Convenient-to-discharge concrete mixer

A technology for concrete mixers and mixing drums, which is applied to cement mixing devices, clay preparation devices, and mixing operation control, etc. It can solve the problems of high technical requirements for operators, slow work progress, and insufficient mixing, so as to reduce labor intensity and improve Molding speed, increase the effect of stirring speed and stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

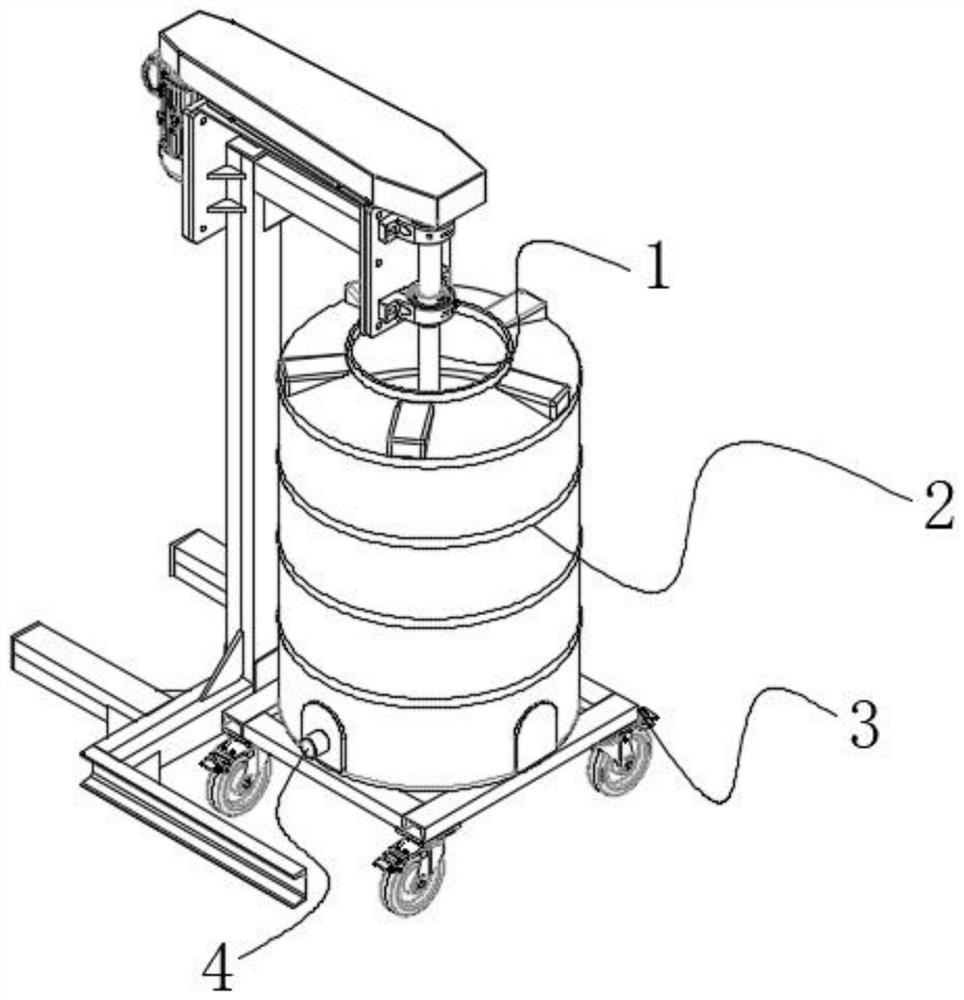

[0023] use Figure 1-Figure 5 A concrete mixer that is convenient for unloading according to an embodiment of the present invention will be described as follows.

