Stirring device for aluminum alloy smelting and manufacturing method of stirring device

A technology of a stirring device and a manufacturing method, which is applied in the direction of chemical instruments and methods, mixers, metal material coating processes, etc., can solve the problems of affecting the stirring effect, burning loss, etc., and achieve prolonging life, high temperature oxidation resistance, good resistance erosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Various embodiments of the present application will be disclosed in the drawings below, and for the sake of clarity, many practical details will be described together in the following description. It should be understood, however, that these practical details should not be used to limit this application. That is, in some embodiments of the present application, these practical details are unnecessary. In addition, for the purpose of simplifying the drawings, some well-known structures and components will be shown in a simple schematic manner in the drawings.

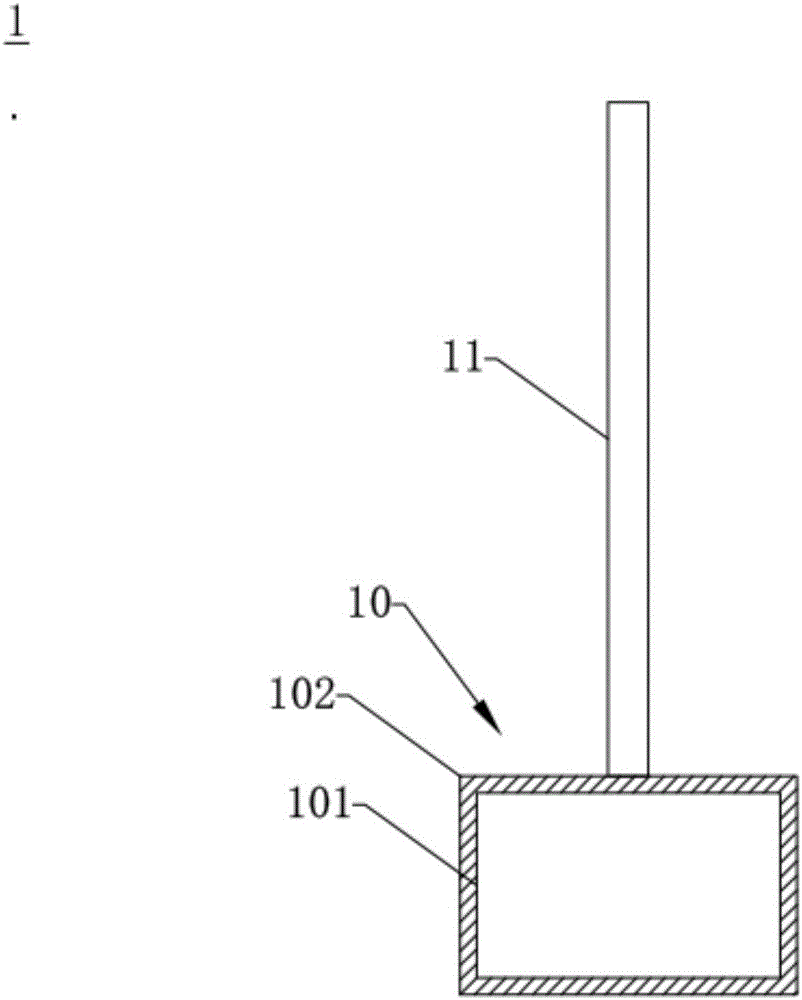

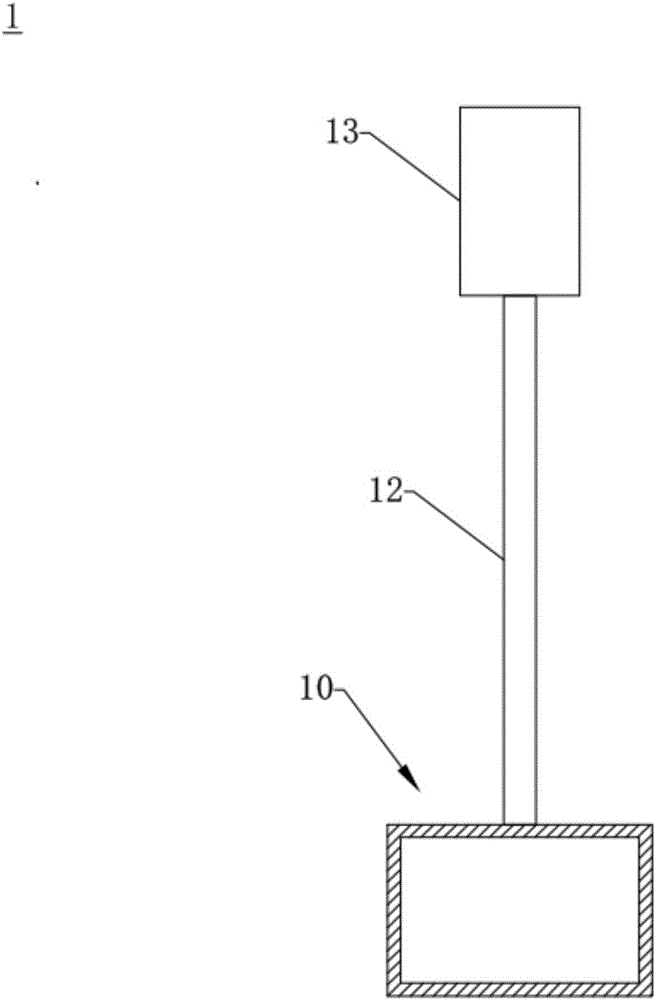

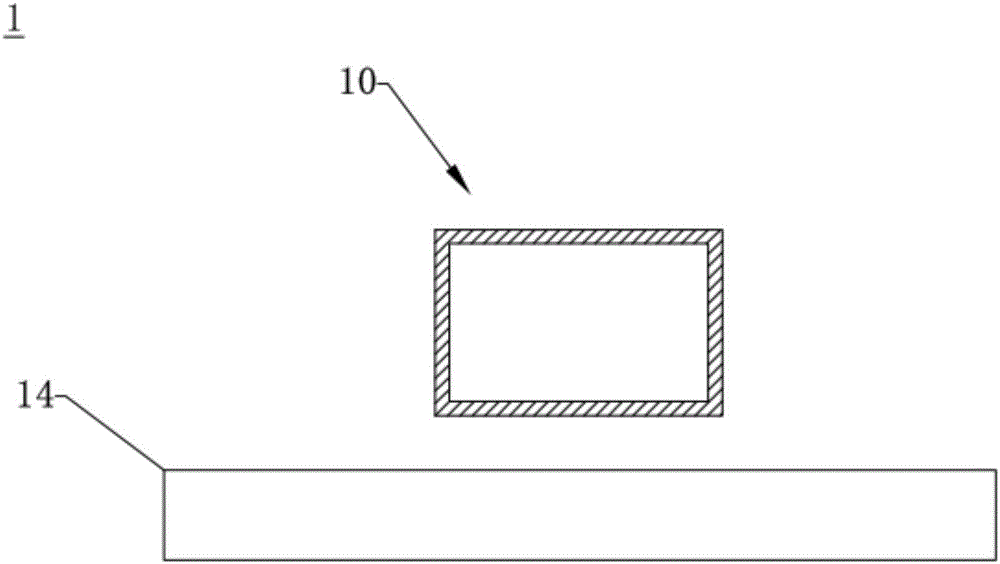

[0021] see figure 1 , which is a schematic diagram of the stirring device 1 according to an embodiment of the application. As shown in the figure, the present application provides a stirring device 1 for aluminum alloy smelting, the stirring device 1 mainly includes a stirring body 10, and the stirring body 10 stirs the aluminum solution. The stirring body 10 includes an iron base 101 and a cladding layer 102. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com