Lifting type manual travelling device

A manual driving and hoisting technology, applied in the direction of mechanical equipment, supporting machines, etc., can solve the problems of noise and complicated operation, and achieve the effect of simple operation and maintenance, flexibility and small space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

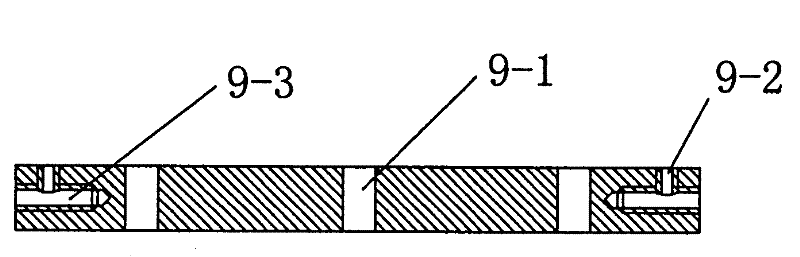

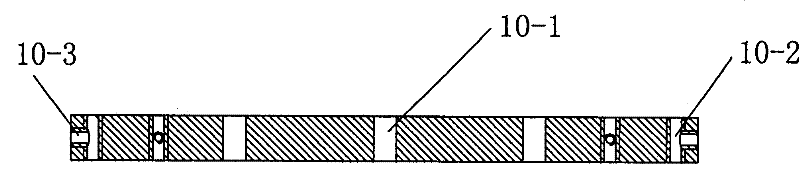

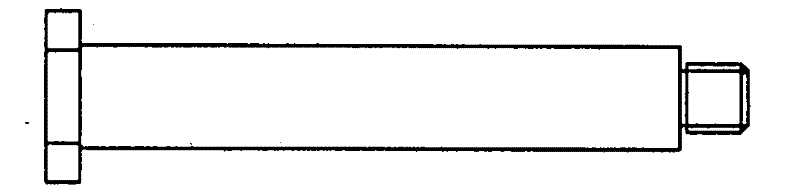

[0017] Such as Figure 1-11 As shown, the hoisting type manual driving device includes an upper support plate 1, a lower support plate 2, a positioning shaft 3, a positioning sleeve 4, a cable nut 5, a spring 6, a wheel shaft 7, a wheel 8, a traveling wheel connecting shaft 9, and a guide wheel Connect shaft 10. The upper support plate 1 is a rectangular iron plate, and the upper support plate 1 is provided with four bushing holes 1-1 and several shaft holes 1-2. The lower support plate 2 is a rectangular iron plate, and the lower support plate 2 is provided with several shaft holes 2-1 and four positioning shaft holes 2-2. The walking wheel connecting shaft 9 is a cylinder made of metal, and the axial surface of the traveling wheel connecting shaft 9 is provided with three shaft holes 9-1, two top screw holes 9-2, and two end faces of the traveling wheel connecting shaft 9 Be respectively provided with axle hole 9-3 on. The guide wheel connecting shaft 10 is a cylinder mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com