Stainless steel molding rod, manufacturing method and application thereof

A technology of stainless steel rods and stainless steel, which is applied in the field of quartz crucible manufacturing, can solve the problems of fragile quartz glass forming rods, poor precision, and misunderstanding of thinking, and achieve the effect of rich raw materials, high precision, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

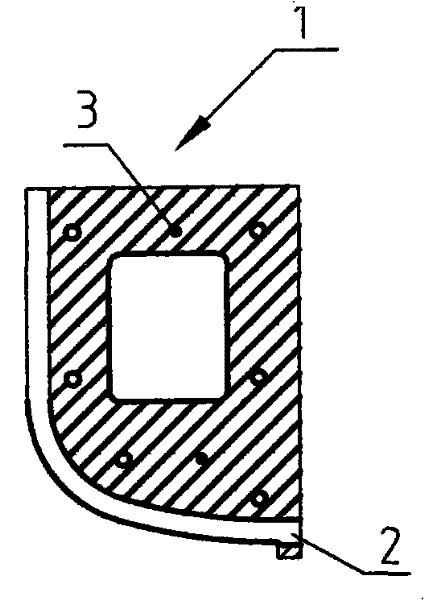

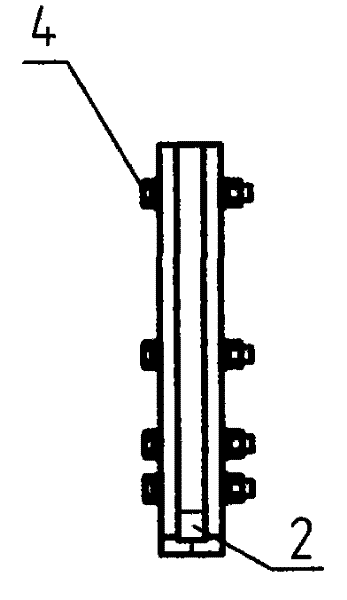

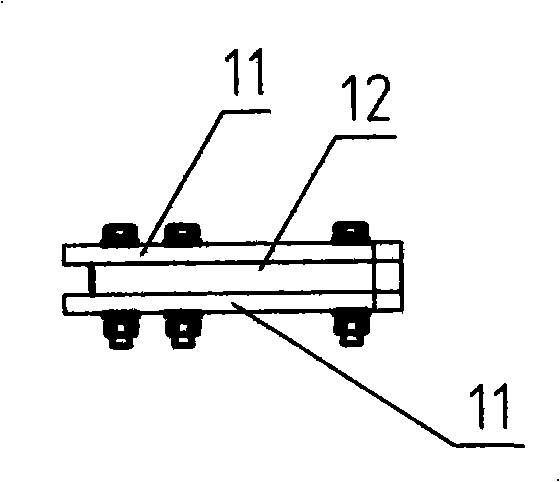

[0048] As shown in Figure 1 (A), (B) and (C), a crucible stainless steel forming rod template includes a splint 1, and also includes an end clamp hole 2, a positioning pin 3, a fastening bolt 4, and a template The working surface is on the left and lower sides of splint 1. The working surface is composed of a straight line and two arcs. The left side is a straight line, the lower side is an R1 arc segment, and the lower left side is an R2 arc segment. The shape of the working face is consistent with the shape of the stainless steel forming rod; the splint 1 is divided into three layers, the two side splints 11 and the center splint 12, and the working surface formed by the two side splints 11 and the center splint 12 is concave; the three-layer splint is used Locating pin 3 locates, connects with fastening bolt 4.

[0049] The end clamp hole 2 is located at the lower right of the former, the upper half of the end clamp hole 2 is the concave working surface of the former, and the...

Embodiment 2

[0052] A stainless steel forming rod 9, comprising a rod body 5 and a positioning pointer 6; the upper part of the rod body is a stainless steel straight rod structure 5.1, and the lower part is a curved stainless steel rod structure 5.2. The bending has two arcs, one of which is R1, one section is R2; the tail end is adjustable positioning pin 6.

[0053] R1 radius is 80mm, R2 radius is 503mm.

[0054] The adjustable positioning needle 6 includes a needle body 6.1 and an adjustment screw 6.2; the top of the needle body has an adjustment groove, the middle part is a threaded structure, and the lower part is a cone-shaped structure; the middle part of the needle body is connected to the threaded structure of the adjustment screw thread 6.2 .

[0055] The tail end of the stainless steel formed rod body is fixedly connected to the adjustment screw part of the adjustable positioning pin, and the fixed connection is welding.

Embodiment 3

[0057] The quartz sand layer 7 is placed in the mold 8, and under the action of centrifugal force, the crucible product can be obtained by using a stainless steel forming rod 9 and forming it at a high temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com