Lengthened piston for optical engine

A technology of optical engine and piston, applied in the direction of engine components, machines/engines, pistons, etc., can solve the problems of power reduction, low cylinder pressure, cumbersome disassembly, etc., and achieve the effect of preventing air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

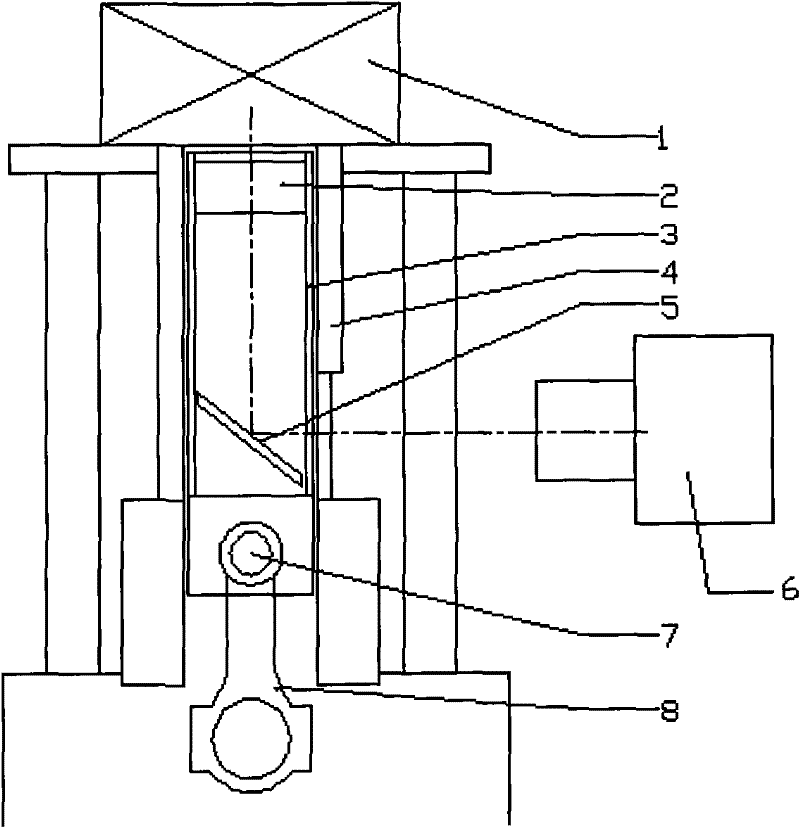

[0019] Such as figure 1 As shown, the cylinder liner 4 is provided with an extended piston 3, the top of the cylinder liner is the cylinder head 1, and the reflector 5 is fixed on the support at an angle of 45°, and placed in the square hole 15 on the side of the extended piston through the support. The other end of the support Fixed to the upper surface of the cylinder body, the CCD camera 6 can take pictures of the situation in the cylinder through the side square hole 15, the reflector 5, and the transparent window 2.

