Grinding device for hardware parts with fixing device

A technology for fixing devices and hardware parts, applied in the direction of grinding drive devices, grinding machine parts, grinding machines, etc., can solve problems such as increased production costs, many defective parts, and damaged hardware, so as to ensure stability and prevent defects parts, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

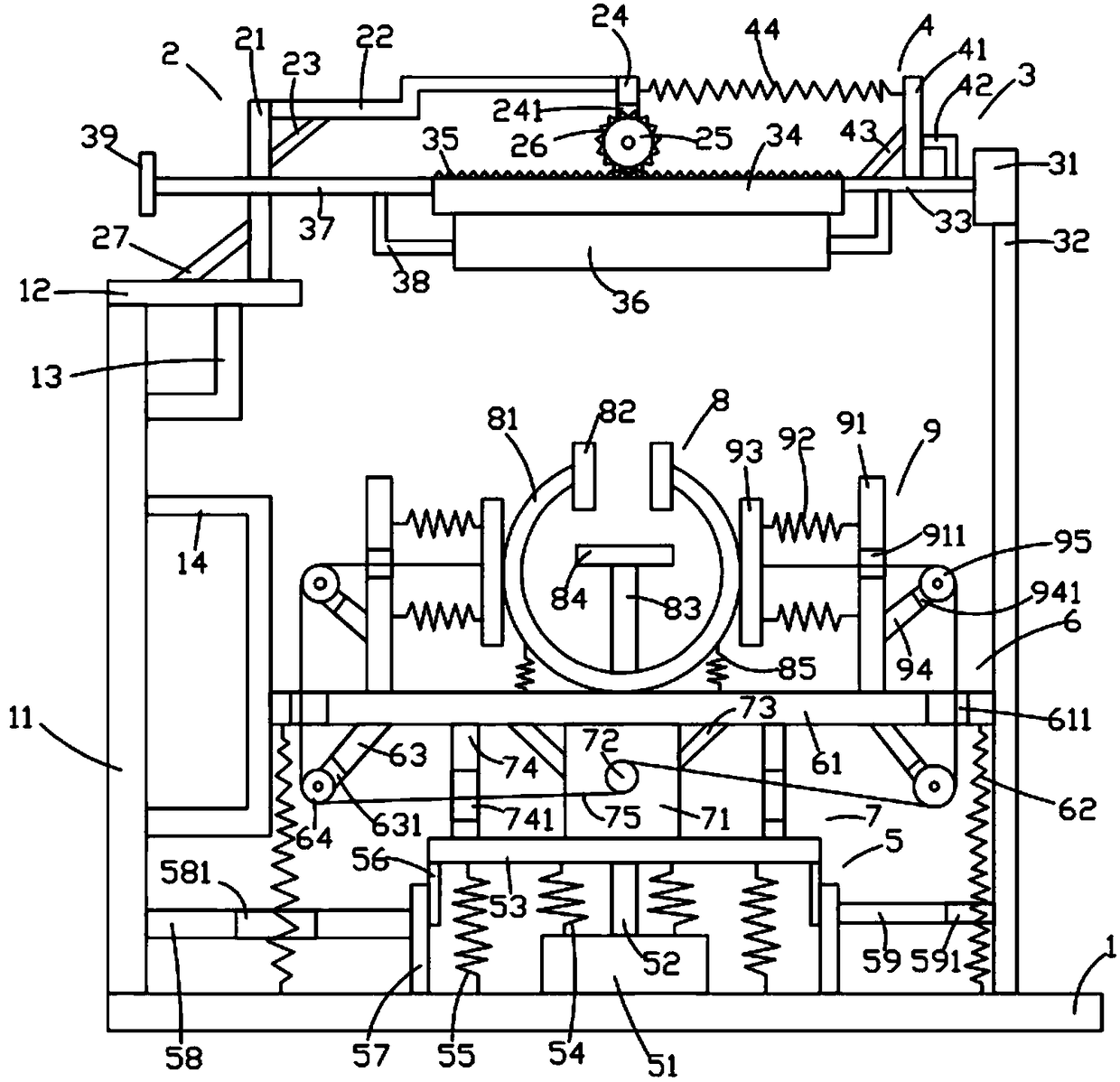

[0018] In the following, a clear and complete description of the grinding device for hardware parts with a fixing device of the present invention will be made with reference to the accompanying drawings.

[0019] like figure 1 As shown, the polishing device for hardware parts with a fixing device of the present invention includes a bottom plate 1, a bracket device 2 located above the bottom plate 1, a polishing structure 3 located on the right side of the bracket device 2, and a polishing structure 3 arranged on the polishing structure 3 The positioning device 4, the electric cylinder device 5 located above the bottom plate 1, the support plate device 6 located above the electric cylinder device 5, the motor device 7 arranged on the support plate device 6, the support plate The fixing device 8 above the device 6 and the abutting devices 9 located on the left and right sides of the fixing device 8 .

[0020] like figure 1 As shown, the bottom plate 1 is in the shape of a cubo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com