A drum concrete mixer

A concrete mixer, drum-type technology, applied in the direction of cement mixing device, mixing operation control, clay preparation device, etc., can solve the problems of poor concrete quality, time-consuming and labor-intensive manual mixing, and the inability of mixing blades to fully mix concrete, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

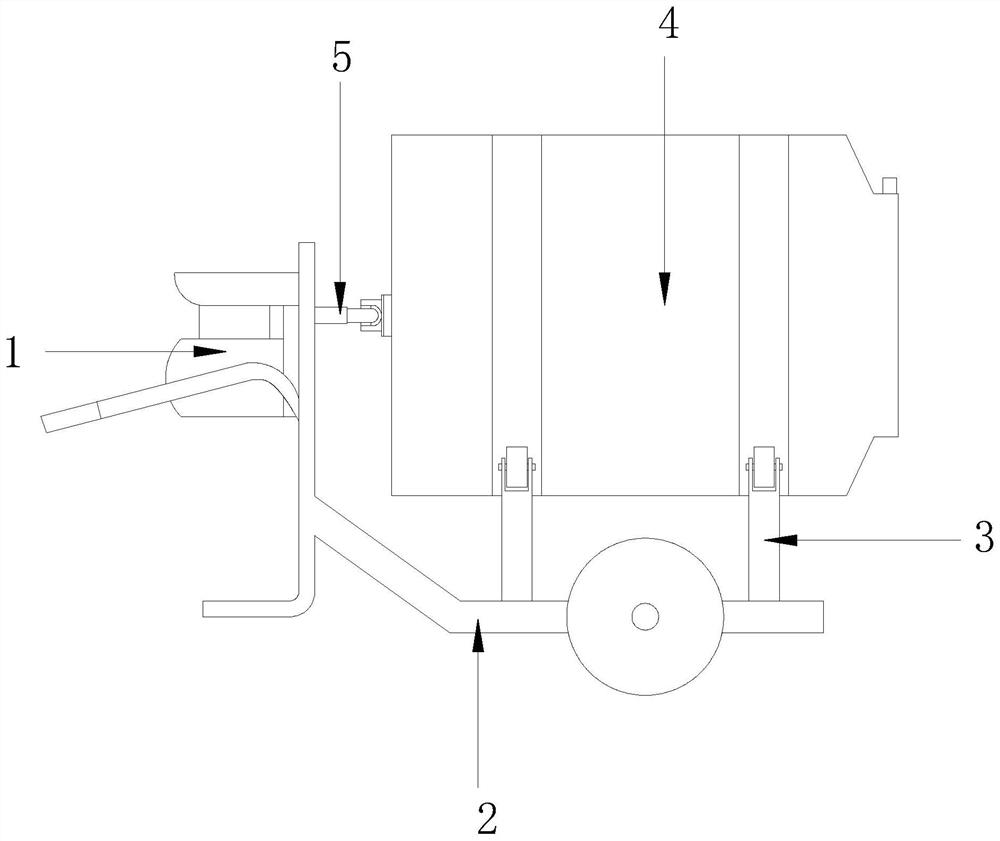

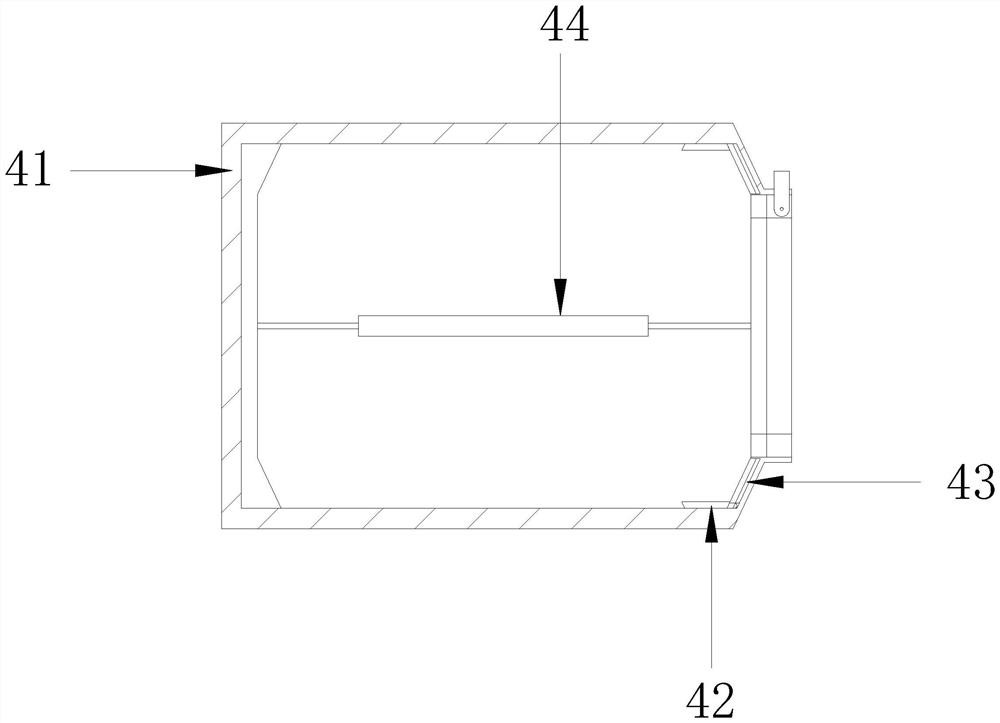

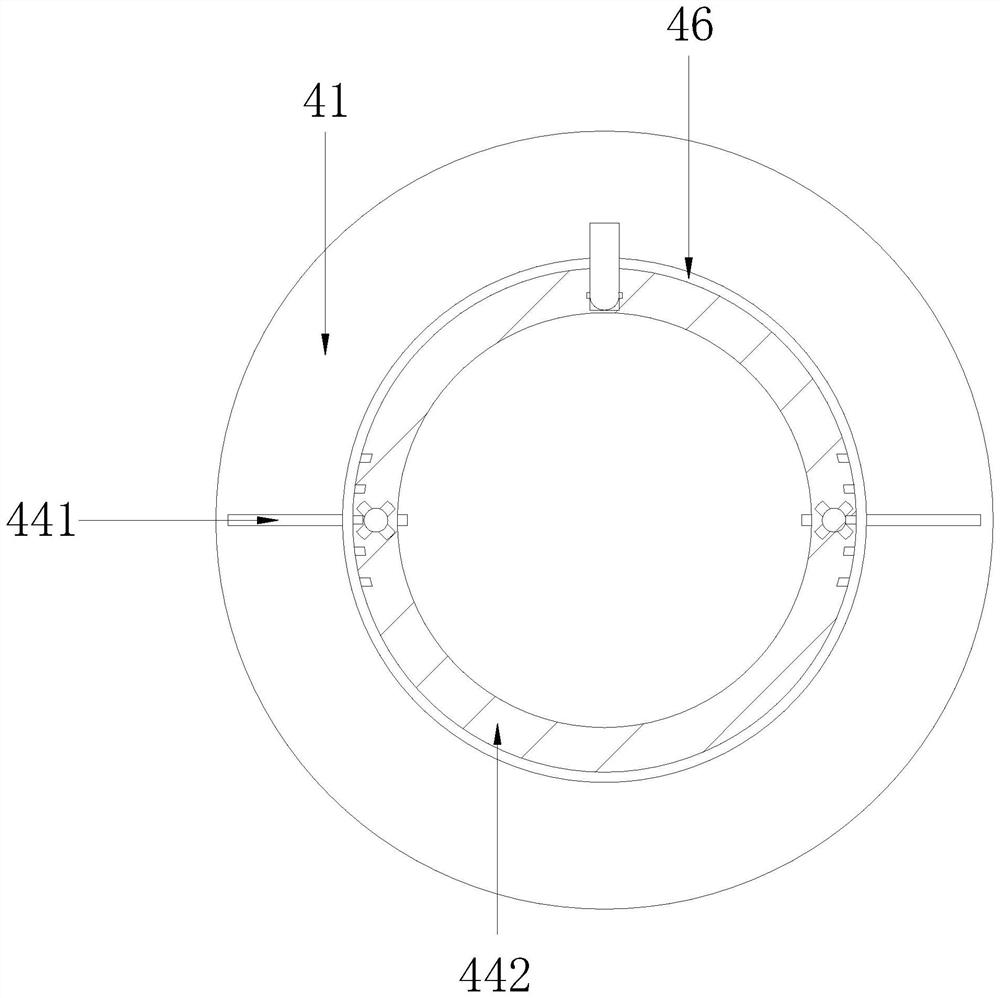

[0027] like Figure 1-Figure 5 As shown in the figure, the present invention provides a technical solution for a drum concrete mixer: its structure includes a motor unit 1, a moving bracket 2, a bracket roller 3, a drum 4, and a universal shaft 5, and the movable bracket 2 is installed on both sides respectively. There are 4 bracket rollers 3, the bracket rollers 3 are movably matched with the drum 4, and a universal shaft 5 is installed on one side of the drum 4, and the universal shaft 5 is connected with the motor group 1 through the moving bracket 2 , the drum 4 includes a cylindrical body 41, a shrinking ring 42, a chute 43, and a stirring assembly 44. The end of the cylindrical body 41 away from the universal shaft 5 is provided with a material port, and the cylindrical body 41 is close to the inclined surface of the material port. There is a chute 43 on it, the chute 43 is movably matched with the shrinking ring 42, the cylinder 41 is in clearance fit with the stirring ...

Embodiment 2

[0032] like Figure 1-Figure 7 As shown in the figure, the present invention provides a technical solution for a drum concrete mixer: its structure includes a motor unit 1, a moving bracket 2, a bracket roller 3, a drum 4, and a universal shaft 5, and the movable bracket 2 is installed on both sides respectively. There are 4 bracket rollers 3, the bracket rollers 3 are movably matched with the drum 4, and a universal shaft 5 is installed on one side of the drum 4, and the universal shaft 5 is connected with the motor group 1 through the moving bracket 2 .

[0033] The drum 4 includes a cylinder 41, a shrinking ring 42, a chute 43, and a stirring assembly 44. The cylinder 41 is provided with a feed opening at one end away from the universal shaft 5, and the cylinder 41 is close to the inclined surface of the feed opening. A chute 43 is provided, the chute 43 is movably matched with the shrinking ring 42, and the cylinder 41 is in clearance fit with the stirring assembly 44. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com