Rolling bearing

A technology of rolling bearings and bearings, applied in the field of rolling bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific structure of the present invention will be further described below in conjunction with the accompanying drawings.

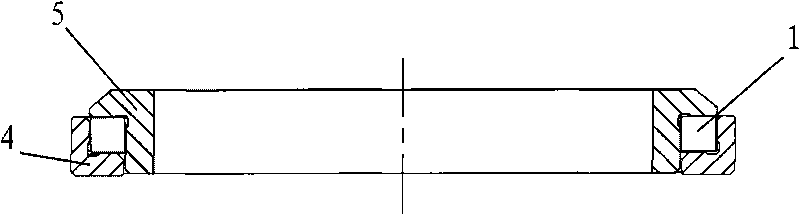

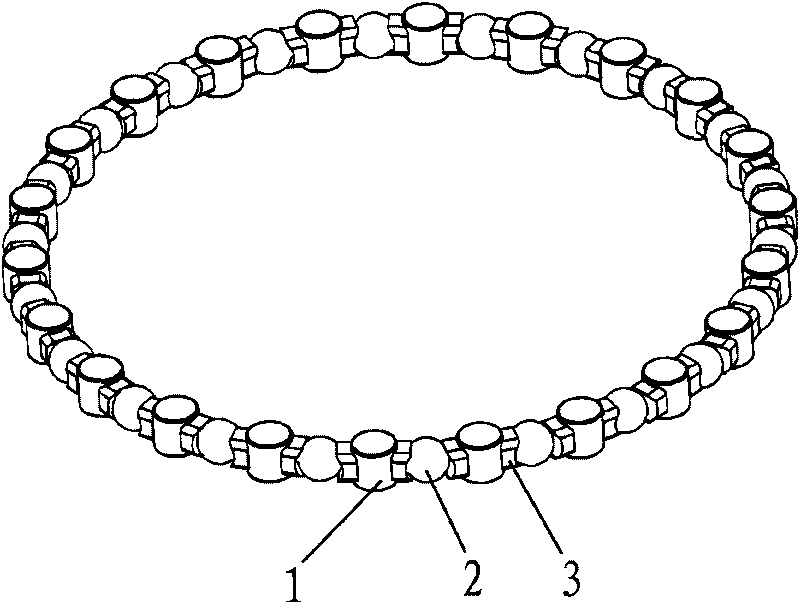

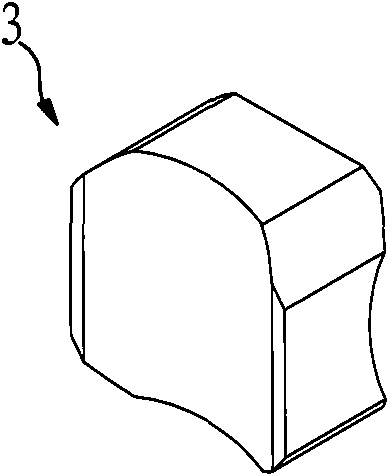

[0018] See attached figure 1 , attached figure 2 As shown, a rolling bearing includes a bearing inner ring 5, a bearing outer ring 4, and rolling elements sandwiched between the bearing and the outer rings 5 and 4, and is characterized in that the rolling elements include a plurality of cylindrical rollers 1 and a plurality of spherical rollers 2, the cylindrical rollers 1 and spherical rollers 2 are arranged at intervals along the same circumference, and a cage 3 is arranged between adjacent cylindrical rollers 1 and spherical rollers 2, The axis line of the cylindrical roller 1 is parallel to the axis line of the bearing, the diameter of the spherical roller 2 is smaller than the diameter of the cylindrical roller 1, and the diameter of the spherical roller 2 is larger than The height of the cylindrical roller 1.

[0019] The differenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com