Film plating device

A technology of coating device and evaporation source, which is applied in the direction of sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problems of time-consuming, inconsistent film characteristics, prolonging the coating processing time, etc., and shorten the coating process time, the effect of reducing the number of times of heating and vacuuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings.

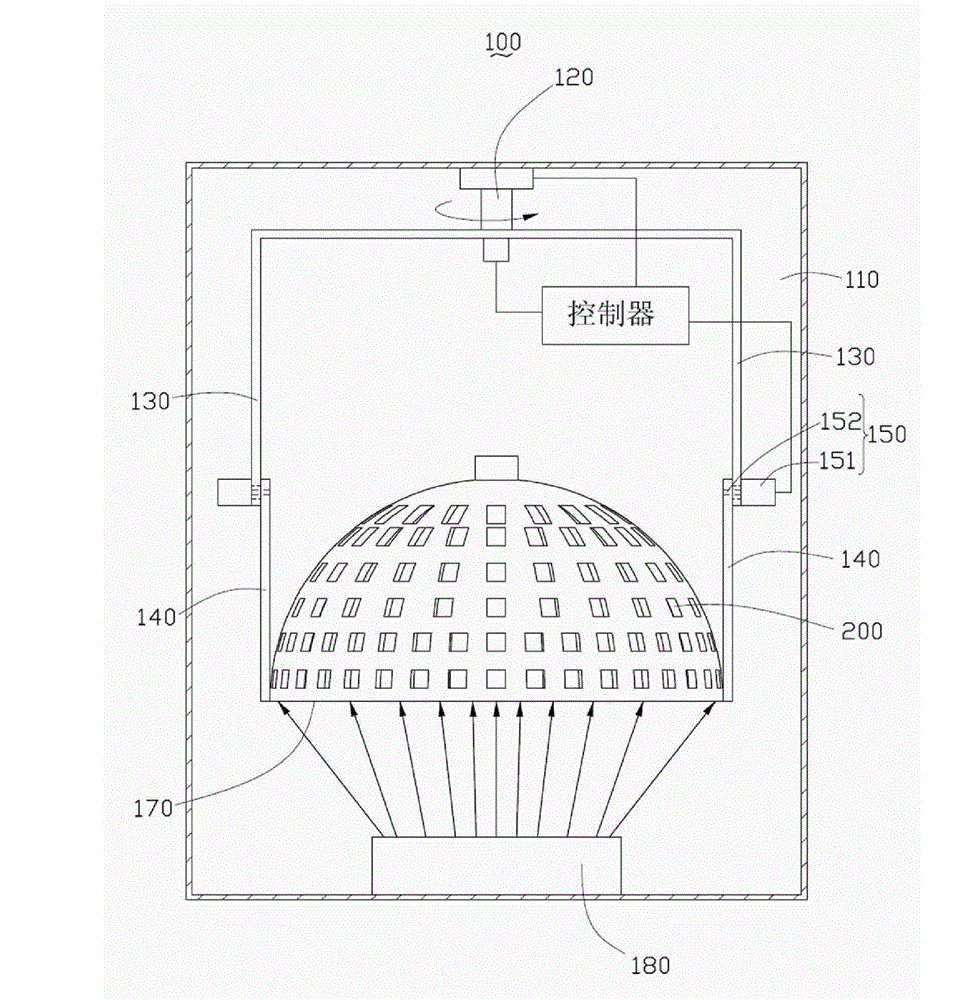

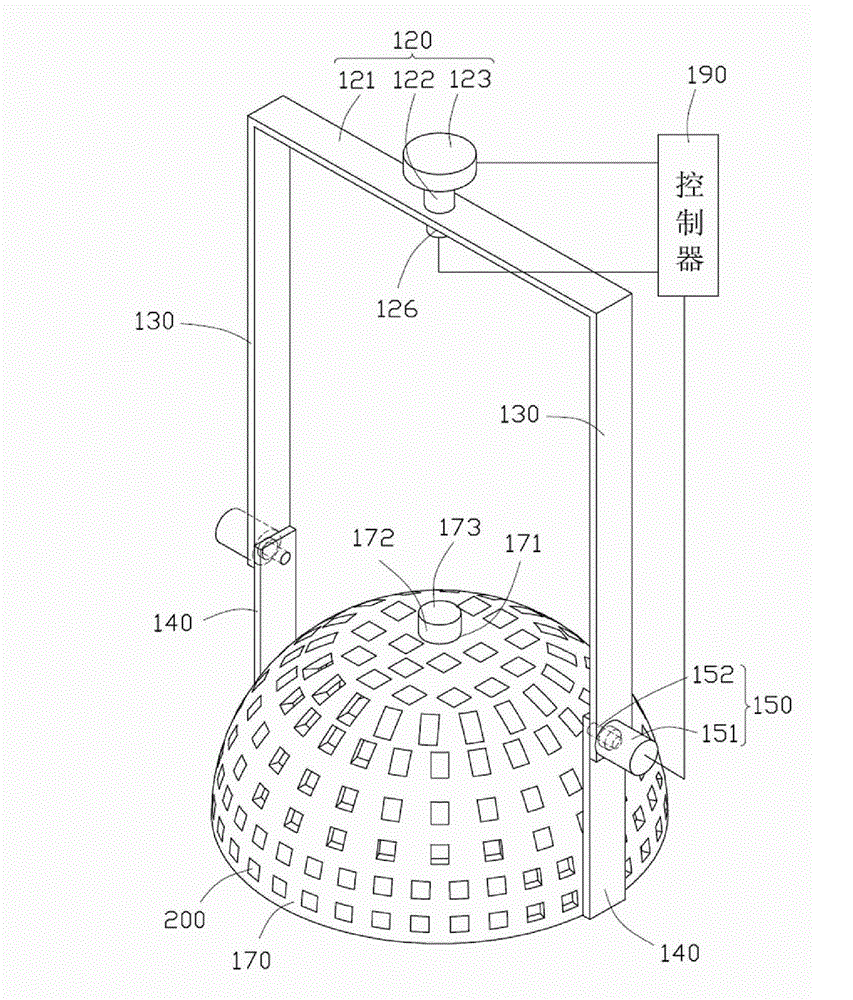

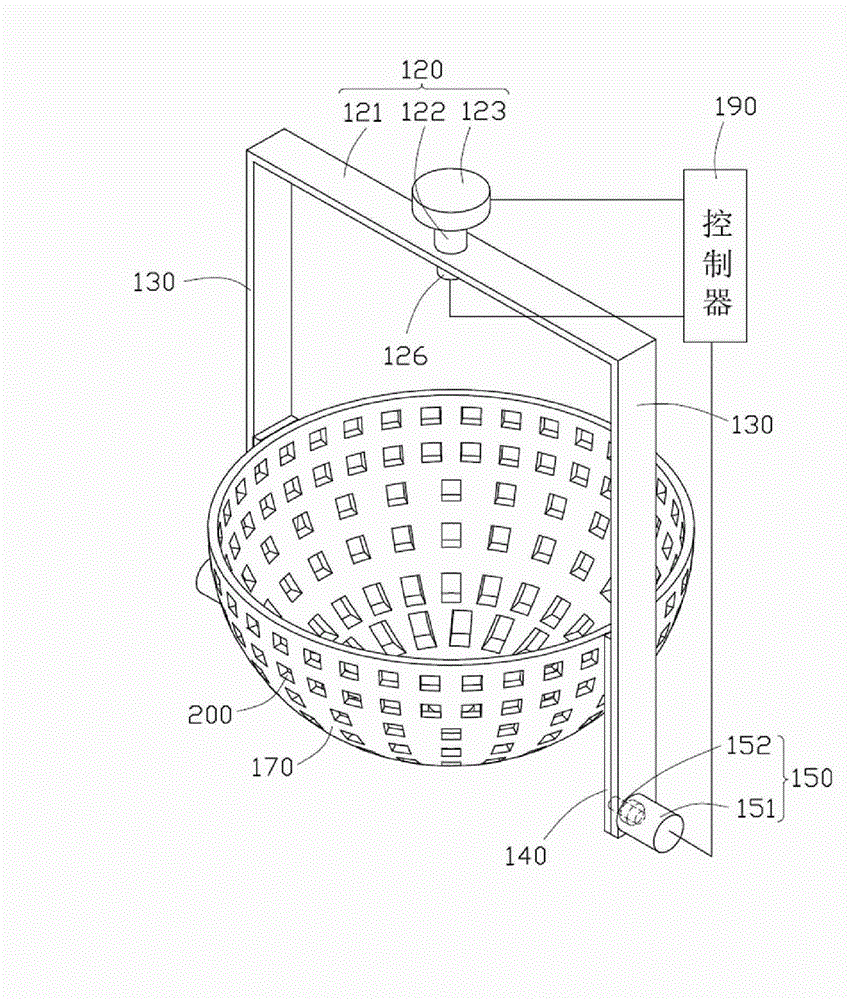

[0012] see figure 1 and figure 2 , is a coating device 100 provided in the first embodiment of the present invention, and is used for coating a product 200 . The coating device 100 includes a vacuum chamber 110, a rotating support assembly 120, two fixed arms 130, two overturning arms 140, two overturning motors 150, a carrier 170, an evaporation source 180, and a controller 190.

[0013] The rotating support assembly 120 includes a supporting frame 121, a rotating shaft 122 and a rotating motor 123, the rotating motor 123 is fixed on the top of the vacuum chamber 110, and the supporting frame 121 is connected to the rotating shaft 122. One end, the other end of the rotating shaft 122 is connected with the rotating motor 123 , so that the supporting frame 121 can rotate in the horizontal plane driven by the rotating motor 123 . An infrared receiver 126 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com