Concrete precast block production device

A technology for production equipment and prefabricated blocks, applied in clay preparation devices, chemical instruments and methods, cement mixing devices, etc., can solve problems such as the influence of concrete molding, the easy adhesion of concrete to mixing blades, etc., and achieve the effect of avoiding solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

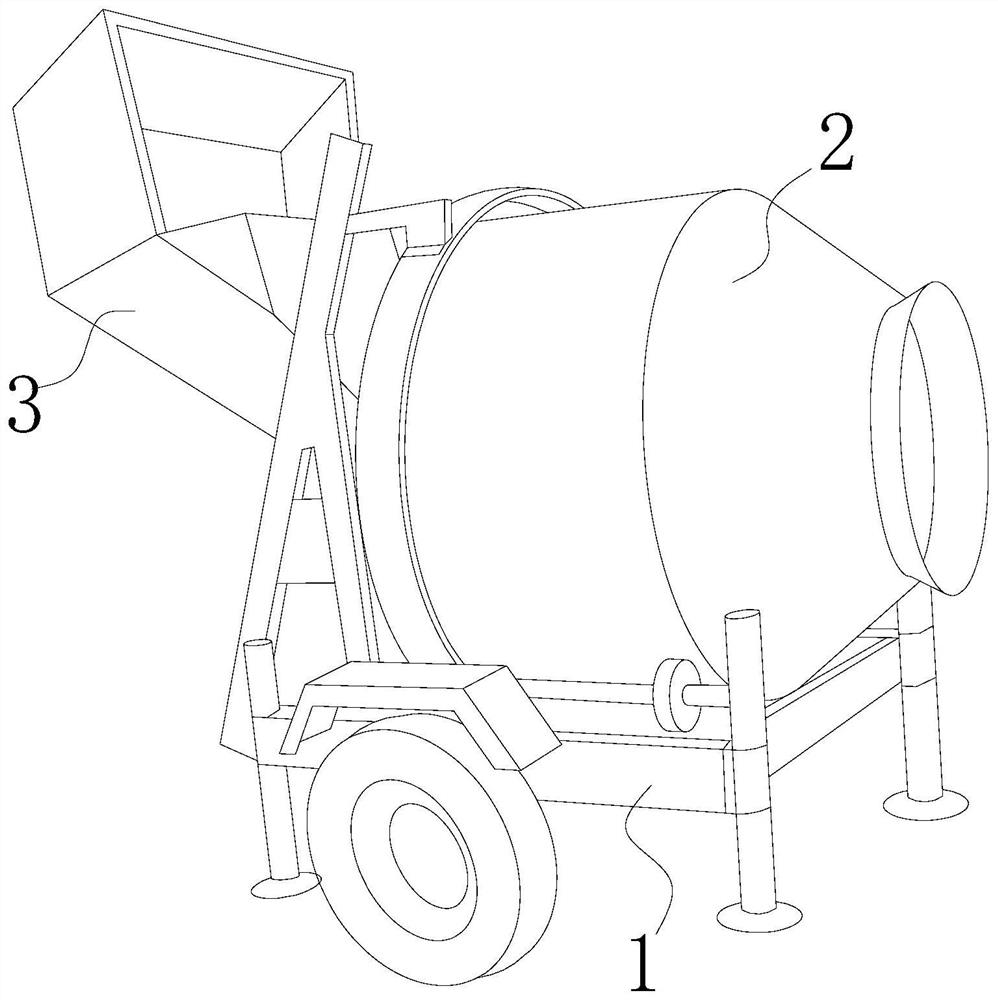

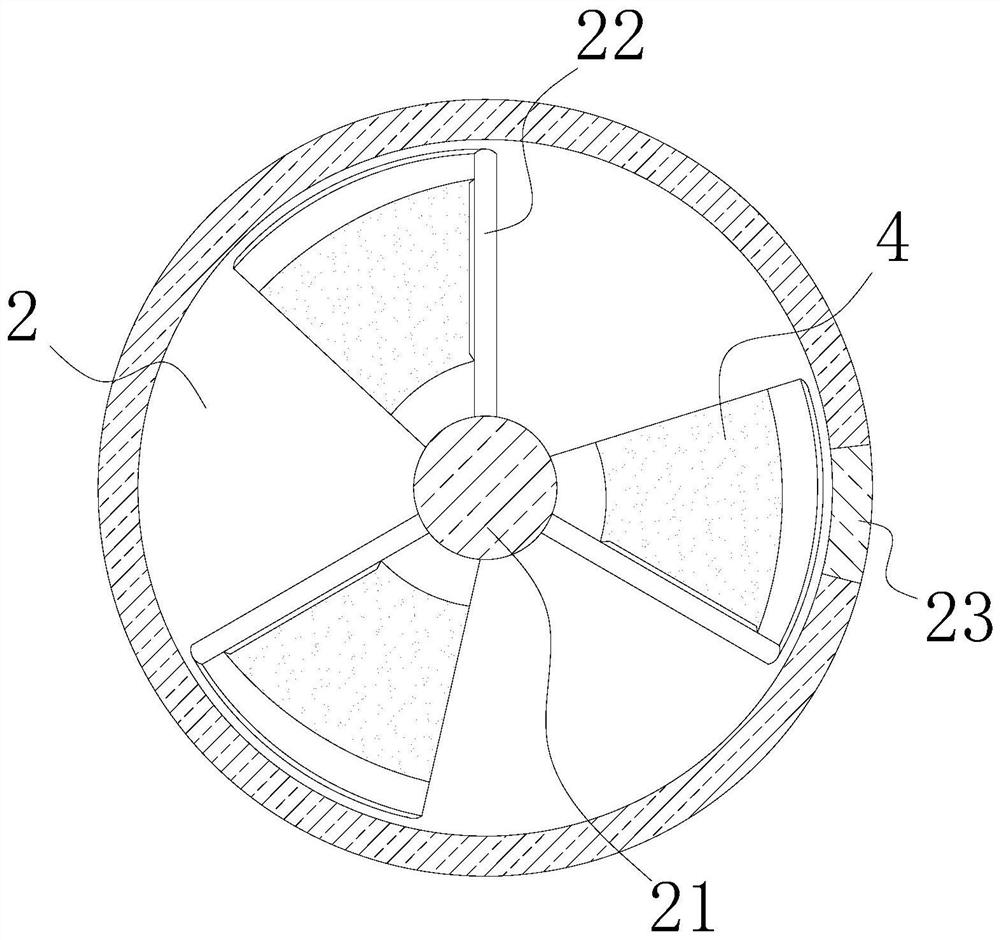

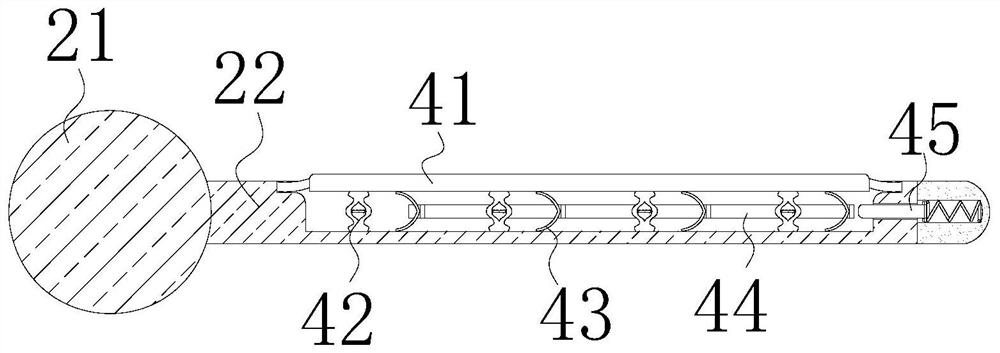

[0026] like Figure 1-Figure 3 As shown, the present invention provides a kind of concrete prefabricated block production equipment, and its structure comprises: frame 1, mixing bucket 2, hopper 3, swinging device 4, described mixing bucket 2 is installed on the frame 1, and described hopper 3 Be located at the rear of mixing bucket 2, be provided with stirring shaft 21, stirring blade 22, magnet bar 23 in described mixing bucket 2, described stirring shaft 21 is arranged in mixing bucket 2 along the axial direction of mixing bucket 2, described mixing blade 22 is a curved plate and is arranged on the stirring shaft 21. The magnet bar 23 is arranged on the right side of the stirring bucket 2 and the inclination range matches the bending arc of the stirring blade 22. The swinging device 4 is arranged on the stirring blade 22. On the top surface of the top surface, the swinging device 4 is composed of a pressure plate 41, an upper bullet column 42, a lower clamp 43, a push frame...

Embodiment 2

[0033] like Figure 1-Figure 3 As shown, the present invention provides a kind of concrete prefabricated block production equipment, and its structure comprises: frame 1, mixing bucket 2, hopper 3, swinging device 4, described mixing bucket 2 is installed on the frame 1, and described hopper 3 Be located at the rear of mixing bucket 2, be provided with stirring shaft 21, stirring blade 22, magnet bar 23 in described mixing bucket 2, described stirring shaft 21 is arranged in mixing bucket 2 along the axial direction of mixing bucket 2, described mixing blade 22 is a curved plate and is arranged on the stirring shaft 21. The magnet bar 23 is arranged on the right side of the stirring bucket 2 and the inclination range matches the bending arc of the stirring blade 22. The swinging device 4 is arranged on the stirring blade 22. On the top surface of the top surface, the swinging device 4 is composed of a pressure plate 41, an upper bullet column 42, a lower clamp 43, a push frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com