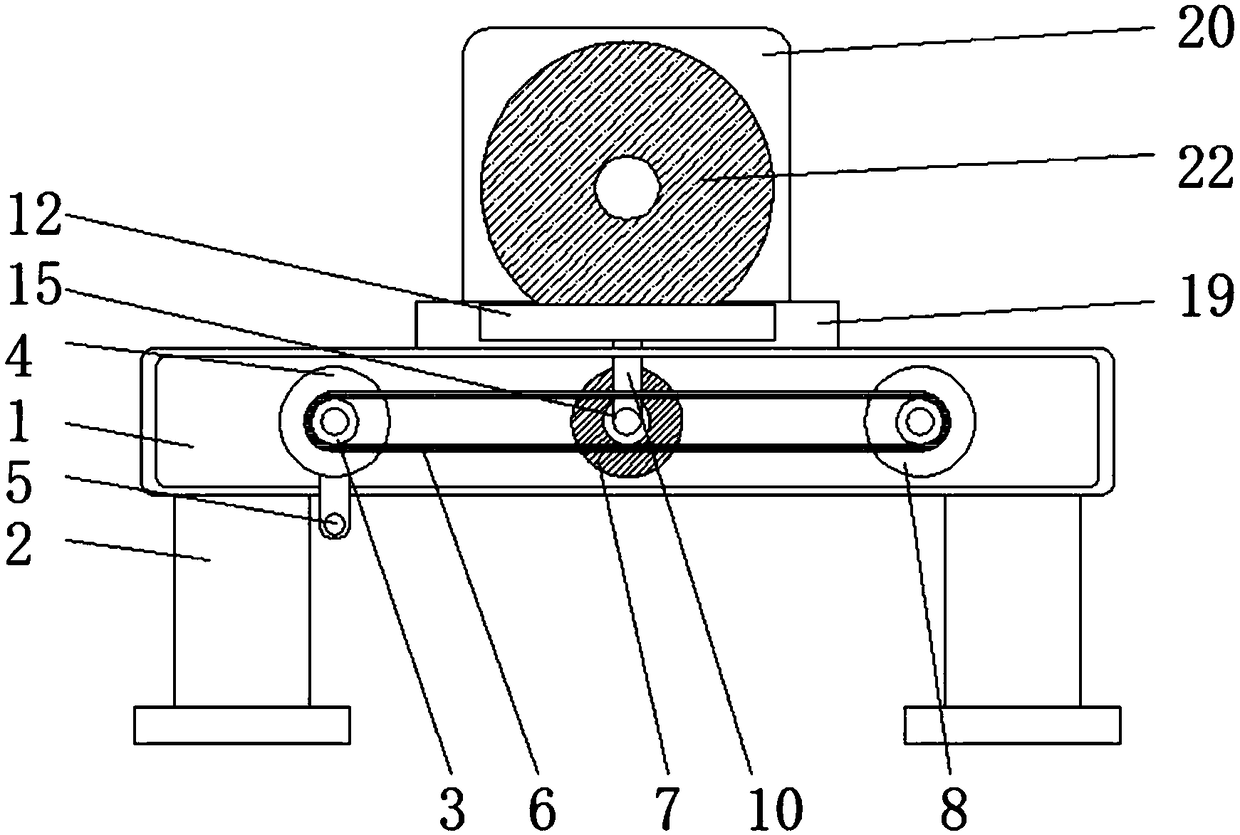

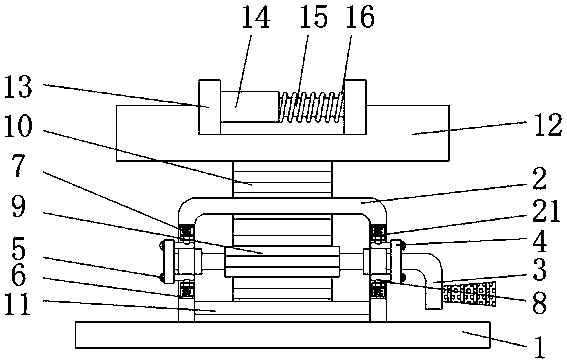

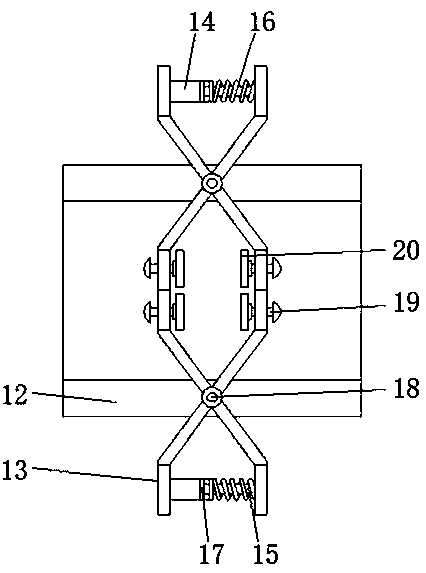

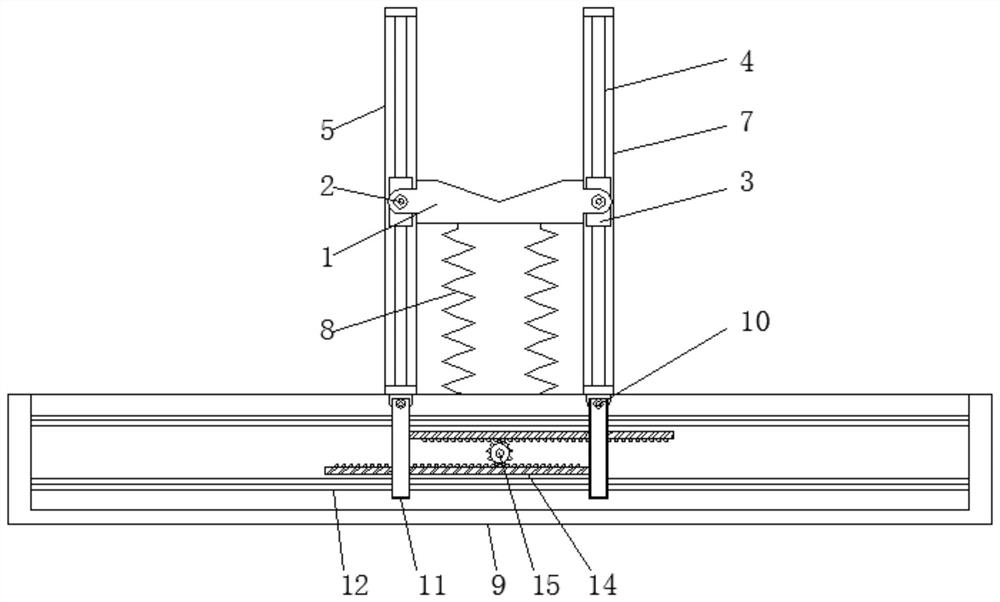

Hardware polishing device capable of conveniently clamping workpiece

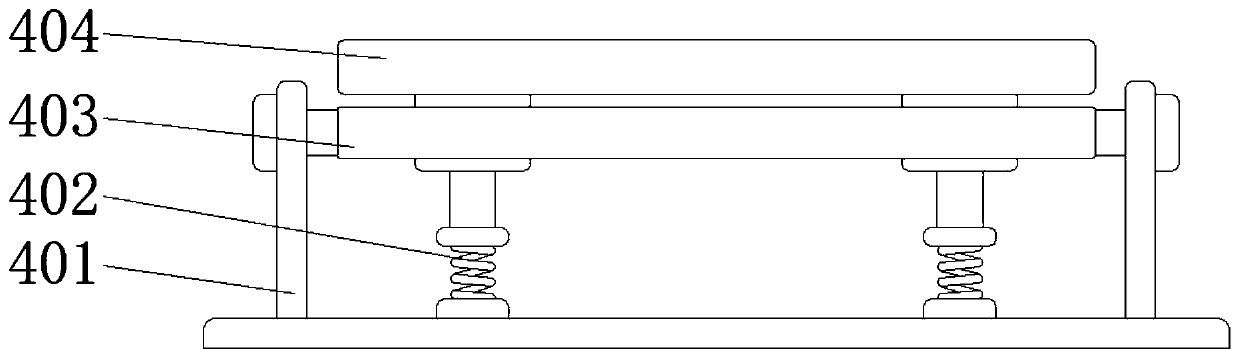

ActiveCN108789145AQuality improvementAvoid affecting the effect of grindingBelt grinding machinesGrinding work supportsPipe fittingEngineering

The invention discloses a hardware polishing device capable of conveniently clamping a workpiece. The hardware polishing device capable of conveniently clamping the workpiece comprises transverse fixing plates, a first fixing side plate, a second fixing side plate, a fixing base and a rotating tooth roller. The two ends of each transverse fixing plate are connected with first sliding blocks through first rotating shafts, and the first sliding blocks are arranged on the first fixing side plate and the second fixing side plate. The bottom end of the second fixing side plate and the bottom end ofthe first fixing side plate are connected with second sliding blocks through hinge shafts. First elasticity springs are arranged between the fixing base and the transverse fixing plates. Moving grooves are formed in the second sliding blocks, and first transmission racks are welded on the second sliding blocks. The two ends of the rotating tooth roller are movably connected with the inner wall ofthe fixing base, and a first electric motor is arranged on the rotating tool roller. By the adoption of the hardware polishing device capable of conveniently clamping the workpiece, pipe fittings with different inner diameters can be firmly fixed, workers can conveniently conduct machining and polishing operation, the clamping effect is good, and the hardware polishing device capable of conveniently clamping the workpiece is simple in integral structure, convenient to operate and high in practicability.

Owner:南通友腾自动化设备有限公司

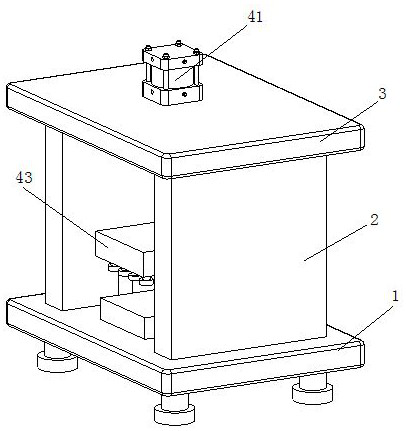

Intelligent grinding device for metal wire-drawing die

InactiveCN114515993AGuaranteed grinding effectFully groundLapping machinesGrinding machinesRotary stageEngineering

The invention relates to the technical field of wire-drawing die processing, in particular to an intelligent grinding device for a metal wire-drawing die, which comprises a lower fixed die and an upper fixed die which are respectively inserted at the upper end and the lower end of the wire-drawing die, and the upper fixed die seals a top opening of the wire-drawing die to form a cavity for storing grinding liquid. A plurality of mounting support arms are arranged on the peripheral side of the rotating table, a lower fixed die of the wire drawing die is inserted into mounting holes formed in one ends of the mounting support arms, the rotating table is fixedly mounted at the working end of a first rotating driving device, and a working shaft of the first rotating driving device and the rotating table are coaxially arranged; according to the technical scheme, grinding liquid in the wire drawing die is attached to one side of the interior of the wire drawing die under the action of centrifugal force generated by rotation of the rotary table, the wire drawing die rotates around the axis of the wire drawing die, and the grinding liquid can be attached to the surface of an inner hole for grinding; and the grinding effect is ensured.

