Pretreatment technical method for strengthening three-phase separation of sludge

A three-phase separation and pretreatment technology, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the complex composition of sludge, strong water-solid stability, and difficult separation technology. major problems, to achieve the effect of enhancing separability, improving technical level, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1-Intensified three-phase separation of sludge from a sewage treatment plant in Changsha

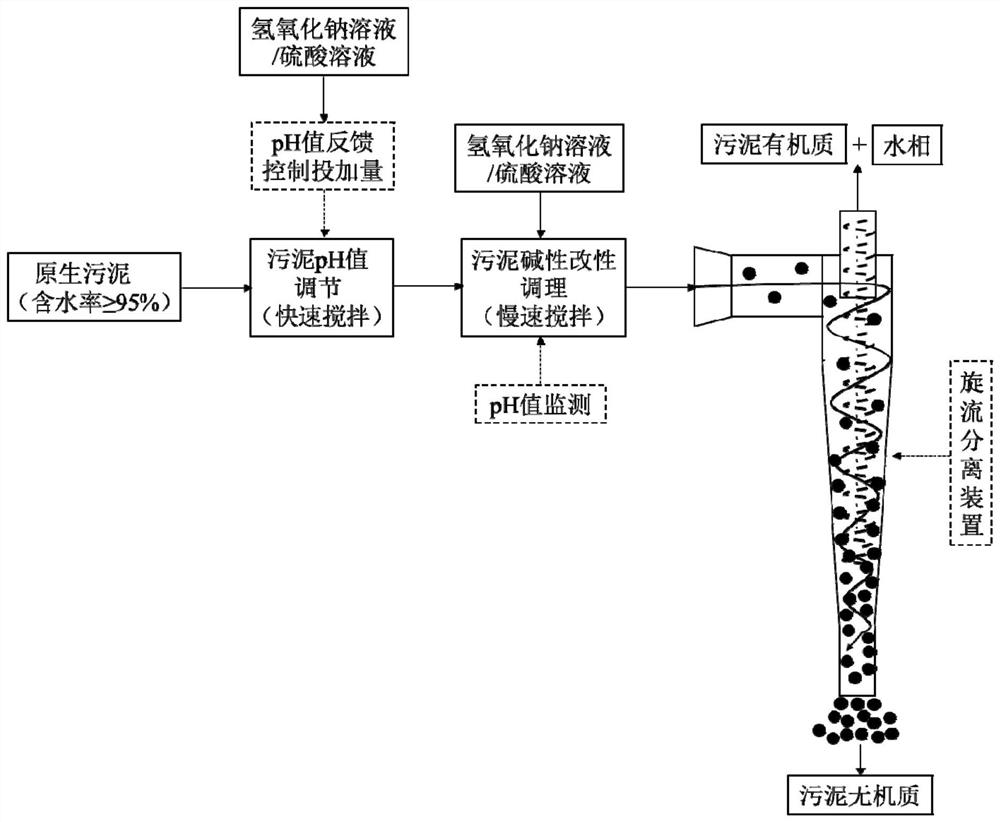

[0022] The technical method for enhancing the three-phase separation of sludge in this embodiment includes the following steps:

[0023] (1) Prepare 1mol / L sodium hydroxide solution and 1mol / L sulfuric acid solution;

[0024] (2) Under fast stirring conditions (speed gradient G value 1000s -1 ), the stirring time is 2 minutes, the sodium hydroxide solution and sulfuric acid solution prepared in step (1) are added to the sludge, the pH value of the sludge is monitored in real time through the pH electrode, and the sodium hydroxide solution or the sodium hydroxide solution or The dosage of sulfuric acid solution will finally adjust the pH value of the sludge to 12;

[0025] (3) Under constant stirring conditions (speed gradient G value is 70s -1 ), using a pH electrode to monitor the pH value of the sludge in real time, by constantly adding sodium hydroxide solution or sulfuric acid...

Embodiment 2

[0028] Example 2-Intensified three-phase separation of sludge from a sewage treatment plant in Changsha City

[0029] The technical method for enhancing the three-phase separation of sludge in this embodiment includes the following steps:

[0030] (1) Prepare 3mol / L potassium hydroxide solution and 1mol / L hydrochloric acid solution;

[0031] (2) Under fast stirring conditions (speed gradient G value 700s -1 ), the stirring time is 5 minutes, the sodium hydroxide solution and sulfuric acid solution in step (1) are added to the sludge, the pH value of the sludge is monitored in real time through the pH electrode, and the potassium hydroxide solution or the hydrochloric acid solution is feedback controlled according to the sludge pH value. Dosing amount, finally adjust the sludge pH value to 10;

[0032] (3) Under constant stirring conditions (speed gradient G value is 70s -1 ), use a pH electrode to monitor the pH value of the sludge in real time, and keep the pH value of the sludge con...

Embodiment 3

[0035] Example 3-Intensified three-phase separation of sludge from a sewage treatment plant in Changsha

[0036] The technical method for enhancing the three-phase separation of sludge in this embodiment includes the following steps:

[0037] (1) Prepare 2mol / L sodium hydroxide solution and 3mol / L sulfuric acid solution;

[0038] (2) Under fast stirring conditions (speed gradient G value 850s -1 ), the stirring time is 5 minutes, the sodium hydroxide solution and sulfuric acid solution in step (1) are added to the sludge, the pH value of the sludge is monitored in real time through the pH electrode, and the sodium hydroxide solution or the sulfuric acid solution is feedback controlled according to the sludge pH value. Dosing amount, finally adjust the pH value of the sludge to 11;

[0039] (3) Under constant stirring conditions (speed gradient G value is 45s -1 ), use a pH electrode to monitor the pH value of the sludge in real time, and keep the pH value of the sludge constant at 11 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com