Bean mixing and stirring equipment

A technology of mixing and stirring equipment, which is applied in the field of bean mixing and stirring equipment, can solve the problems of affecting product quality, affecting product sales, and low mixing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

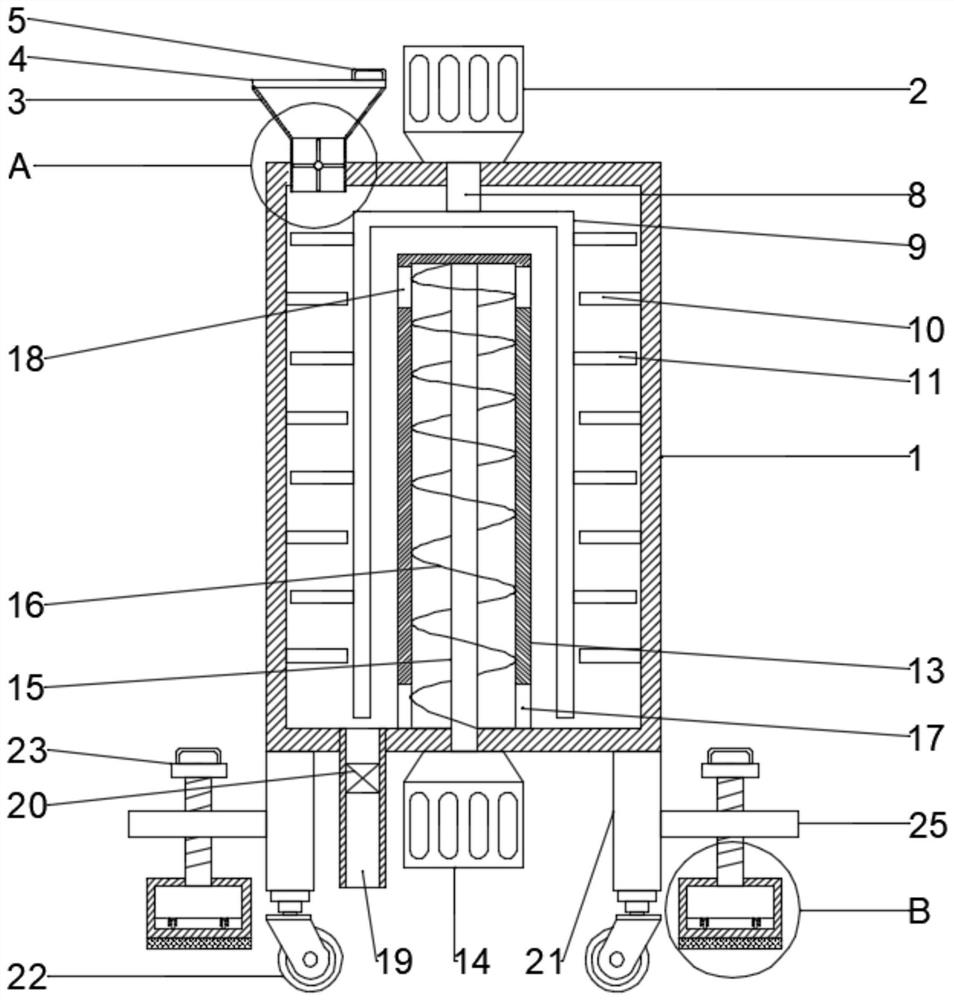

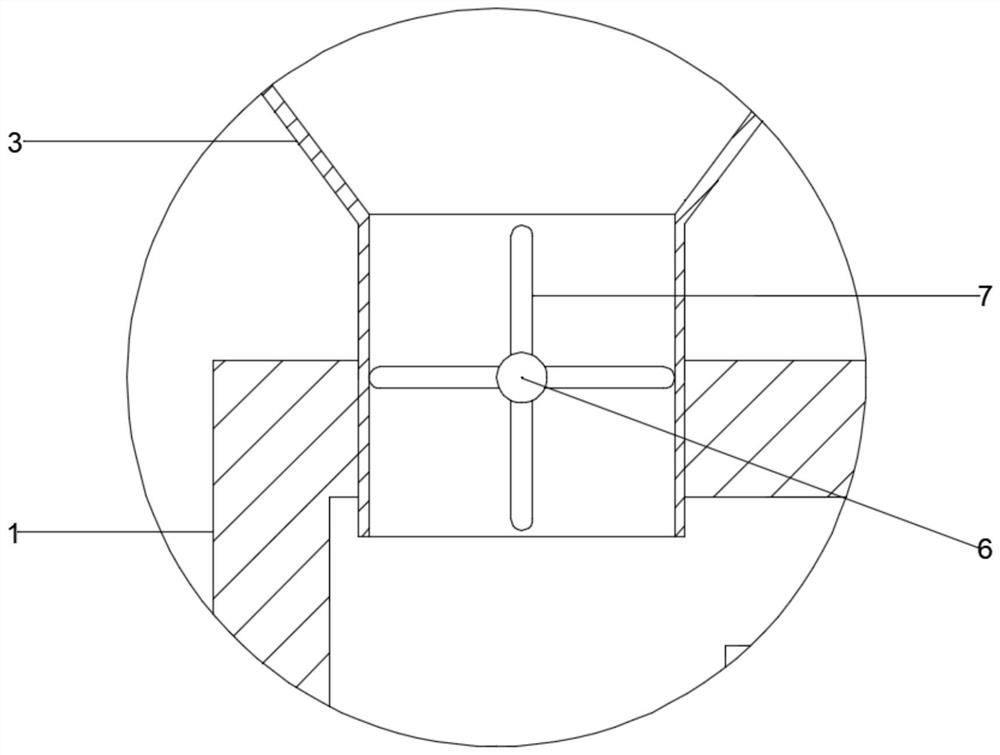

Embodiment 1

[0022] see Figure 1~3 , in the embodiment of the present invention, a bean mixing and stirring equipment includes a box body 1, a feeding port 3 is opened on the top side of the box body 1, and a sealing cover 4 is hinged on the side of the feeding material 3 through a hinge. , the upper surface of the sealing cover 4 away from the hinged side of the hinge is fixedly connected with the first handshake 5, and the inside of the feed port 3 is provided with a dial shaft 6, and one end of the dial shaft 6 is connected to the feed port 3. Side rotation connection, the other end of the dial shaft 6 is fixedly connected with a power device that drives its rotation. In this embodiment, the power device is preferably a motor, and four shafts are fixedly connected at equal intervals on the circumferential surface of the dial shaft 6. The shifting plate 7, in the present embodiment, the length of the shifting shaft 6 is equal to the length of the feed port 3, the length of the shifting ...