Owner:周玉洁

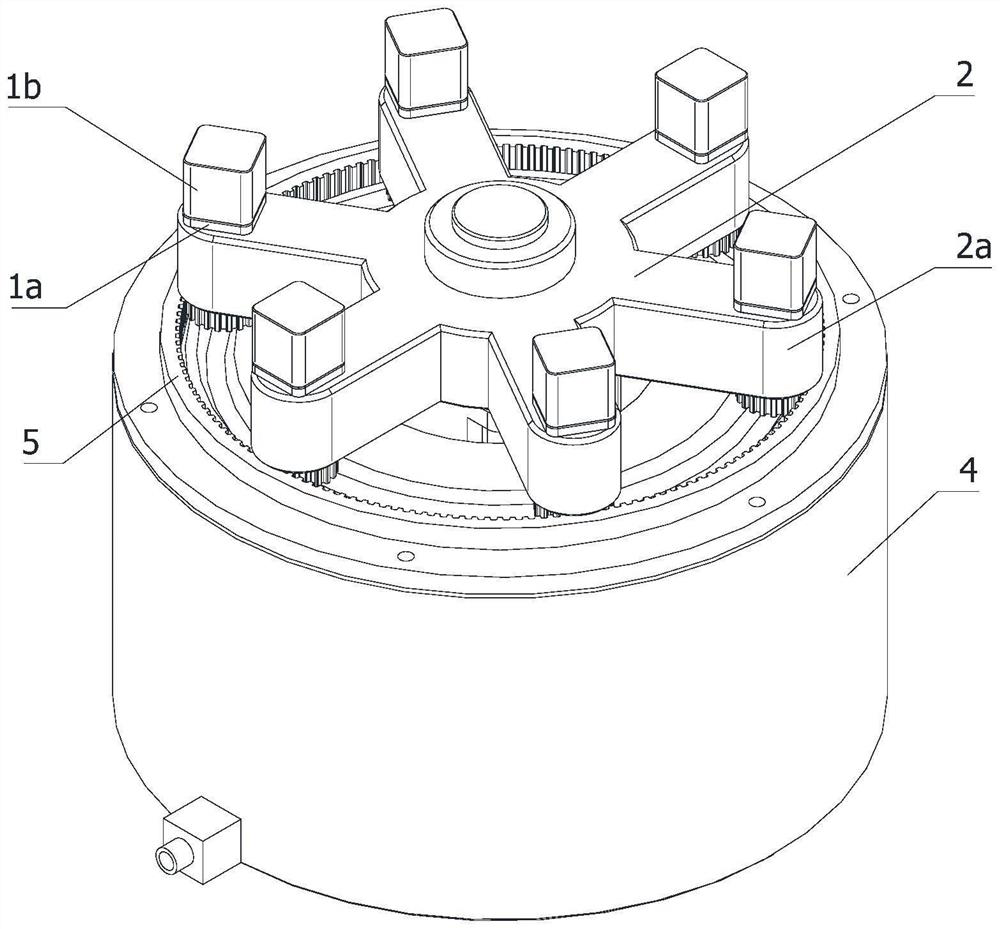

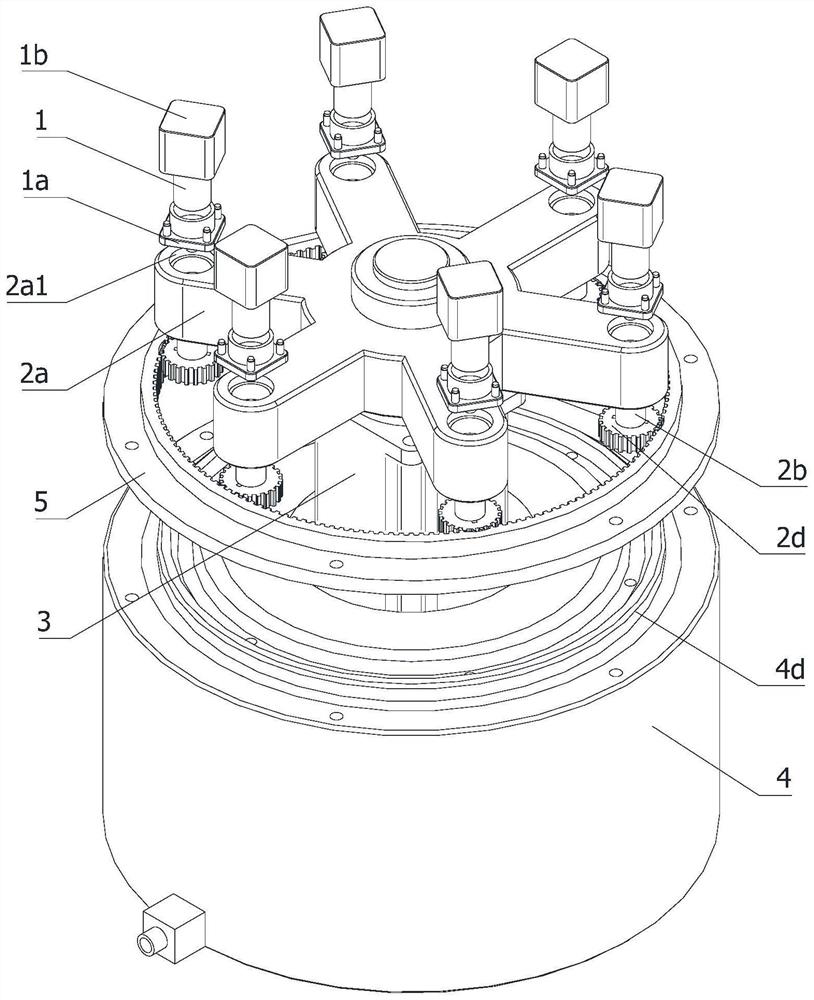

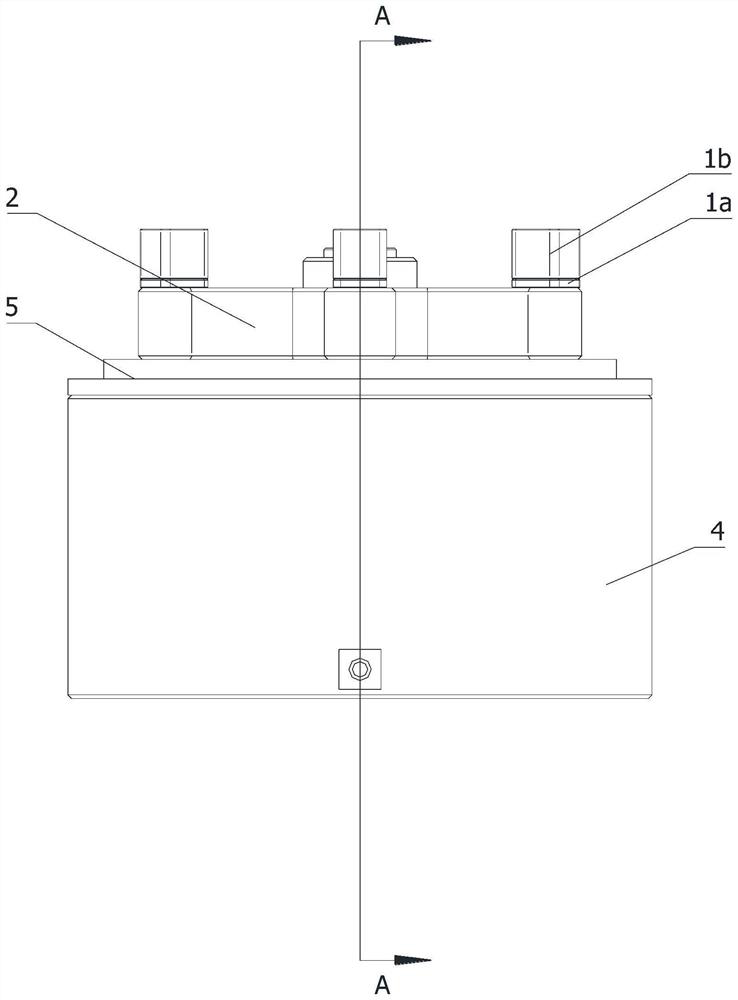

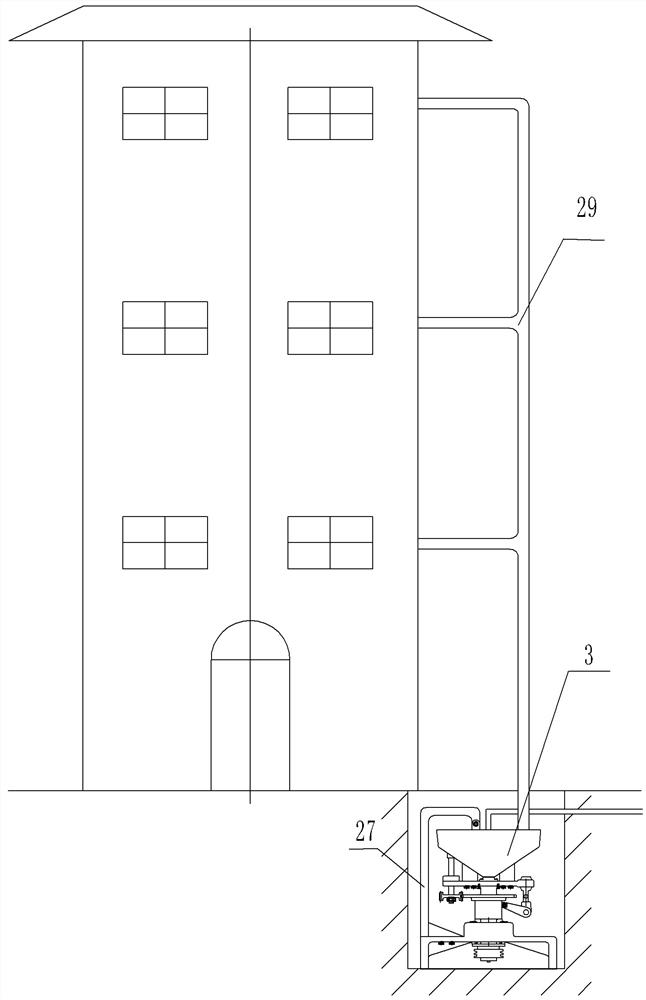

Green building sewage treatment system and sewage treatment device

ActiveCN112791771AEasy to handleAvoid affecting the effect of grindingGrain treatmentsWater treatment systemSewage

The invention relates to the field of sewage treatment, in particular to a green building sewage treatment system and sewage treatment device. A green building sewage treatment device is used for treating sewage and impurities in a building and comprises a grinding device and a restraining device; the grinding device comprises a grinding disc and a grinding kettle with an upward opening, the grinding disc is installed on a support and located in the grinding kettle, and a grinding gap is formed between the grinding disc and the grinding kettle; the restraining device includes a plurality of first restraining portions and a plurality of second restraining portions, each first restraining portion comprises a movable part and a centrifugal arm, each second restraining portion comprises a first transmission gear, an eccentric grinding hammer, a connecting rod and a second transmission gear. According to the restraining device of the sewage treatment system and device, the rotational inertia of an eccentric grinding hammer is utilized to restrain the increase or decrease of the grinding gap, so that the grinding quality of garbage and the impurities is ensured, therefore, the sewage treatment device has a better treatment effect on the sewage and the impurities.

Owner:云南凌翔建筑管理有限公司

Hardware fitting anti-shaking device for grinding of grinding materials and grinding tools

PendingCN108527150AAvoid offsetPrevent slipping outGrinding machine componentsDrive wheelEngineering

The invention relates to the technical field of grinding materials and grinding tools and discloses a hardware fitting anti-shaking device for grinding of grinding materials and grinding tools. The hardware fitting anti-shaking device comprises a support plate. A fixing barrel is fixedly mounted at the top of the support plate. A handle is movably connected to the side face of the fixing barrel. Aconnecting block is fixedly connected to one end of the handle, wherein the connecting block is located outside the fixing barrel. A movable rod is movably connected to the side face of the connecting block. One end of the movable rod penetrates and extends out of the connecting block. According to the hardware fitting anti-shaking device for grinding of the grinding materials and grinding tools,through cooperation between the support plate and the fixing barrel, the support plate is prevented from shifting from the original position in the grinding process; through cooperation between the handle and the connecting block, the problem that after moving and being stressed, a cutting table shifts from the original position is prevented; through cooperation between the movable rod and a limiting rod, the movable rod is prevented from sliding out of the fixing barrel; and through cooperation between a driving wheel and a rack, the problem that the grinding effect is affected due to the fact that undersize objects cannot be ground is prevented.

Owner:郑州博尔德磨料磨具有限公司

A metal grinding device convenient for clamping workpieces

ActiveCN108789145BQuality improvementAvoid affecting the effect of grindingBelt grinding machinesGrinding work supportsComputer hardwareRotational axis

The invention discloses a hardware polishing device capable of conveniently clamping a workpiece. The hardware polishing device capable of conveniently clamping the workpiece comprises transverse fixing plates, a first fixing side plate, a second fixing side plate, a fixing base and a rotating tooth roller. The two ends of each transverse fixing plate are connected with first sliding blocks through first rotating shafts, and the first sliding blocks are arranged on the first fixing side plate and the second fixing side plate. The bottom end of the second fixing side plate and the bottom end ofthe first fixing side plate are connected with second sliding blocks through hinge shafts. First elasticity springs are arranged between the fixing base and the transverse fixing plates. Moving grooves are formed in the second sliding blocks, and first transmission racks are welded on the second sliding blocks. The two ends of the rotating tooth roller are movably connected with the inner wall ofthe fixing base, and a first electric motor is arranged on the rotating tool roller. By the adoption of the hardware polishing device capable of conveniently clamping the workpiece, pipe fittings with different inner diameters can be firmly fixed, workers can conveniently conduct machining and polishing operation, the clamping effect is good, and the hardware polishing device capable of conveniently clamping the workpiece is simple in integral structure, convenient to operate and high in practicability.

