Automatic adjusting locking pliers

A technology of automatic adjustment and pliers, applied in the field of pliers, can solve the problems of difficult control of clamping force, low working efficiency, and inability to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

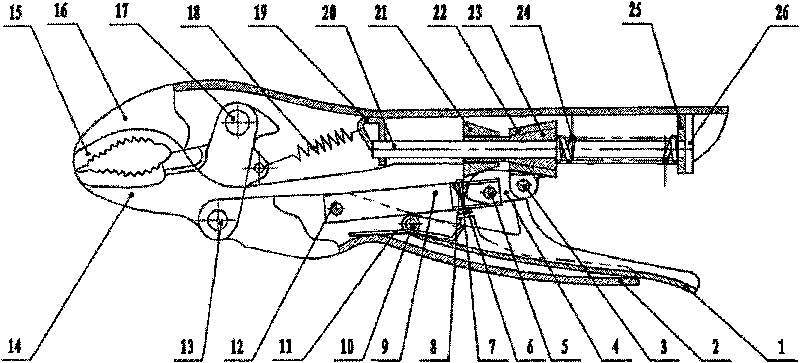

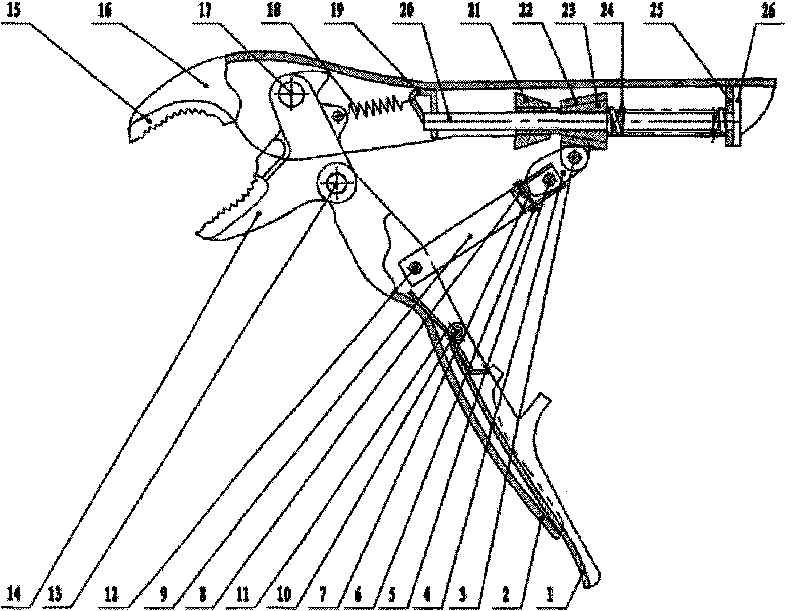

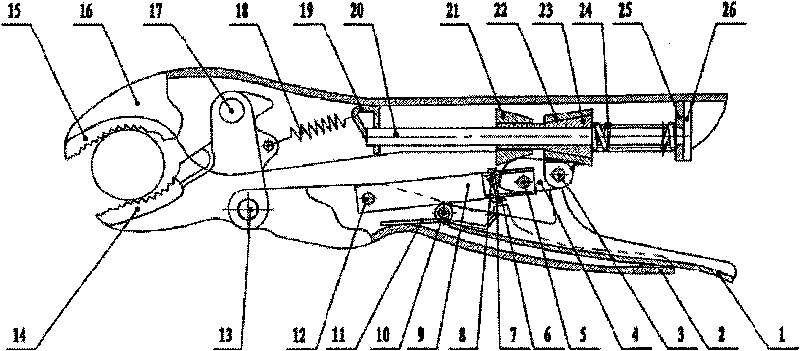

[0013] As shown in Figure 1, the pliers of the present invention consists of an unlocking handle (1), an auxiliary pliers body (2), a connecting sleeve (3), an engaging pressing block (4), an adjusting screw (6), and a snap ring (7) , engaging block (8), connecting rod (9), spring (110, jaw two (14), jaw one (15), main jaw body (16), spring (18), guide rod (20), cone Type screw rises (21), connecting sleeve (22), circular claw (23), resistance spring (24) etc. are formed.

[0014] Jaw one (15) is consolidated with the main jaw body (16), while jaw two (14) and the auxiliary jaw body (2) are hinged with rivets (13). It is characterized in that the main and auxiliary pliers are hinged together with rivets (17). Guide rod (20) is located in the main pliers body (16), and guide locking device (21,22,23) is enclosed within on the guide rod (20), and it can slide or lock on the guide rod (20). The engaging briquetting block (4) is hinged with the guide locking device with a rivet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com