Rotor structure of switched reluctance motor for reducing vibration and noise

A technology of switched reluctance motor and rotor structure, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc. Torque fluctuation and other problems, to achieve the effect of smooth torque, reduce severe vibration, and reduce large fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is specifically described as follows in conjunction with accompanying drawing:

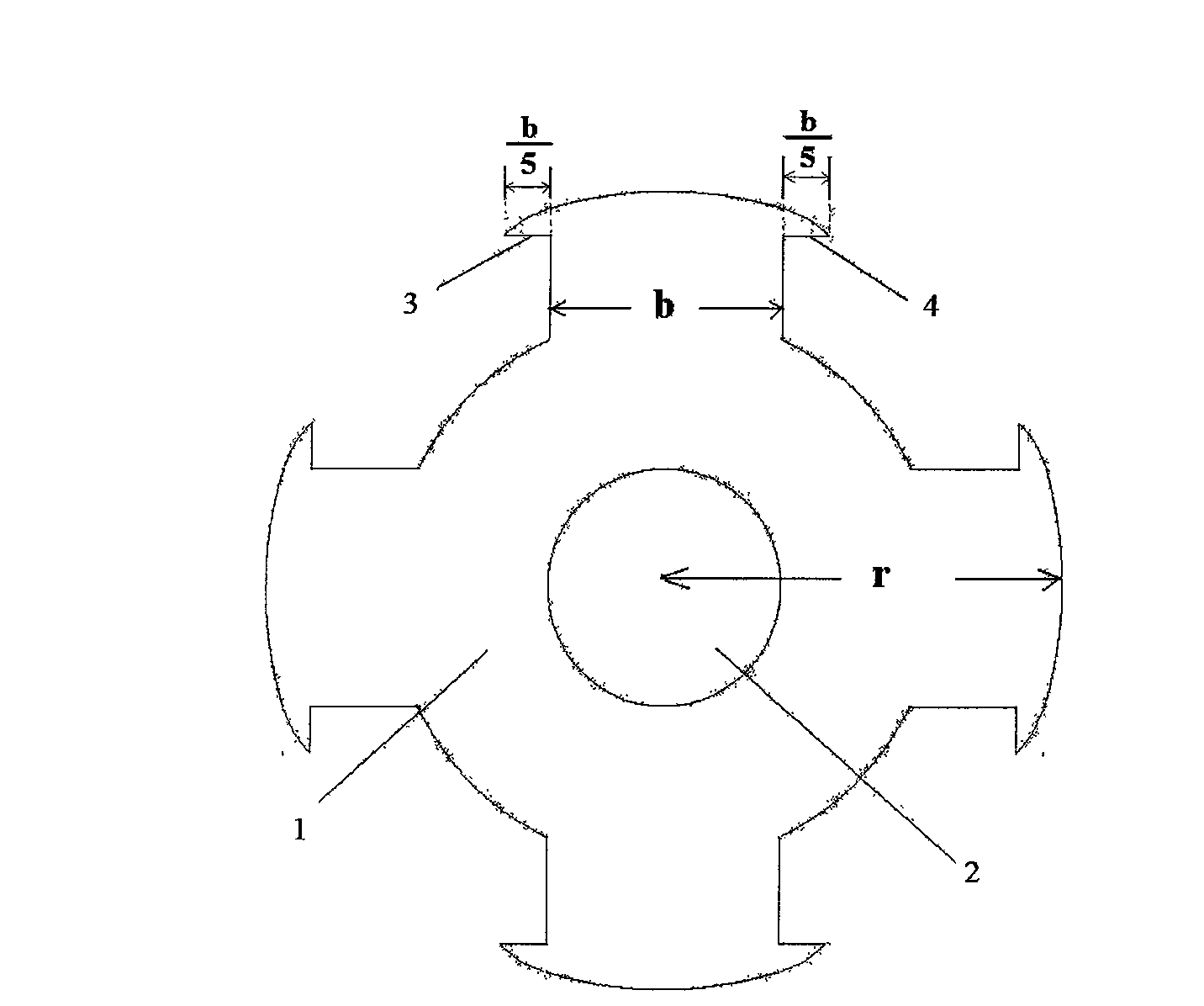

[0019] The rotor of the switched reluctance motor provided by the present invention is made of laminated silicon steel sheets, and the pole-shaped end of the rotor is a salient pole structure with arc-shaped pole tips. The rotor salient pole structure is as follows: each rotor salient pole ends with an arc-shaped pole tip extending left and right along the outer diameter of the rotor.

