Temperature-controllable rubber dissolving tank

A technology for dissolving tanks and rubber, which is applied in the direction of dissolving, dissolving, and mixers with rotating stirring devices, etc., which can solve the problems of reducing rubber concentration, reducing device production capacity, and prolonging dissolution time, so as to increase the dissolution rate of rubber and avoid heat. Loss, the effect of accelerating the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

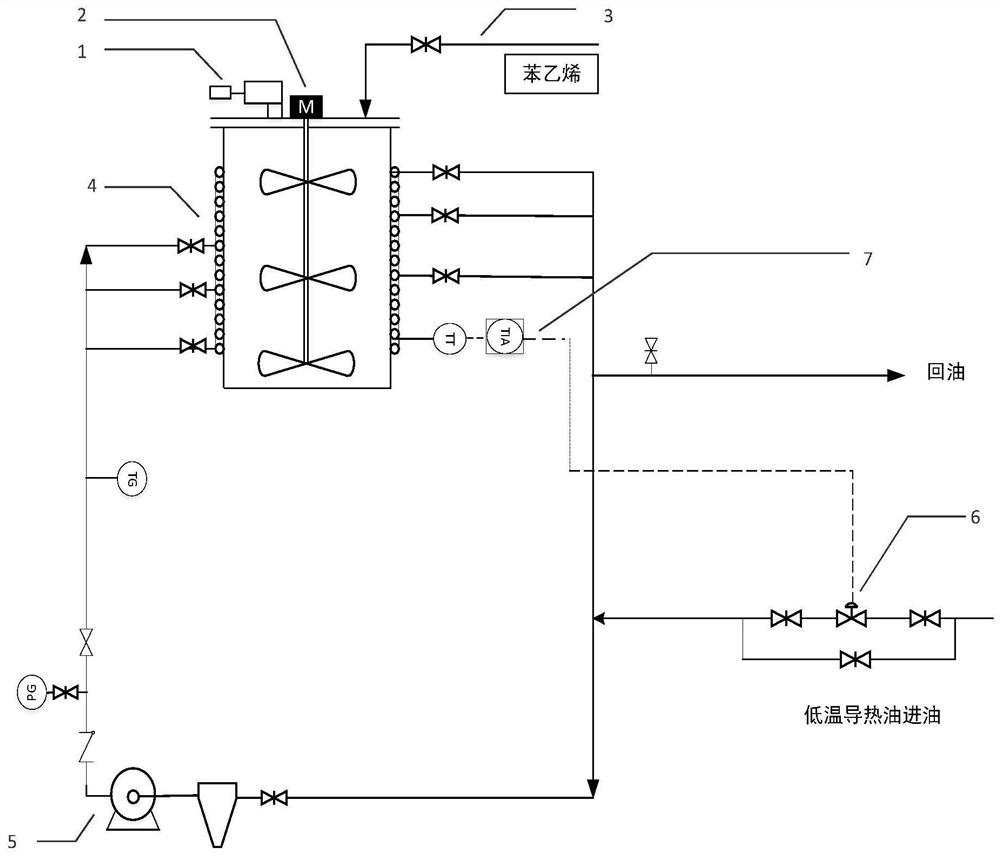

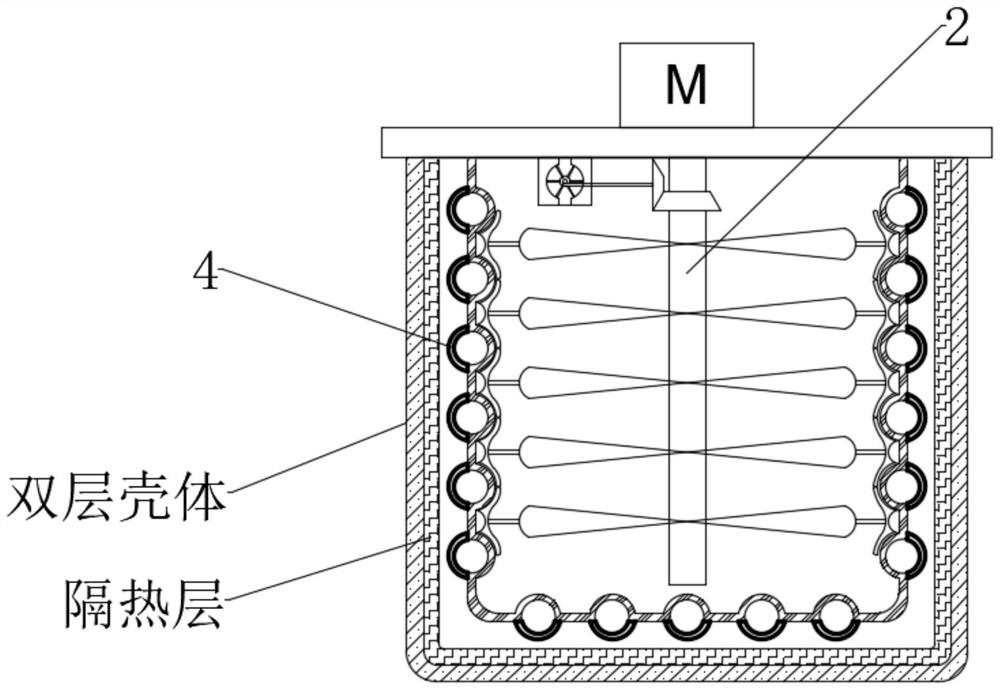

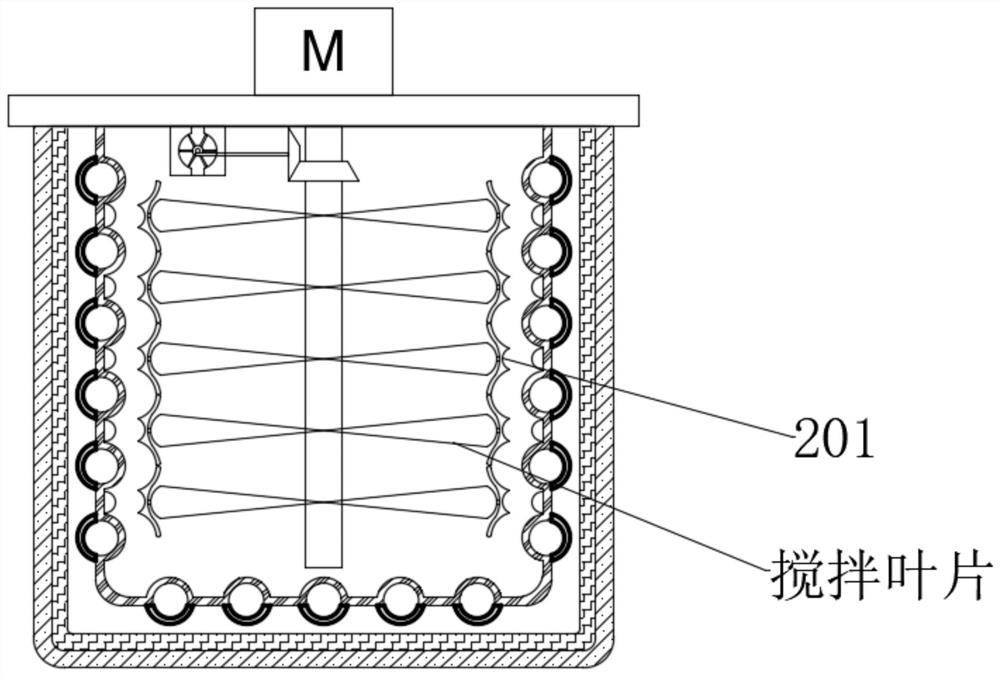

[0047] see Figure 1-10 , a temperature-controllable rubber dissolution tank, see Figure 1-Figure 3 , including a dissolution tank, the dissolution tank is a double-layer shell, and the inner wall of the shell of the dissolution tank is also fixedly connected with a heat insulation layer (this is a well-known technology well known to those skilled in the art, and the specific materials can be selected according to actual needs, which will not be described here. To repeat in detail), it is to prevent the heat from exchanging heat with the outside air through the shell, effectively avoiding the loss of heat, and a rubber cutter 1 is installed above the dissolving tank, and a styrene adding pipeline 3 is connected to the top of the dissolving tank, and the dissolved A mixer 2 is provided inside the tank, a jacket 4 is provided between the outer shell and the inner shell of the dissolving tank, and the jacket 4 is filled with heat transfer oil, and a thermal oil circulation pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com