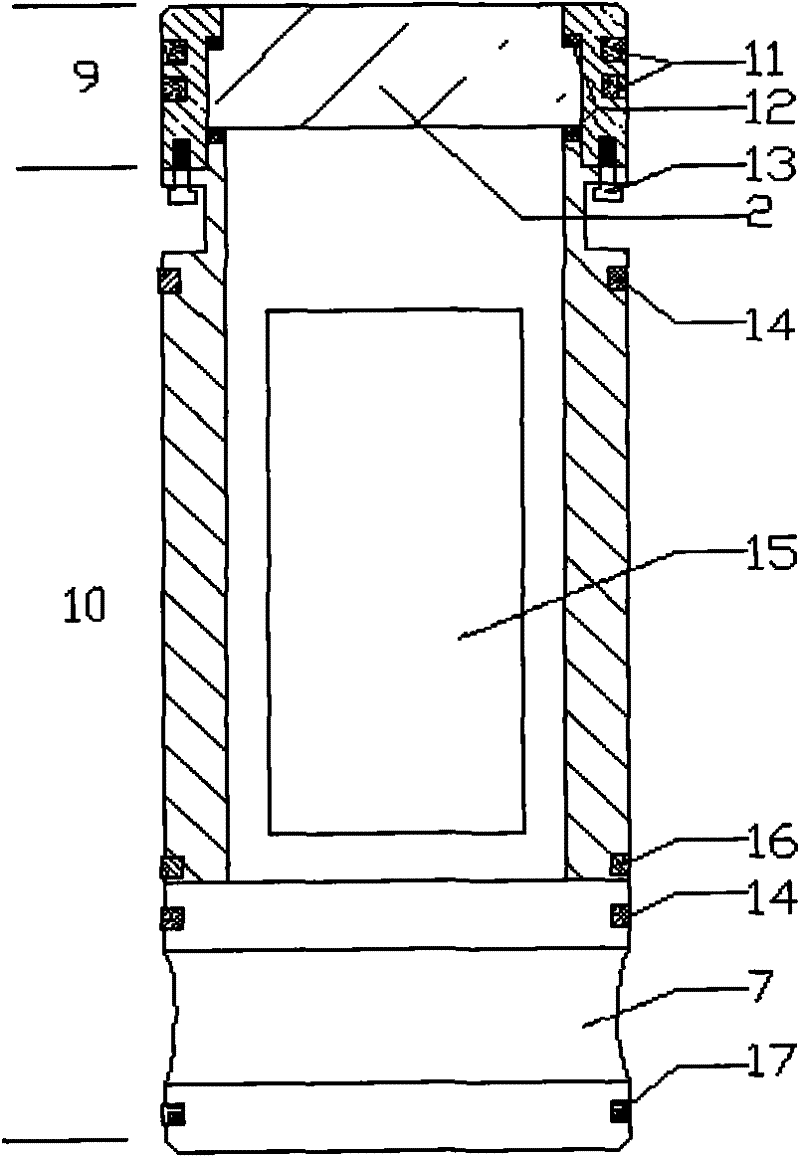

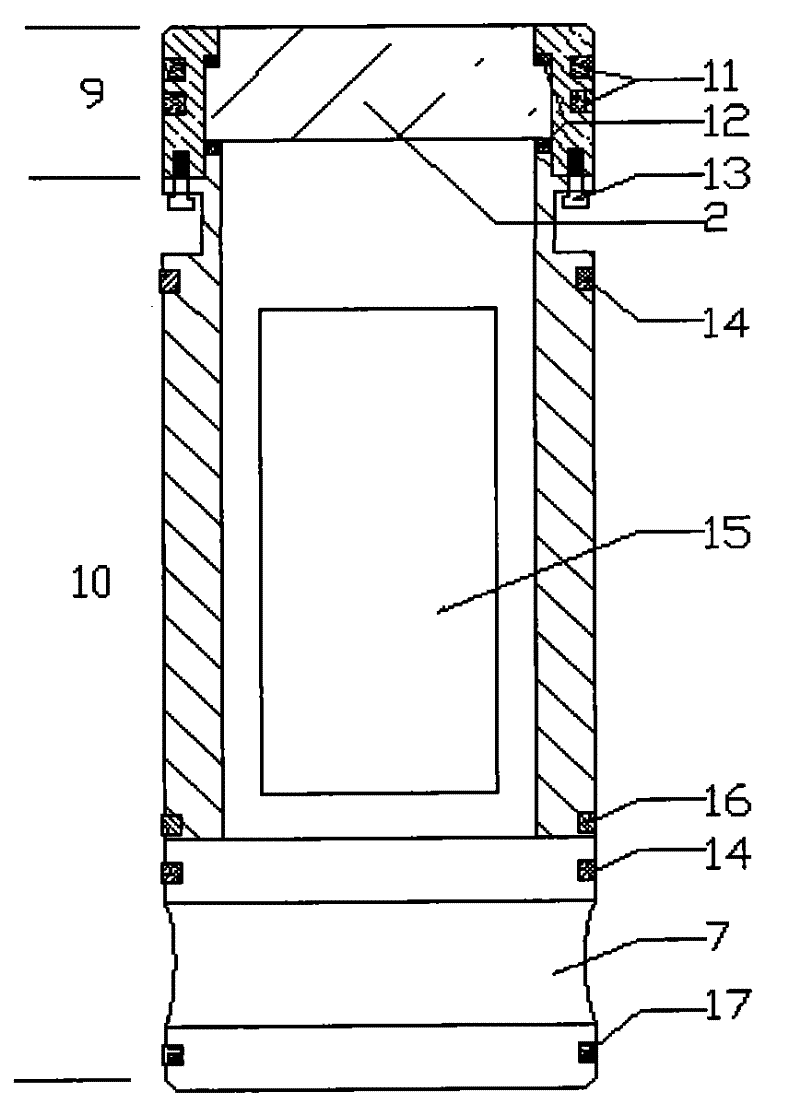

[0020] Such as figure 2 As shown, the extended piston 3 includes a piston top window portion 9 and a piston extension portion 10, both of which are made of aluminum alloy material, which reduces the overall piston mass. The piston top window part 9 and the piston extension part 10 are connected together by bolts 13. The top of the piston top window part 9 is provided with a round hole for installing a transparent window 2. The transparent window 2 is in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com