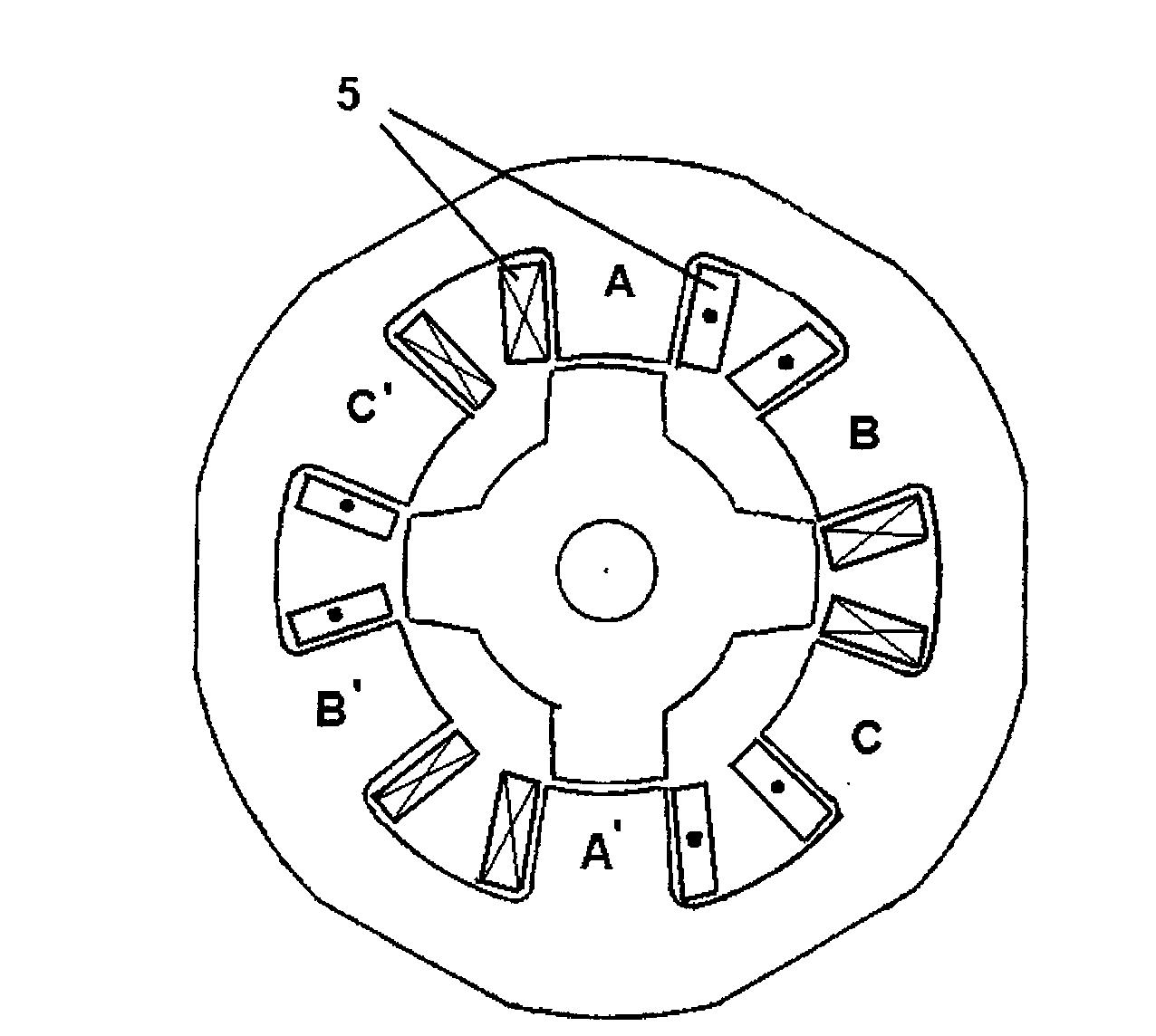

[0020] The left and right arc-shaped pole tips extending along the outer diameter of the rotor are symmetrical; the horizontal length of the arc-shaped pole tips is 1 / 5 of the rotor pole width; the rotor salient pole structure is mainly suitable for three-phase 6 / 4-pole, three-phase 6 / 8-pole switched reluctance motor, four-phase 8 / 6-pole switched reluctance motor.

