A welding seam grinding device for hyperboloid aluminum veneer for processing

A technology of aluminum veneer and double-curved surface, which is applied in the direction of grinding drive devices, metal processing equipment, grinding machines, etc., can solve the problems of difficulty in fixing, unsafe, and low efficiency of manual grinding, and achieve strong practicability and high grinding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

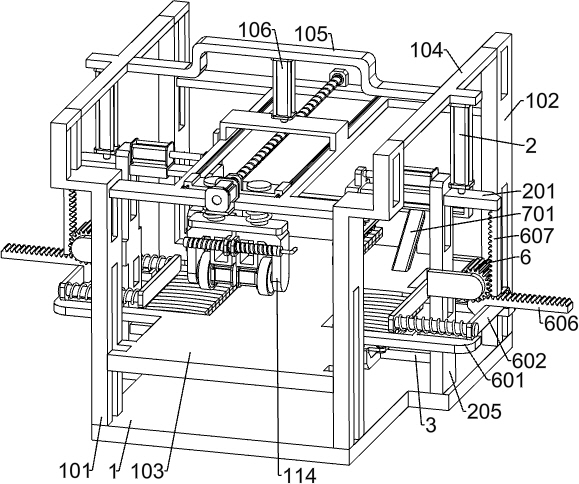

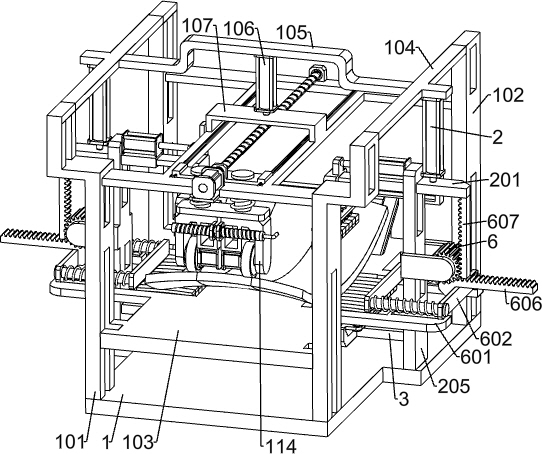

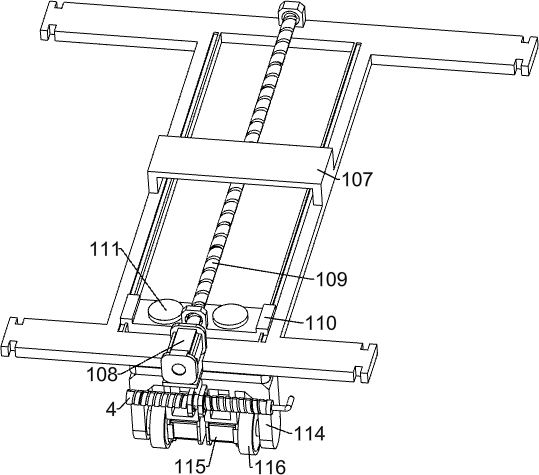

[0034]A welding seam grinding device for a hyperboloid aluminum veneer for processing, such as Figure 1-8 As shown, it includes a bottom plate 1, a first bracket 101, a second bracket 102, a processing plate 103, a support plate 104, a carrier frame 105, a first electric push rod 106, a lead screw slide, a grinding mechanism and a pressing mechanism, the bottom plate The first bracket 101 and the second bracket 102 are fixed symmetrically on the 1, the processing plate 103 is fixed to the first bracket 101 and the second bracket 102, and the first bracket 101 and the second bracket 102 on the same side are fixed together. A support plate 104 is connected, a carrier frame 105 is fixedly connected to the two support plates 104, a first electric push rod 106 is installed on the support frame 105, and a lead screw slide table is installed on the telescopic rod of the first electric push rod 106, The lead screw slide table includes a slide frame 107, a first motor 108, a drive scr...

Embodiment 2

[0043] On the basis of Example 1, as figure 2 and Image 6 As shown, a support mechanism is also included, and the third bracket 205 is connected with a support mechanism. The support mechanism provides support for the hyperboloid aluminum veneer during processing and automatically adjusts according to the shape of the bottom surface of the hyperboloid aluminum veneer. The support mechanism includes a lower bracket 3, a lower guide plate 301, a lower clamping block 302 and a third spring 303. Two lower brackets 3 are symmetrically fixed on the two third brackets 205, and lower brackets 3 are provided with lower guide plates 301. The lower guide plate 301 is slidably connected with a plurality of lower clamping blocks 302, the lower clamping blocks 302 are provided with anti-slip rubber pads, and the sliding shafts of the lower clamping blocks 302 are all sleeved with a third spring 303, the pressing mechanism is used to press the aluminum veneer against the aluminum veneer. ...

Embodiment 3

[0046] On the basis of Example 2, as figure 2 and Figure 7 As shown, it also includes a positioning mechanism for positioning the processing position of the hyperboloid aluminum veneer. The positioning mechanism includes a positioning guide plate 602, a positioning guide rod 603, a positioning plate 604, a fourth spring 605 and a transmission assembly. The processing plate 103 is symmetrical on the There are two positioning guide plates 602 connected to each other, and two positioning guide rods 603 are slidably connected to the positioning guide plates 602. The two positioning guide rods 603 on the same side are both fixed with a positioning plate 604 at one end away from the positioning guide plate 602. The guide rod 603 is covered with a fourth spring 605, and the upper slide plate 201 is connected with a transmission assembly for driving the positioning guide plate 602 to slide. The transmission assembly includes a gear 6, a first toothed plate 606 and a second toothed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com