Vertical variable-volume mixing barrel

A mixing drum and variable technology, applied in the direction of cement mixing equipment, clay preparation equipment, chemical instruments and methods, etc., can solve the problems of increased experimental costs, waste of materials, environmental pollution, etc., and achieve simple structure, reliable operation, and high utilization rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

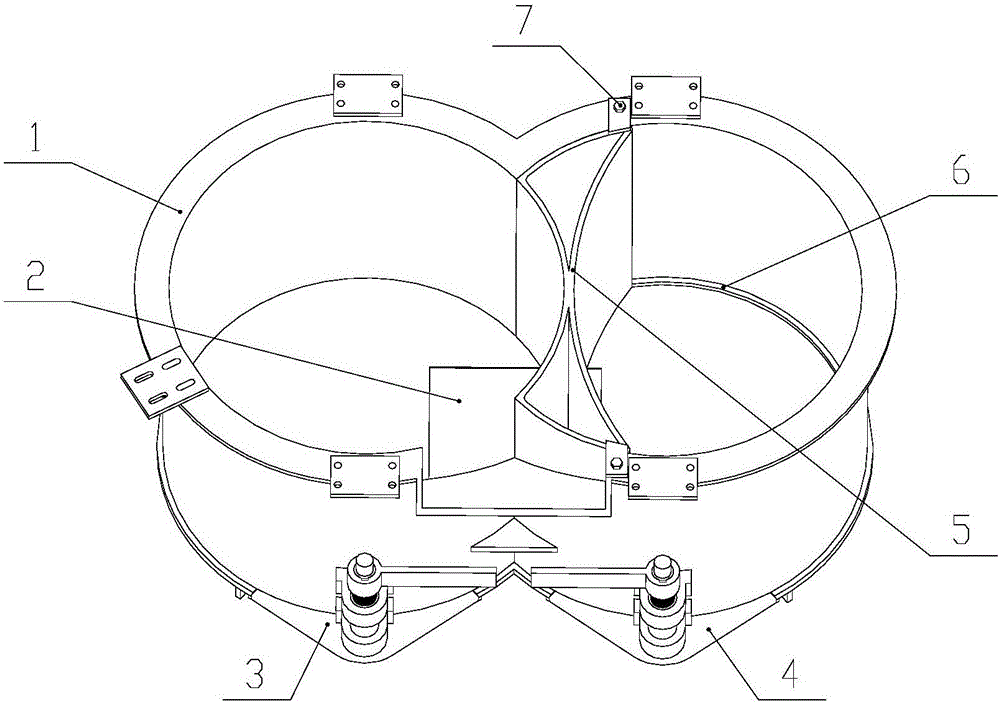

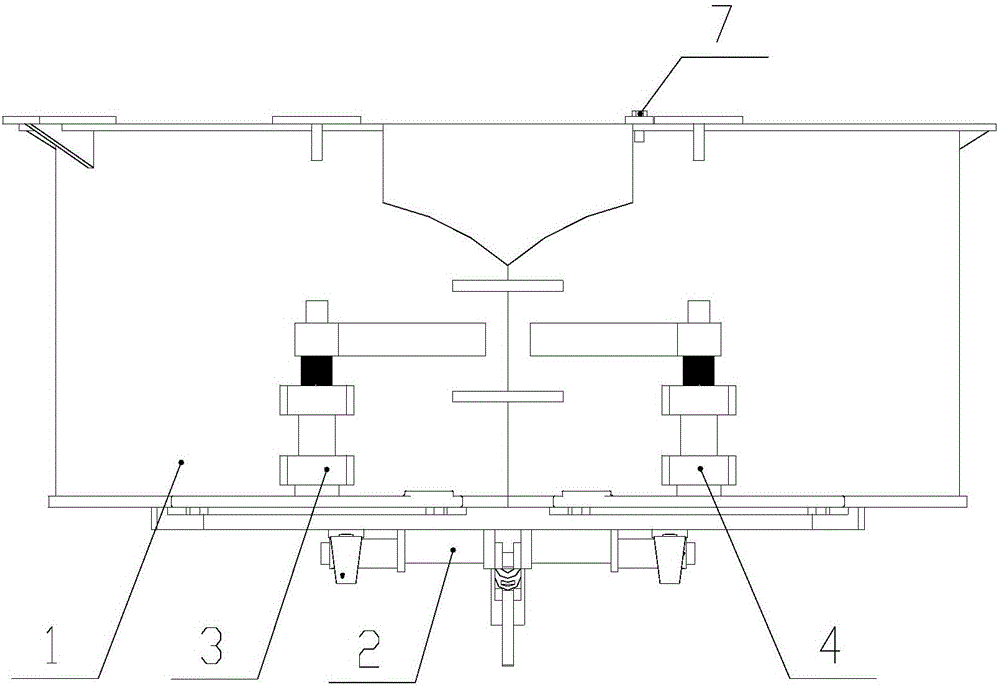

[0025] Such as Figure 4 As shown, this embodiment includes a mixing drum body 1, a left stirring device 9 and a right stirring device 8; the bottom of the mixing drum body 1 is provided with a main discharge door 2, a left discharge door 3 and a right side The discharge door 4, the main discharge door 2 is a reversing door structure controlled by a connecting rod mechanism, and the left discharge door 3 and the right discharge door 4 are both revolving door structures controlled by a handle; The side stirring device 9 and the right stirring device 8 are symmetrically installed in the left and right stirring areas of the mixing drum body 1, and the left stirring device 9 and the right stirring device 8 of the present invention are not limited to the illustrated situation.

