Method for controlling dewatering operation of washing machine

A washing machine, eccentric technology, applied in the control device of washing machine, other washing machines, applications, etc., can solve problems such as wear and support damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

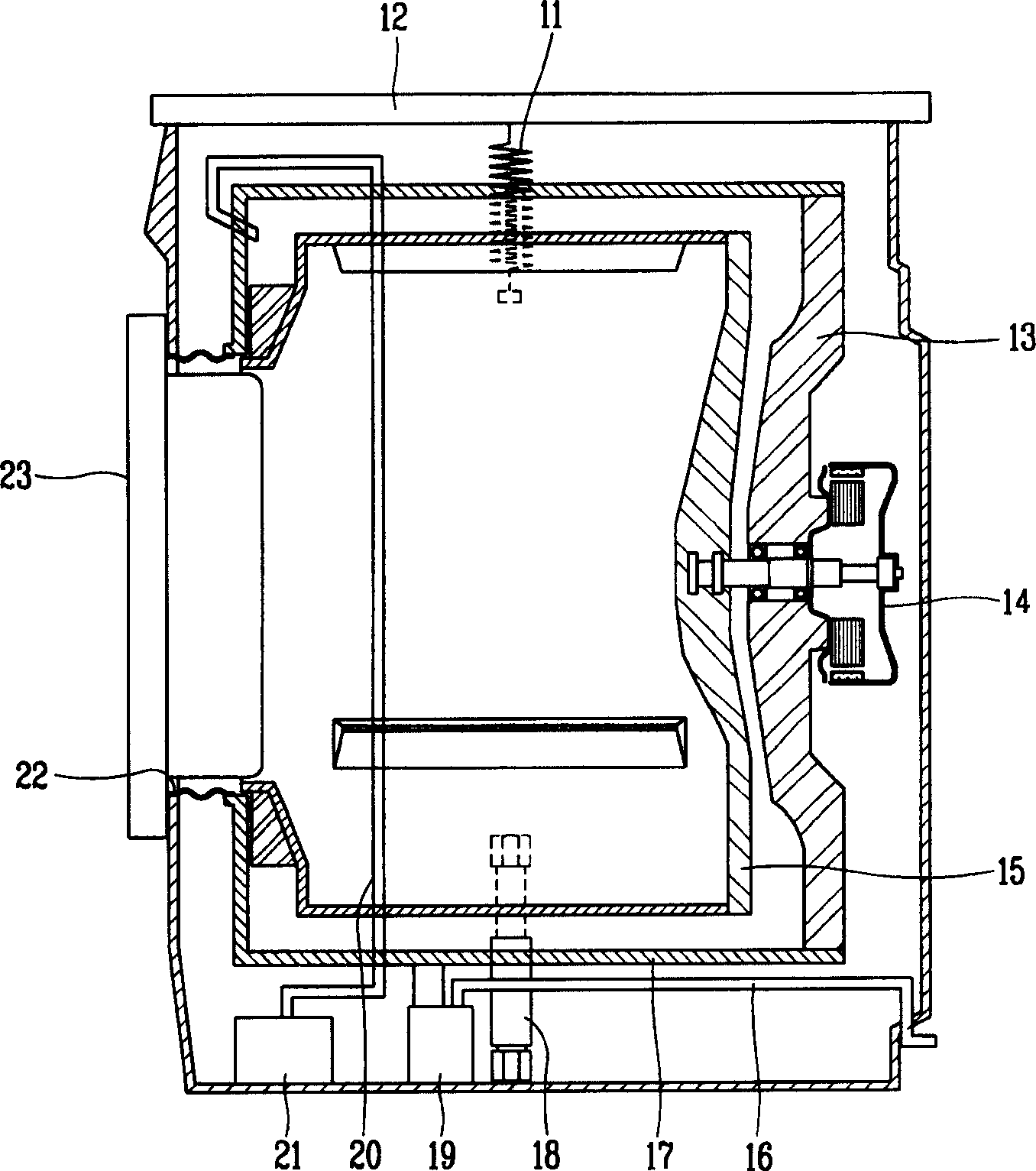

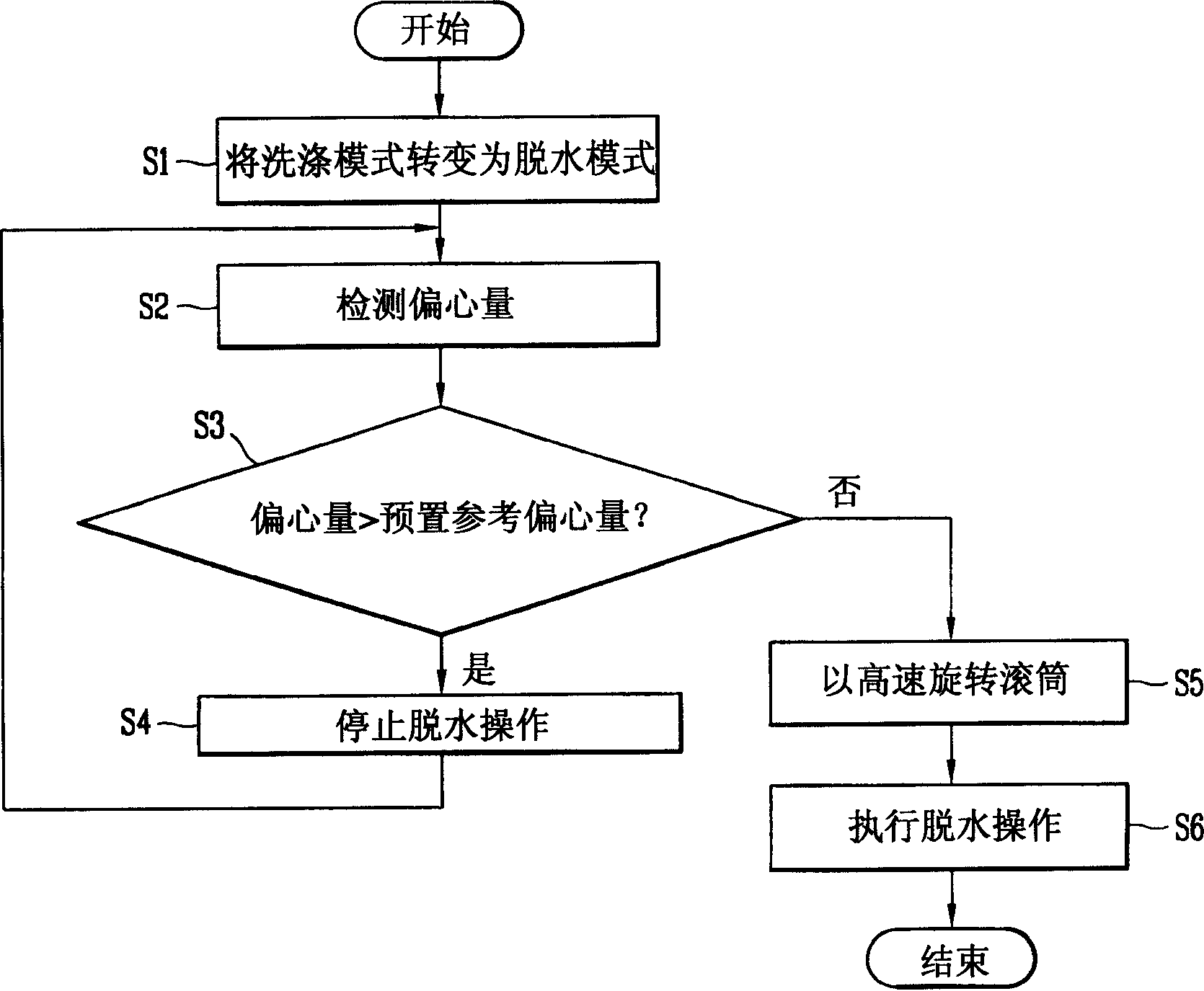

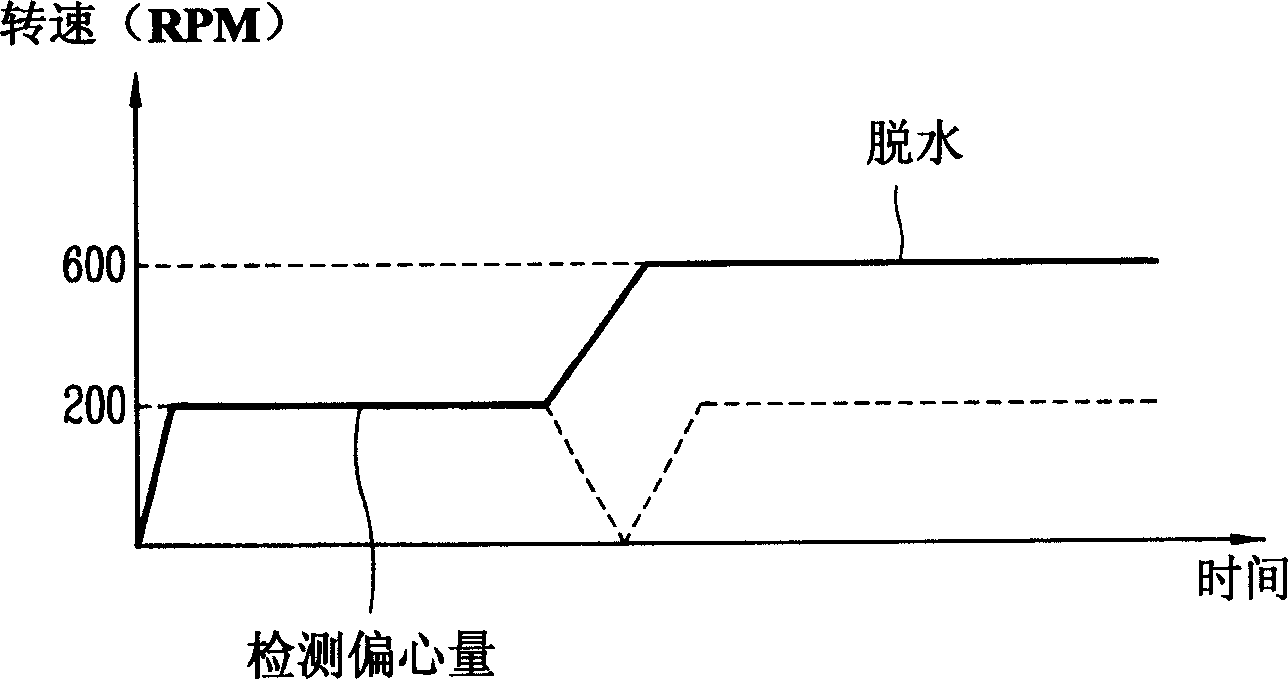

[0033] In the following, reference will be made below to Figure 4 to 6 describe a preferred embodiment for controlling the dehydration operation method of a washing machine configured to reduce excessive vibration and noise generated during the dehydration process by detecting an initial reference eccentric position and Initial eccentricity; detect the current eccentric position and the current eccentricity of the drum when the drum rotates at a high speed and rotates again at a low speed, and based on the detected initial reference eccentric position, initial eccentricity, current eccentric position, and current eccentricity Controlling the dehydration operation achieves the above objectives.

[0034] Figure 4 It shows an operation flowchart for controlling the dehydration operation method of the washing machine according to one embodiment of the present invention.

[0035] As shown in the figure, the method for controlling the dehydration operation of the washing machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com