Fly-by-wire device for trainer aircraft

A technology of fly-by-wire control and trainer aircraft, which is applied in the field of aircraft flight control system, can solve the problems of complex mechanical interface between the front cabin cockpit and pedals, unfavorable cockpit sealing, and increased difficulty in structural design, so as to meet the requirements of simplicity and improve training efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

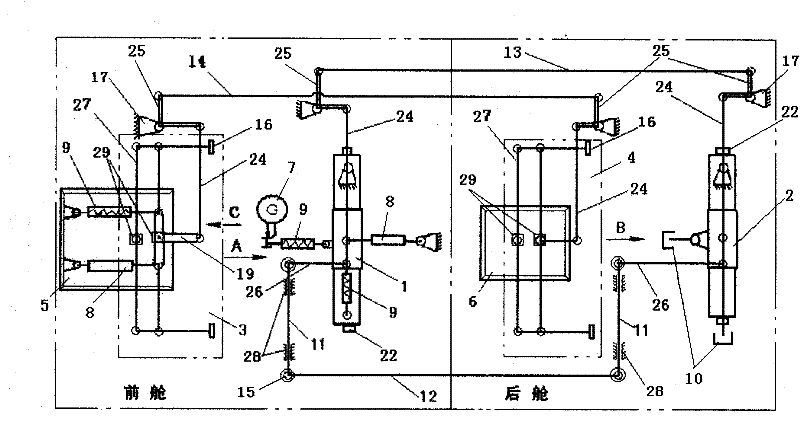

[0023] A fly-by-wire control device for a trainer, which consists of a front cabin control rod assembly 1, a rear cabin control rod assembly 2, a front cabin pedal mechanism 3, a rear cabin pedal mechanism 4, a longitudinal linkage rod 12, a transverse linkage rod 13, and a heading linkage A rod 14, a displacement sensor 8, a load mechanism 9, an eddy current damper 10 and a longitudinal adjustment mechanism 7 form a longitudinal control system, a lateral control system and a heading control system:

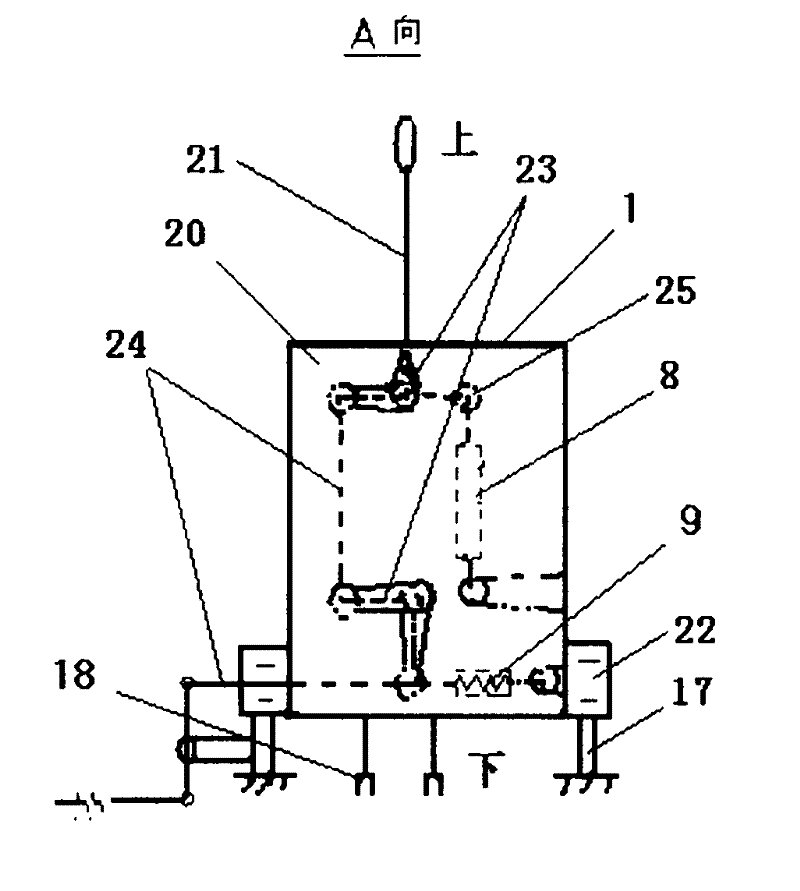

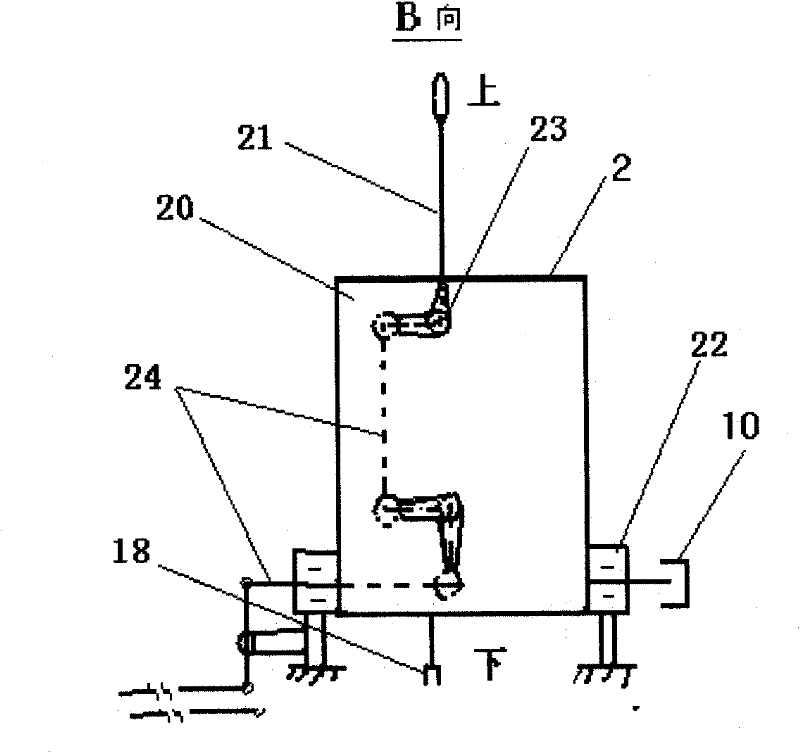

[0024]The longitudinal control system consists of front and rear cabin control rod assemblies (YKH-10A, YKH-11A) 1, 2, displacement sensor (2588A) 8, longitudinal adjustment mechanism (DG-195) 7, eddy current damper (ZNQ-1Z ) 10, the load mechanism 9 and the longitudinal linkage rod 12 of the linkage of the front and rear compartments. The displacement sensor 8 is installed behind the front cabin driving rod assembly 1 and is hinged with the support arm 18 on the driving rod rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com