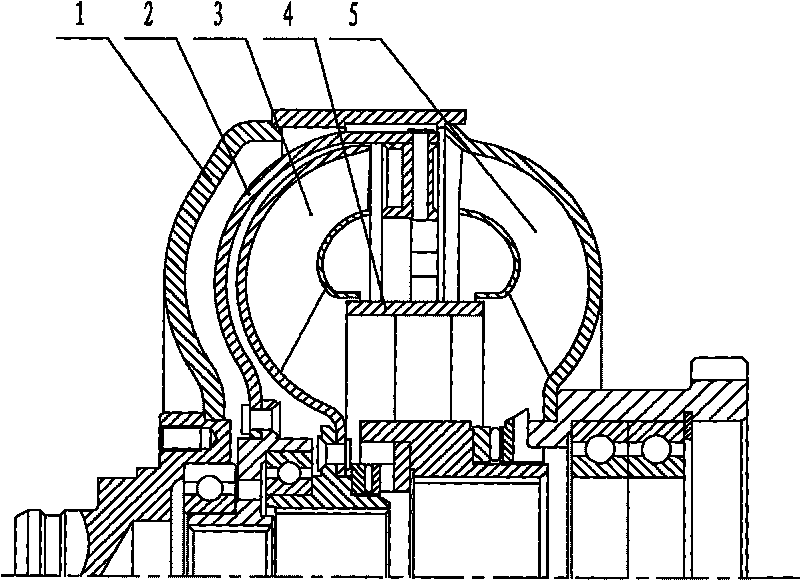

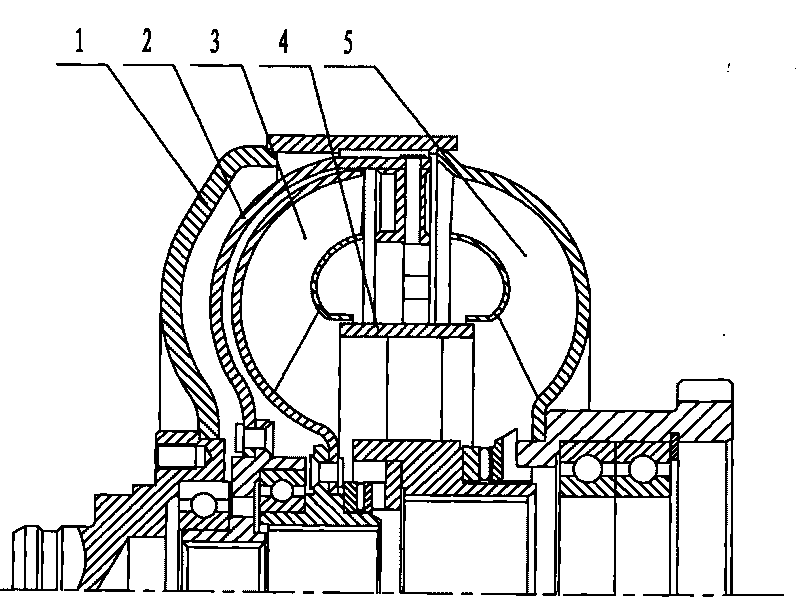

Hydraulic torque converter for low-speed diesel engine

A technology of hydraulic torque converter and diesel engine, which is applied in the field of hydraulic torque converter, can solve the problems that the low-speed diesel engine cannot be reasonably matched, and achieve the effect of reasonable structure and improved output torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The hydraulic torque converter for the low-speed diesel engine of the present invention, the cover wheel 1, the first turbine 2, the second turbine 3, the pump wheel 4 and the guide wheel 5 are assembled to form a liquid flow circulation circle, and the liquid flow circulation circle of the torque converter is The diameter is 340.28mm and the height is 150.35mm; the inlet blade angle of the blade of the first turbine 2 is 101-110°, the outlet blade angle is 145-155°, and the inlet blade angle of the blade of the second turbine 3 is 30-42° , the outlet blade angle is 140-152°, the inlet blade angle of the blade of the pump wheel 4 is 100-110°, the outlet blade angle is 94-106°, the inlet blade angle of the guide wheel 5 blade is 80-87°, and the outlet blade angle is 80-87°. The blade angle is 19.5-25°. The outer ring of the pump wheel of the pump wheel 4 and the outer ring of the turbine of the turbine assembly are both arranged in an asymmetric arc shape, which is benef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com