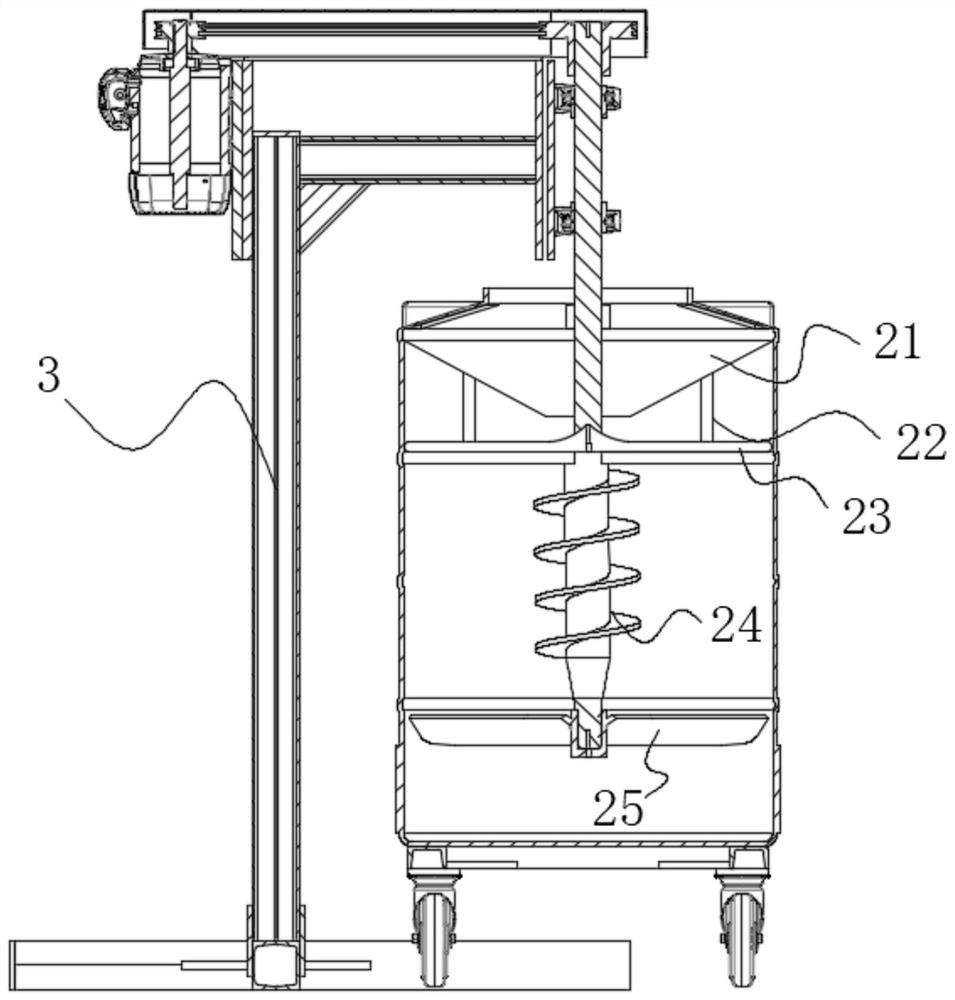

[0024] Such as Figure 1-Figure 5 As shown, a concrete mixer convenient for blanking according to the present invention includes a support 3; There is a mixing drum 2, and the bottom of the support 3 is fixedly connected with the bottom of the mixing drum 2, the bottom of the mixing drum 2 is provided with a water injection port 4, and the purpose of the bracket 3 is to improve the stability of the concrete mixer that is convenient for blanking.

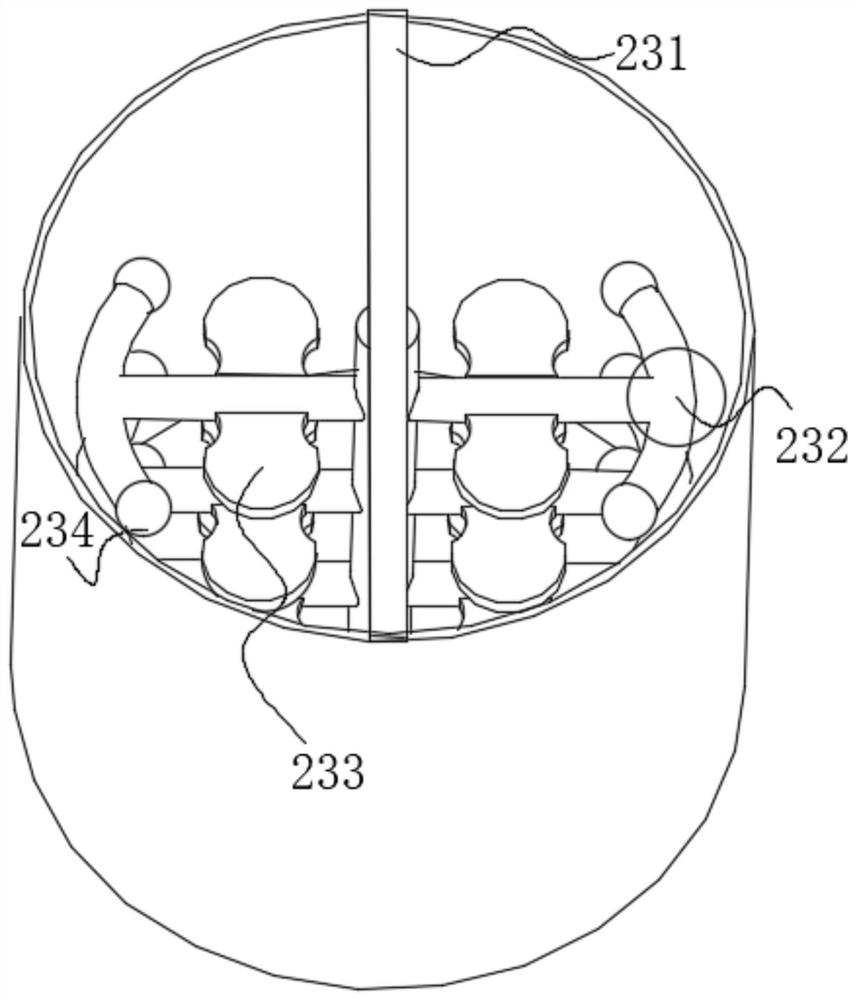

[0025] The inside of the mixing drum 2 is provided with a feeding drum 21, and the inner wall of the mixing drum 2 is fixedly connected with the outer surface of the feeding drum 21, and the bottom of the feeding drum 21 is symmetrically provided with a support column 22, and the bottom of the feeding drum 21 is connected to the outer surface of the feeding drum 21. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com