Mixing equipment for production of fluorinated silicone rubber and use method of mixing equipment

A fluorosilicone rubber and mixing technology, applied in the field of mixing equipment for fluorosilicone rubber production, can solve the problems of inability to disassemble rubber mixing rollers, waste, and inability to adjust the distance of rubber mixing rollers, and achieve the effect of enhancing the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

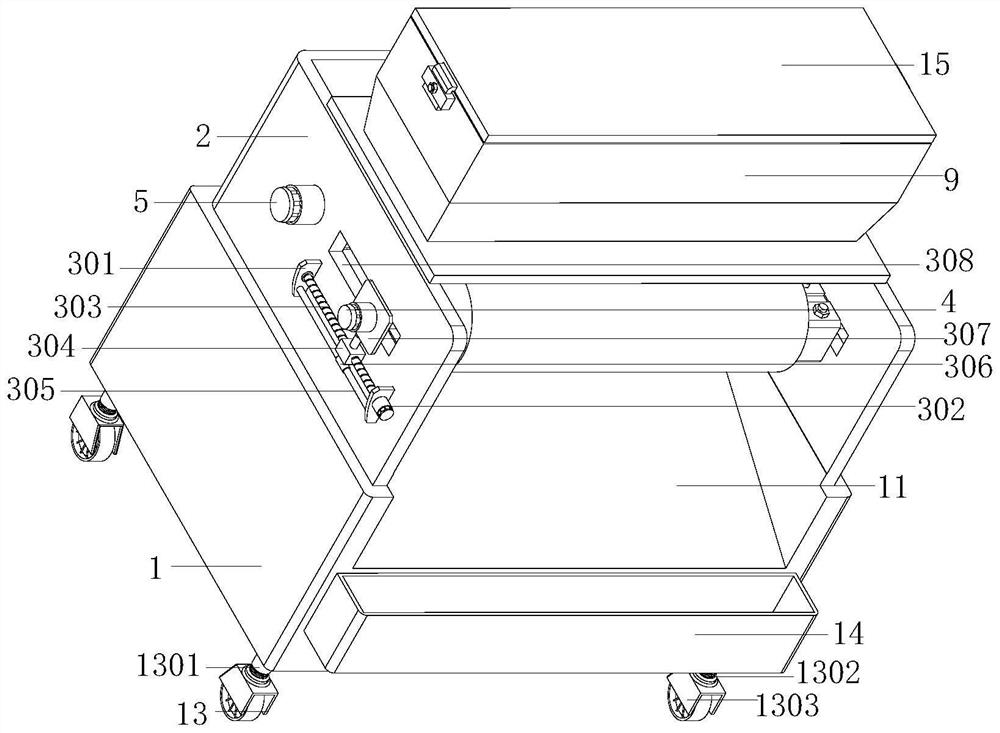

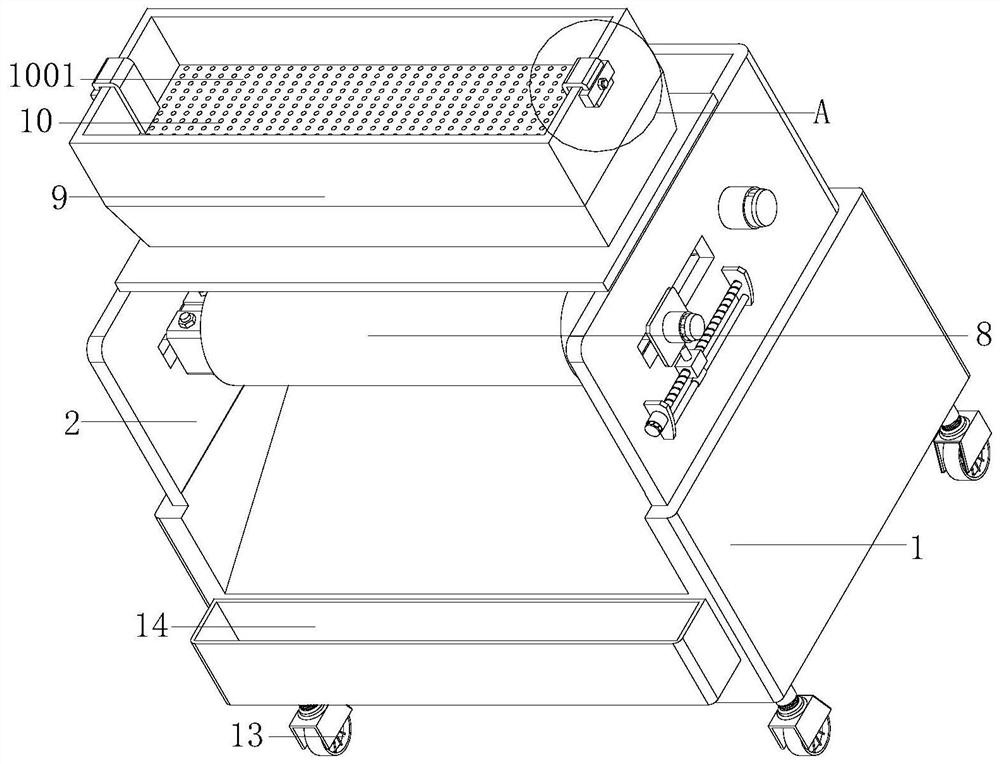

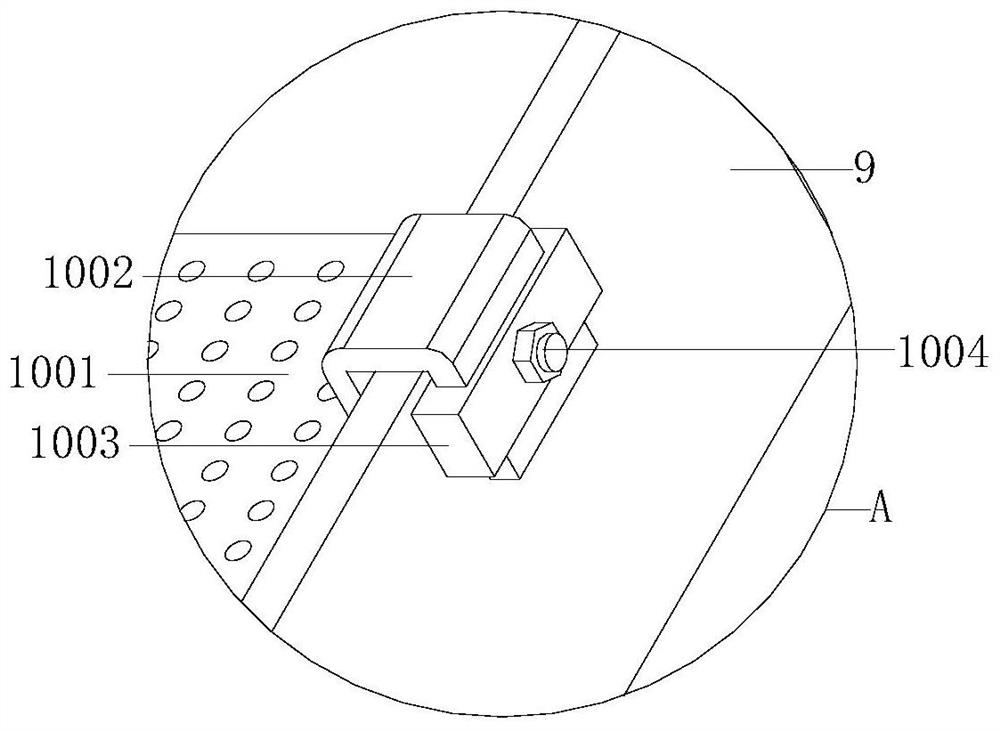

[0036] Such as figure 1 , figure 2 , Figure 4 and Figure 5 As shown, a mixing equipment for the production of fluorosilicone rubber proposed by an embodiment of the present invention includes a device body 1, a mounting plate 2 is fixed on the top of the device body 1, and an adjustment mechanism 3 is provided on one side of the mounting plate 2. A first motor 4 is installed on one side of the mechanism 3, a second motor 5 is installed on one side of the mounting plate 2, and the output shaft ends of the first motor 4 and the second motor 5 are connected with a dismounting mechanism 6, and the two dismounting mechanisms 6 There are fixed roller 7 and kneading roller 8 that slide respectively inside. The fixed roller 7 and the inner wall bearing of the installation plate 2 rotate, and the kneading roller 8 is slidably installed with the dismounting mechanism 6 on the other side. The top of the installation plate 2 is equipped with a feed Box 9, the interior of the feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com