Stirring device for premixed mortar

A technology of mixing device and ready-mixed mortar, which is applied in cement mixing device, unloading device, clay preparation device, etc., can solve the problems of low work efficiency, affecting the effect of mortar pouring, uneven mixing of mortar, etc., so as to improve work efficiency, The effect of improving mixing quality and use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

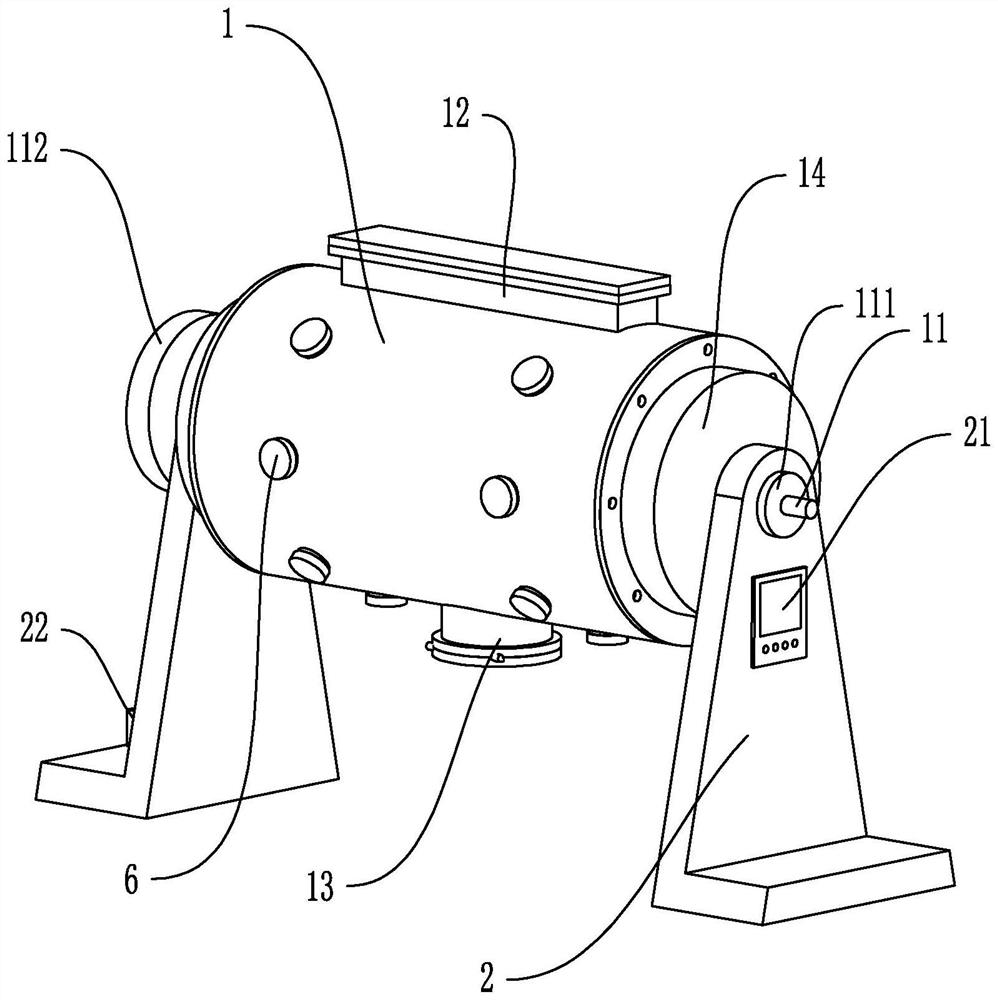

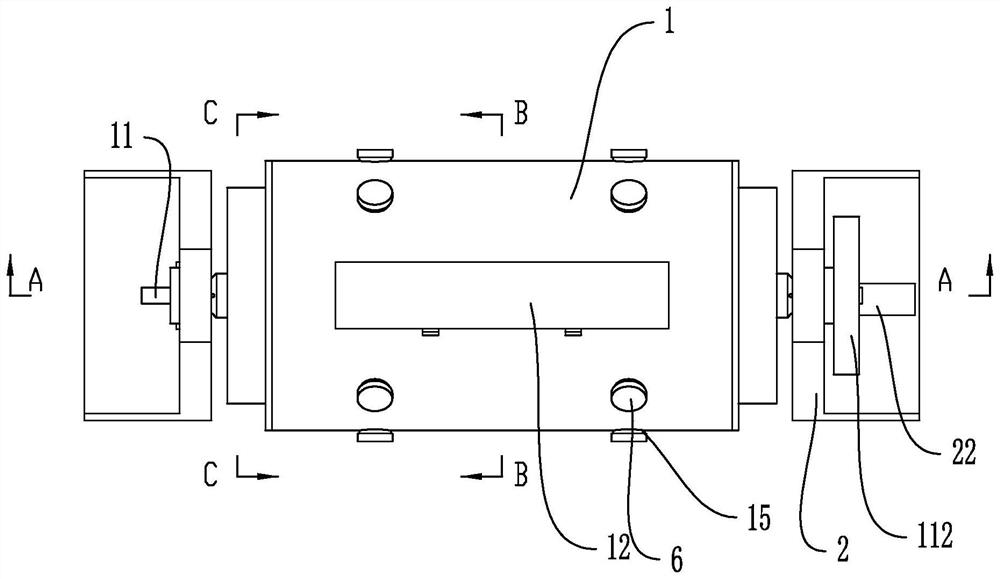

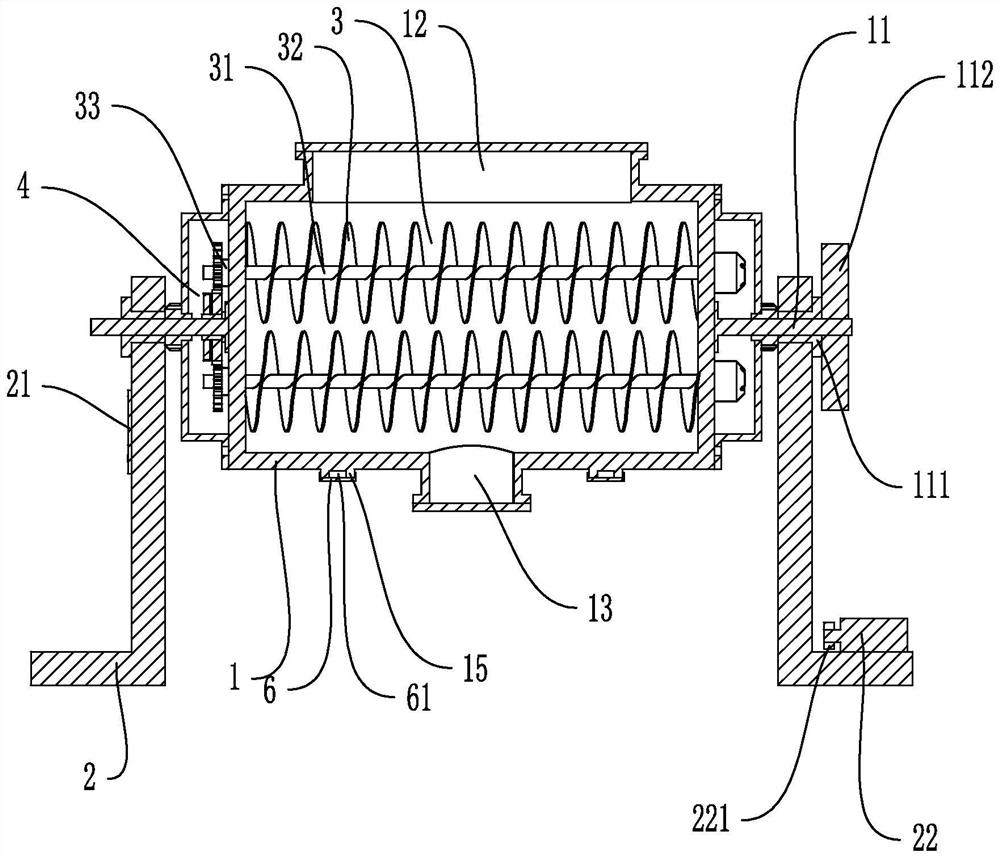

[0033] Embodiment 1, this embodiment discloses a stirring device for ready-mixed mortar, such as Figures 1 to 7 As shown, it includes a stirring bin 1 and a fixed frame 2 positioned at both sides of the stirring bin 1, the fixed frame 2 is provided with a controller 21 and a rotating motor 22, the stirring bin 1 is arranged in a cylindrical structure, and the stirring bin 1 Both ends are provided with a fixed shaft 11 which is fixedly connected to it by means of bolts, and the fixed shaft 11 is movably connected with the fixed frame 2 through the first bearing structure 111, and the fixed shaft 11 and the rotating motor 22 are provided with a slave pulley 112, a transmission belt and a main belt. The wheels 221 are movably connected to each other. The upper and lower sides of the mixing chamber 1 are respectively provided with a feed port 12 and a discharge port 13. The inside of the stirring chamber 1 is interspersed with at least three sets of mixing assemblies 3 parallel to...

Embodiment 2