Embodiment 2

[0027] see Figure 4 , On the basis of Embodiment 1, a plurality of third stirring rods 12 are fixedly connected to the lower surfaces of the first stirring rod 10 and the second stirring rod 11 .

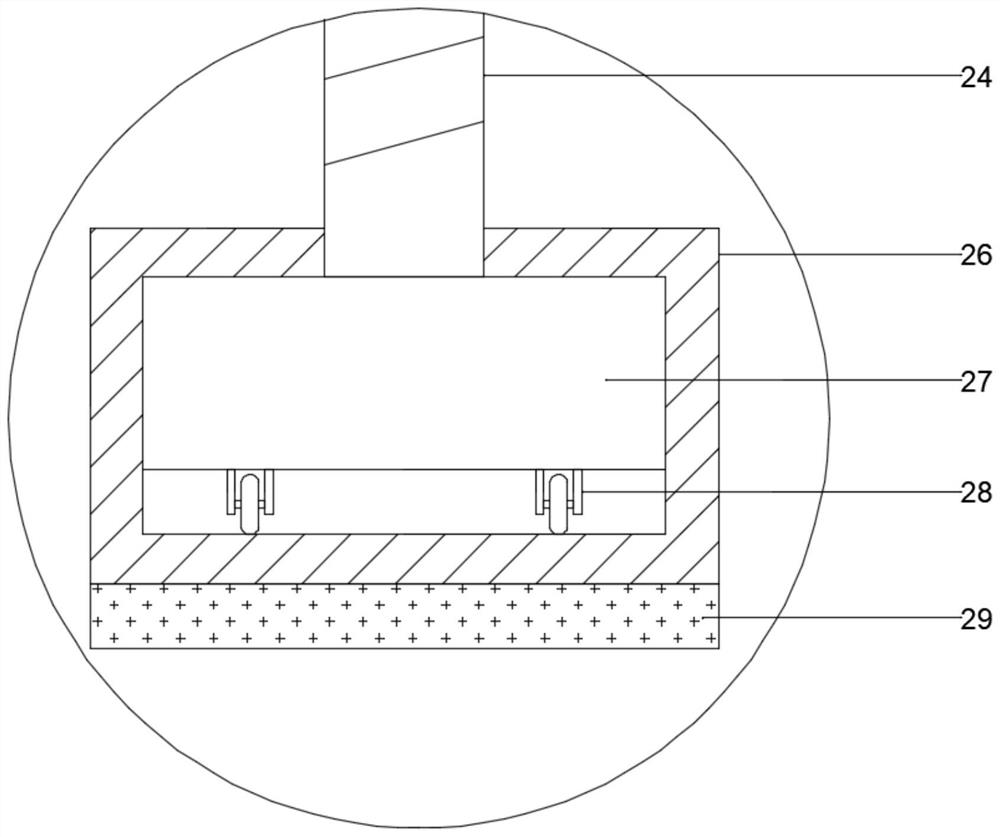

[0028] The working principle of the present invention is: after utilizing the universal wheel 22 to move the device to the designated position, hold the second handle 23 to turn the threaded rod 24, the threaded rod 24 drives the fixed seat 26 and the rotating table 27 to move downward, and the anti-skid pad 29 After touching the ground, continue to rotate the threaded rod 24 so that the rotating table 27 continues to press the fixing seat 26 downwards, so that the anti-slip pad 29 is tightly attached to the ground, thereby fixing the device and preventing the device from occurring during use. Slide, open the sealing cover 4 and pour the beans into the feed port 3, start the motor to drive the dial shaft 6 to rotate, and the dial shaft 6 drives the dial 7 to rotate, so as to feed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com