Dropwise adding reaction kettle for shoe glue

A technology of dripping reaction kettle and shoe glue, which is applied in the field of shoe glue, can solve the problems of not having the function of heat preservation reaction solution, uneven reaction, low fusion efficiency, etc., and achieve the effect of improving the stirring effect, stirring evenly, and preventing deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

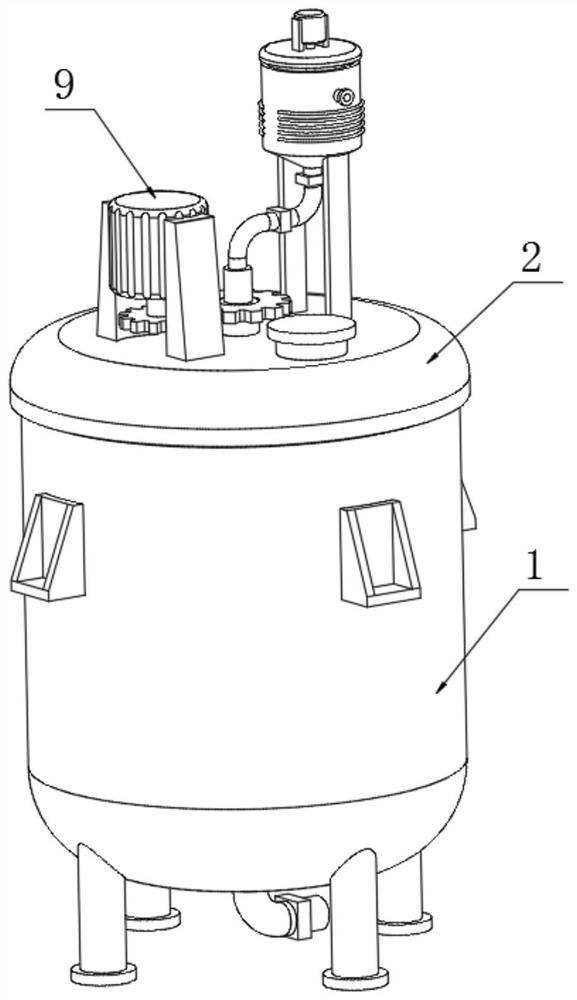

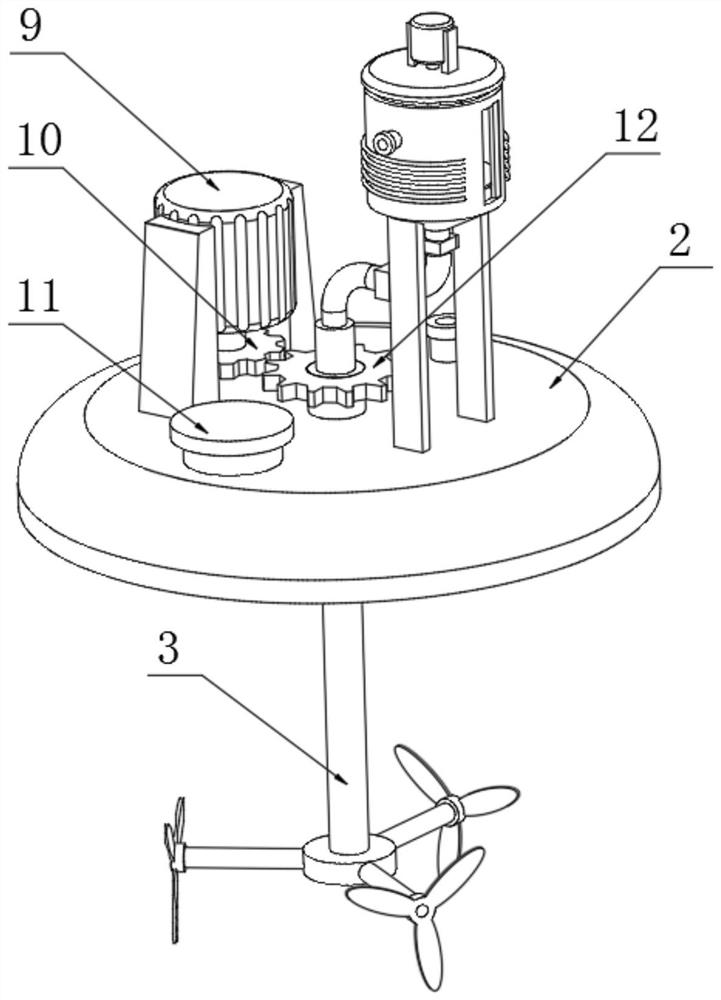

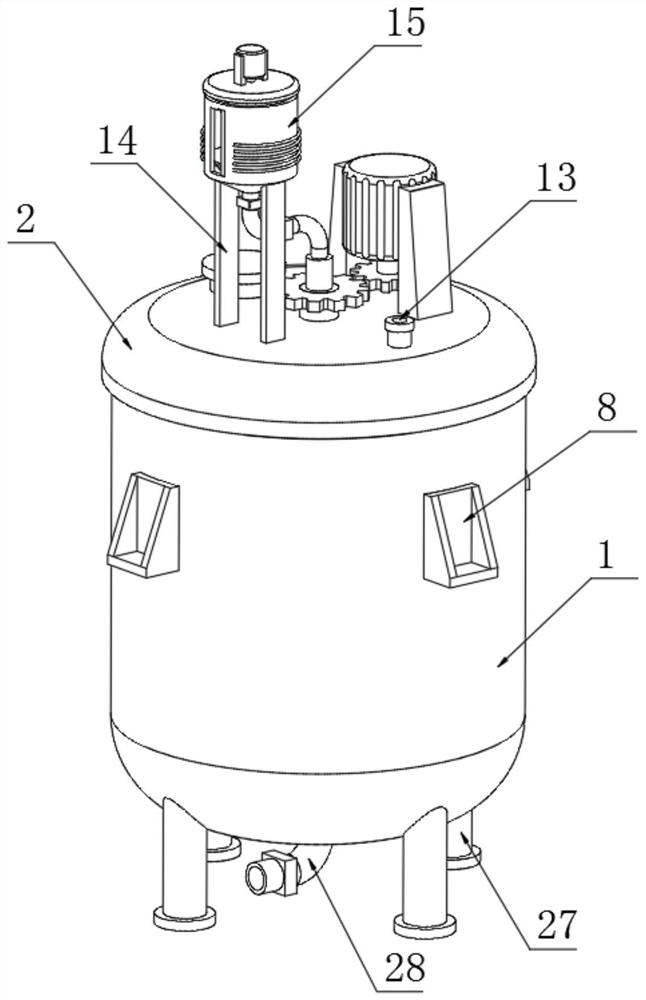

[0028] see Figure 1-6 , the present invention provides the following technical solutions: a dripping reactor for shoe glue, comprising a kettle body 1, the upper surface of the kettle body 1 is provided with a kettle cover 2, and the middle part of the upper surface of the kettle cover 2 is movably connected by a coupling There is a hollow shaft 3, one end of the hollow shaft 3 runs through the upper surface of the kettle cover 2 and extends to the inside of the kettle body 1, the bottom end of the hollow shaft 3 is fixedly connected with a fixed disk 4, and the outer surface of the fixed disk 4 is inserted with a transmission rod 5. The end of the transmission rod 5 away from the fixed disk 4 is rotatably connected to the stirring blade 6, and the outer surface of the transmission rod 5 is provided with a diversion port 7, which is connected with the interior of the hollow shaft 3, and the outer surface of the kettle body 1 The fixed connection has a support 8 .

[0029] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com