An infrared stealth material and production equipment for preparing the material

A stealth material, infrared technology, applied in the field of infrared stealth materials, can solve the problems affecting the mixing uniformity of mixing drum materials, affecting the preparation effect of infrared stealth materials, increasing the labor burden of staff, etc., to avoid multiple reflections and prevent absorption Excessive, mass-increasing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

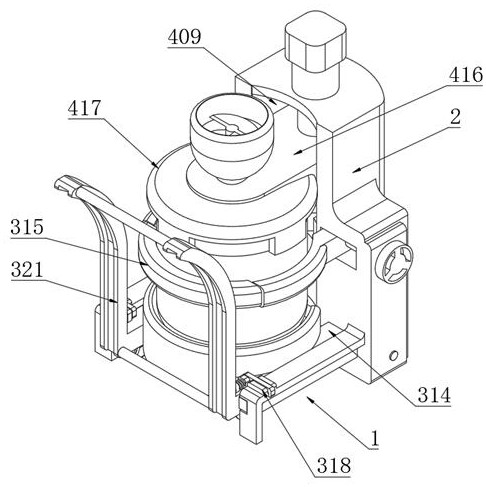

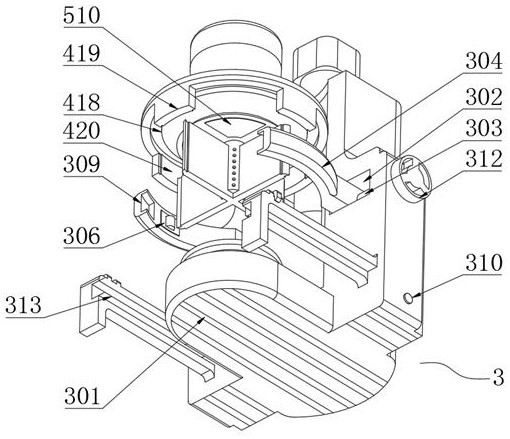

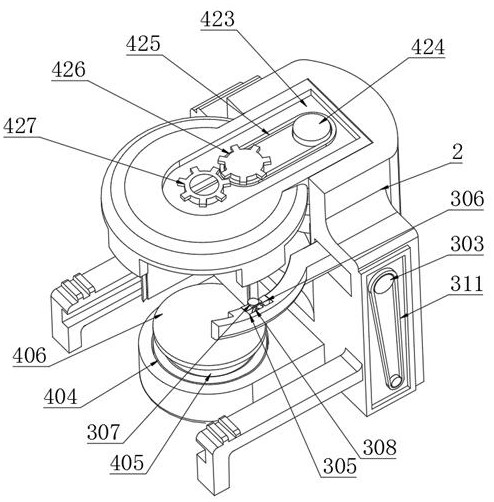

[0053] Example: such as Figure 1-9 As shown, the present invention provides a technical solution, a production equipment required for infrared stealth materials, including a chassis 1, a pillar 2 is fixedly connected to the top position of one end of the chassis 1, and a fixing mechanism 3 is embedded in the pillar 2, The fixing mechanism 3 includes a support plate 301, a notch 302, a screw mandrel 303, an arc splint 304, a groove 305, a movable block 306, a guide wheel 307, a support spring 308, a draw groove 309, a rotating rod 310, a first belt 311, Turntable 312, chute 313, moving plate 314, universal wheel 315, fixed block 316, positioning pin 317, limit block 318, stop block 319, tension spring 320, push handle 321, upper fixed plate 322, clamping block 323 And the lower fixed plate 324, one end of the pillar 2 is fixedly connected with a support plate 301, one end of the pillar 2 is provided with a notch 302 at the position corresponding to the top of the support plate...

Embodiment 2

[0062] Example 2, such as Figure 10 Shown: a kind of preparation method of infrared stealth material, comprises as follows:

[0063] S1. Put the hydroxyl acrylic resin and melamine formaldehyde resin into the mixing drum according to the proportion and mix them:

[0064] S2. After mixing the diluent, leveling agent and defoamer evenly according to the proportion, add them into the mixing drum and mix with hydroxyacrylic resin and melamine formaldehyde resin;

[0065] S3, then mix the copper powder and HDI biuret according to the proportion evenly, then add to the mixing drum and stir;

[0066] S4. During each mixing and stirring process, the materials inside the mixing drum are heated to improve the mixing effect between materials;

[0067] S5, preheating the premixed material at the same time, so that the material is more easily heated;

[0068] S6. Take out the materials that have been fully mixed and stirred, and clean the mixing drum.

Embodiment 3

[0069] Embodiment 3, an infrared stealth material, the infrared stealth material is composed of the following components by weight;

[0070] 87-93 parts of hydroxyl acrylic resin, 7.8-8.5 parts of melamine formaldehyde resin, 248-252 parts of thinner, 72-76.5 parts of copper powder, 2-3.2 parts of leveling agent, 2-3 parts of defoamer and HDI biuret 32-34 servings.

[0071] The hydroxyacrylic resin is specifically a mixture of one or more of methyl acrylate, ethyl acrylate, n-butyl acrylate, methyl methacrylate and n-butyl methacrylate;

[0072] The melamine formaldehyde resin is specifically formed by mixing melamine, formaldehyde solution, urotropine and triethanolamine;

[0073] The diluent is specifically an ethyl acetate mixture;

[0074] The defoaming agent is polysiloxane mixture;

[0075] The leveling agent is specifically an acrylate mixture.

[0076] The working principle and application process of the present invention: in the process of using a production equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com