Owner:南通友腾自动化设备有限公司

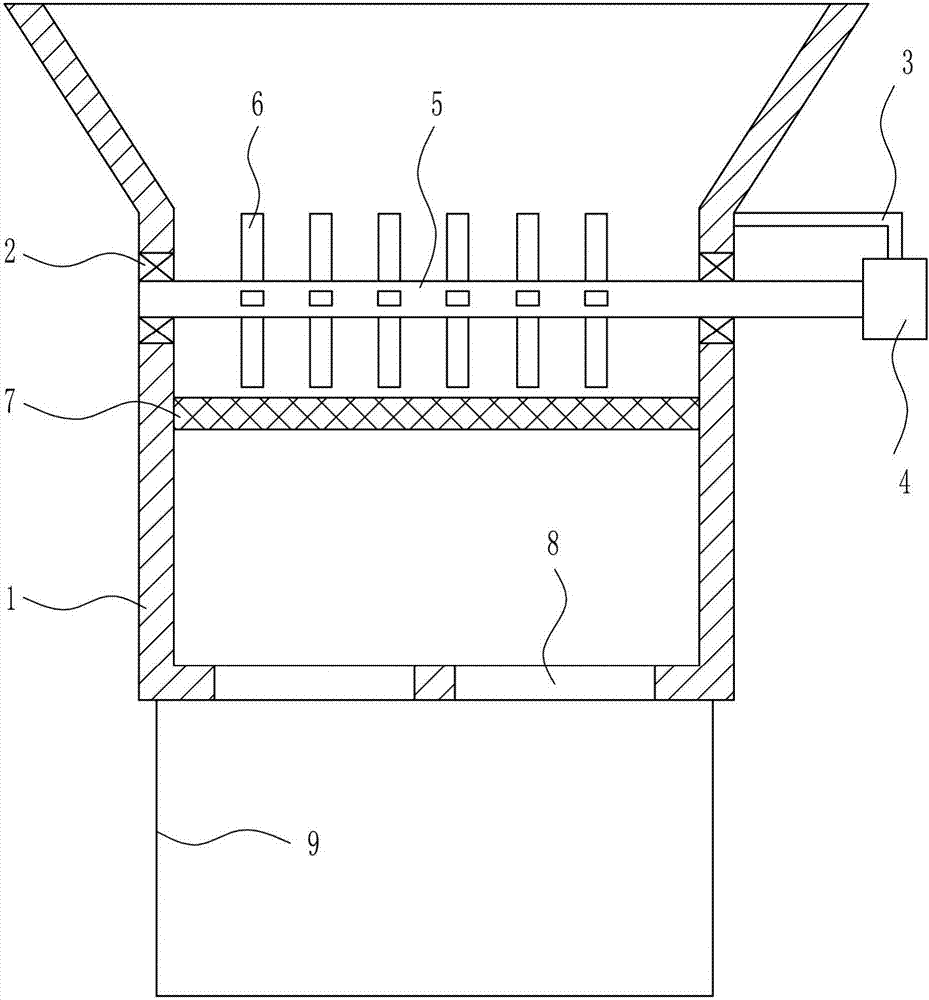

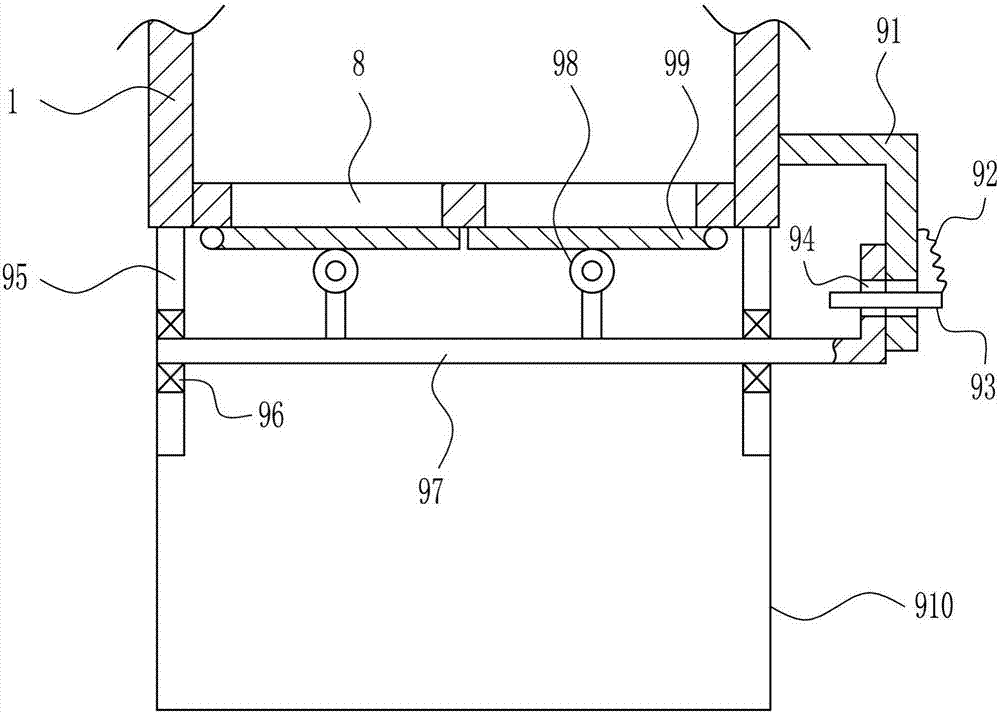

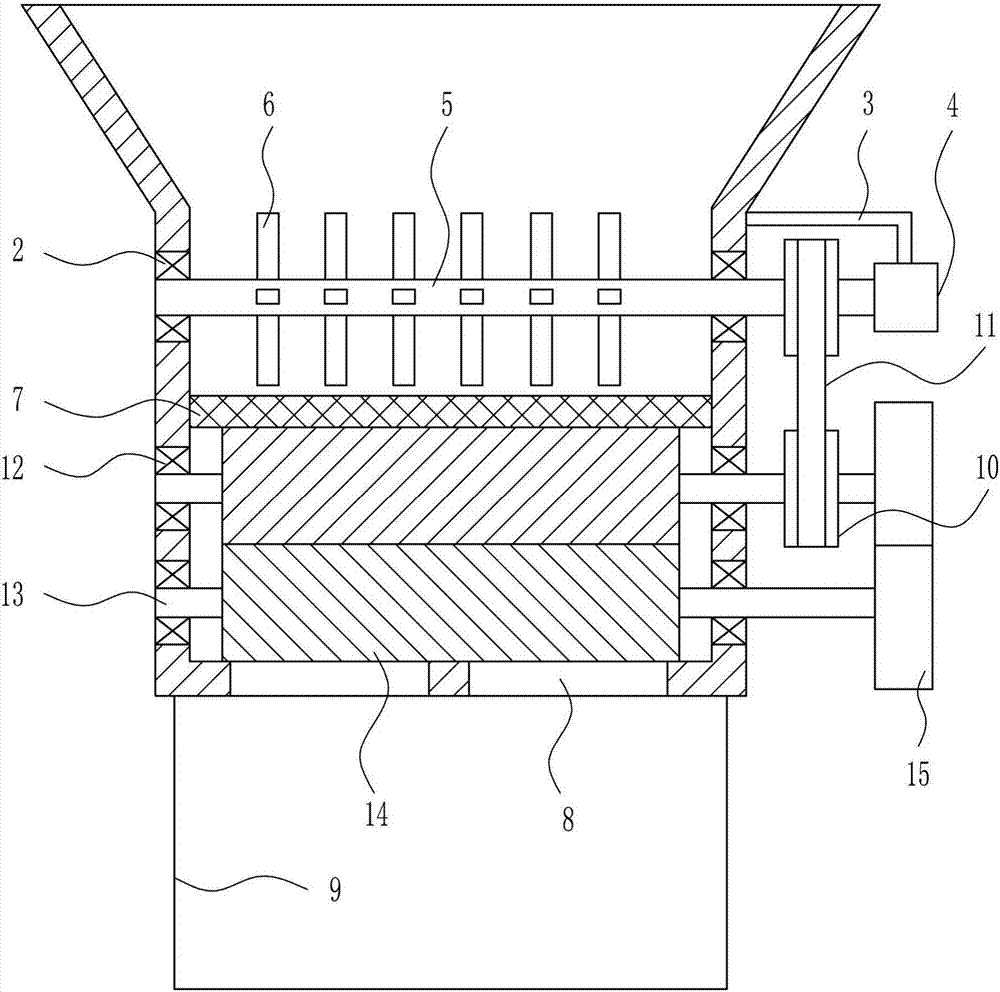

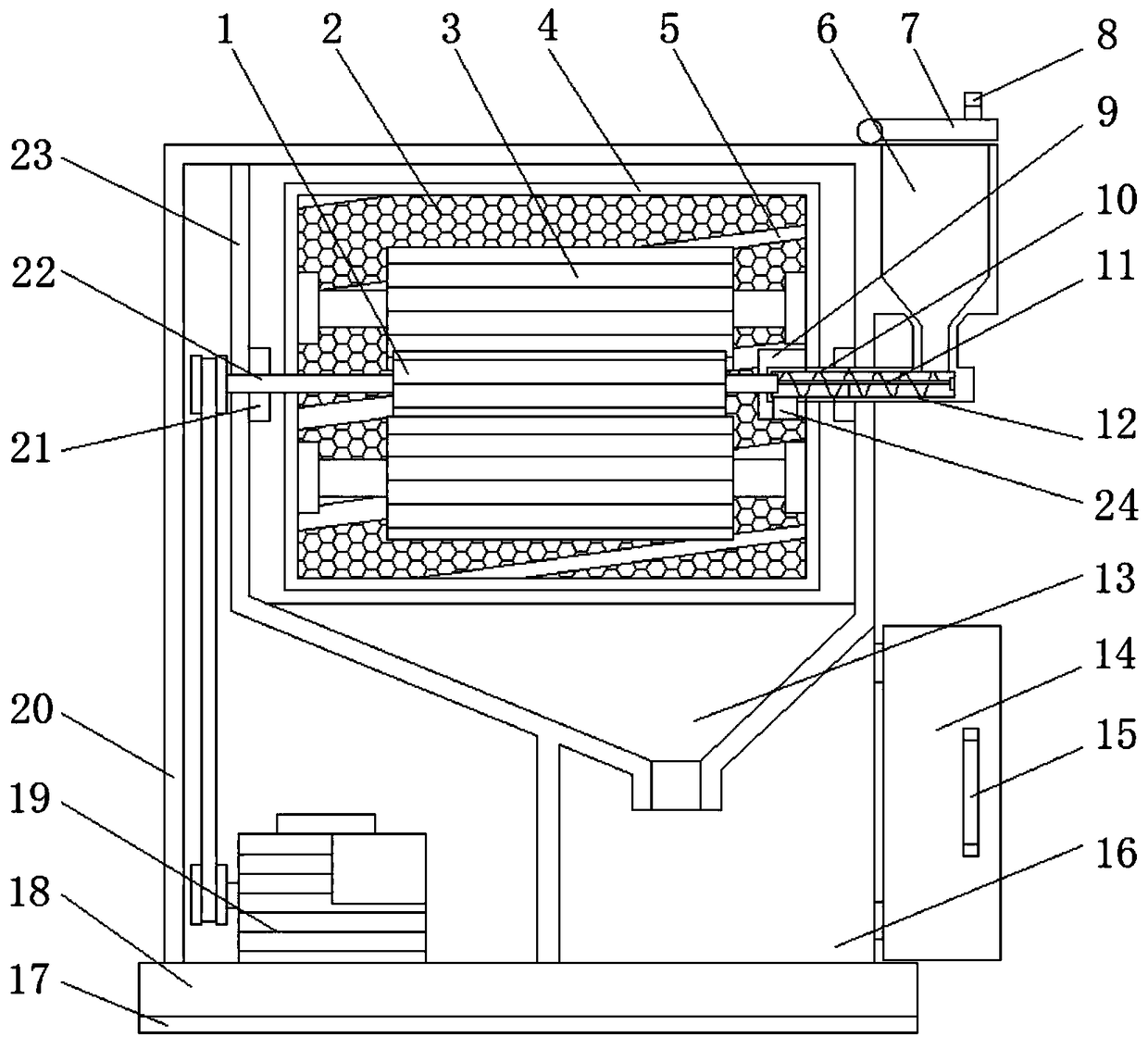

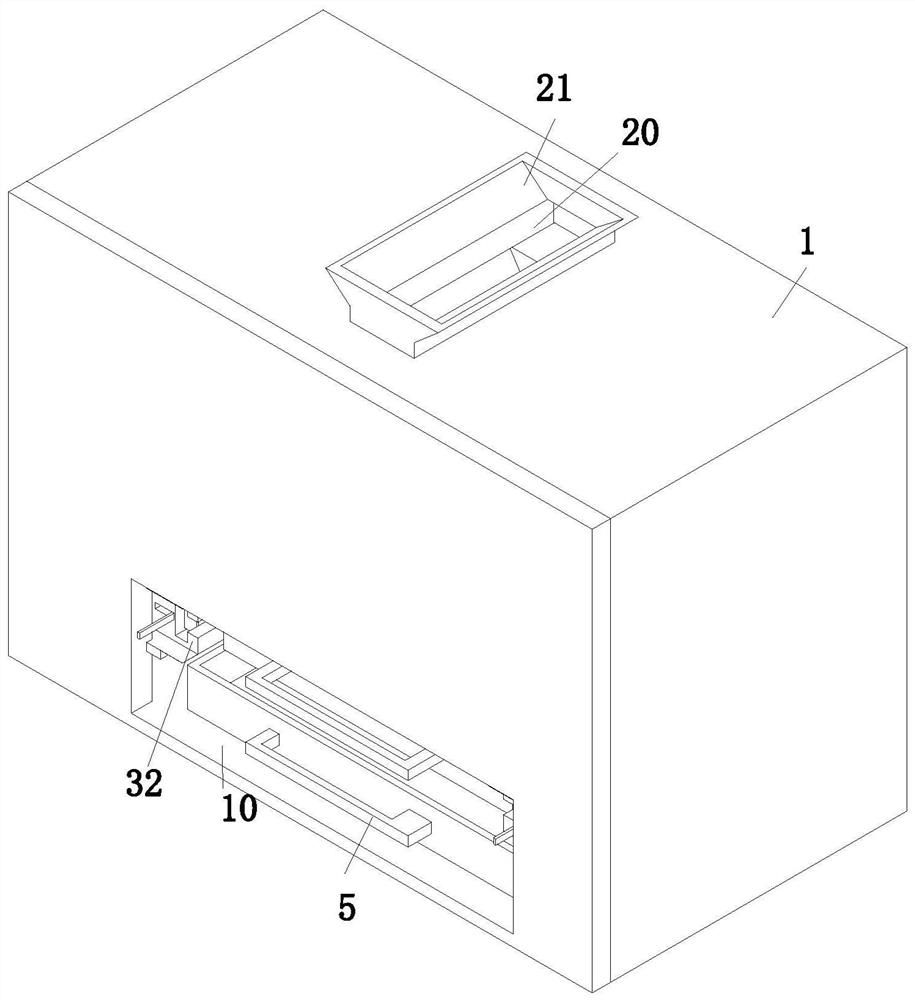

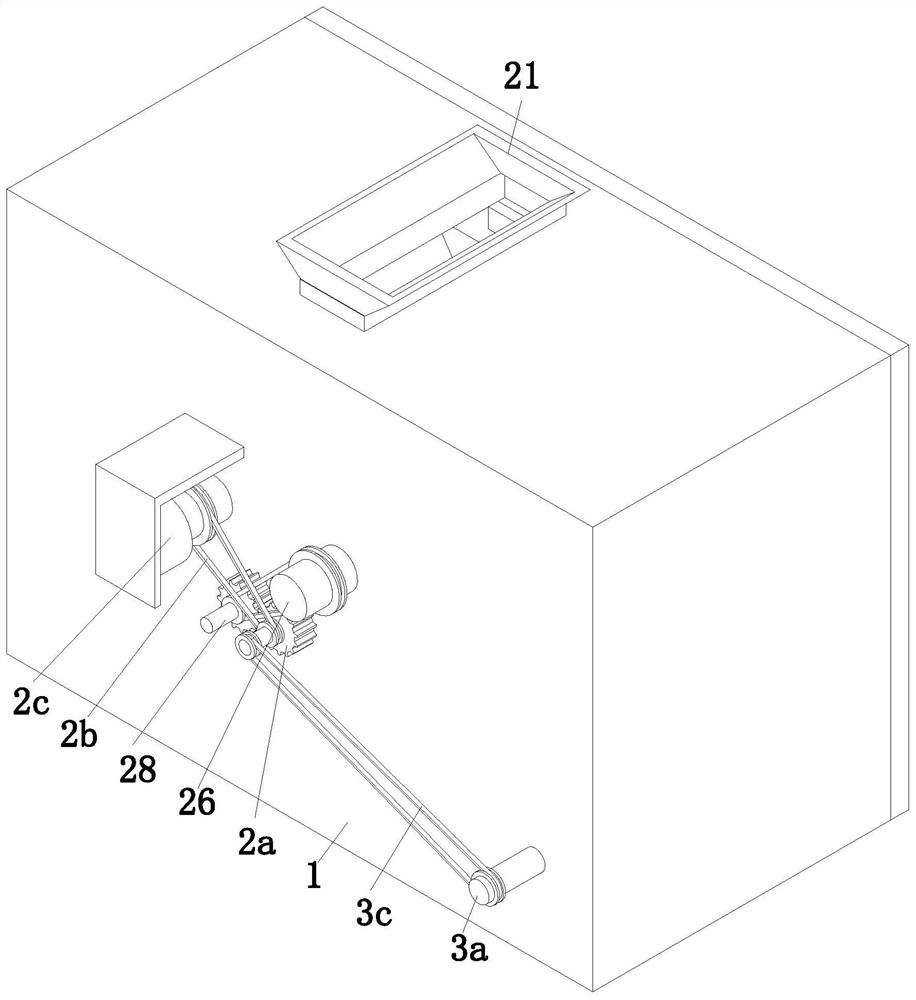

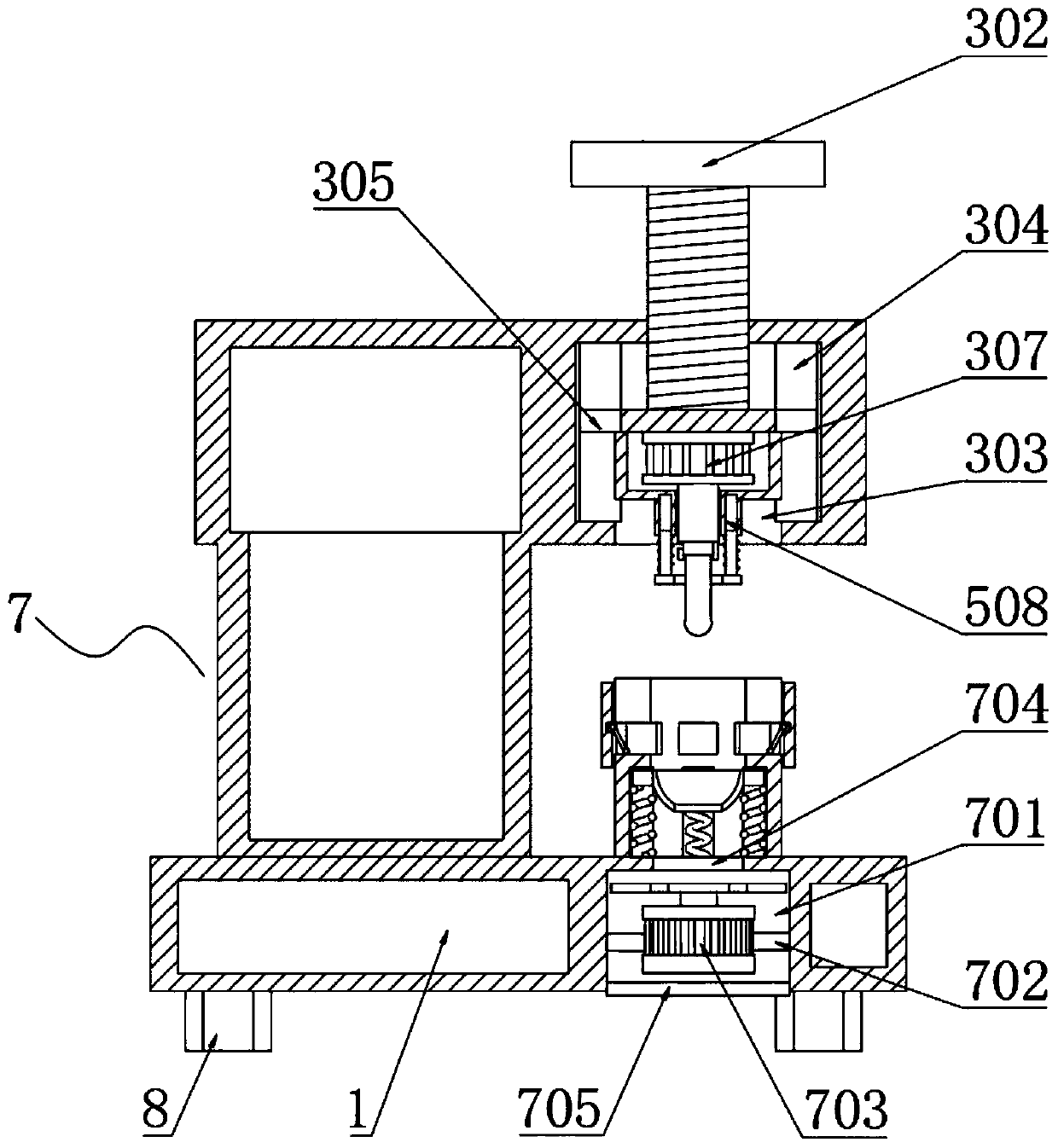

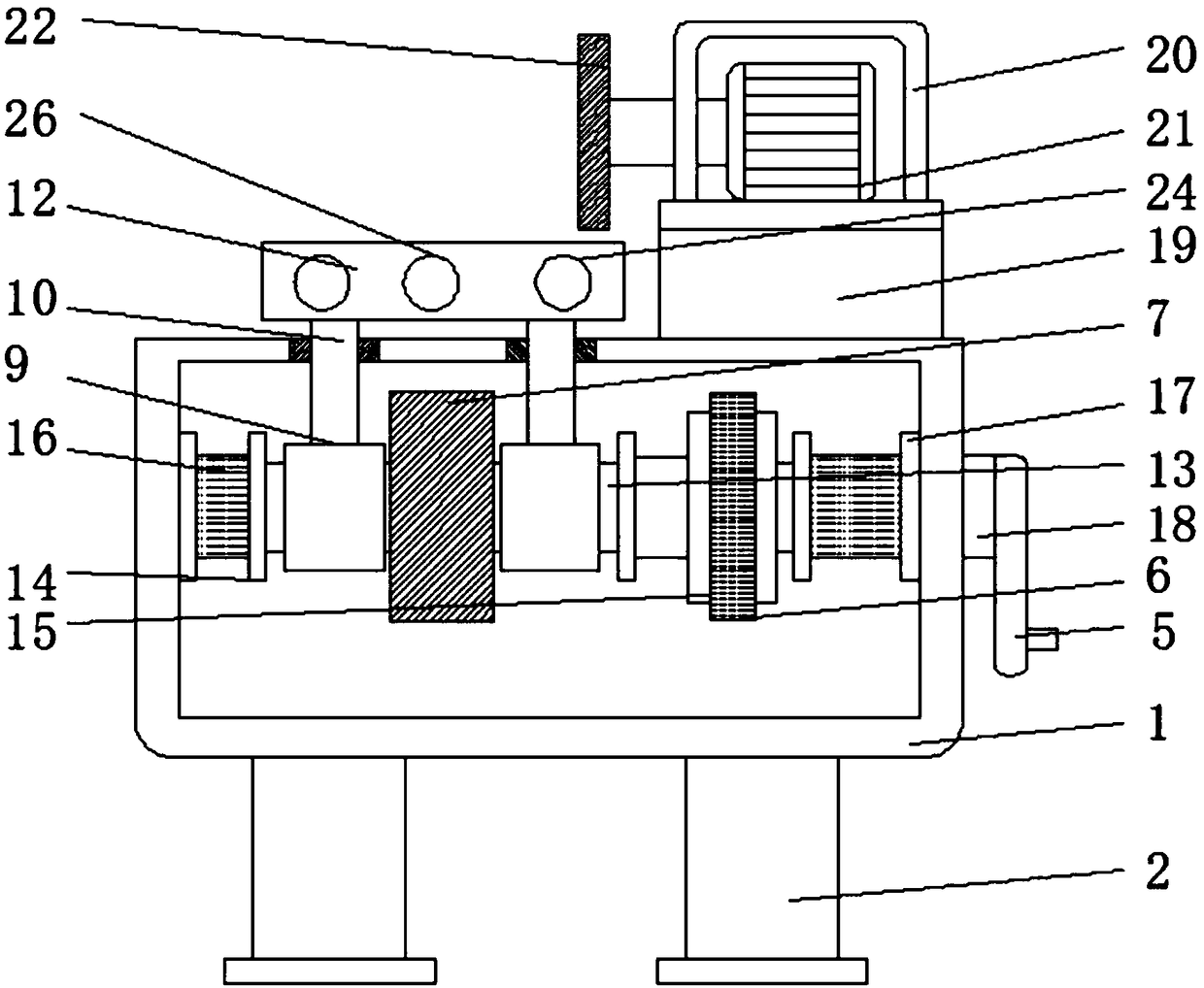

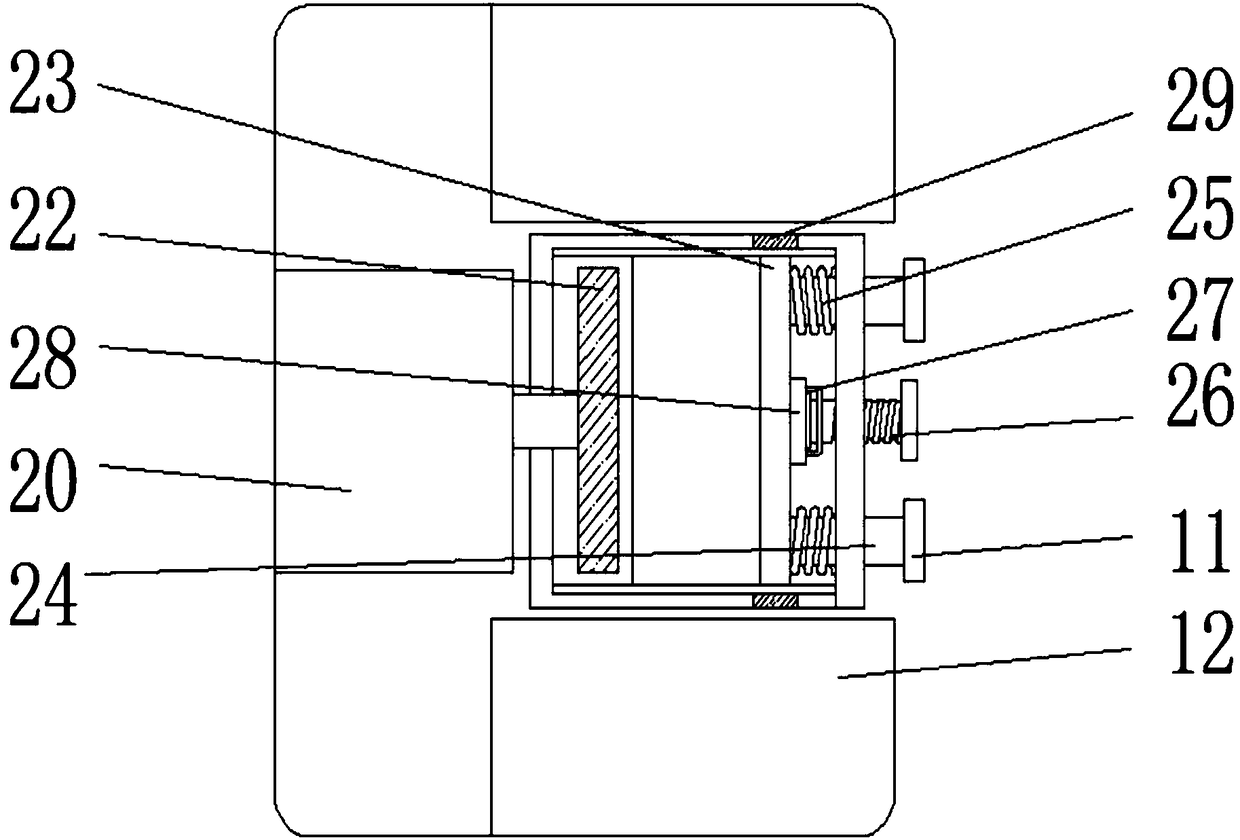

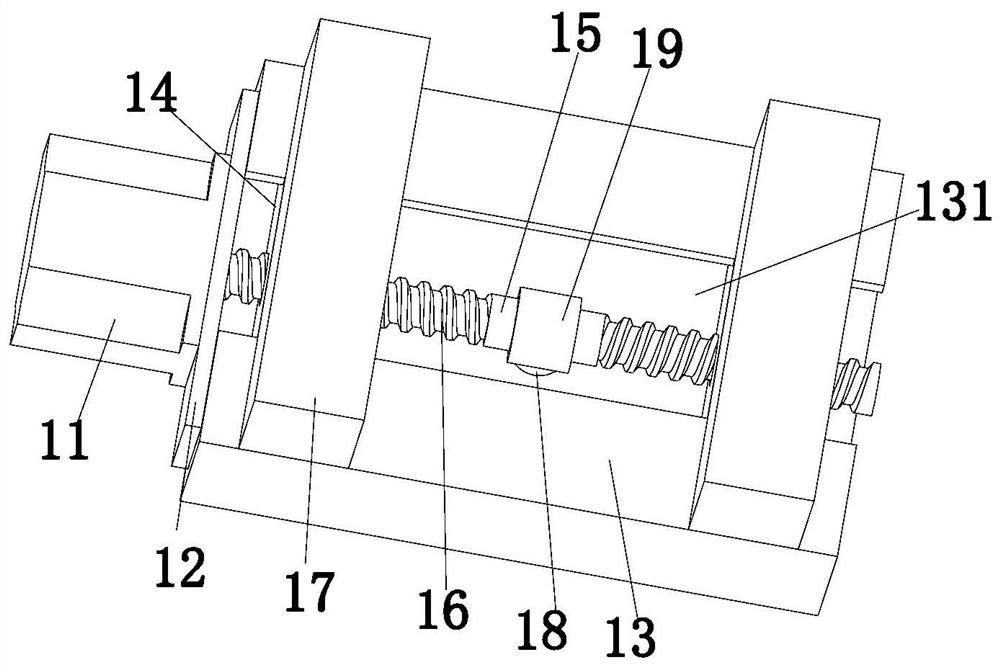

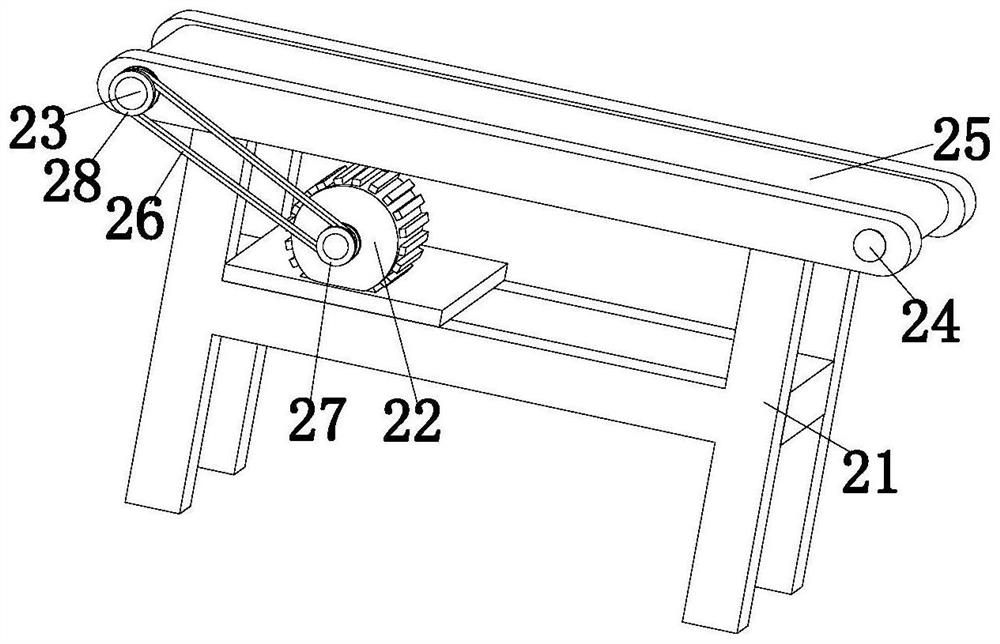

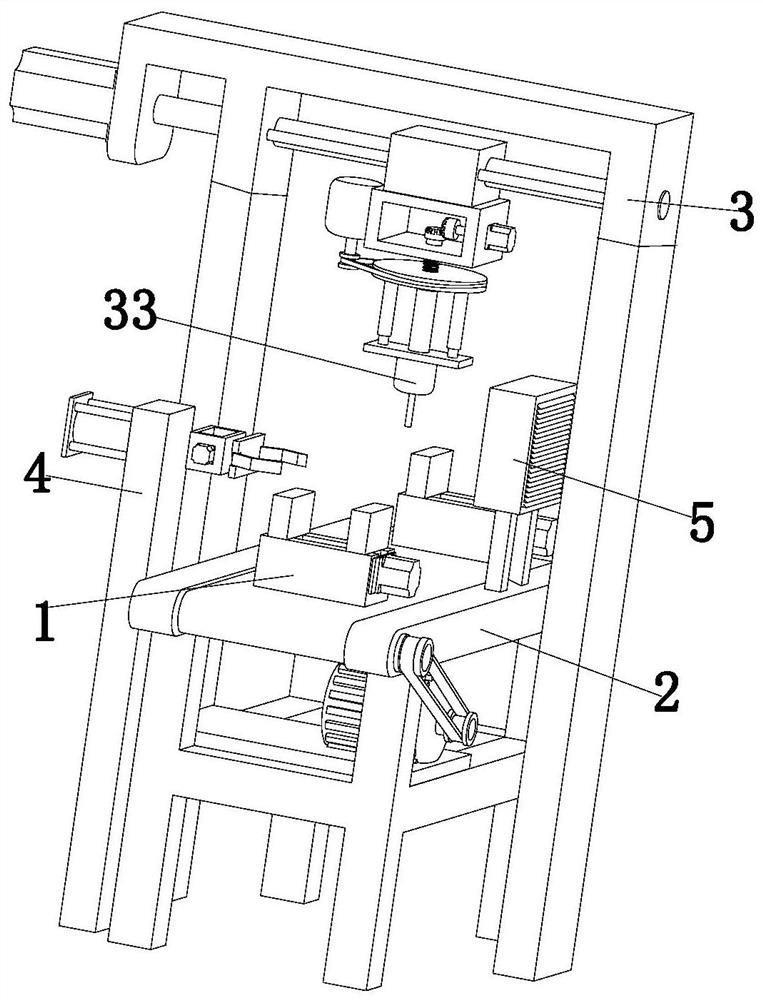

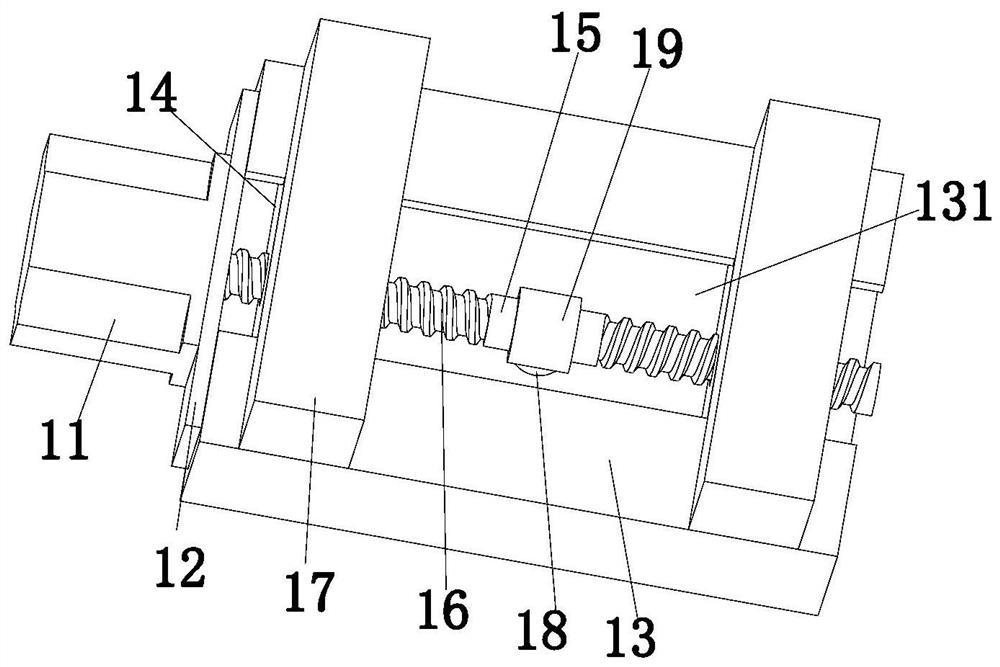

