Preparation method of sliding plate bricks without iron shells and asbestos boards

A technology of sliding bricks and asbestos boards, which is applied in the direction of manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problems of waste of auxiliary materials, weakening of competitiveness, increase of production and processing costs, etc., to protect performance and slow down heat transfer , the effect of many production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

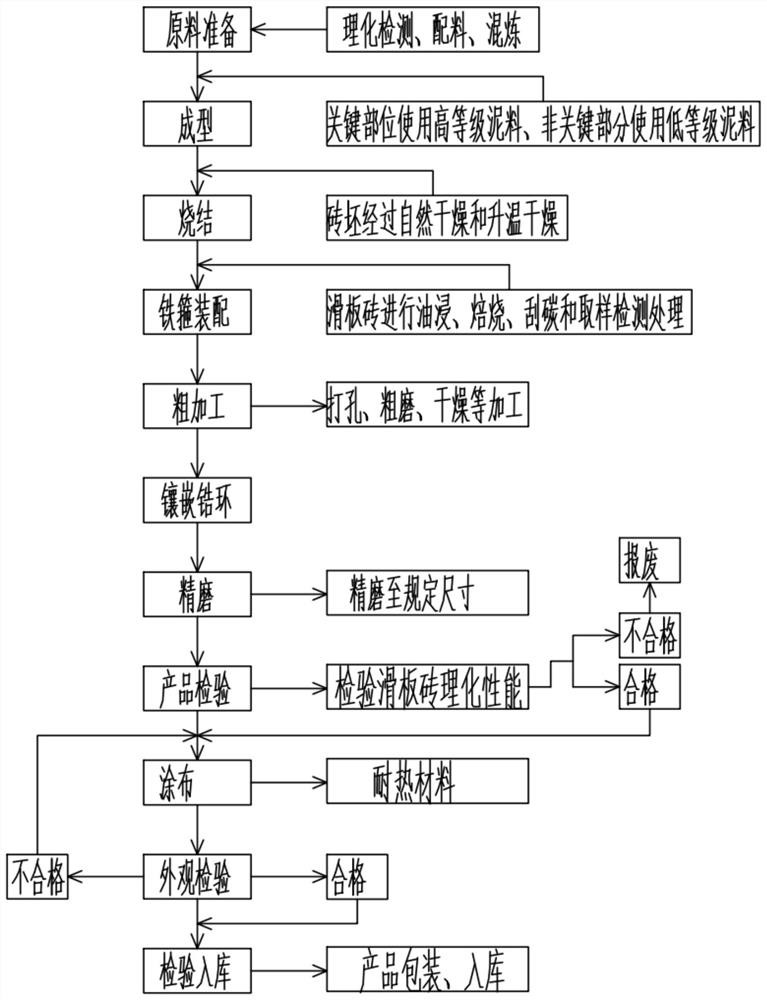

[0027] Such as figure 1 Shown, the preparation method of the slide brick without iron shell and asbestos board may further comprise the steps:

[0028] (1) Raw material preparation, combining and mixing the required raw materials;

[0029] (2), forming, the ingredients and the mixed raw materials in the step (1) are compressed into the slide brick adobe;

[0030] (3), sintering, enter the kiln and sinter the skateboard brick adobe into skateboard bricks;

[0031] (4) Assembling iron hoops, hot-matching iron hoops and skateboard bricks;

[0032] (5) Rough processing, punching, rough grinding and drying the skateboard bricks;

[0033] (6) Inlay the zirconium ring, and inlay the zirconium ring into the vent hole;

[0034] (7), fine grinding, the skateboard bricks are finely ground to the specified size;

[0035] (8) Product inspection, check the physical and chemical properties of the skateboard bricks, pass the qualified ones into the next process, and discard the unqualifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com