[0039] Embodiment two, this embodiment is on the basis of embodiment one, such as Figure 8 As shown, the inner wall of the stirring chamber 1 is also provided with a number of heating through holes, the heating through holes are evenly distributed along the inner wall of the stirring chamber 1, and a ceramic heater 7 matching it is interspersed in the heating through holes, and the heating through holes The left and right sides of the mixing chamber 1 are connected, and the end of the heating through hole cooperates with the fixed cover plate 14. The inner wall of the stirring chamber 1 is provided with a temperature sensor 16 that is compatible with the ceramic heater 7; 7 and the temperature sensor 16 cooperate with each other to prevent the temperature in the mixing chamber 1 from being too low, causing the ready-mixed mortar to freeze and affecting subsequent use. The heating through holes are evenly distributed along the inner wall of the mixing chamber 1, so that the ins...

Embodiment 3

[0041] Embodiment three, this embodiment is on the basis of embodiment two, such as Figure 9 As shown, the feed port 12 is respectively provided with an air vent 121 and a water outlet 122 communicating with the inside of the mixing chamber 1, and a solenoid valve 123 is arranged on the through hole and the water outlet 122, and the stirring chamber 1 The inner wall of the tank is provided with a pressure sensor 17 and a humidity sensor 18 that are compatible with the vent 121 and the water port 122; the vent 121, the solenoid valve 123 and the pressure sensor 17 cooperate with each other to adjust the internal pressure of the mixing chamber 1. , when the internal pressure of the mixing chamber 1 is small, the air pressure can be increased by ventilating into the vent 121, otherwise the vent 121 is opened to remove excess pressure to improve the effect of ready-mixed mortar; the water port 122, the solenoid valve 123 and the humidity sensor 18 cooperate , Play the effect of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com