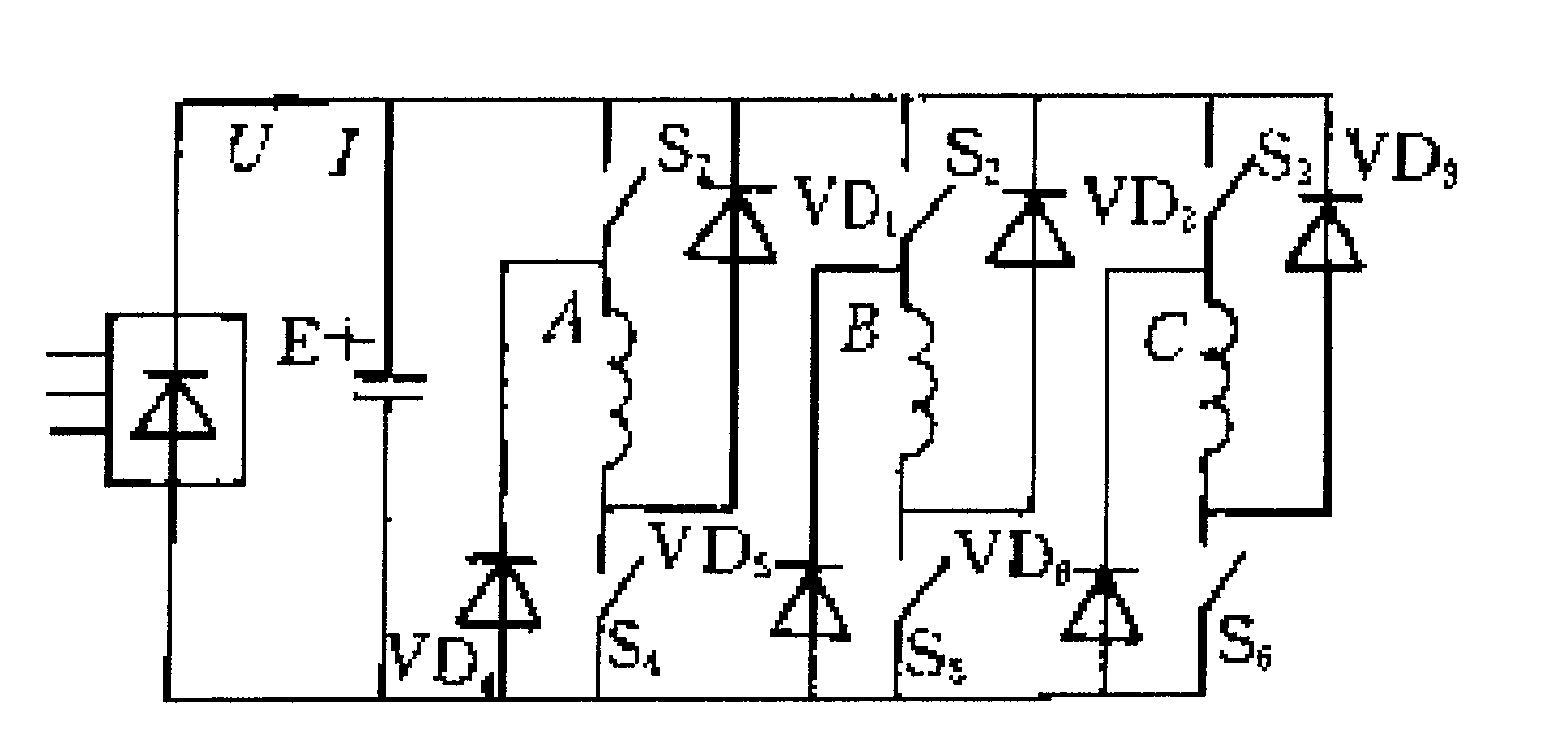

[0021] Taking a three-phase 6 / 4-pole switched reluctance motor as an example for illustration, the three-phase 6 / 4-pole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com