[0026] This embodiment is a double-drum mixing condition, the mixing drum body 1 is at the maximum working volume, and its left and right mixing areas are all utilized; at this time, the material is forced ...

Embodiment 2

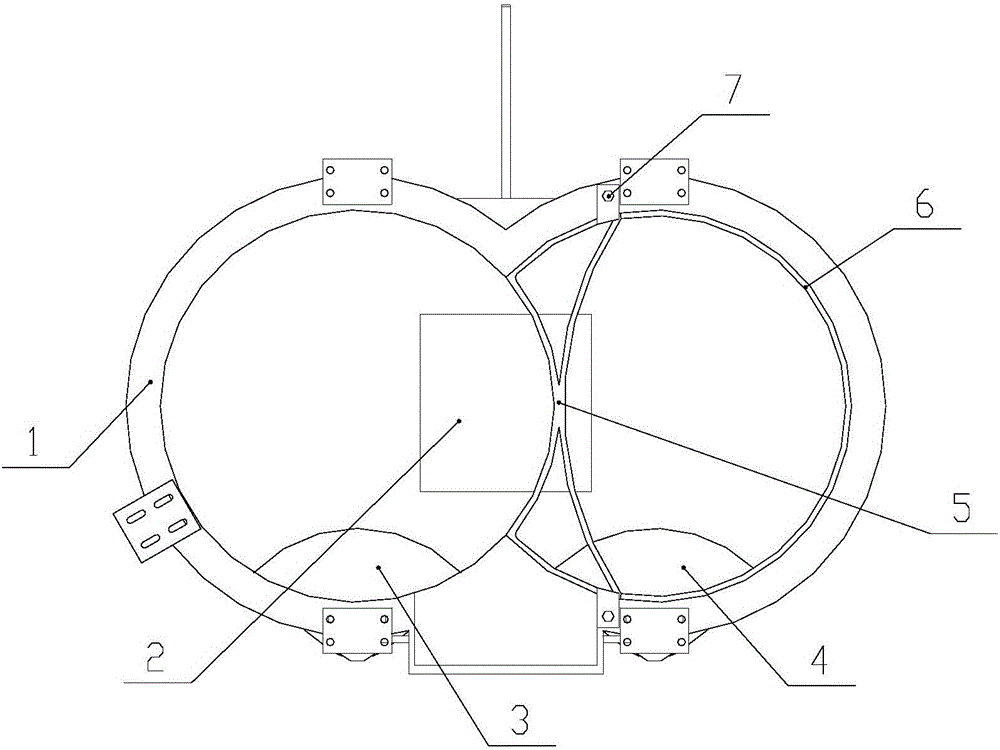

[0028] Such as Figure 5 As shown, this embodiment includes a mixing drum body 1, a left stirring device 9, a single cylinder partition 5 and a limit plate 6; the bottom of the mixing drum body 1 is provided with a main discharge door 2 and a left discharge door 3 and the right discharge door 4, the main discharge door 2 is a flip door structure controlled by a linkage mechanism, and the left discharge door 3 and the right discharge door 4 are revolving door structures controlled by a handle; The left stirring device 9 is installed in the left stirring area of the mixing drum body 1, and the left stirring device 9 of the present invention is not limited to the situation shown in the figure.

[0029] The single-tube partition 5 is welded by an arc-shaped plate equal to the inner diameter of the mixing drum body 1, and is installed in the mixing area on the right side of the mixing drum body 1. The lower end of the single-tube partition 5 is limited by a stop plate 6 Its posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com