Mixed coating stirring device

A stirring device and a technology for mixing paints, which are used in mixers, mixer accessories, mixers with rotating containers, etc., can solve the problems of physical effort, troublesome cleaning, uneven mixing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

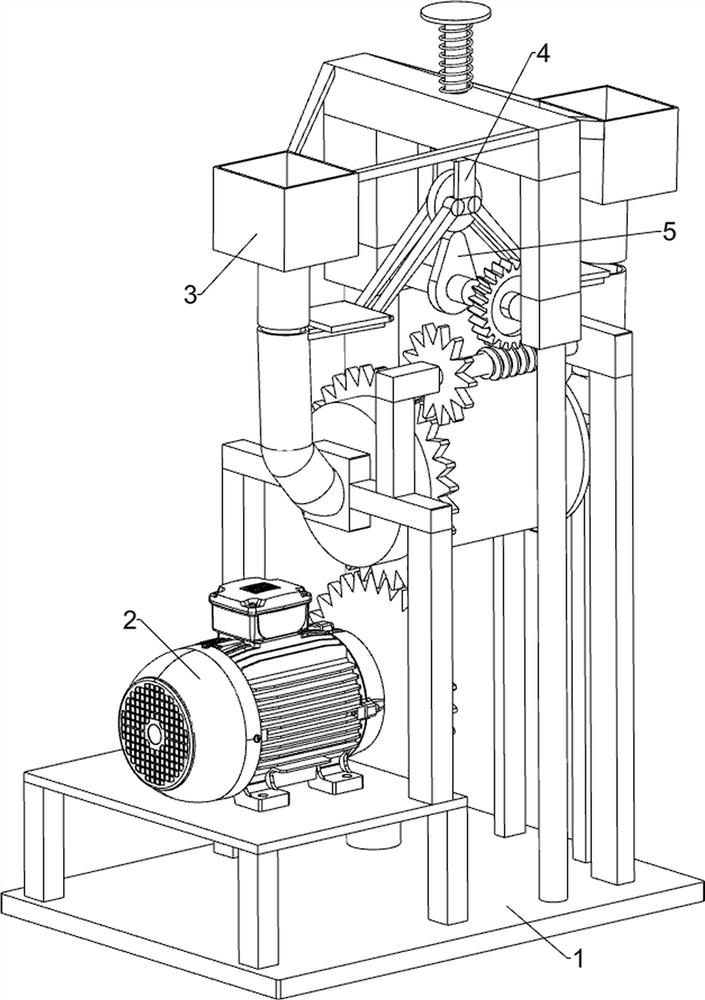

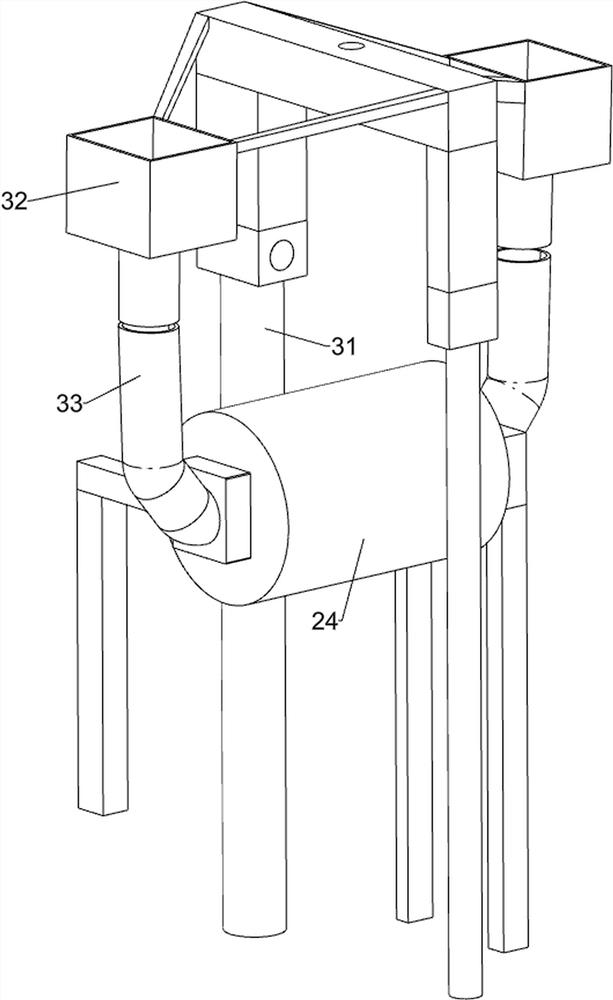

[0023] A stirring device for mixing paint, such as Figure 1-3 As shown, it includes a support frame 1 , a mixing assembly 2 and a blanking assembly 3 , the mixing assembly 2 is provided on the front upper side of the support frame 1 , and the blanking assembly 3 is provided on the upper side of the support frame 1 .

[0024] When the paint needs to be stirred, start the mixing component 2, then put the paint into the feeding component 3, the paint will enter the mixing component 2 through the feeding component 3, and the mixing component 2 will stir the paint at the same time, and the stirring is completed After that, close the mixing component 2.

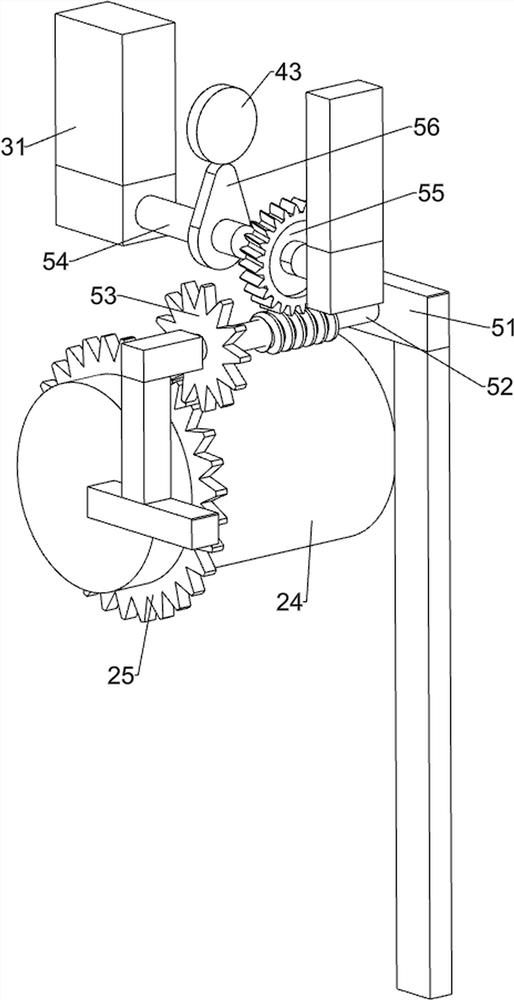

[0025] The mixing assembly 2 includes a reduction motor 21, a first gear 22, a first support 23, a rotating drum 24 and a second gear 25, and the upper side of the front part of the support frame 1 is fixed with a reduction motor 21 by bolts, and the output of the reduction motor 21 The first gear 22 is connected to the shaft, th...

Embodiment 2

[0030] On the basis of Example 1, such as figure 1 , Figure 4 and Figure 5 As shown, a blocking assembly 4 is also included, and the blocking assembly 4 includes a guide rod 41, a spring 42, a disk 43, a connecting rod 44, a baffle plate 45 and a slide rail 46, and the second bracket 31 is slidably provided with a guide rod 41 A spring 42 is connected between the guide rod 41 and the second bracket 31, the underside of the guide rod 41 is connected with a disc 43, and the inside of the feeding pipe 33 is connected with a slide rail 46, and the slide rail 46 is provided with sliding The baffle 45 is rotatably provided with a connecting rod 44 between the baffle 45 and the disc 43 .

[0031] After the paint is put into the storage boxes 32 on both sides, the guide rod 41 can be controlled to move upwards, so that the spring 42 is stretched, and at the same time, the disc 43 is driven to move upwards, and the connecting rod 44 drives the baffle plates 45 on both sides to move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com