Method for designing printing bottom piece of aluminum two-sheet zip-top can

A design method and technology of pop-up cans, applied in the directions of printing, printing devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

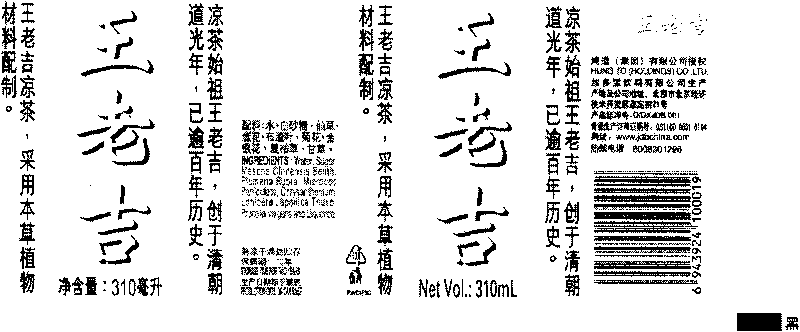

[0030] image 3 It shows the overall printing effect diagram of the "Wanglaoji" appearance pattern formed by color separation design according to the printing negative film design method of the present invention, Figure 3A , Figure 3B , Figure 3C , Figure 3D , Figure 3E , Figure 3F Respectively show red, brown, black, yellow 1, yellow 2, blue version; Figure 3G Shows a print overprint effect diagram formed according to the printing negative film design method of the present invention; Figure 3H Shows the actual printing renderings of the product. Please refer to Table 2 for specific markings of junctions of different colors.

[0031] Such as image 3 , Figure 3A to Figure 3H As shown, first, the yellow in the overall pattern is decomposed into two parts in the negative film design. In addition to white, the five colored colors (yellow,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com