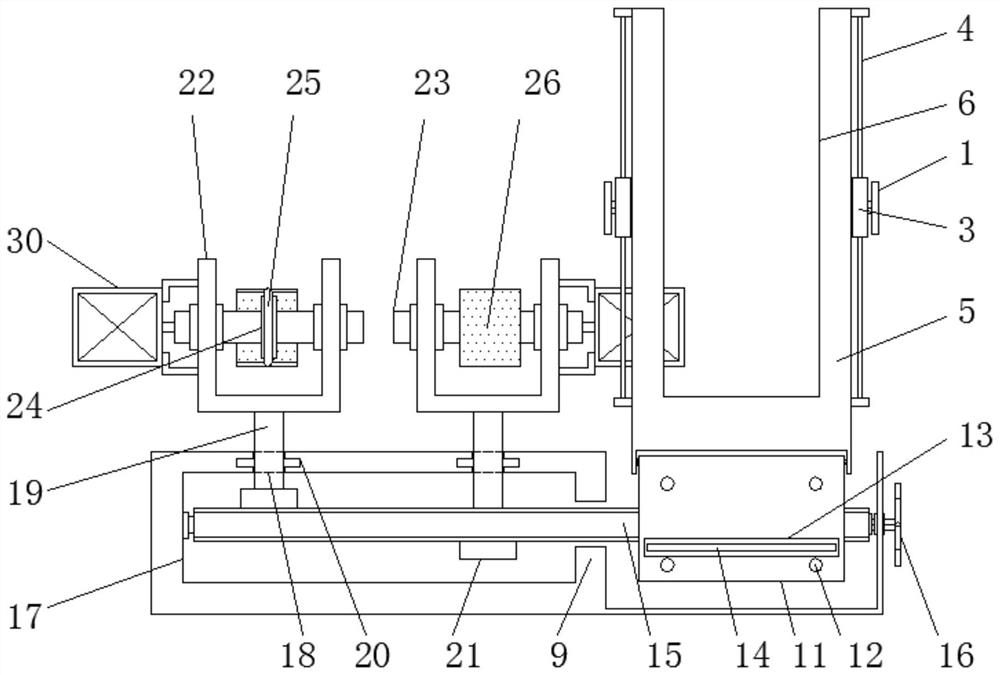

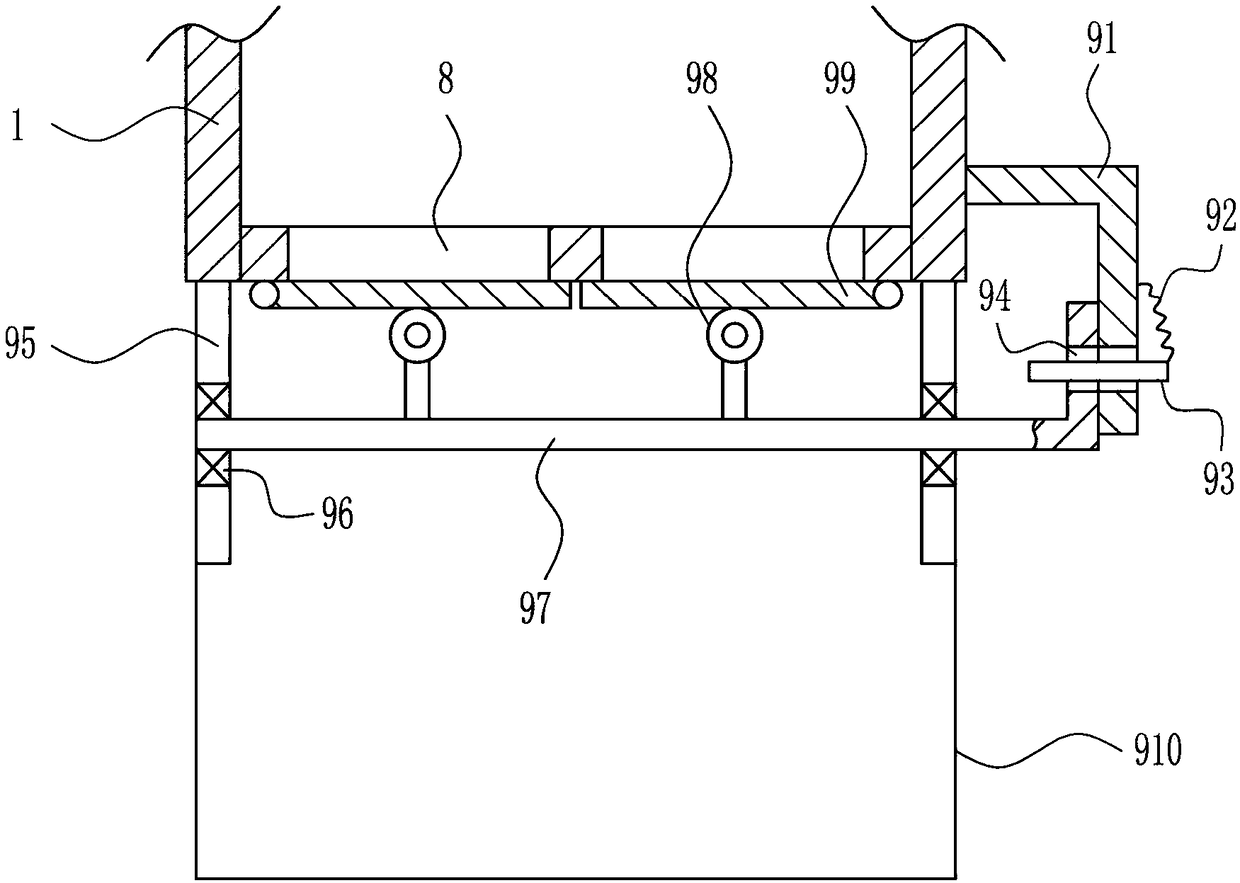

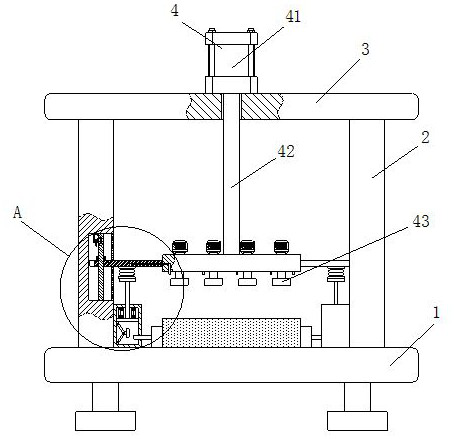

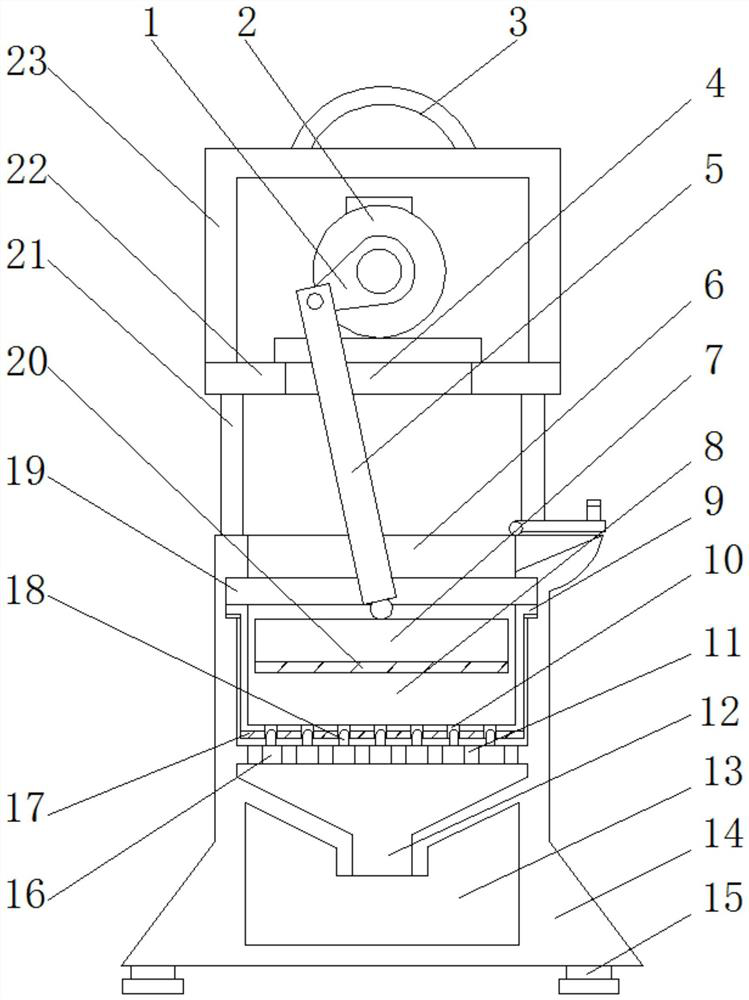

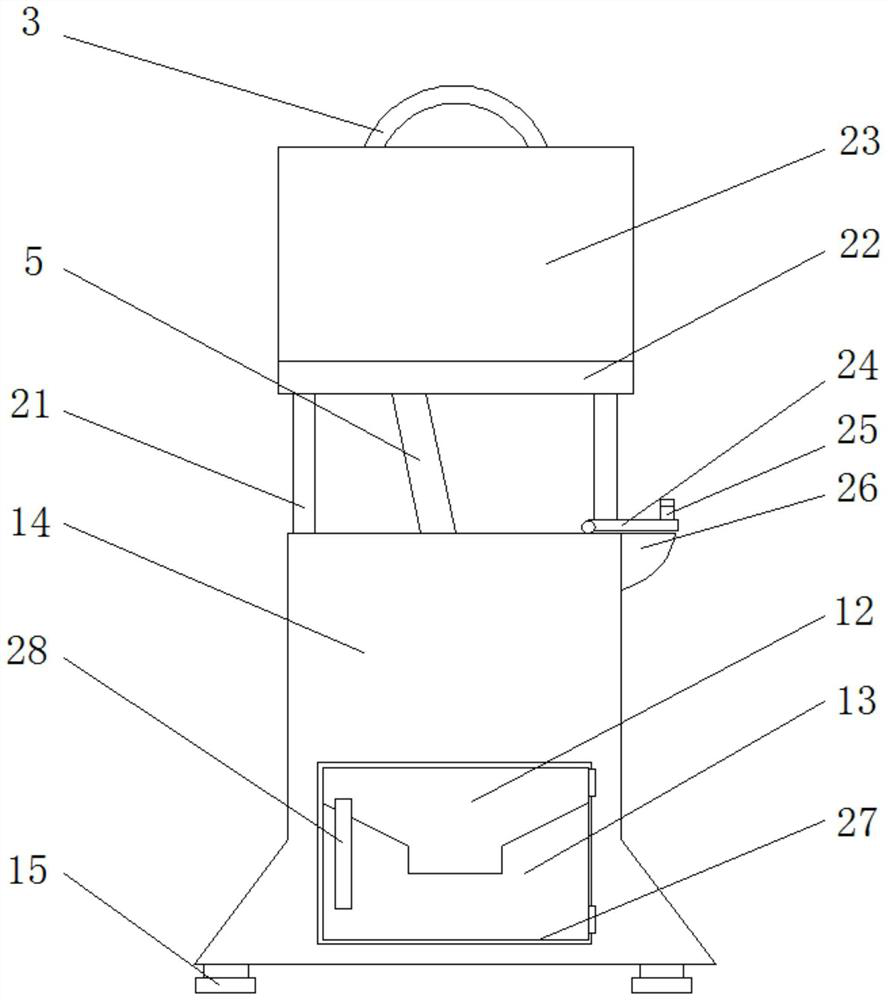

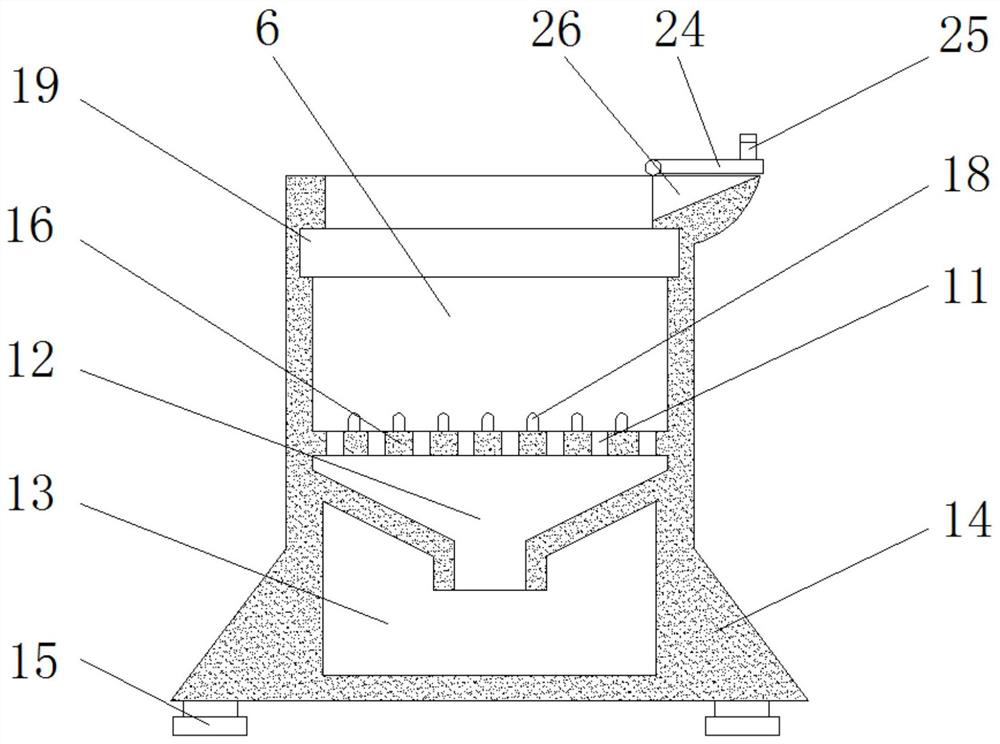

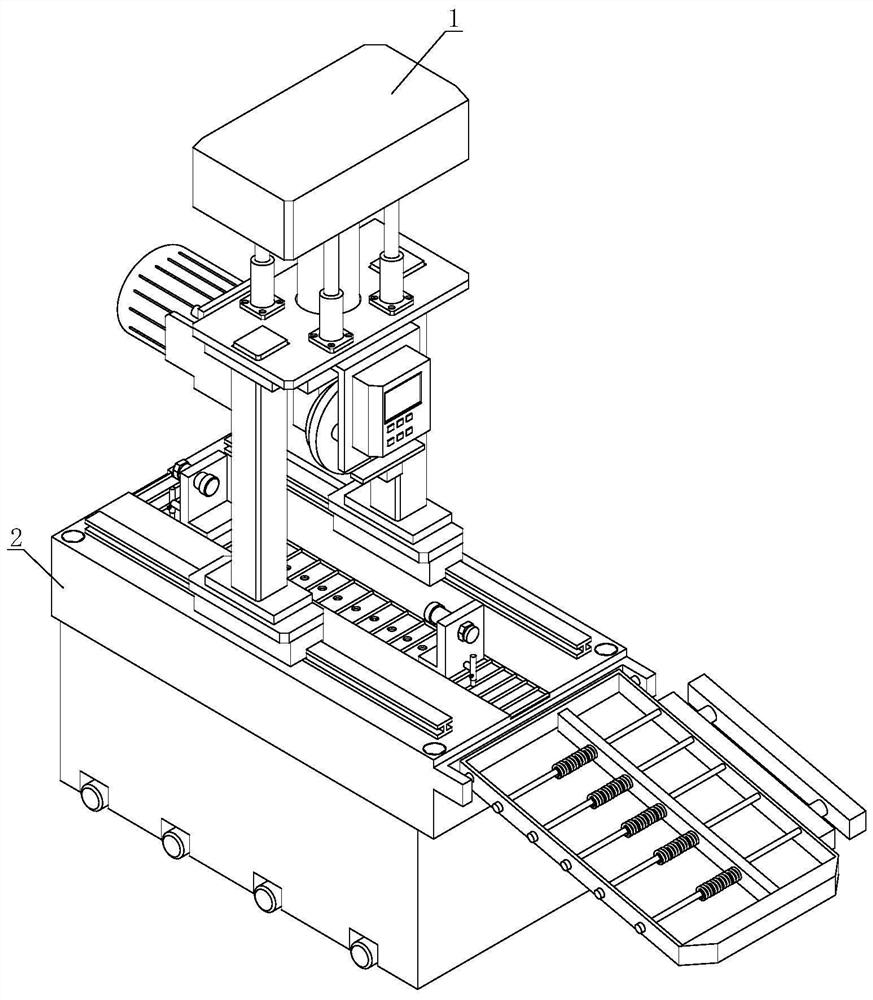

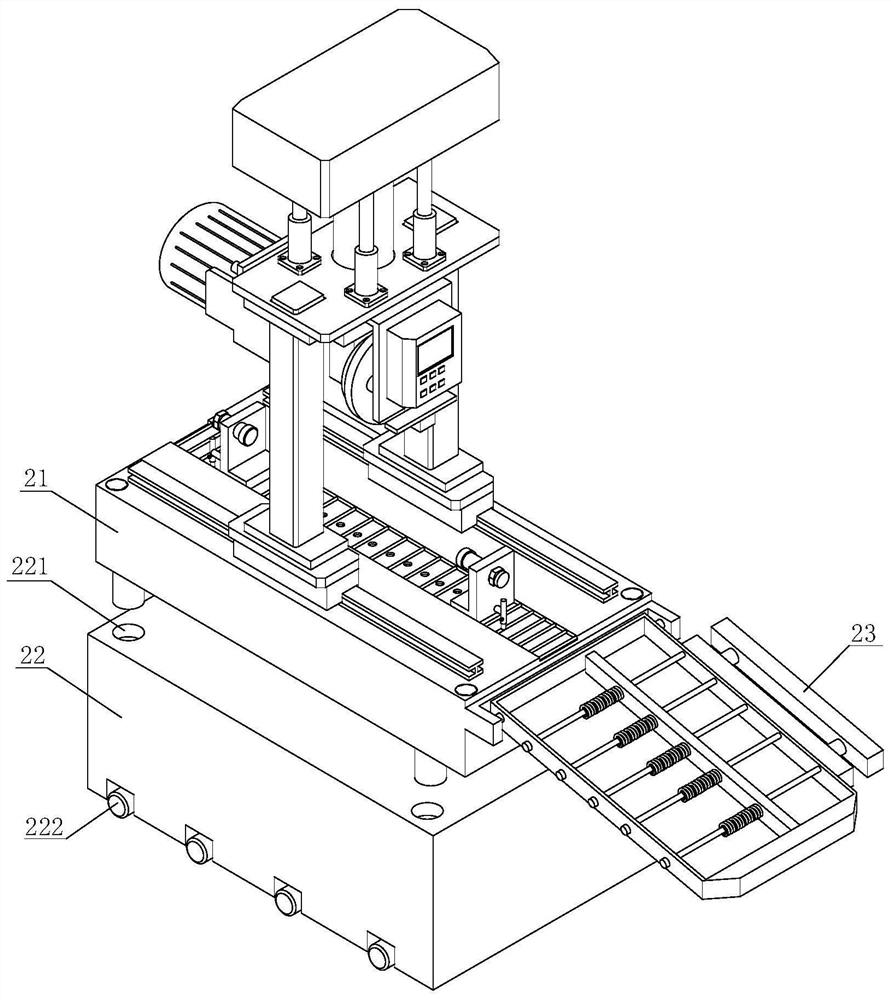

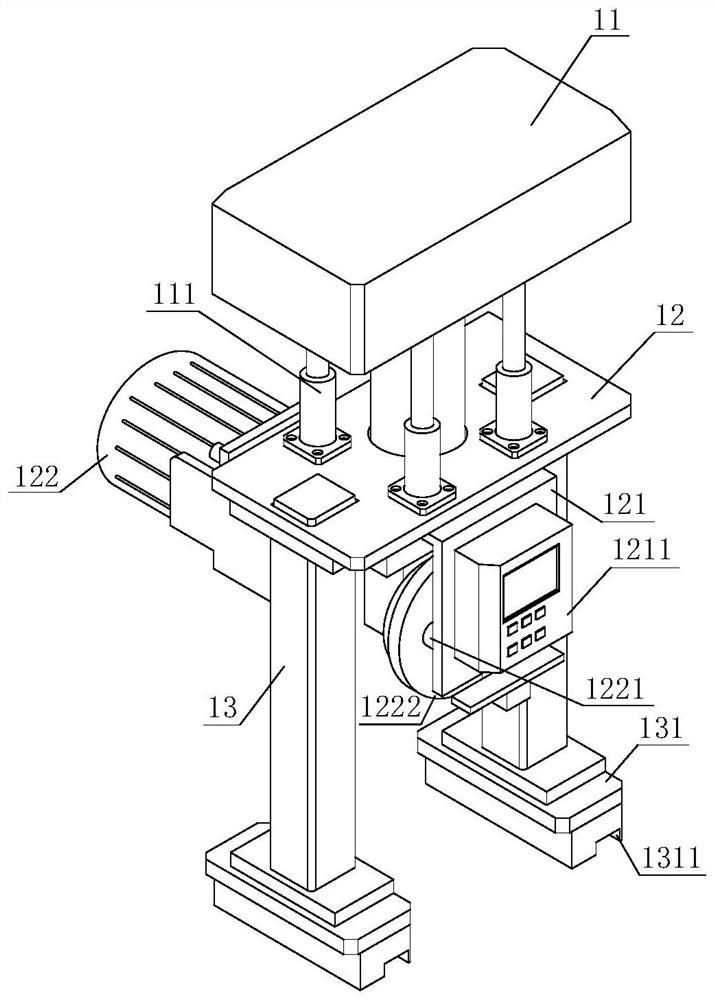

A multi-stage grinding equipment for rubber powder

The invention relates to grinding equipment, in particular to rubber powder multi-stage grinding equipment and aims to achieve the technical effect of providing the rubber fine powder grinding equipment capable of performing multi-stage grinding and can reach the required specification. To achieve the technical effect, the rubber powder multi-stage grinding equipment comprises a grinding box, first bearing seats, a supporting rod, a motor, a first rotating rod, crushing cutters and the like; the middle of the inner side of the grinding box is connected with a filtering mesh, the upper portion of the left wall and the upper portion of the right wall of the grinding box are both connected with the first bearing seats, the first bearing seats are connected with the first rotating rod, and the first rotating rod penetrates through the first bearing seat on the right side; and the upper portion of the right side of the grinding box is connected with the supporting rod, and the bottom end of the supporting rod is provided with the motor. A collection mechanism is arranged in the first place, it can be convenient for workers to collect falling grinding powder, and belt wheels, a flat belt, second bearing seats, second rotating rods, grinding rolls and gears are also arranged.

Owner:NANTONG ELITE MARINE EQUIP & ENG INC JIANGSU

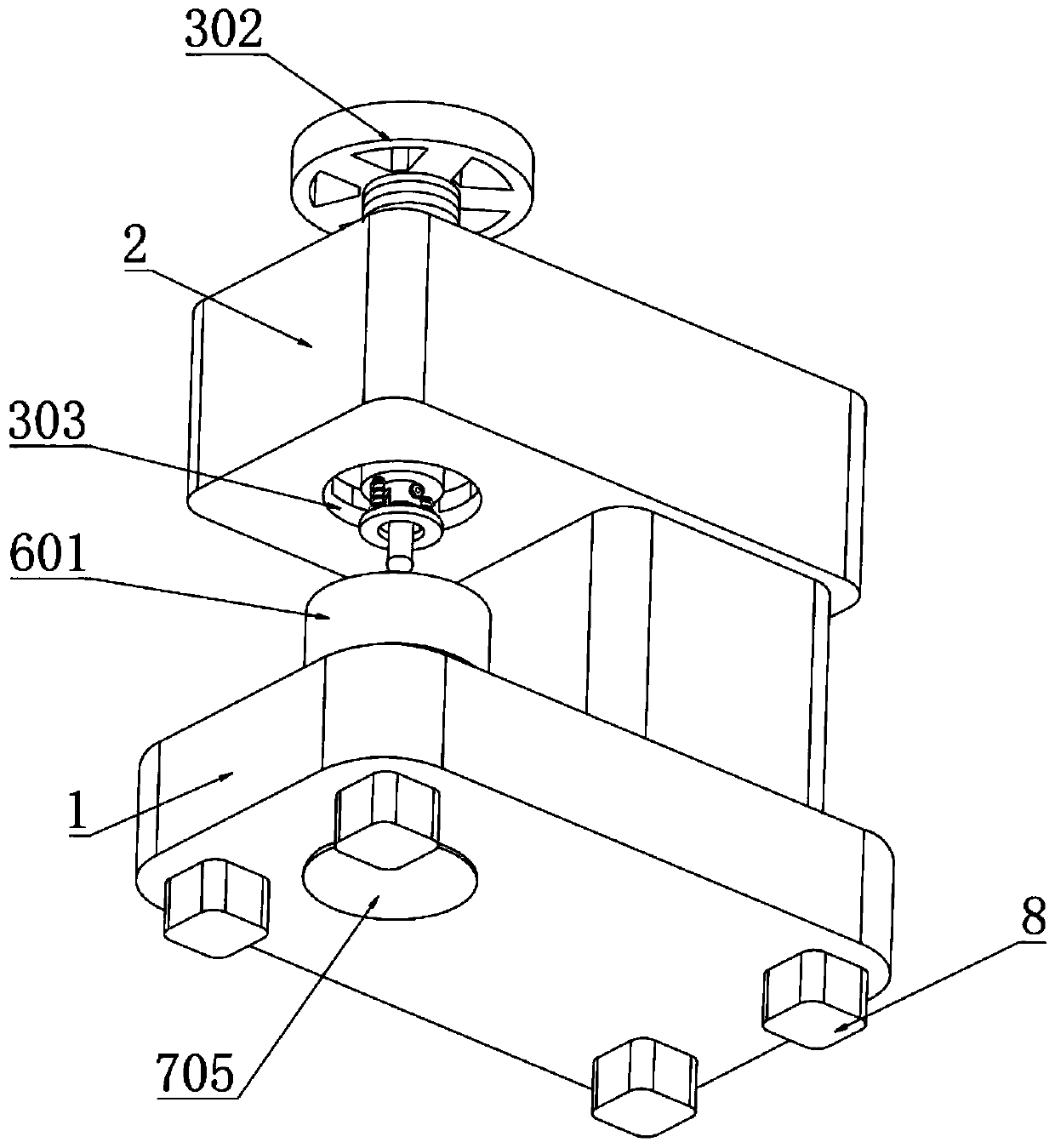

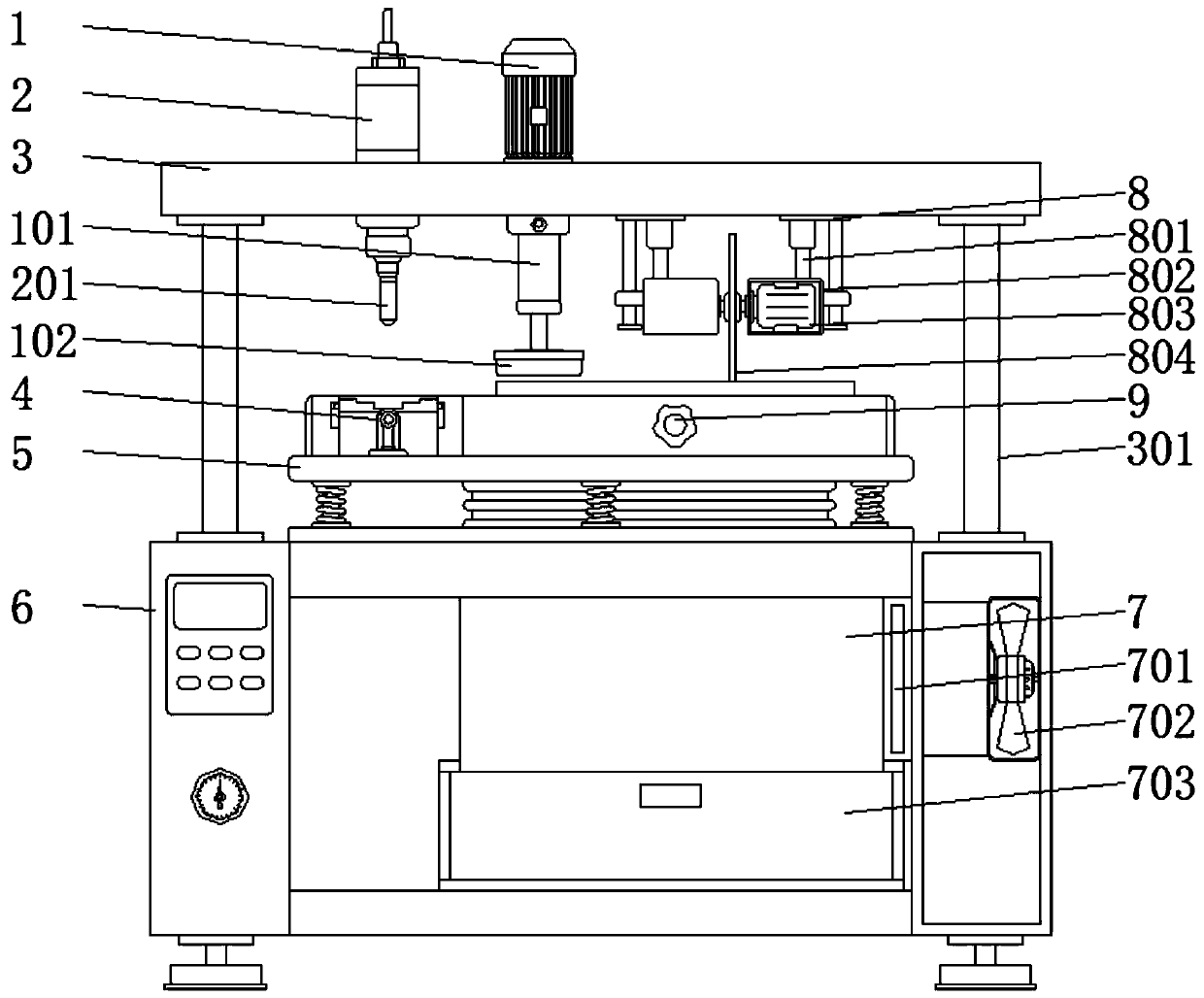

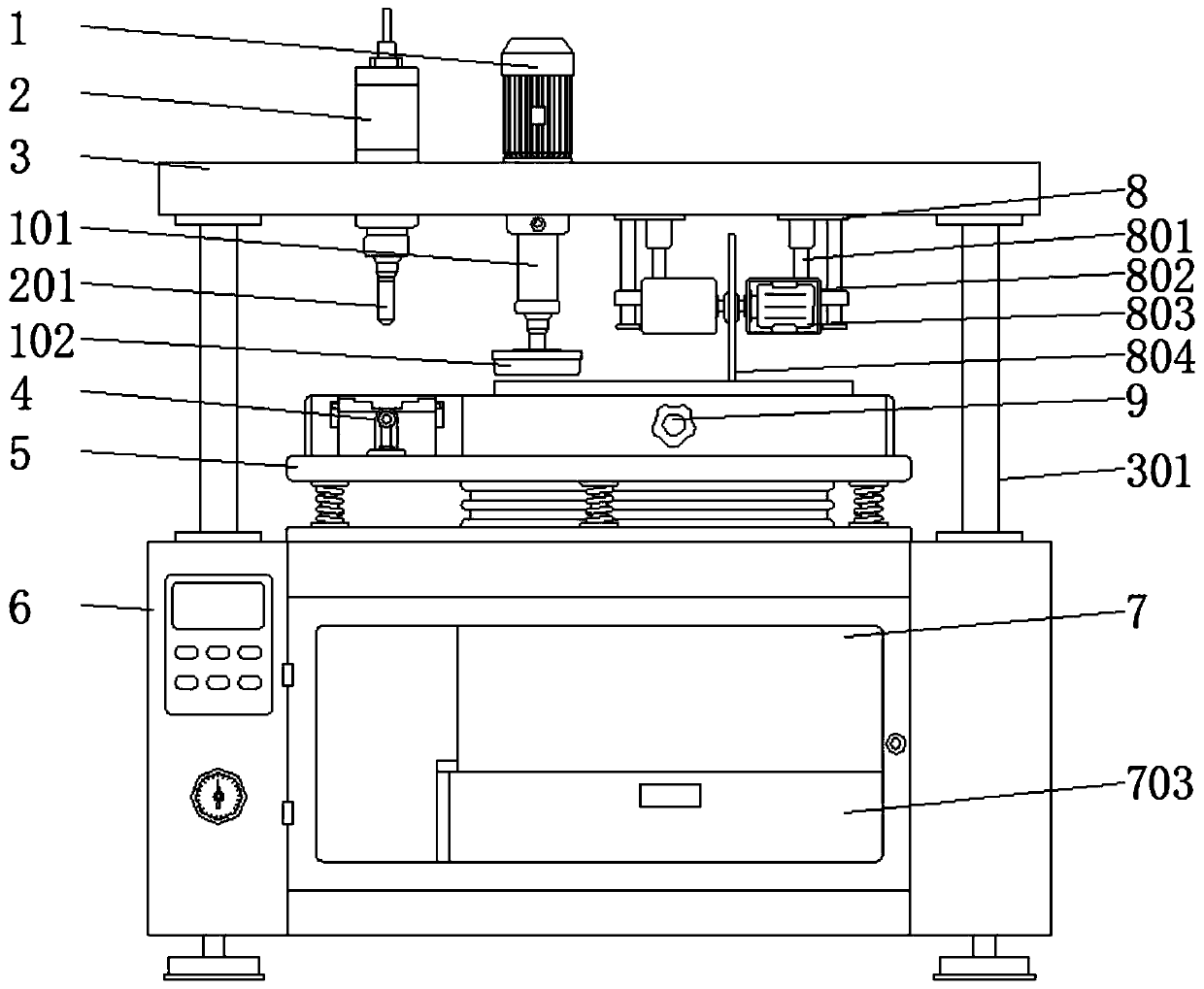

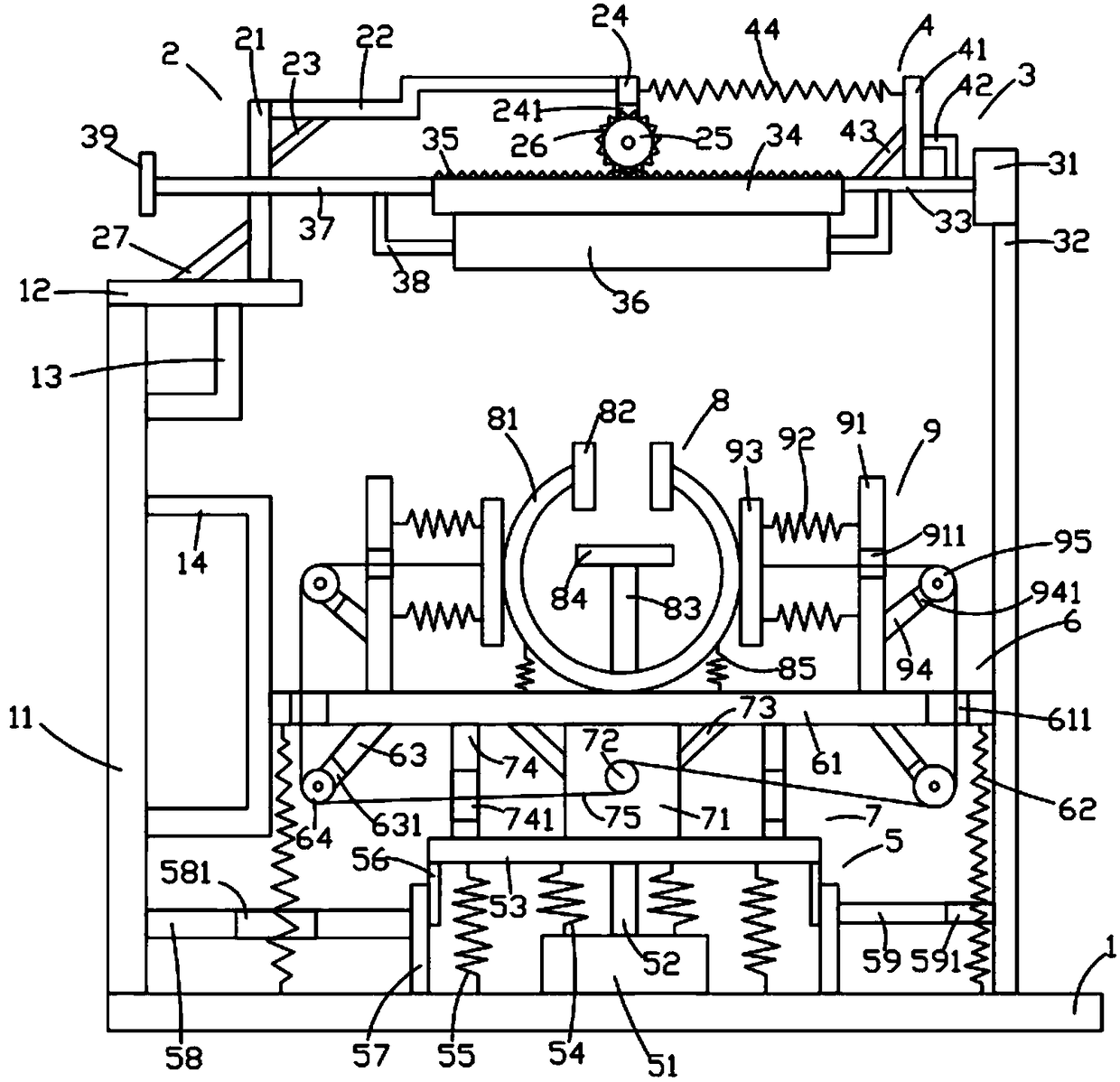

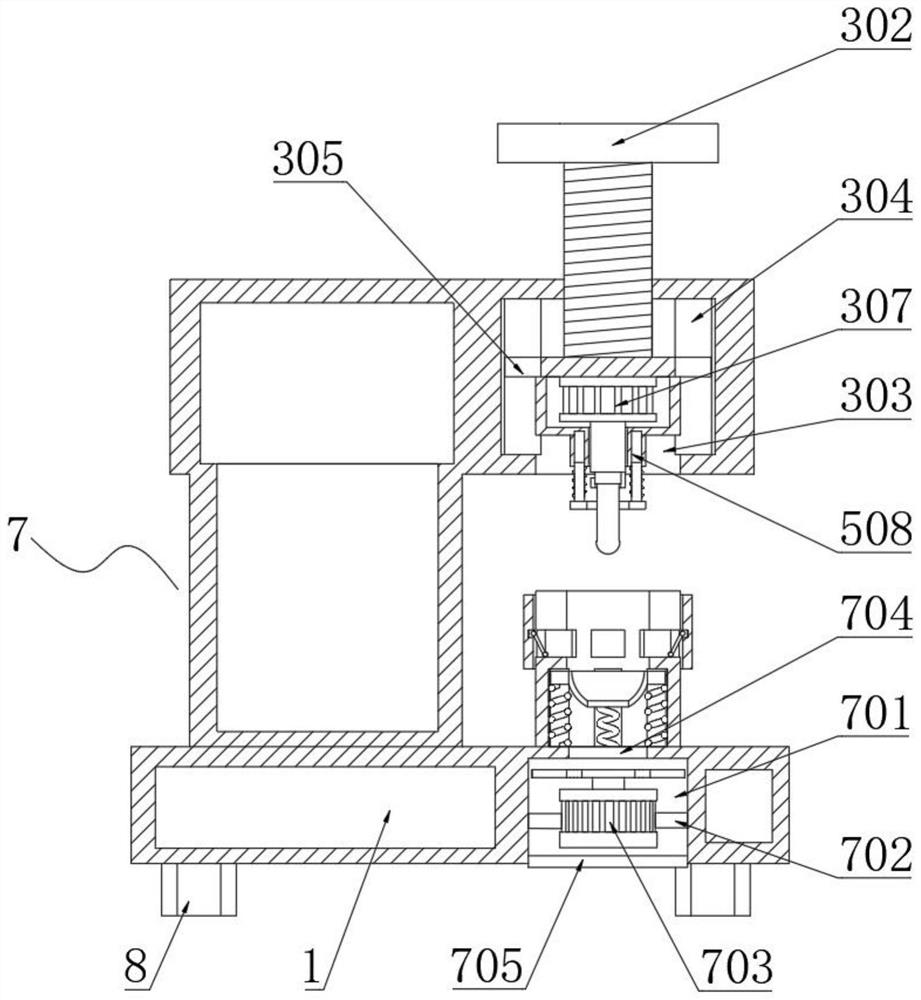

Grinding device for hardware parts with fixing device

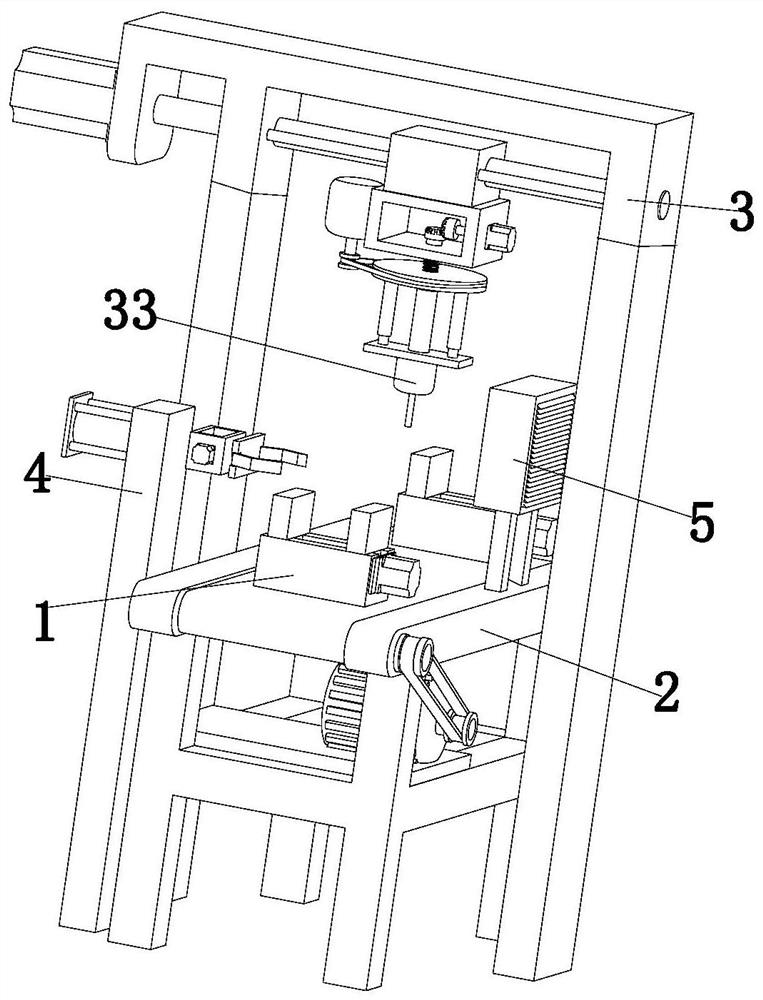

ActiveCN106425760BEasy to useAvoid affecting the effect of grindingGrinding carriagesGrinding drivesEngineeringMechanical engineering

The invention discloses a hardware component grinding device with a fixing device. The hardware component grinding device with the fixing device comprises a bottom plate, a bracket device, a grinding structure, a positioning device, an electric cylinder device, a supporting plate device, a motor device, a fixing device and a pressing device; a first supporting rod, a first transverse rod, a first bracket and a first positioning frame are arranged on the bottom plate; the bracket device comprises a second supporting rod, a second bracket, a fixing rod, a first vertical rod, a first roller, first saw teeth and a second fixing rod; the grinding structure comprises a first electric cylinder, a first third supporting rod, a first push rod, a first moving plate, second saw teeth, a grinding block, a first positioning rod, a third bracket and a first limiting rod; the positioning device comprises a fourth supporting rod, a fourth bracket, a third fixing rod and a first spring; the electric cylinder device comprises a second electric cylinder, a second push rod, a first transverse plate, second springs, third springs, second vertical rods, third vertical rods, a second transverse rod and a third transverse rod. The hardware component grinding device with the fixing device can fix a hardware component effectively during a grinding process.

Owner:平湖永鑫五金制品股份有限公司

Hardware polishing device with antirust function

PendingCN114770292AAvoid Spraying EffectsTo achieve anti-rust effectGrinding machinesGrinding feedersEngineeringGrinding

The invention discloses a hardware grinding device with an anti-rust function, and relates to the technical field of hardware grinding. The hardware grinding device with the antirust function comprises a device body, a supporting plate is fixedly installed on the inner wall of the device body, a conveying belt is arranged on the supporting plate, a driving device is fixedly installed at the top of the inner wall of the device body, and a grinding plate is fixedly installed at the output end of the driving device. According to the hardware grinding device with the anti-rust function, a grinding plate can be driven by the driving device to move up and down, after grinding is completed, the grinding plate can be driven by the driving device to move upwards, a connecting rod and a pull rod can be driven to move upwards when the grinding plate moves upwards, and a sealing plate can be driven to move upwards after the pull rod moves upwards; and at the moment, a discharging opening of the sealing plate communicates with a spray head, so that the anti-rust oil in the storage frame can be sprayed out of the spray head, and therefore the anti-rust oil can be sprayed to the polished hardware in time to achieve the anti-rust effect.

Owner:蚌埠滤佳纳米科技有限公司

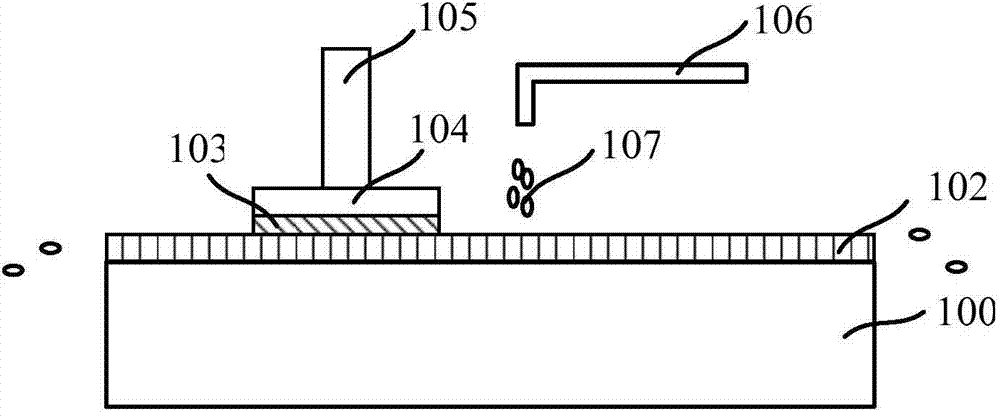

A kind of corrosion-resistant wooden door processing technology

ActiveCN112720123BAchieve positioningAvoid affecting the effect of grindingGrinding drivesSpecial surfacesPowder talcumMachining process

The invention belongs to the field of wooden door processing and manufacturing, and specifically relates to a corrosion-resistant wooden door processing technology. S1: use a grinding device to sand the surface of the wooden door to make the surface of the wooden door smooth, then add talcum powder and cooked rubber powder to the clear water, and Stir it well, then apply it to the surface of the wooden door to fill the holes on the surface of the wooden door, and finally dry it properly; S2: Spray the primer on the wooden door blank obtained through S1, and continue to use it after the surface of the wooden door is dry The grinding device grinds the surface to make the surface of the wooden door smooth and flat, which is convenient for subsequent paint spraying; S3: spray the wooden door obtained through S2 with anti-corrosion paint, and then dry it so that the wooden door has a corrosion-resistant effect; among them, S1 The grinding device described in S2 includes a workbench, a support plate, a cover plate and a grinding unit; the grinding effect on wooden doors is good.

Owner:浙江瀚霖门业有限公司

A combined high-efficiency traditional Chinese medicine grinder

ActiveCN109107648BAvoid cloggingGood activity spaceNon-rotating vibration suppressionGrain treatmentsChinese drugDust pollution

Owner:安徽金国源中药股份有限公司

Double-curved-surface aluminum veneer welding seam polishing device for machining

ActiveCN114571310AImprove grinding efficiencySolve the problem of safety hazards in manual grindingEdge grinding machinesGrinding carriagesPolishingSingle plate

The invention relates to a grinding device, in particular to a double-curved-surface aluminum veneer welding seam grinding device for machining. The double-curved-surface aluminum veneer weld joint polishing device for machining can fix a double-curved-surface aluminum veneer and automatically polish the double-curved-surface aluminum veneer. According to the technical scheme, the double-curved-surface aluminum veneer welding seam polishing device for machining comprises a bottom plate, a first support, a second support, a machining plate, a supporting plate, a bearing frame, a first electric push rod, a lead screw sliding table, a polishing mechanism and a pressing mechanism; two first supports are symmetrically and fixedly connected to the bottom plate, two second supports are symmetrically and fixedly connected to the bottom plate, and a machining plate is jointly and fixedly connected to the two first supports and the two second supports. According to the device, the double-curved-surface aluminum veneer can be automatically fixed and ground, and the problems that in the prior art, the efficiency of manual grinding is low, and the surface of the aluminum veneer is ground unsmoothly are solved.

Owner:河南嘉色铝业有限公司

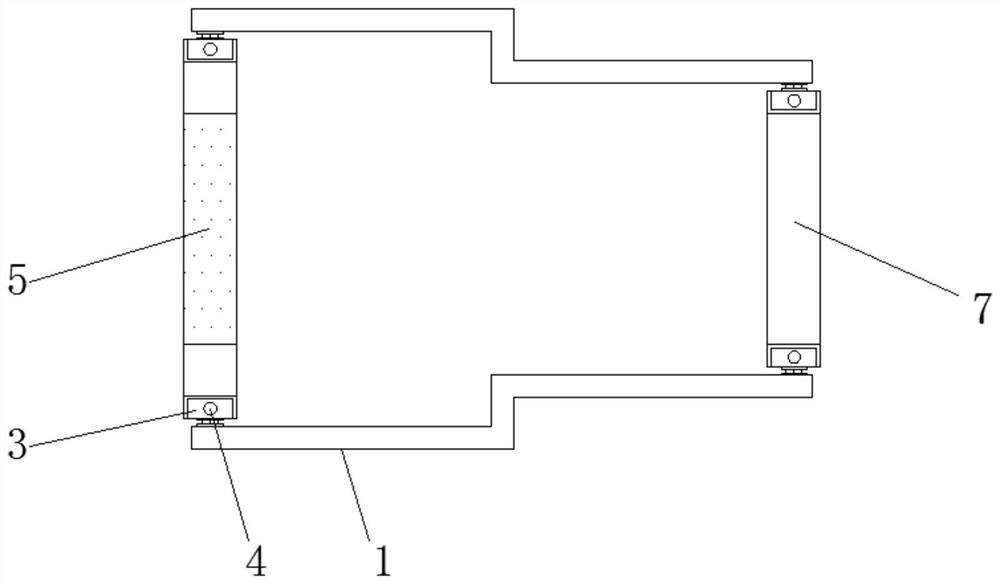

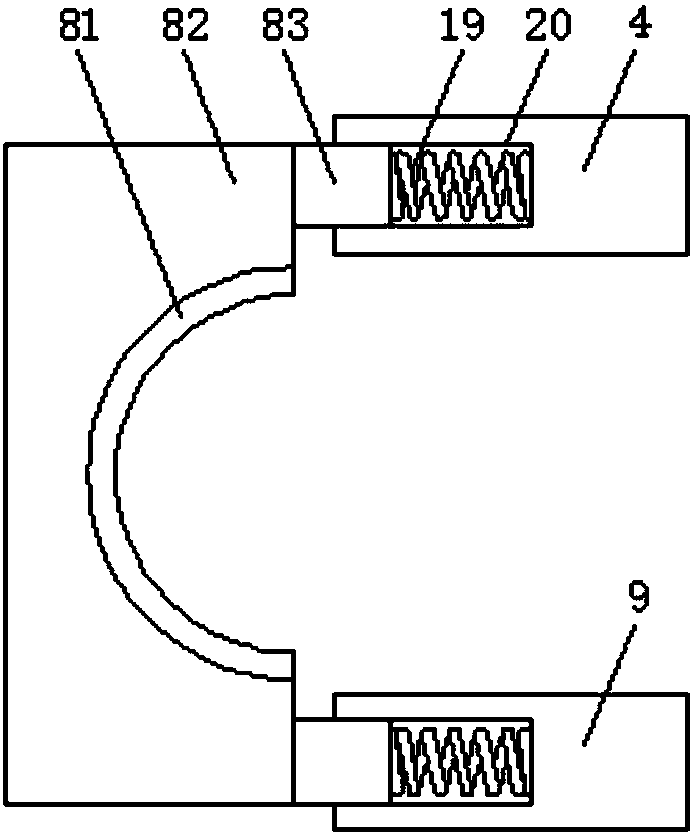

Histocyte nucleic acid extraction cryogrinding box

InactiveCN108342309AAvoid affecting the effect of grindingThe grinding effect is convenientBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringNucleic acid

The invention discloses a histocyte nucleic acid extraction cryogrinding box, which comprises a shell, a first side plate is arranged on one side of the shell, a second side plate is arranged on the other side of the shell, a sliding rail is arranged at one sides of the first side plate and the second side plate, a sliding strip is arranged in the sliding rail, the first side plate is connected with a driving plate through the sliding strip, fixing frames are arranged at two ends of the first side plate, fixing columns are arranged in the fixing frames, a mounting frame is arranged on the fixing columns, racks are arranged on the top end and the bottom end of the mounting frame, incomplete gears are meshed on the racks, the second side plate is connected with a driven plate through the sliding strip, spring grooves are formed in two sides of the driving plate and the driven plate, springs are arranged in the spring grooves, the driving plate and the driven plate are connected with a scraper device through the springs, and the scraper device is composed of a scraper blade, a mounting plate and a connecting column. The histocyte nucleic acid extraction cryogrinding box provided by the invention is better in grinding effect and is more convenient to use.

Owner:郑州檀乐科技有限公司

A loss-proof molecular biology experiment sample grinder

ActiveCN111530536BScientific and reasonable structureEasy to useGrain treatmentsRotational axisClassical mechanics

The invention discloses a wear-resistant molecular biology experiment sample grinder, which includes a base, a support frame is fixedly connected to the top side of the base, and a lifting mechanism is movably connected to the top side of the support frame. The lifting mechanism includes a rotating rod, a turntable, a circular groove, a chute, a slider, a fixed seat, a rotating motor and a rotating shaft seat. The top of the support frame is threaded and connected to a rotating rod, and the top of the rotating rod is cast with a rotating disc. , the present invention has a scientific and reasonable structure, is safe and convenient to use, and is equipped with a lifting mechanism. By turning the turntable, the turntable drives the rotating rod to rotate, and through the cooperation of the chute and the slider, the fixing seat is pushed to slide up and down along the circular groove, and the fixing seat is adjusted. , The height of the rotating motor and the rotating shaft seat, and then adjust the gap between the grinding rod and the grinding tube according to the needs, improve the grinding effect, and make the biological experiment samples can be ground more fully.

Owner:QINGDAO AGRI UNIV

A welding seam grinding device for hyperboloid aluminum veneer for processing

ActiveCN114571310BImprove grinding efficiencySolve the problem of safety hazards in manual grindingEdge grinding machinesGrinding carriagesSingle plateEngineering

The invention relates to a grinding device, in particular to a welding seam grinding device of a hyperboloid aluminum veneer for processing. The purpose of the present invention is to provide a double-curved aluminum veneer welding seam grinding device for processing, which can fix the hyperboloid aluminum veneer and automatically grind it. Technical scheme: a welding seam grinding device for a hyperboloid aluminum veneer for processing, including a bottom plate, a first bracket, a second bracket, a processing plate, a support plate, a bearing frame, a first electric push rod, a lead screw slide, a grinding mechanism and pressing mechanism; two first brackets are fixed symmetrically on the bottom plate, two second brackets are fixed symmetrically on the bottom plate, and a processing plate is fixed on the two first brackets and the two second brackets together . The device can automatically fix and grind the hyperboloid aluminum veneer, which solves the problems of low efficiency of manual grinding and uneven surface grinding of the aluminum veneer in the prior art.

Owner:河南嘉色铝业有限公司

Rebound type blanking machine tool for blackening and grinding of stainless steel plate surface

ActiveCN112571176BCutting is not easyAvoid cloggingGrinding carriagesGrinding drivesReciprocating motionStructural engineering

The invention discloses a rebound type blanking processing machine tool for blackening and grinding the surface of a stainless steel plate, which comprises a driving grinding mechanism and a bearing blanking mechanism. The output end of the telescopic cylinder of the processing machine tool is provided with a tie rod, and one end of the tie rod extends into the inner cavity of the fixed outer frame and is connected to the rebound component, so that after the machine tool finishes grinding and processing the stainless steel plate, the one close to the blanking component can be removed first. The clamping and limiting structure slides down from the installation bottom groove, and then the movable roller rod is used to slide the stainless steel plate from the fixed outer frame. The inner side is pulled, and the reciprocating positioning column is moved in the opposite direction by using the elastic rope and the elastic member. This reciprocating movement prevents the stainless steel plate from being difficult to unload due to the excessive friction on the bottom surface, and also prevents clogging when there are many processed materials. cutting speed.

Owner:NANJING YUSHENG ROBOT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com